Scope of Supply

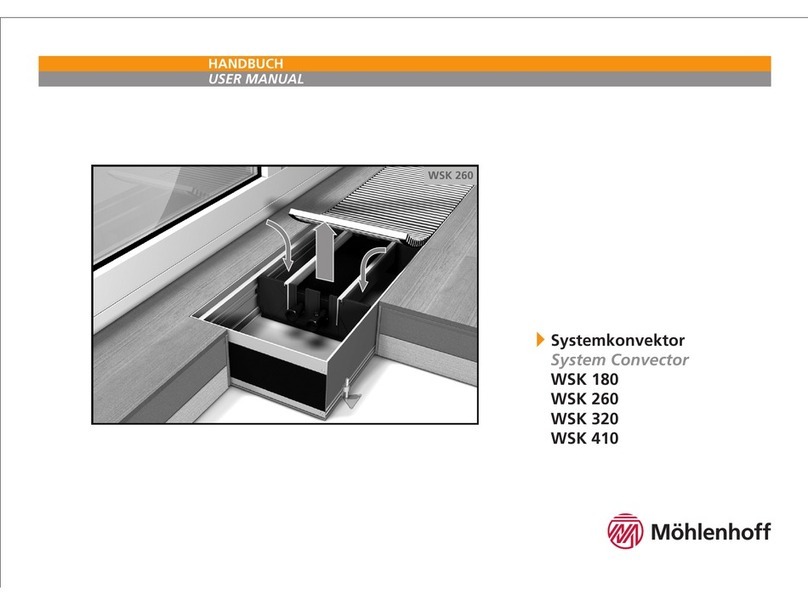

Product Overview

Standard Components

Electric System Convector

ESK 180-110

2 x JB 8.80 without anchors 4 x JB 8.80 with anchors

Adjustment Blocks 8.80 – Set

Installation Protection Cover

Manual

2 x Designer

Roll-Up Grille

with Roll-Up Grille Guard

Alpha Thermostat Standard

AR 2010 S2-S, 230 V, 50/60 Hz

Digital room temperature thermostat for controlling

Alpha-Actuators depending on target and actual tempe-

rature.

OR

Alpha Thermostat Control

AR 2010 C2-S, 230 V, 50/60 Hz

Digital room thermostat with operating mode switch and

plug-in digital clock for engaging Alpha-Actuators depen-

ding on the target and actual temperature.

PLUS

Alpha Mounting Base AS 1000

Mounting Base and electrical connection for Alpha-

Thermostats. Wall and electrical-box mounting

HANDBUCH

Elektro-Systemkonvektor Heizen

ESK 180-110

Inhalt

Möh lenho ff Wärm etec hnik Gm bH

Mus eumst raße 5 4a

DE- 38229 S alzg itter

Int ernet : www.m oehle nhoff .com

DEU

ENG

RUS

I T A

DAN

8-D24-53-030.12 ESK 180-110

Infosymbole

Wa r n u n g vo r ei n e r

Ge f a h r s t e l l e

Wa r n u n g vo r ge f ä h r l i c h e r

el e k t r i s c h e r Sp a n n u n g

Wa r n u n g vo r

Ha n d v e r l e t z u n g e n

Wa r n u n g vo r he i ß e r

Ob e r f l ä c h e

Hi l f r e i c h e r Ti p p

Produktübersicht....................................2

Lieferumfang...................................... 2

Standardkomponenten?.................... 2

Optionale Komponenten?................. 2

Geräteübersicht.................................. 4

Produktinformationen........................... 5

Bestimmungsgemäße Verwendung.. 5

Produktbeschreibung ........................ 5

Einsatzbereiche .................................. 5

Abmessungen ..................................... 6

Technische Daten ............................... 6

Typenschild ......................................... 6

Konformitätszeichen ......................... 6

Voraussetzungen................................... 7

Fachkenntnisse ................................... 7

Montageort ........................................ 7

Funktionsweise...................................... 8

Konvektionsprinzip ............................ 8

Montage............................................................. 9

Montagevorbereitung ................................... 9

Höhenjustierung ...........................................9

Freie / volle Begehbarkeit.............................. 9

Installation und Nivellierung ........................ 9

Hydraulischer Anschluss ................................ 10

Heizungstechnische Arbeiten ....................... 11

Elektrischer Anschluss ................................... 11

Leitungsplan .................................................. 12

Interne Verdrahtung ..................................... 13

Detailanschlussplan interne Verdrahtung ...13

Anschlussplan ................................................ 14

Inbetriebnahme................................................. 15

Voraussetzungen für die Inbetriebnahme .. 15

Bedienung / Betrieb ...................................... 15

Instandhaltung.................................................. 16

Wartung / Reinigung .................................... 16

Aufbewahrung Handbuch ............................ 17

Technischer Service........................................ 17

Alpha Thermostat Comfort

AR 2010 K2-S, 230 V, 50/60 Hz

Digital room thermostat with operating mode switch for

engaging Alpha-Actuators depending on the target and

actual temperature.

OR

Digital Timer – DS 1000

Together with the digital timer, the fan control with room

thermostats and actuators make up for a comfortable and

energy-saving individual room control system.

The 2-channel digital timer controls the desired setback

times. The clearly visible LCD display and the program keys

allow convenient programming of the digital timer.

Component for Night Setback Control