7 | P a g e

Quick Setup

Quick SetupQuick Setup

Quick Setup

CONNECTING THE AIR COMPRESSOR TO THE LIQUEFIER:

1. Connect Air Hose from Air Compressor to Liquefier. Hand ti hten only.

2. Connect Air Compressor Data cable to Liquefier and Air Compressor.

3. Connect both power leads from Air Compressor and Liquefier to suitable wall

outlets.

4. Turn on Air Compressor and Liquefier.

5. Switch the device to ‘Run’ 11

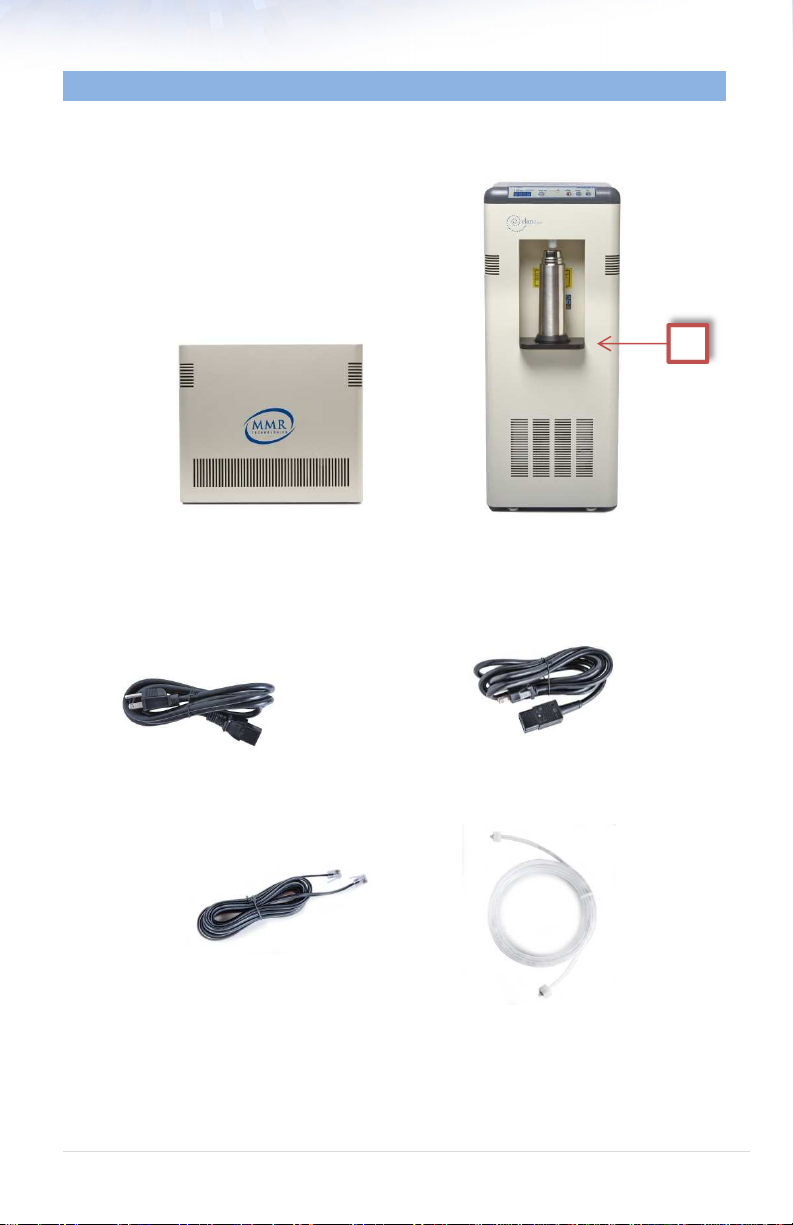

SETTING THE CLOC (IF NECESSARY): The clock is factory set, and is displayed when the

unit powers up, followed by the day. Press ‘Reset ’13 to view the clock at any time.

See pa e 8 if the time or date are incorrect. The clock is used for automatic

maintenance, which takes place at 9PM every Saturday ni ht.

TESTING THE AIR SUPPLY: With the unit runnin , press and hold the ‘Test Air Pressure’

button 14 on the rear of the unit. Over a period of 30 seconds, the ‘Pressure’ 10

should rise to a minimum of 90psi. If it doesn’t reach 90psi, check the air hose

connections for leaks.

DEFROST: Each time the unit starts up followin installation, a power failure, or resettin of

the unit, a 90 minute defrost is commenced. This can be cancelled at any time by

pressin the ‘Defrost’ button 8 on the front panel. Subsequent defrosts can be

started if required by pressin and holdin the ‘Defrost’ button for 2-3 seconds.

VIEWING SENSOR VALUES: When the system is not defrostin pressin the ‘Mode’ button

6 will to le the sensor value as indicated by the li hts 1

COOLDOWN: Once defrostin has completed, the refri eration system will become active

and will be in to cool down the liquefier. This can be monitored by watchin the

“Cryo Temp”. See Viewing Sensor Values. When the Temp has reached 77K, cool

down is complete and production will be in. This should take about 30 minutes.

LOC ING AND UNLOC ING: The ‘Lock’ feature 9 is a security device to stop unwanted

dispensin . If the unit is unlocked and the Dewar is in place, dispensin is enabled

indicated by the ‘Ready’ li ht 2. To unlock the unit, first hold down the ‘Lock’ button

9. While holdin the ‘Lock’ button, press and hold the ‘Mode’ button 6

simultaneously until the lock li ht oes out. To relock, simply hold the ‘Lock’ button 9

until the lock li ht comes on. Note: When locked, the unit will produce internally and

stay in the Dewar; it will maintain a full level in the liquefier until the device is

unlocked Unlocking can only take place in normal operation