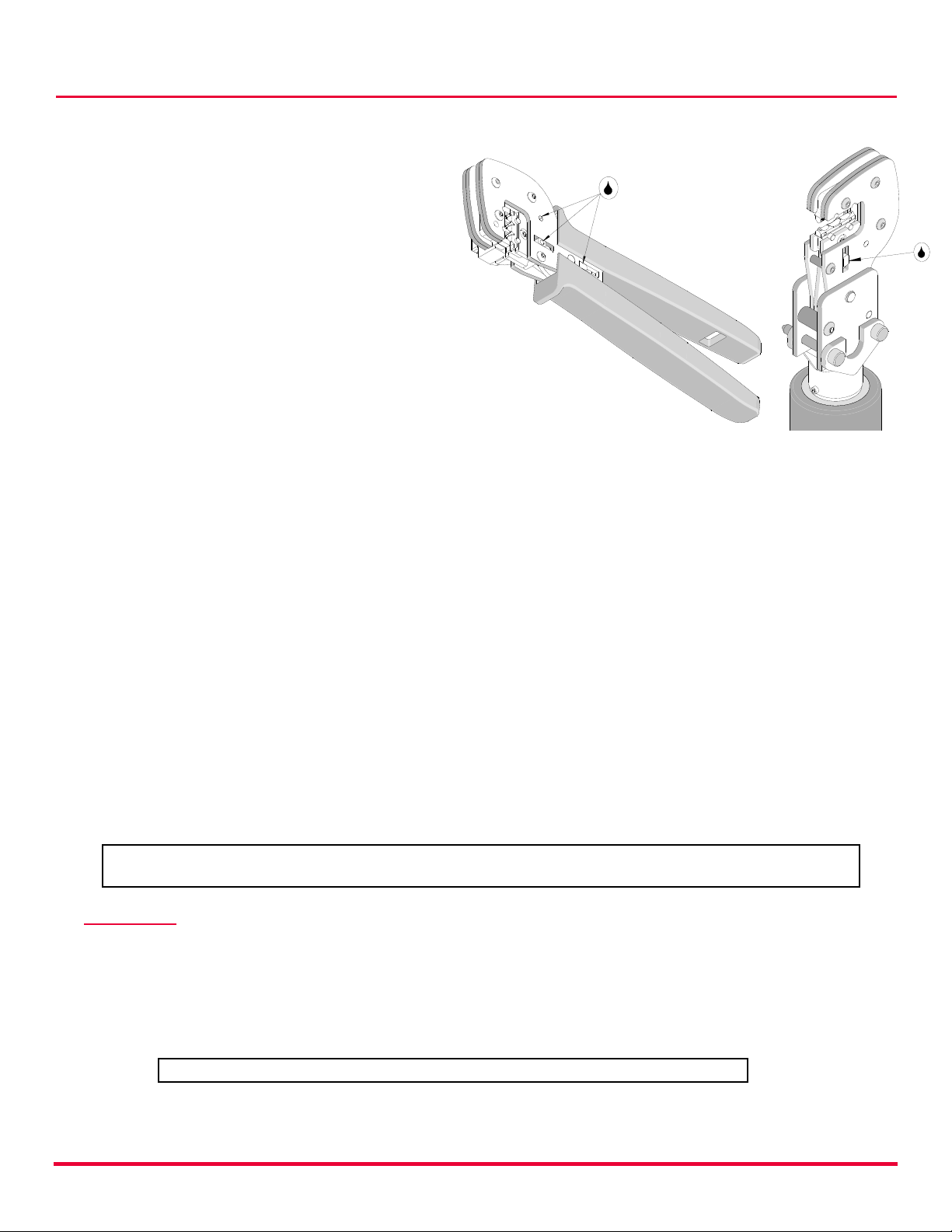

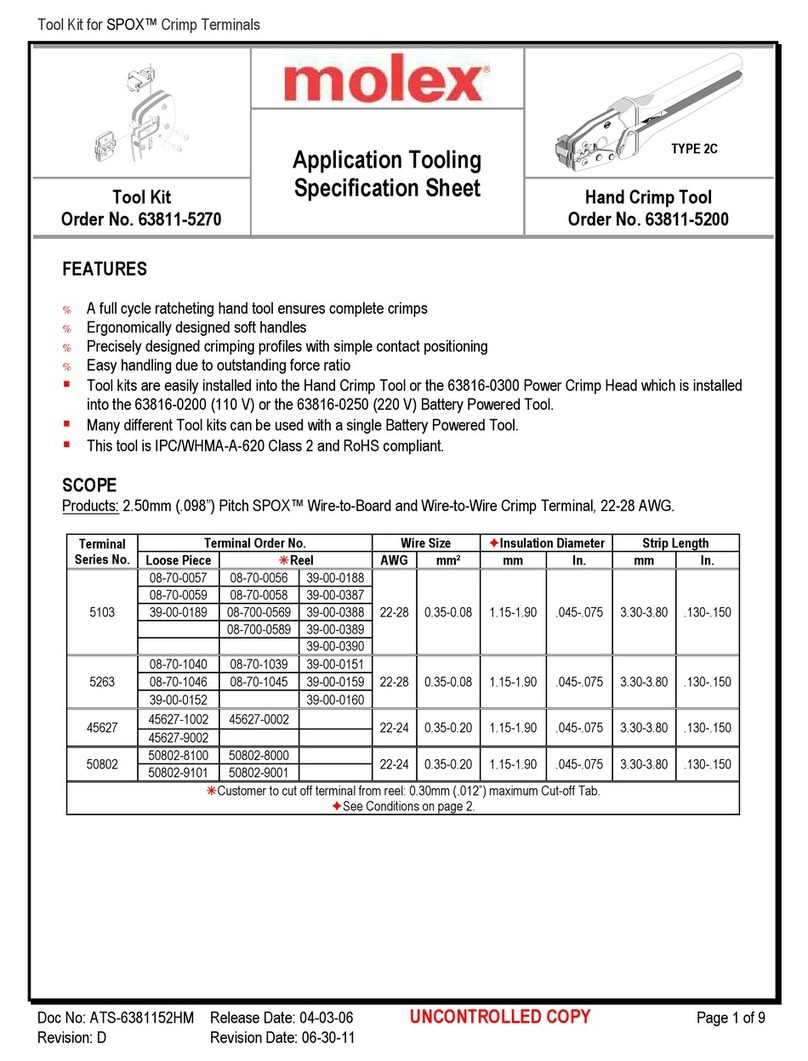

molex 63827-1600 User manual

Other molex Crimping Tools manuals

molex

molex 207129 Series User manual

molex

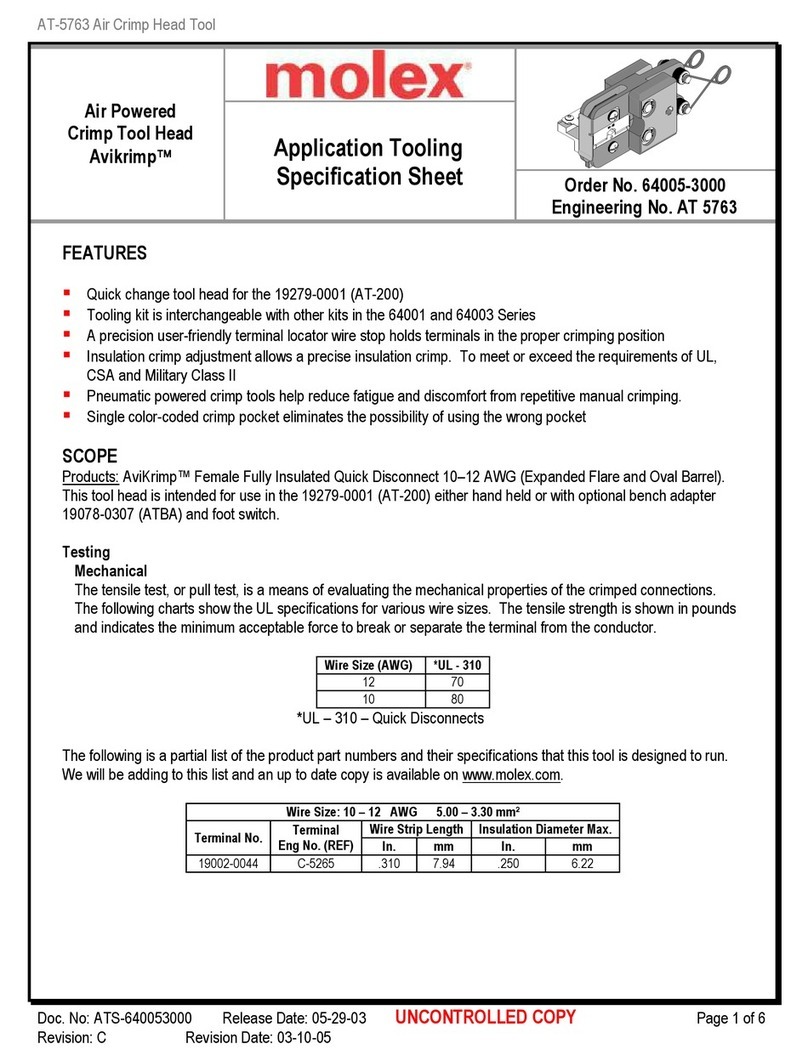

molex Avikrimp 64005-3000 User manual

molex

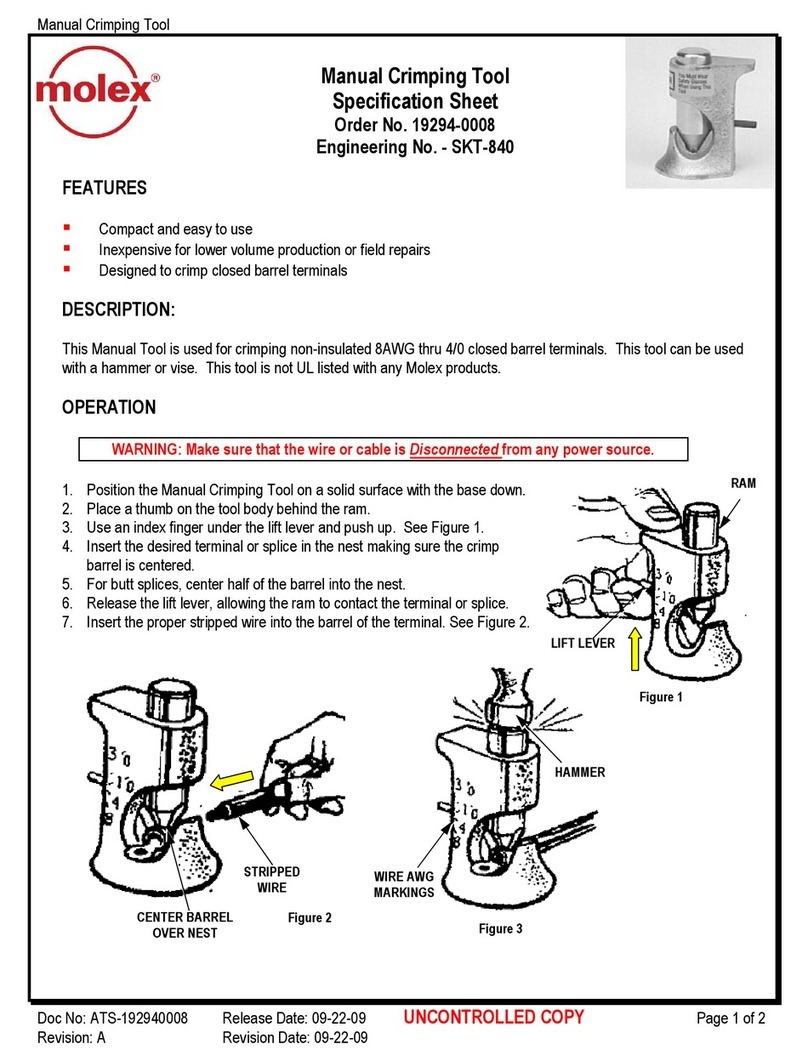

molex 19294-0008 User manual

molex

molex 207129 Series User manual

molex

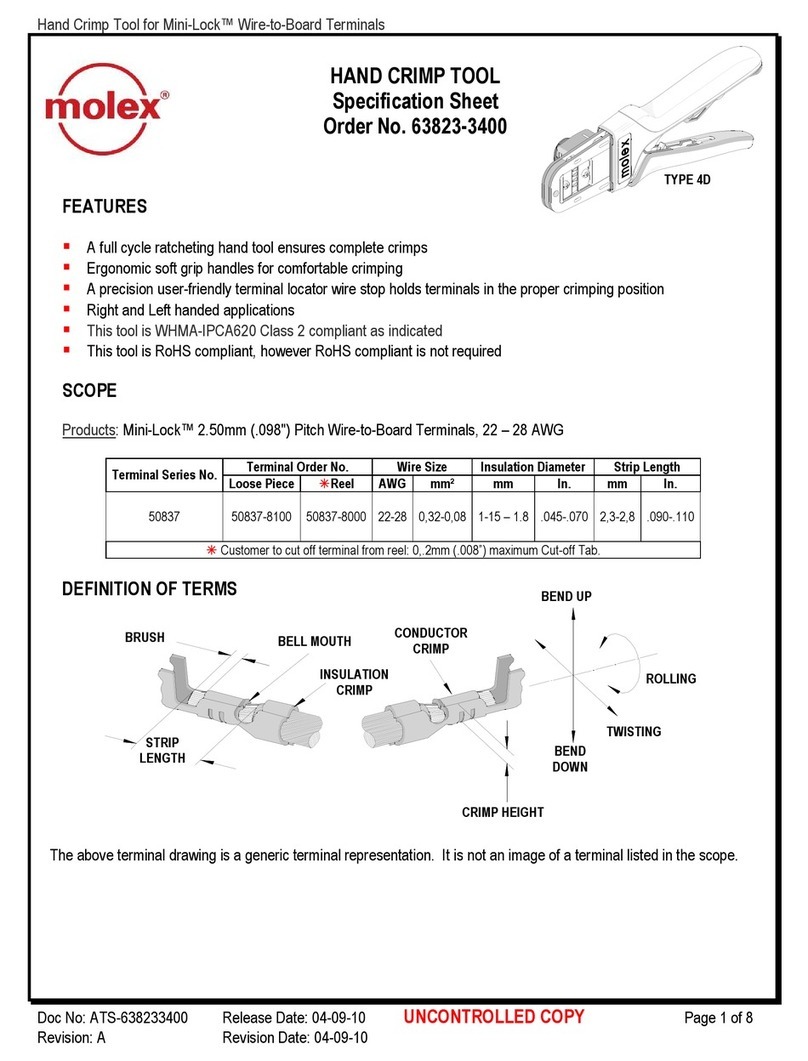

molex 50837 User manual

molex

molex 207129 Series User manual

molex

molex 64005-4100 User manual

molex

molex 207129 Series User manual

molex

molex 63827-6070 User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

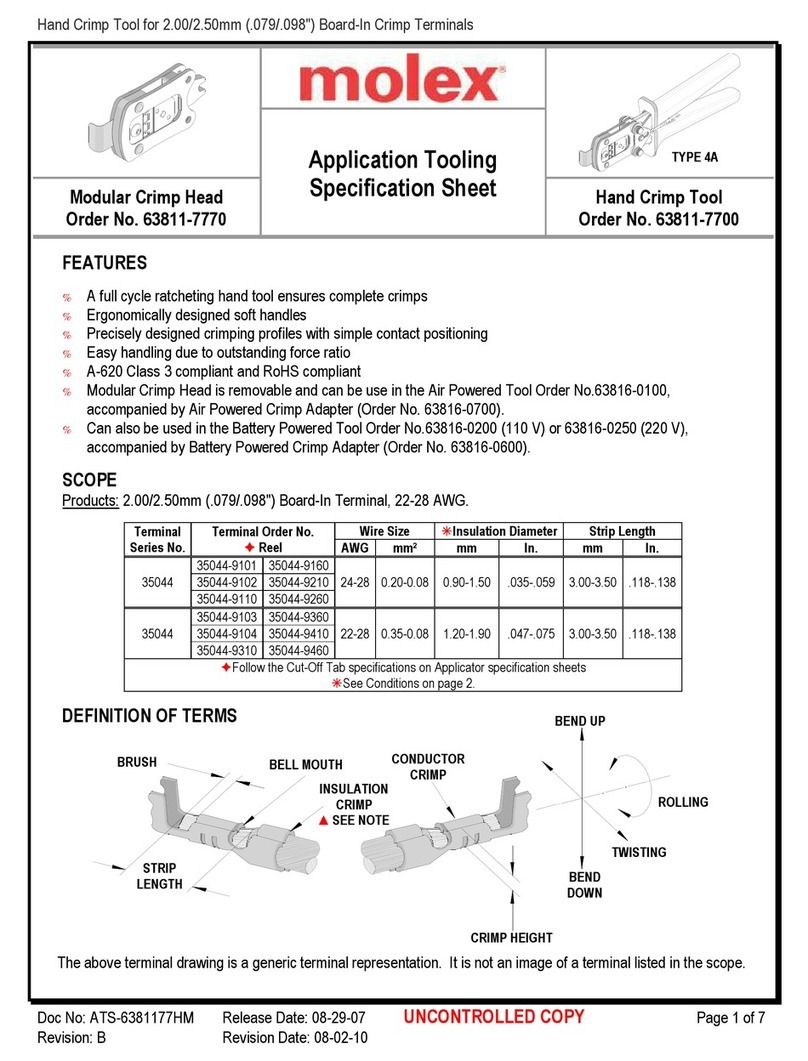

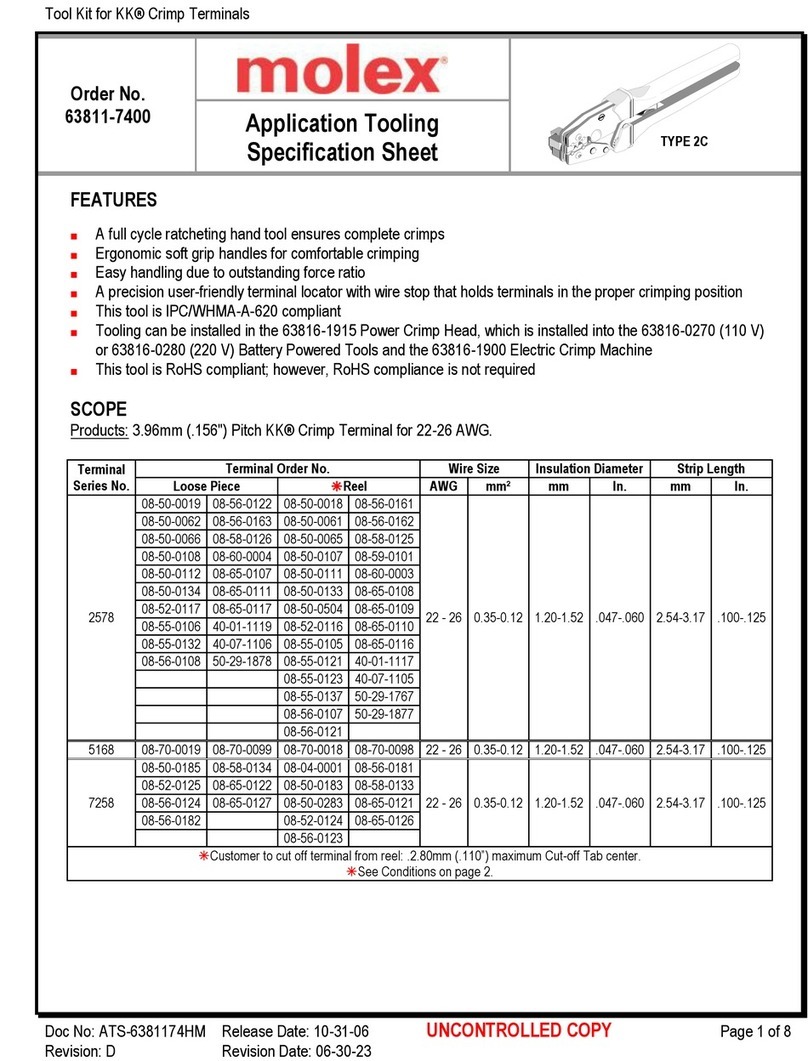

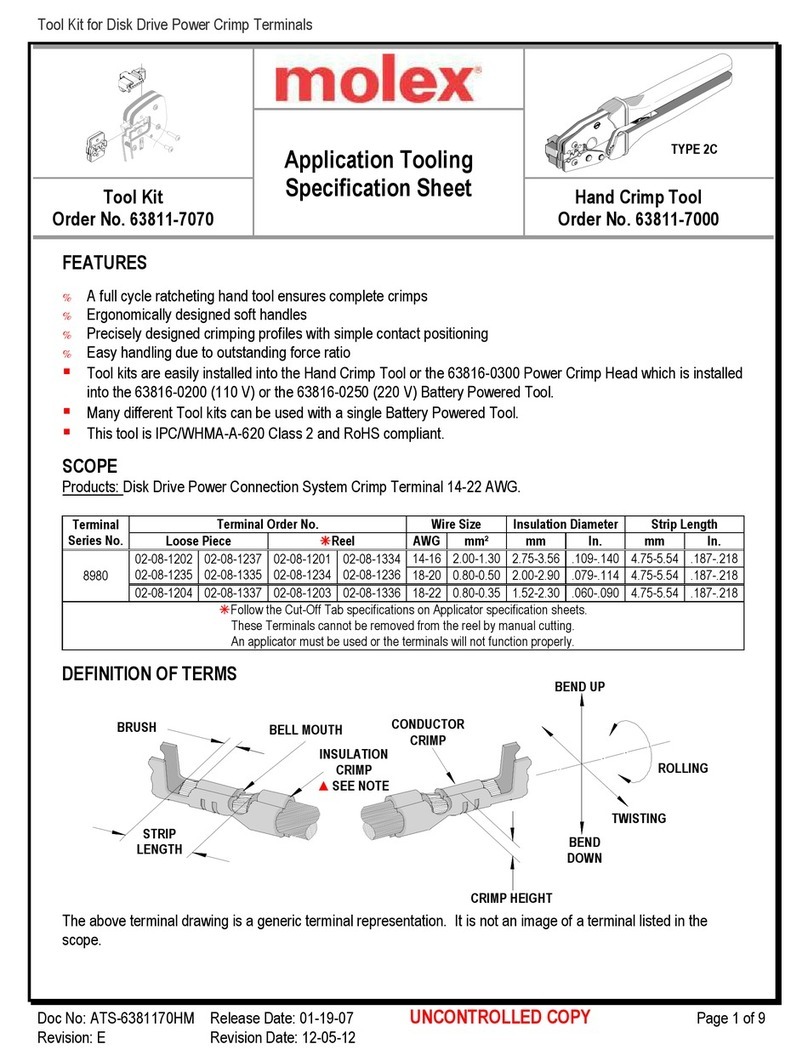

molex 63811-7070 User manual

molex

molex AT-200 Manual

molex

molex 207129 Series User guide

molex

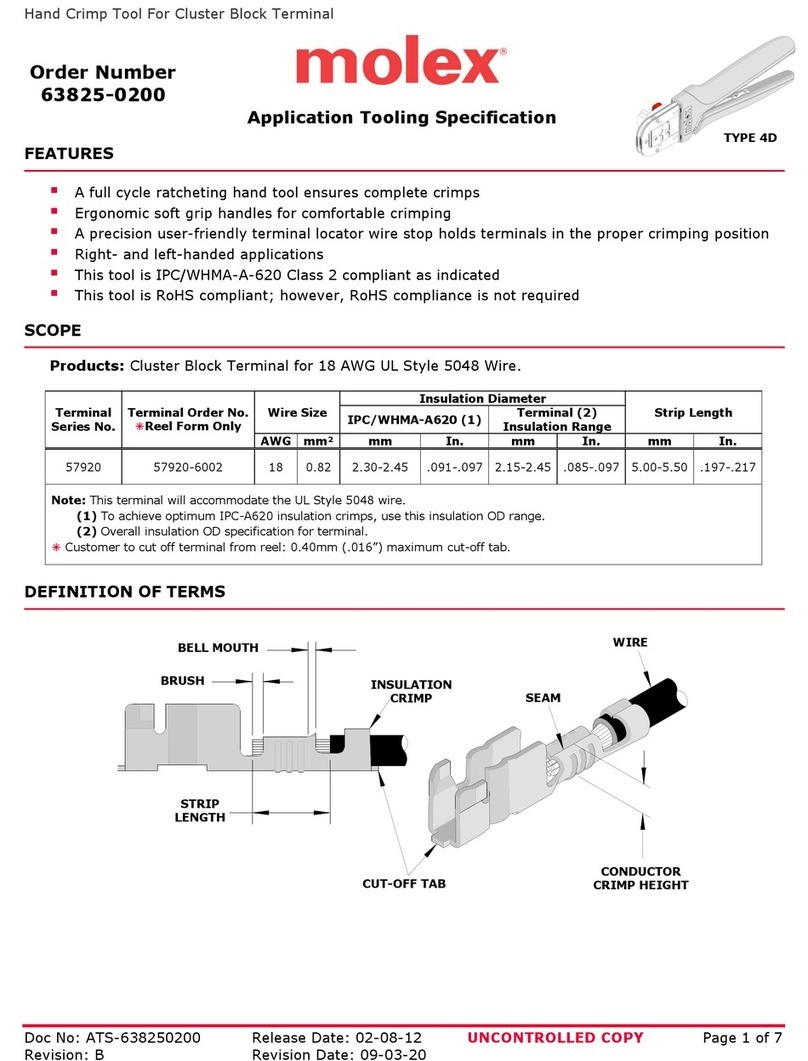

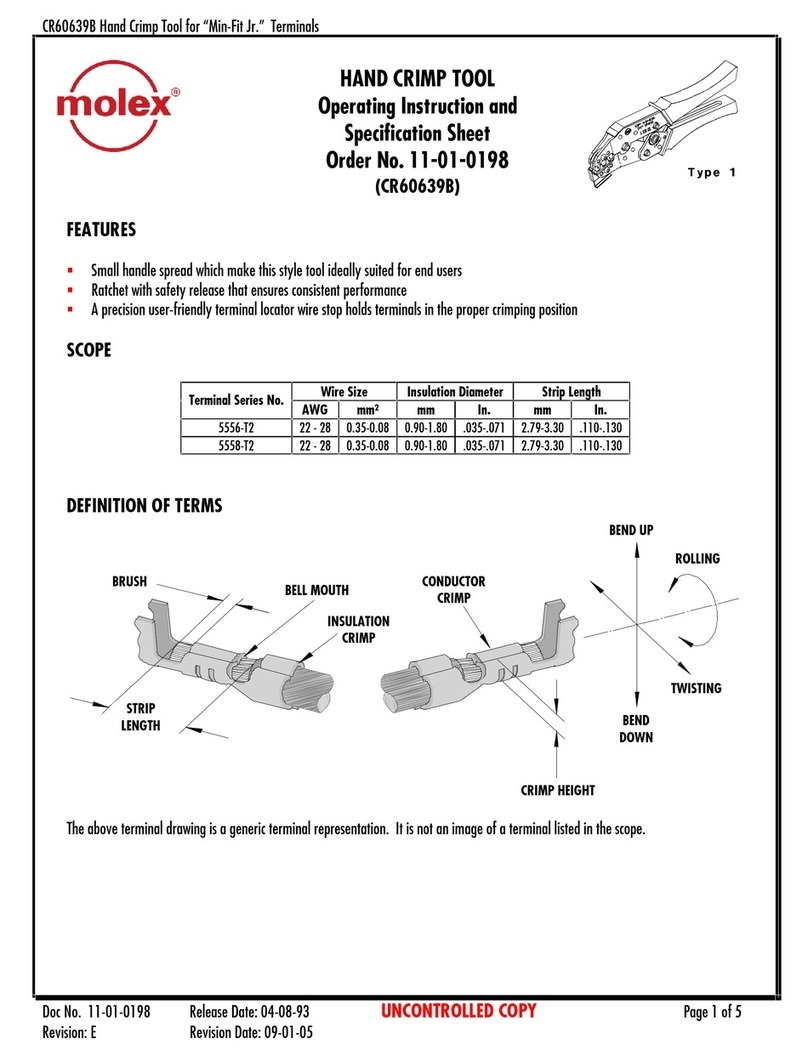

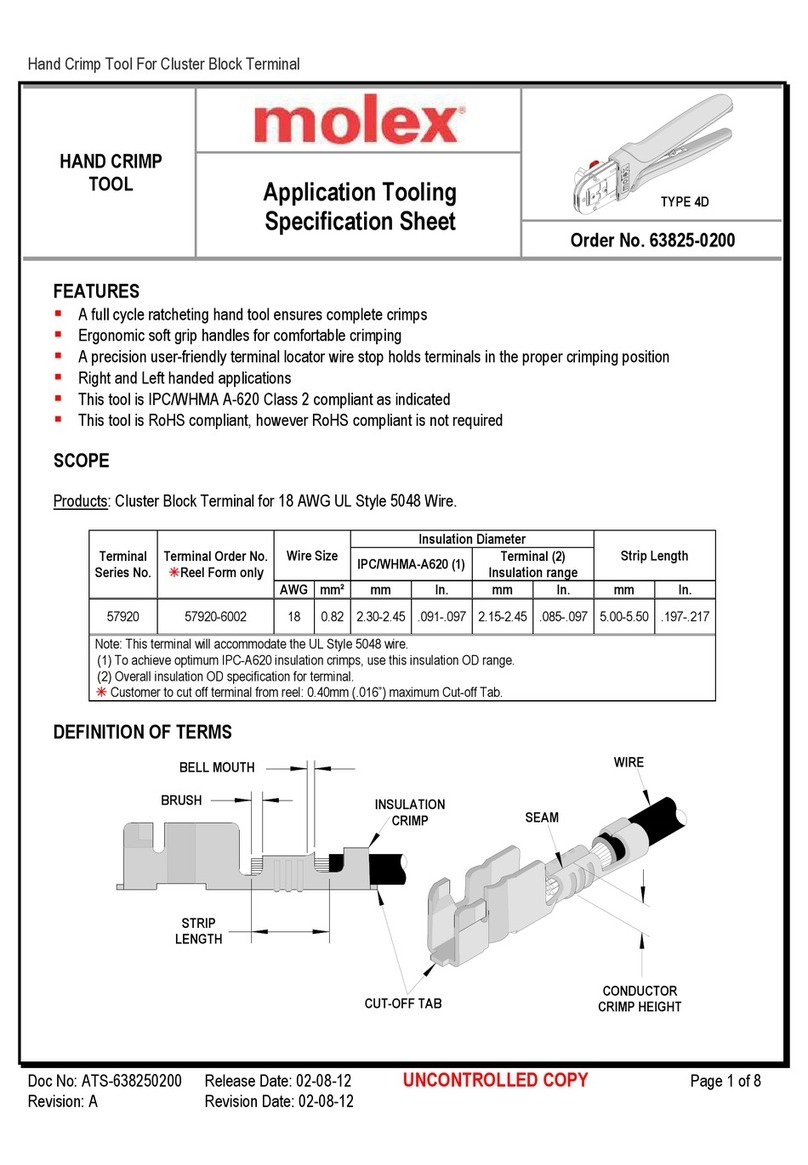

molex CR60639B User manual

molex

molex 69008-1100 User manual

molex

molex 207129 Series User manual

molex

molex 63811-7100 User manual

molex

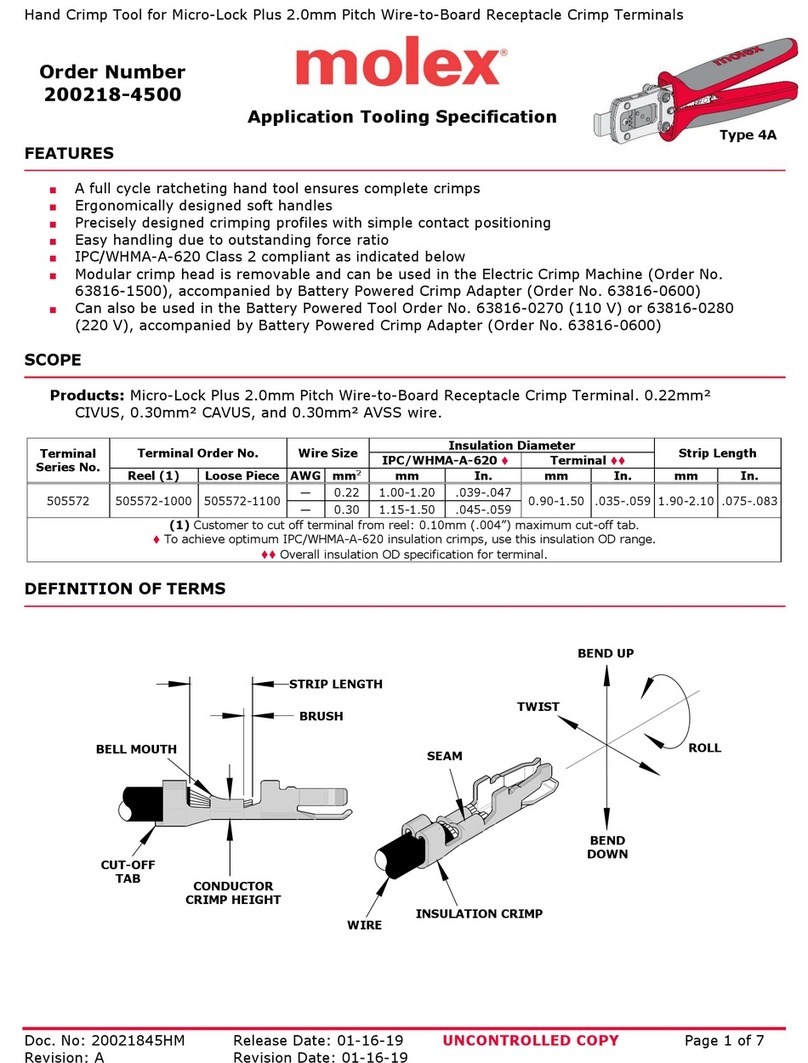

molex 200218-4500 User guide

molex

molex 207129 Series User manual

Popular Crimping Tools manuals by other brands

Emerson

Emerson Klauke ES 20RMCCFB manual

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

TE Connectivity

TE Connectivity ERGOCRIMP 1-1579001-3 instruction sheet

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

TE Connectivity

TE Connectivity 539 726-2 instruction sheet