Index

www.modine.com 3

Indice - Istruzioni per l'uso originali

Versione linguistica originale

1. Importante . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. Applicazioni . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

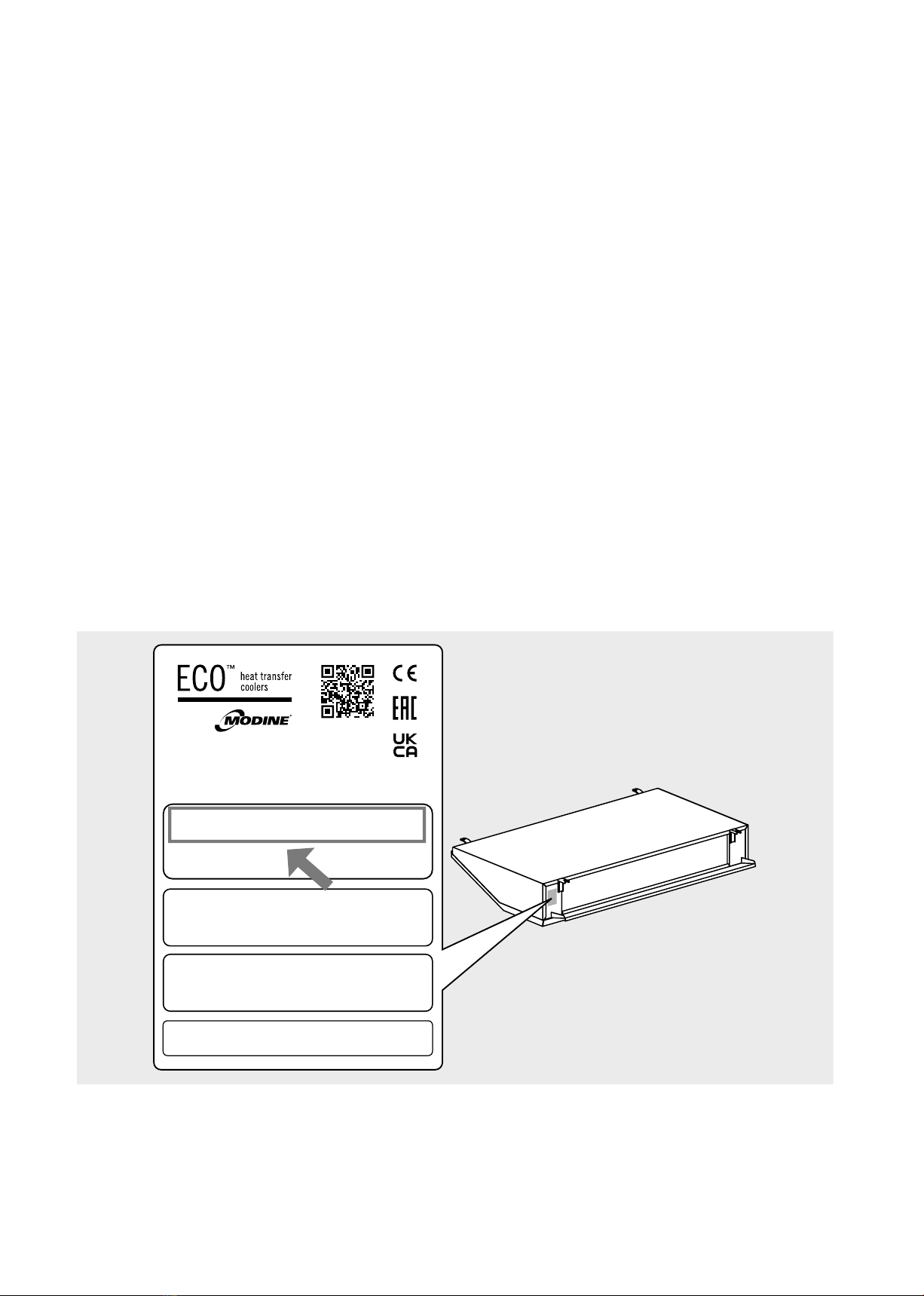

3. Identicazione . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4. Ispezione - Stoccaggio. . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5. Movimentazione e installazione . . . . . . . . . . . . . . . . . . . . . . 7

6. Condizioni di installazione . . . . . . . . . . . . . . . . . . . . . . . . . 8

7. Caratteristiche costruttive e dimensionali . . . . . . . . . . . . . . . . 10

8. Suggerimenti per un corretto accesso all’unità . . . . . . . . . . . . . .11

9. Schemi elettrici. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

10. Controlli da eseguire prima della messa in funzione . . . . . . . . . . 14

11. Controlli dopo la messa in funzione . . . . . . . . . . . . . . . . . . . 14

12. Manutenzione . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

13. Rischi residui. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

14. Norme e direttive di riferimento . . . . . . . . . . . . . . . . . . . . . 19

15. Dati tecnici . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Dichiarazione di incorporazione – Garanzie . . . . . . . . . . . . . . .101

1. Important. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2. Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3. Identication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4. Inspection - Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5. Handling and installation. . . . . . . . . . . . . . . . . . . . . . . . . 23

6. Installation conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7. Construction and dimensional features . . . . . . . . . . . . . . . . . 26

8. Recommendations for a proper access to the model . . . . . . . . . . 27

9. Wiring diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

10. Checks to be performed before start-up . . . . . . . . . . . . . . . . . 30

11. Checks to be performed after start-up . . . . . . . . . . . . . . . . . . 30

12. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

13. Residual risks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

14. Reference standards and directives . . . . . . . . . . . . . . . . . . . 35

15. Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Index - Translation of the original instructions

Declaration of incorporation – Warranties . . . . . . . . . . . . . . . . 101

1. Wichtig . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2. Anwendungen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3. Identizierung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4. Inspektion - Lagerung . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5. Handhabung und Montage . . . . . . . . . . . . . . . . . . . . . . . 39

6. Montagebedingungen . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7. Konstruktionseigenschaften und Abmessungen. . . . . . . . . . . . . 42

8. Ratschläge für einen korrekten Zugang zum Gerät . . . . . . . . . . . 43

9. Elektrische Pläne . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

10. Kontrollen vor Inbetriebnahme. . . . . . . . . . . . . . . . . . . . . . 46

11. Kontrollen nach Inbetriebnahme. . . . . . . . . . . . . . . . . . . . . 46

12. Wartung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

13. Restrisiko . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

14. Bezugsnormen und Richtlinien . . . . . . . . . . . . . . . . . . . . . 51

15. Technische Daten . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Index - Übersetzung der Originalanleitung

Einbauerklärung – Garantie . . . . . . . . . . . . . . . . . . . . . . . 101

1. Importante . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

2. Aplicaciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3. Identicación. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4. Inspección - Almacenamiento . . . . . . . . . . . . . . . . . . . . . . 55

5. Movilización e instalación . . . . . . . . . . . . . . . . . . . . . . . . 55

6. Condiciones de instalación . . . . . . . . . . . . . . . . . . . . . . . 56

7. Características constructivas y dimensionales . . . . . . . . . . . . . 58

8. Sugerencias para un correcto acceso al modelo . . . . . . . . . . . . 59

9. Esquemas eléctricos. . . . . . . . . . . . . . . . . . . . . . . . . . . 60

10. Controles antes de la puesta en funcionamiento . . . . . . . . . . . . 62

11. Controles después de la puesta en funcionamiento. . . . . . . . . . . 62

12. Mantenimiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

13. Riesgos restantes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

14. Normas y directivas de referencia . . . . . . . . . . . . . . . . . . . . 67

15. Datos técnicos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Ìndice - Traducción de las instrucciones originales

Declaración de incorporación – Garantías. . . . . . . . . . . . . . . .101

1. Important. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

2. Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

3. Identication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4. Inspection - Stockage . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5. Manutention et installation . . . . . . . . . . . . . . . . . . . . . . . . 71

6. Conditions d’installation . . . . . . . . . . . . . . . . . . . . . . . . . 72

7. Caractéristiques constructives et dimensionnelles . . . . . . . . . . . 74

8. Instructions pour accéder à l’appareil . . . . . . . . . . . . . . . . . . 75

9. Schémas électriques. . . . . . . . . . . . . . . . . . . . . . . . . . . 76

10. Contrôles à eectuer avant la mise en marche . . . . . . . . . . . . . 78

11. Contrôles à eectuer après la mise en marche . . . . . . . . . . . . . 78

12. Entretien/maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . 78

13. Risques résiduels . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

14. Normes et directives de référence . . . . . . . . . . . . . . . . . . . . 83

15. Données techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Déclaration d’incorporation – Garanties

Déclaration d’incorporation – Garanties . . . . . . . . . . . . . . . . . 101

1. Важно . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

2. Использование . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

3. Идентификация . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

4. Проверка - Хранение . . . . . . . . . . . . . . . . . . . . . . . . . . 87

5. Транспортировка и установка . . . . . . . . . . . . . . . . . . . . . 87

6. Условия установки . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

7. Конструкция и габаритные характеристики . . . . . . . . . . . . . . 90

8. Рекомендации по корректному доступу к аппарату . . . . . . . . . 91

9. Схемы подключения . . . . . . . . . . . . . . . . . . . . . . . . . . 92

10. Контроль перед вводом в эксплуатацию . . . . . . . . . . . . . . . 94

11. Контроль после ввода в эксплуатацию . . . . . . . . . . . . . . . . 94

12. Техобслуживание . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

13. Остаточные риски . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

14. Справочные стандарты и директивы . . . . . . . . . . . . . . . . . 99

15. Технические Данные . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Содержание - Перевод оригинала инструкции

Декларация о включении – Гарантия . . . . . . . . . . . . . . . . . 101