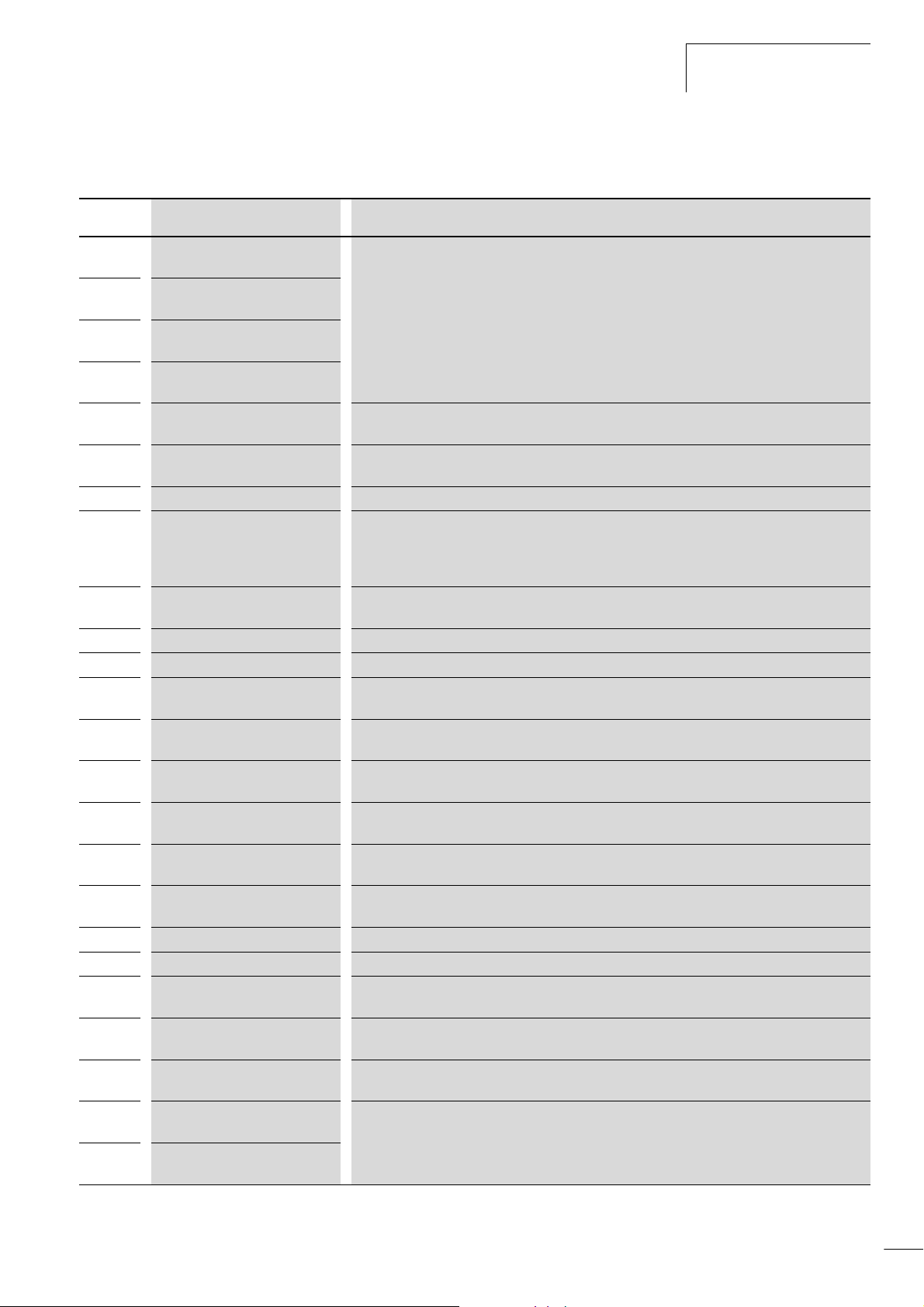

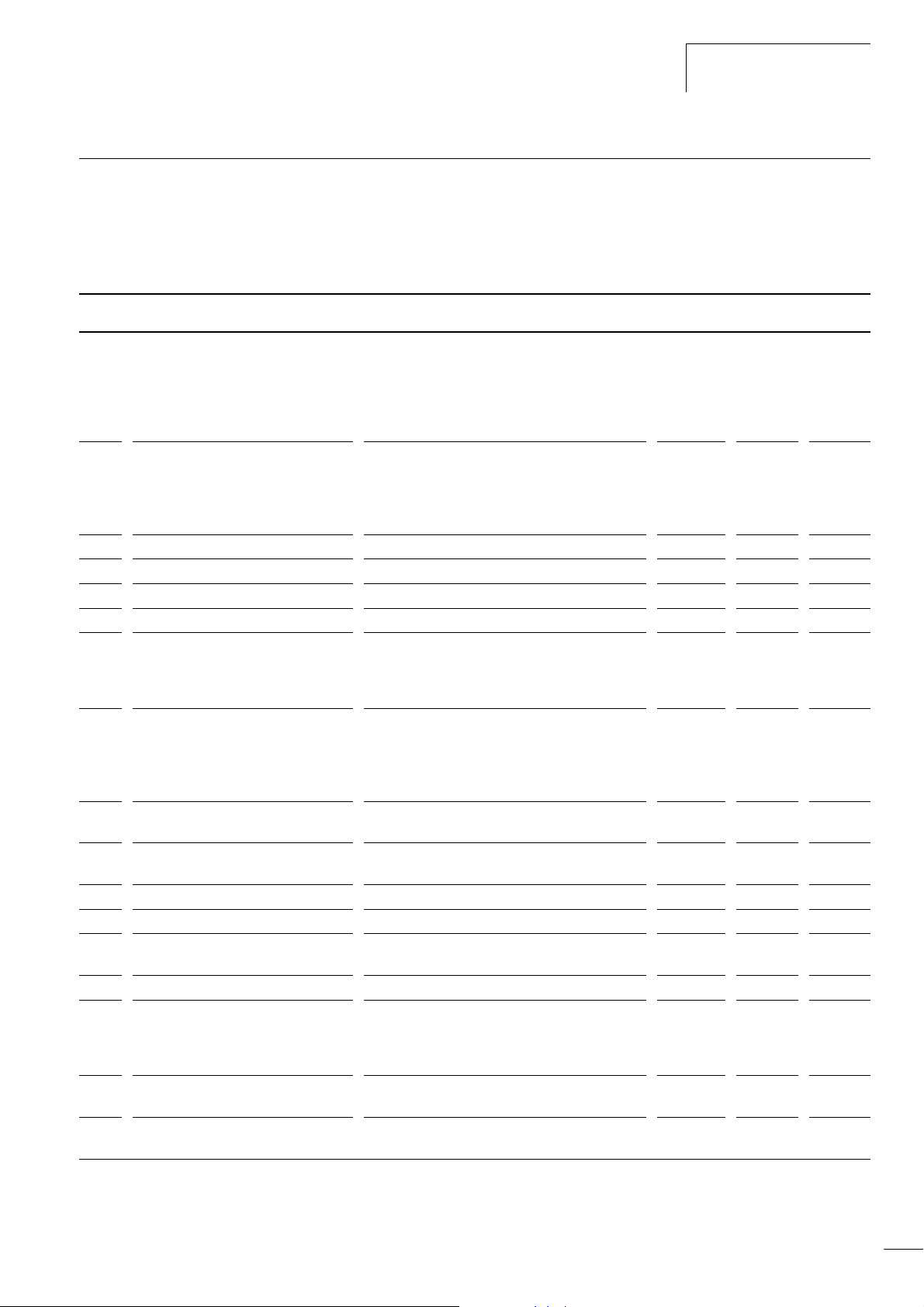

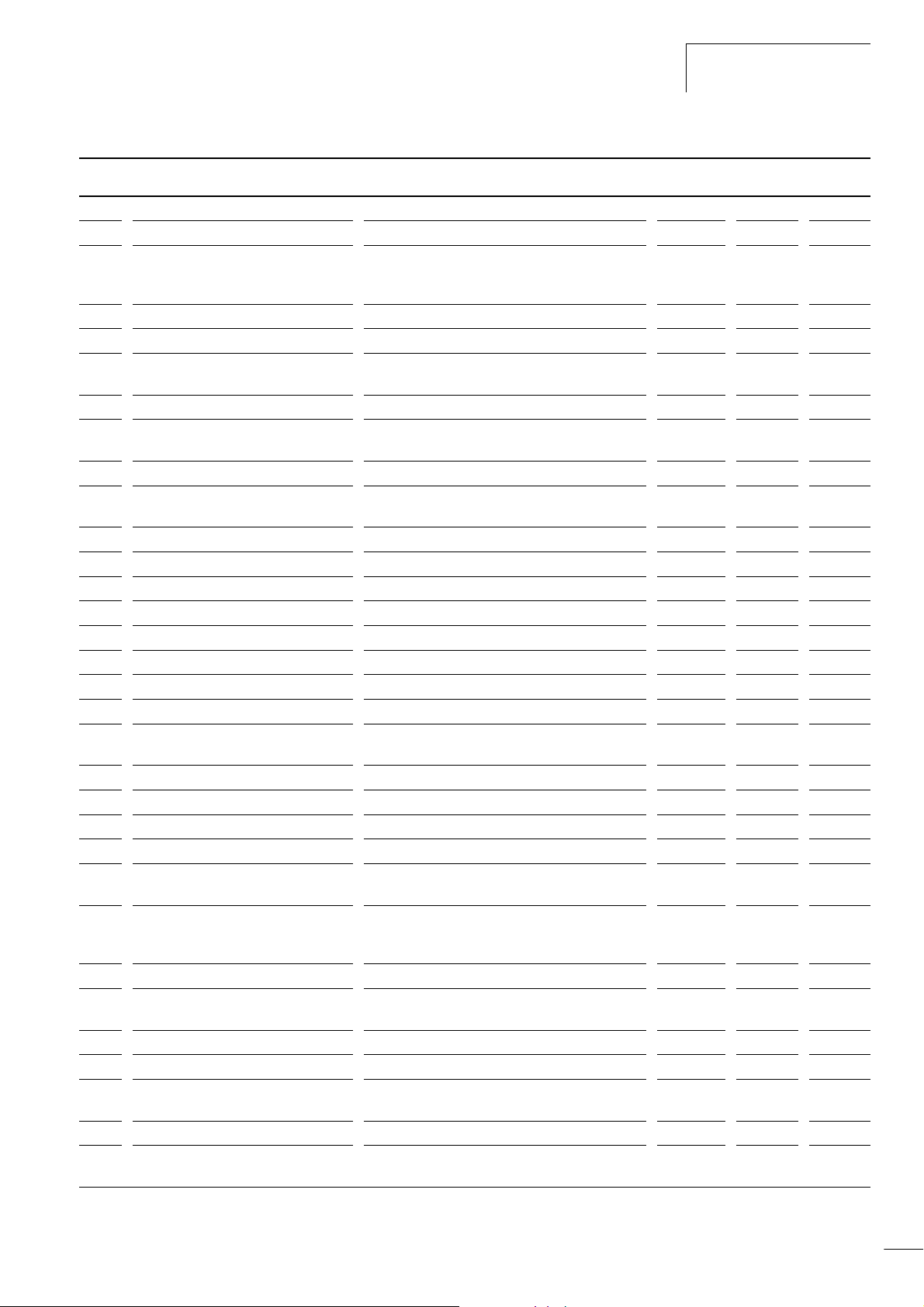

02/02 AWB8230-1449GB Fault messages

5

Fault message indication

Display Cause Description

E01 Overcurrent in the output stage in

static operation

If the output current reaches an excessive level, the output voltage is switched off. This happens

when

• the frequency inverter’s output is short-circuited,

• the motor is blocked,

• an excessive load is suddenly applied to the output.

E02 Overcurrent in the output stage

during deceleration

E03 Overcurrent in the output stage

during acceleration

E04 Overcurrent in the output stage at

standstill

E05 Overload The internal electronic motor protection has switched off the output voltage because the motor was

overloaded.

E06 Overload If the duty factor of the built-in braking transistor of the DF6 is too great, the braking transistor is

switched off (the generated overvoltage disconnects the output voltage).

E07 Overvoltage The output voltage has been switched off because the motor was operating regeneratively.

E08 EEPROM fault If the program memory does not operate reliably due to radio frequency interference or excessive

temperature, the output voltage is switched off.

If the supply voltage is switched off while the RST input is active, an EEPROM fault occurs when the

supply voltage is reapplied.

E09 Undervoltage If the DC voltage is too low, the output voltage is switched off (fault-free function of electronics no

longer possible; any problems, such as overheating of motor and insufficient torque).

E10 Fault in current transformer The output voltage is disconnected when a fault occurs in the built-in current transformer of the DF6.

E11 Processor malfunction The processor does not operate correctly. The output voltage is switched off.

E12 External fault message The output voltage is switched off due to an external fault message which is present on a digital

input configured as an EXT input.

E13 Restart inhibit activated The mains voltage was switched on or an intermittent interruption in the supply voltage has occurred

while unattended start protection (input USP) was active.

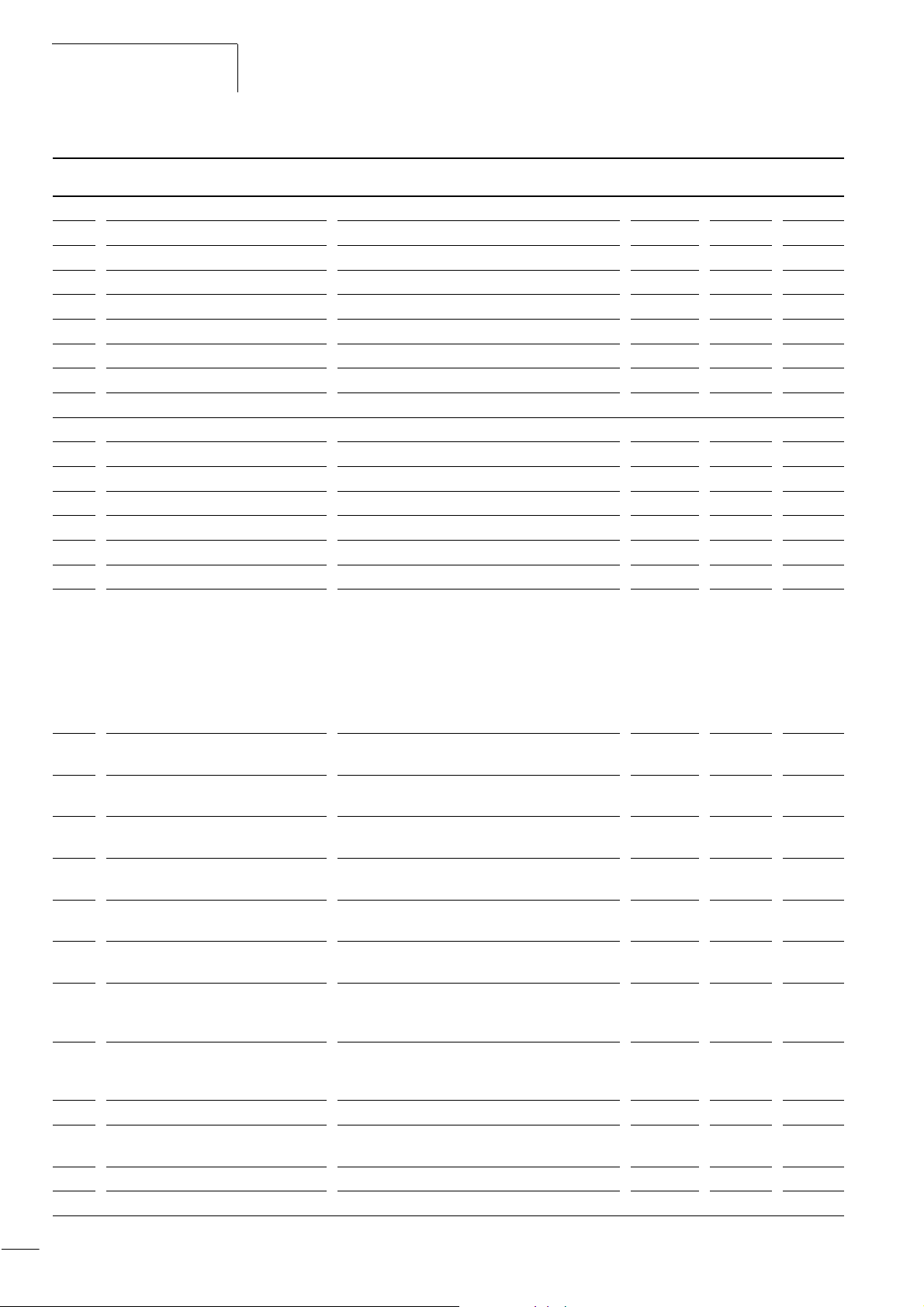

E14 Earth fault Earth faults between the U, V or W terminals and earth are being reliably detected. A protective

circuit prevents destruction of the frequency inverter, but does not protect the operating personnel.

E15 Mains overvoltage If the supply voltage is higher than permitted, the output voltage is switched off 100 seconds after

the voltage supply has been switched on.

E16 Intermittent mains failure An intermittent mains failure of at least 15 ms has occurred. This message appears when the

duration of the mains failure is longer than the time entered under PNU b002 (apage 134)

E21 Overtemperature If the temperature sensor installed in the power section records an operating temperature above the

permissible limit value, the output voltage is switched off.

E23 Gate array fault Internal communication error between CPU and gate array

E24 Mains phase failure One of the three mains phases has failed.

E30 IGBT fault If an excessive current is applied at an IGBT (transistor in the power end stage), the output voltage

is switched off to protect the transistor.

E35 Thermistor fault signal If the resistance of the external PTC thermistor connected to the PTC input (terminals TH and CM1)

is too high, the output voltage is switched off.

---- Undervoltage Because the input voltage is too low, the frequency inverter attempts a restart. If the restart fails, a

fault message is triggered to save the undervoltage fault and the frequency inverter switches off.

E60 to

E69

Fault, expansion module 1 A fault has occurred in expansion modules 1 or 2 and their connections. For further information, refer

to the manuals for the affected expansion module.

E70 to

E79

Fault, expansion module 2