2

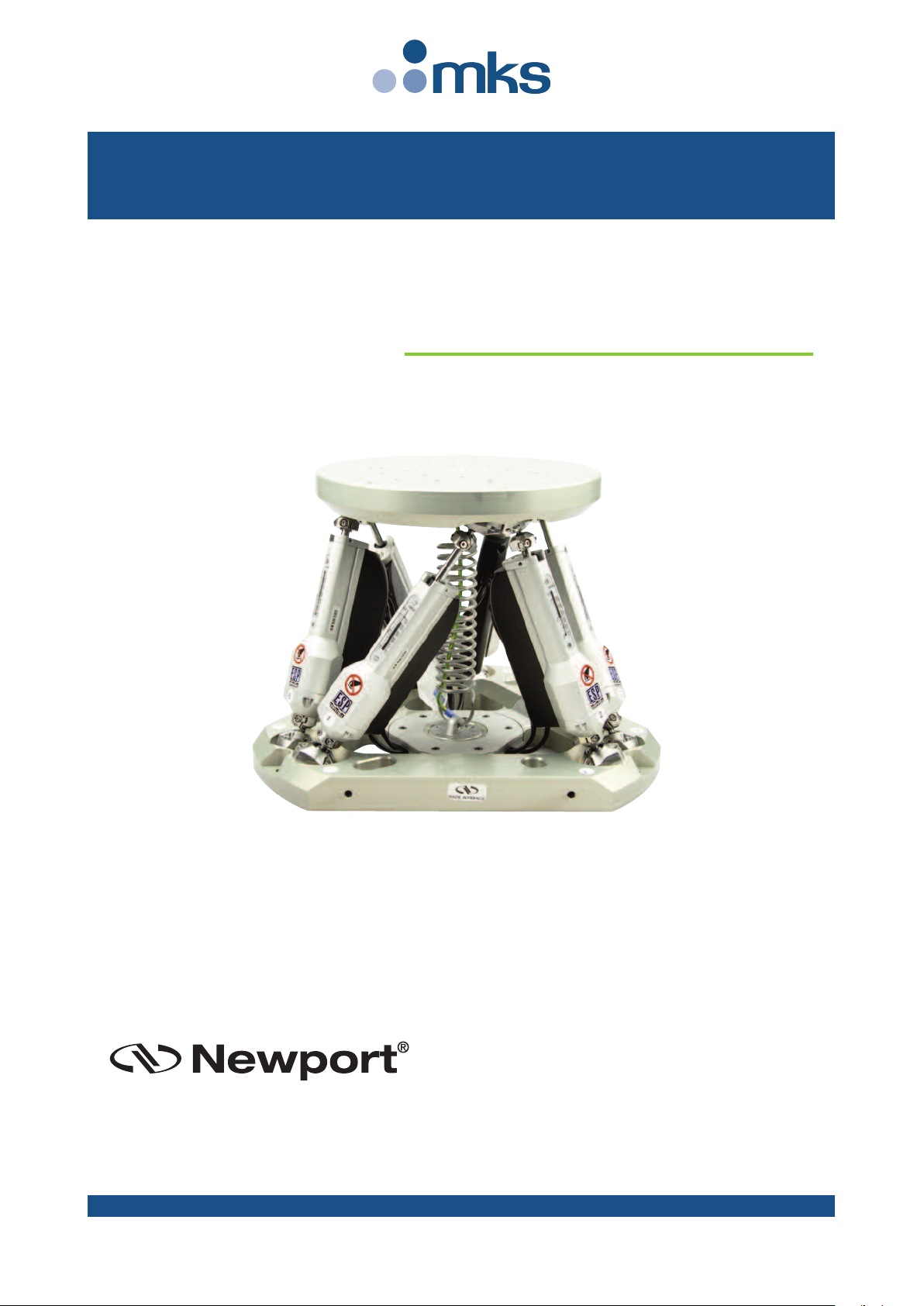

HXP100-MECA & HXP100HA-MECA 6-Axis-Parallel Ki ematic Positio i g Systems

2.0 —Description

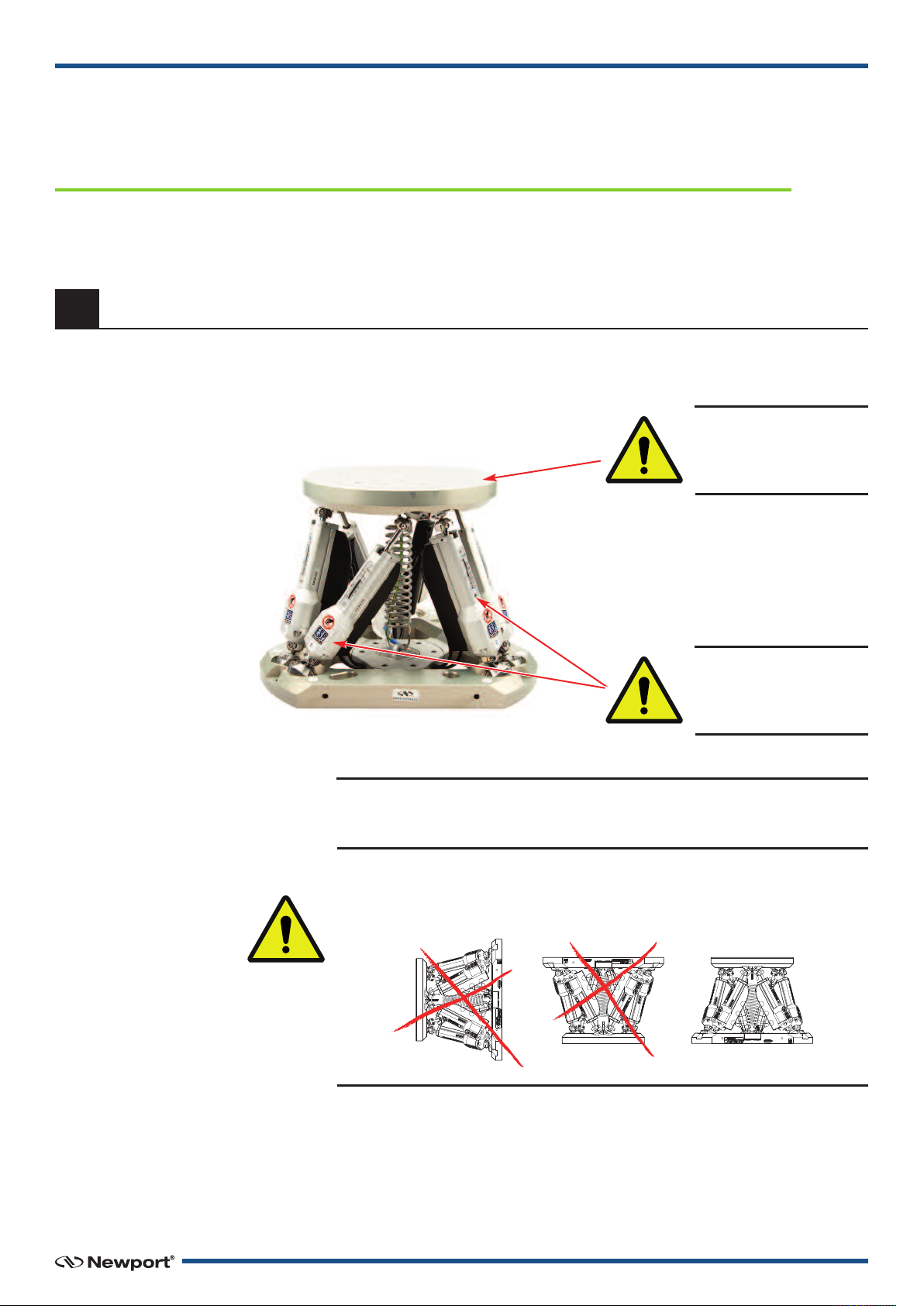

The HX 100-MECA 6-Axis Hexapod is a parallel kinematic motion device

that provides six degrees of freedom: X, Y, Z, pitch, roll, and yaw. The

HX 100-MECA has long travel capability and is an effective solution to

complex motion applications that demand high load capacity and

accuracy in up to six independent axes. Contrary to the image of being

complex and highly priced, the HX 100-MECA hexapod is not only

affordable but extremely easy to use. The HX 100-MECA design also

includes two programmable pivot points, enabling more flexibility to align

a sample at a particular point or points of that sample. The HX 100-MECA

Series also takes advantage of the low-runout, Right ath™ trajectory

capability. Available in the standard performance, higher precision and

vacuum versions. Order with the corresponding HX 100-ELEC controller.

To further ensure positioning performance, the High Accuracy (HA)

HX 100HA-MECA is available with guaranteed accuracy values. This

enables the use of a Newport Hexapod in positioning applications, where

position accuracy is required. In addition to accuracy along an axis, the

itch and Yaw deviations during axial motion are also monitored and

guaranteed. When the HA Hexapod is used with Right ath™, this

combination achieves positioning performance close to standard Newport

stages.

The HX 100-ELEC-D and HX 100HA-ELEC-D provide advanced features

including instrument grade I/O's, hardware based input triggers, event

triggers, high-speed on-the-fly data acquisition, fast TC /I

communication, and integrated TCL programming language for on-board

processes. All these features improve accuracy and throughput, making

the programmer’s life much easier.

A common requirement for many Hexapod motion applications is a virtual

pivot point, allowing the user to freely choose the point in space that is a

pivot point for all rotations. The Newport Hexapod can not only relocate

the pivot point, but through our advanced technology, the entire

coordinate system can be relocated. In addition, two user-definable

coordinate systems are provided, called tool (moves with the Hexapod)

and work (stationary coordinate systems). Incremental displacements are

possible in either one of these systems in user-friendly Cartesian

coordinates, and positions can be easily calculated from one system to the

other by a function call, without the need for complex external coordinate

transformations.

Absolute moves and positions a e

defined in the wo k coo dinate

system. Inc emental moves can

be done in the tool o in the wo k

coo dinate systems.

WORLD

WORK

CARRIAGE

TOOL

BASEBASEBASE

As a standa d featu e, the HXP100-ELEC-D

and HXP100HA-ELEC-D cont olle s allow

the use to choose a vi tual pivot point in

space fo all otations.

A698J0 - EDH0239En1070 - 12/19