iii

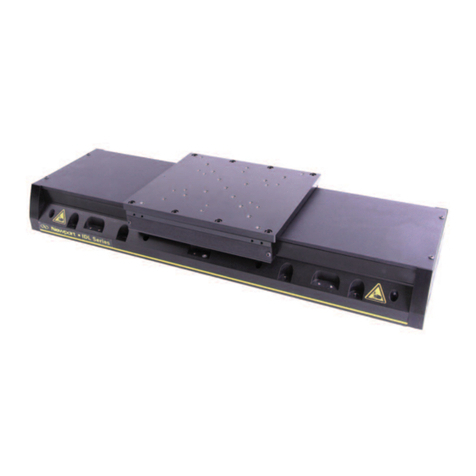

HXP1000-MECA High L ad 6-Axis-Parallel Kinematic P siti ning System

able of Contents

Warranty .................................................................................................................ii

EC Declaration of Conformity...............................................................................v

Definitions and Symbols.......................................................................................vi

Warnings ...............................................................................................................vii

Caution .................................................................................................................viii

1.0 — Introduction.................................................................................1

1.1 Unpacking ..................................................................................................2

2.0 — Description ...................................................................................3

3.0 — Characteristics............................................................................4

3.1 Mechanical Specifications .......................................................................4

3.2 Max. Cantilever Distance of the Load.....................................................4

Horizontal Base Plate ...............................................................................4

Vertical Base Plate ....................................................................................4

Base Plate at Any Position .......................................................................5

Horizontal Base Plate - Lateral Force .....................................................5

3.3 Weight.........................................................................................................5

4.0 — Connection to the HXP1000-ELEC-D Controllers .....6

4.1 Warnings on Controllers ..........................................................................6

4.2 Connection.................................................................................................7

4.3 Cables .........................................................................................................8

5.0 — Dimensions...................................................................................9

6.0 — Maintenance ..............................................................................10

6.1 Maintenance ............................................................................................10

6.2 Repair .......................................................................................................10

Service Form .........................................................................................................11

A863E0 - EDH0328En1040 - 12/19