MACHINE

EMPLOYMENT

The machine

is

a hay-rake tedder.

Use

it

only and exclusively for raking

and

ted-

ding

hay

and

cut grass.

The manufacturer declines any responsi-

bility for a different

use

from the de-

scribed one.

Familiarize yourself with the operating

controls and the correct

use

of

the ma-

chine.

~Never

permit children or inexpert

~

to operate your machine.

& Avoid working whilst people,

especially children

and

pets, are

nearby.

Keep

in

mind that the

operator

is

responsible for accidents to

people and to their property.

The user must know the characteristics

and

the safety procedures of the ma-

chine.

The accident prevention rules and any

other requirement

of

safety and

of

occu-

pational medicine must always

be

ob-

served.

The manufacturer declines any re-

sponsibility for possible damages

deriving from any arbitrary change

on

the

machine.

&

Do

not get

on

the machine whilst

working, nor have yourself car-

ried

by

it.

ACCIDENT

PREVENTION

MEASURES

Follow the instructions described

on

the

labels stuck

on

the machine.

Q Scour the

area

where the ma-

chine

is

to

be

used

and remove

all foreign matters (stones, wire,

sticks, etc...).

4

Carry out the checks, the operations of

maintenance, adjustment and repair

when the machine

is

not working and

is

unhooked from the tractor.

In

case

of

road haulage, the highway

code rules have to

be

observed.

& Danger through rotating parts!

It

is

absolutely forbidden to take

away

or

to damage the guards

and

to

use

the machine without them.

& Danger through thrown objects!

The machine

can

throw objects

or stones that

may

lie

on

the

ground.

A

It

is

forbidden to stay within the

~

working radius

of

10

m.

&

Do

not carry out operations of

cleaning or maintenance with

engine on, nor with connected

power take-off.

& While working

in

presence

of

dust, wear a mask

and

glasses to

protect your throat and

eyes

if

your tractor

is

lacking a cabin.

The acoustic pressure level

is

inferior to

70

dB.

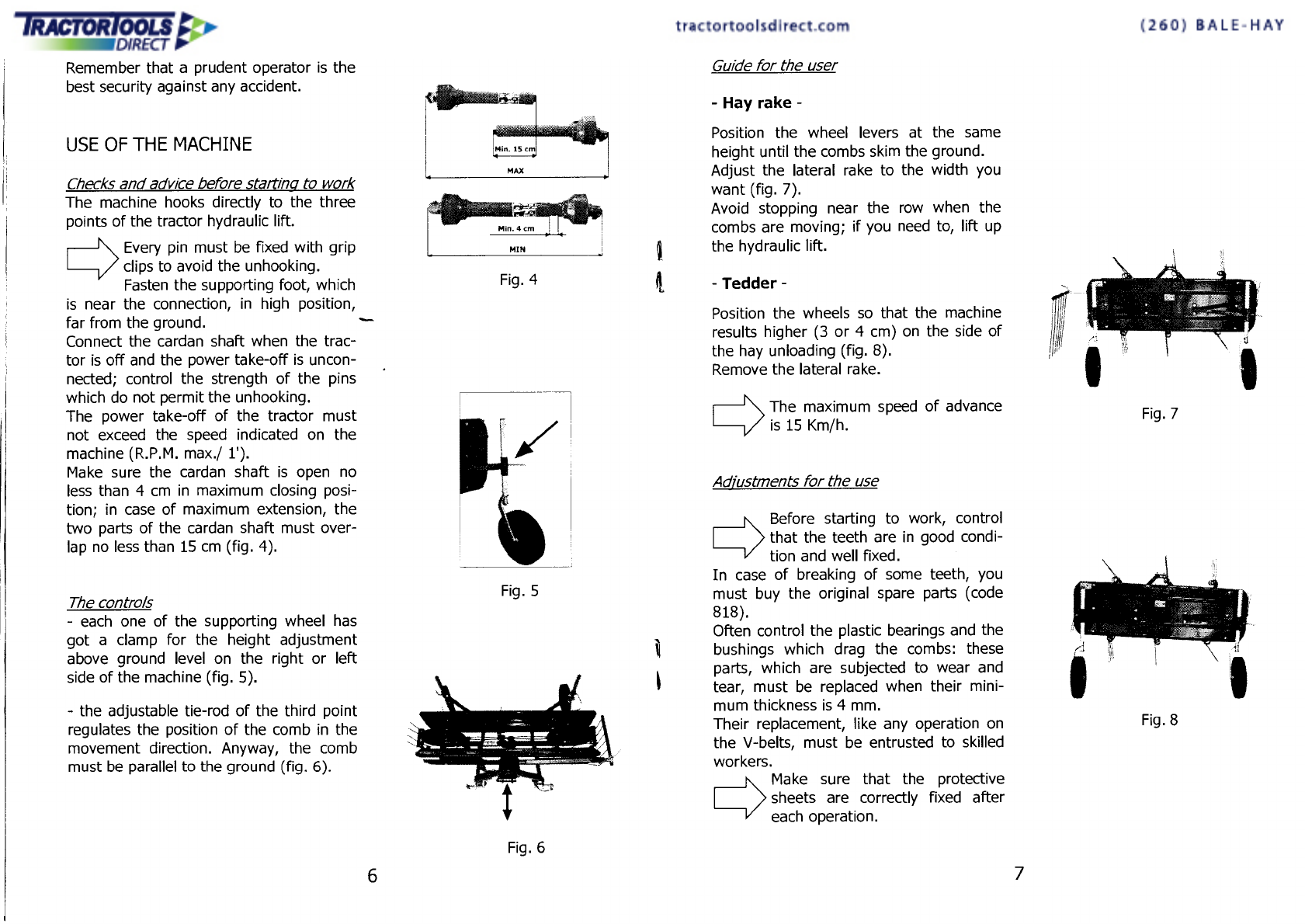

The safety signals are (fig. 2):

A= Before the

use

of

the machine,

read

the manual.

B=

Danger through thrown objects;

keep

the safety distance.

C=

Danger through drive belts;

do

not

take away the guards with machine

on.

D= Turn

off

the engine and take away the

key

before any operation

of

repair

and

maintenance.

The corresponding labels are stuck

on

the

machine

in

the indicated places. (fig. 3)

These signals must always

be

visible and,

when lost or illegible, they have to

be

replaced with original ones.

A

B

c

D

5

&tW\1

~--j

r~-~-;-----

\i£DH1

~

II'&&

::

.

i[

~0

u

~~

&;;:]

Fig.

2

Fig.

3