Issue 03 –June 2018 4

Guide Contents

Introduction: ...........................................................................................................................................6

Tools that you will need:..................................................................................................................... 6

Safety & Disclaimer Notice ................................................................................................................. 7

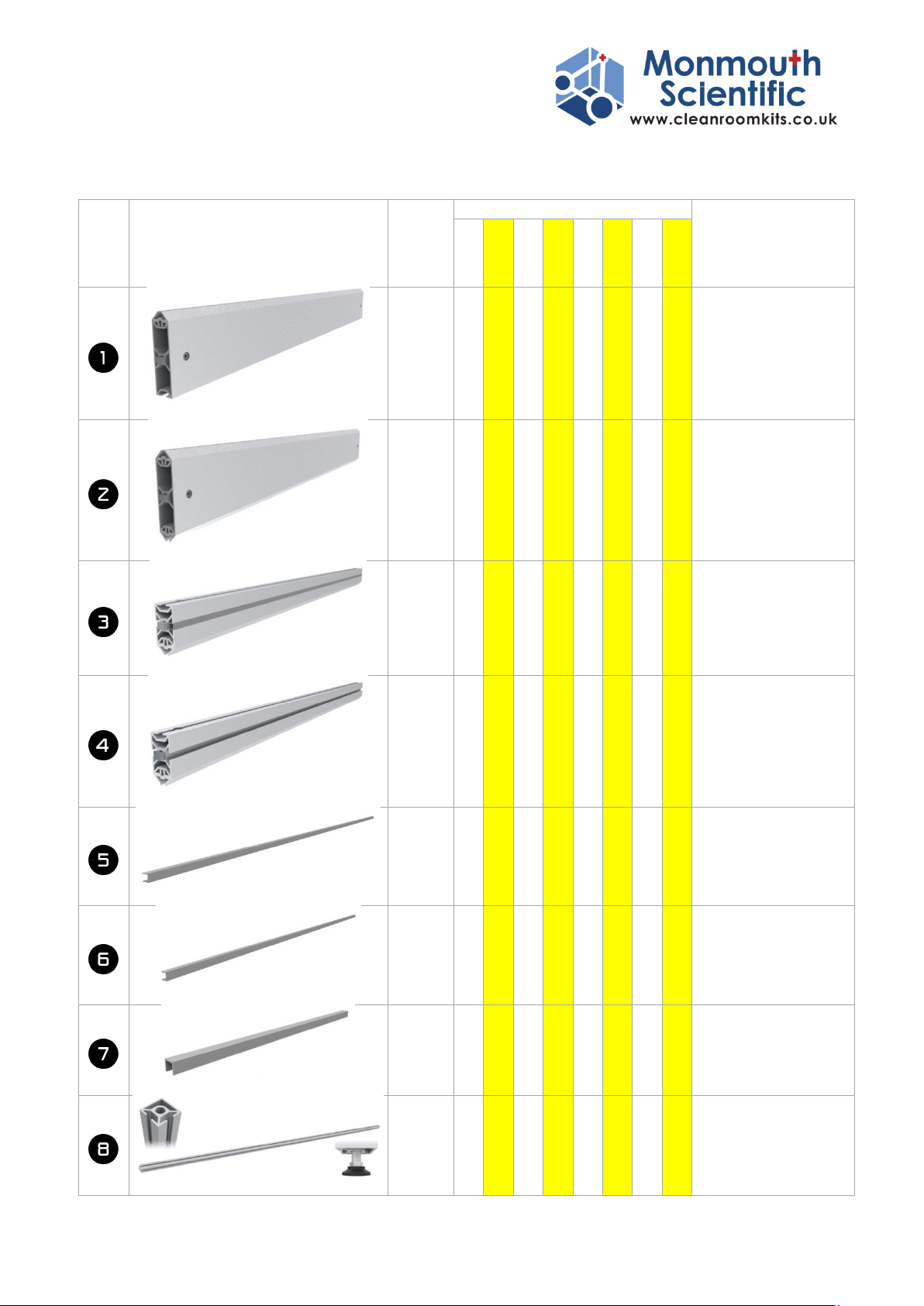

Complete Parts List ................................................................................................................................. 8

Unions? .................................................................................................................................................15

Union Parts........................................................................................................................................15

How does the Union Work?..............................................................................................................16

The Union in the Monmouth Cleanroom: ............................................................................................ 17

Joining two pieces:................................................................................................................................19

Fitting a panel: ...................................................................................................................................... 21

Fitting a ceiling tile support: .................................................................................................................23

Standard Wall Panel..............................................................................................................................24

Door Panels...........................................................................................................................................25

Door ......................................................................................................................................................26

Ceiling Assembly ...................................................................................................................................27

4M –2m x 2m room.......................................................................................................................... 27

4Mplus –2m x 2m room with 1m x 2m atrium ................................................................................28

6M –3m x 2m room.......................................................................................................................... 29

6Mplus –3m x 2m room with 1m x 2m atrium ................................................................................30

9M –3m x 3m room.......................................................................................................................... 31

9Mplus –3m x 3m room with 1m x 3m atrium ................................................................................32

12M –4m x 3m room........................................................................................................................33

12Mplus –4m x 3m room with 1m x 3m atrium ..............................................................................34

Using CAM1000 in 9M, 9M+, 12M & 12M+...................................................................................... 35

Top Door Runner Assembly ..................................................................................................................36

Hanging the door(s) .......................................................................................................................... 37

Bottom Door Runner Assembly ............................................................................................................38

Soft Close Door Adjustment..................................................................................................................39

Room Assembly.....................................................................................................................................41

WARNINGS........................................................................................................................................41

Installing Clean Air Modules (CAM) ......................................................................................................47

CAM1000...........................................................................................................................................48

Introduction ......................................................................................................................................48

Installation ........................................................................................................................................49

Setting the fan speed ....................................................................................................................50

Maintenance .....................................................................................................................................51