Using a temperature sensor as an example.

If the sensor is using factory calibrations the Calibrate Active eld is set True (1) so the bit

values are 00010000 and it is represented as 16.

If the sensor is outside the Min or Max threshold, the Aware State is set True (1) so the bit

values are 00000010 and it is represented as 2.

If the customer has calibrated the sensor this eld the Calibrate Active eld is set False

(0) AND the sensor is operating inside the Min and Max Thresholds, the bits look like

00000000 this is represented as 0.

If the sensor is using factory calibrations and it is outside the threshold the bit values are

00010010 and it is represented as 18 (16 + 2 because both the bit in the 16 value is set

and the bit in the 2 value is set).

Note: These two are the only bits that typically observed outside of our testing procedures.

CALIBRATING SENSOR DATA

Certain wireless sensors can be calibrated for more accurate readings (Example: For

Temperature sensors). If calibration is possible for a sensor, the “Calibrate” tab will be

visible in the tab bar.

A. Go to the tab to open the sensor calibration settings window.

B. To calibrate a sensor, you will want to ensure that the environment of the sensor and

other calibration device is stable. Note the “Expected Next Check-in” time for the sensor

you are calibrating and take a reading from your calibration device a few minutes prior to

the sensors next check-in.

C. Enter the actual (accurate) reading from the calibration device into the text eld.

D. If you need to change the unit of measurement you can do that here.

E. Press “Calibrate”.

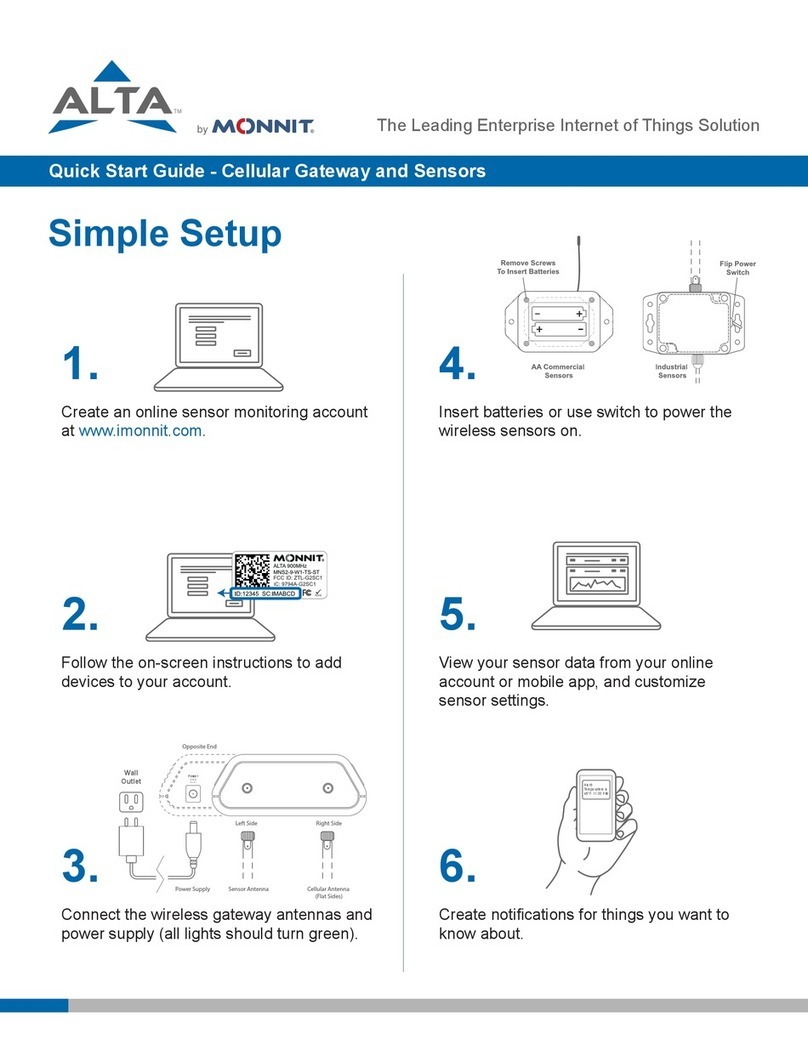

To ensure that the calibration command is received prior to the sensors next check-in,

press the control button on the back of the gateway, once, to force communication (Cellular

and Ethernet gateways).

After pressing the "Calibrate" button and choosing the gateway button, the server will send

the command to calibrate the specied sensor to the gateway. When the sensor checks-in,

it will send the pre-calibration reading to the gateway, then receive the calibration command

and update it’s conguration. When the process is completed, it will send a “Calibration

Successful” message. The server will display the sensor’s last pre-calibrated reading for

this check-in, then all future readings from the sensor will be based on the new calibration

setting.

It is important to note that after calibrating the sensor, the sensor reading returned to the

server is based on pre-calibration settings. The new calibration settings will take affect on

the next sensor heartbeat.

Note: If you would like to send the changes to the sensor right away, please remove the battery(s) for a full 60

seconds, then re-insert the battery(s). This forces the communication from the sensor to the gateway and this the

message to make a change from the gateway back to the sensor. (If the sensors are industrial sensors, turn the

sensor off for a full minute, rather than removing the battery).

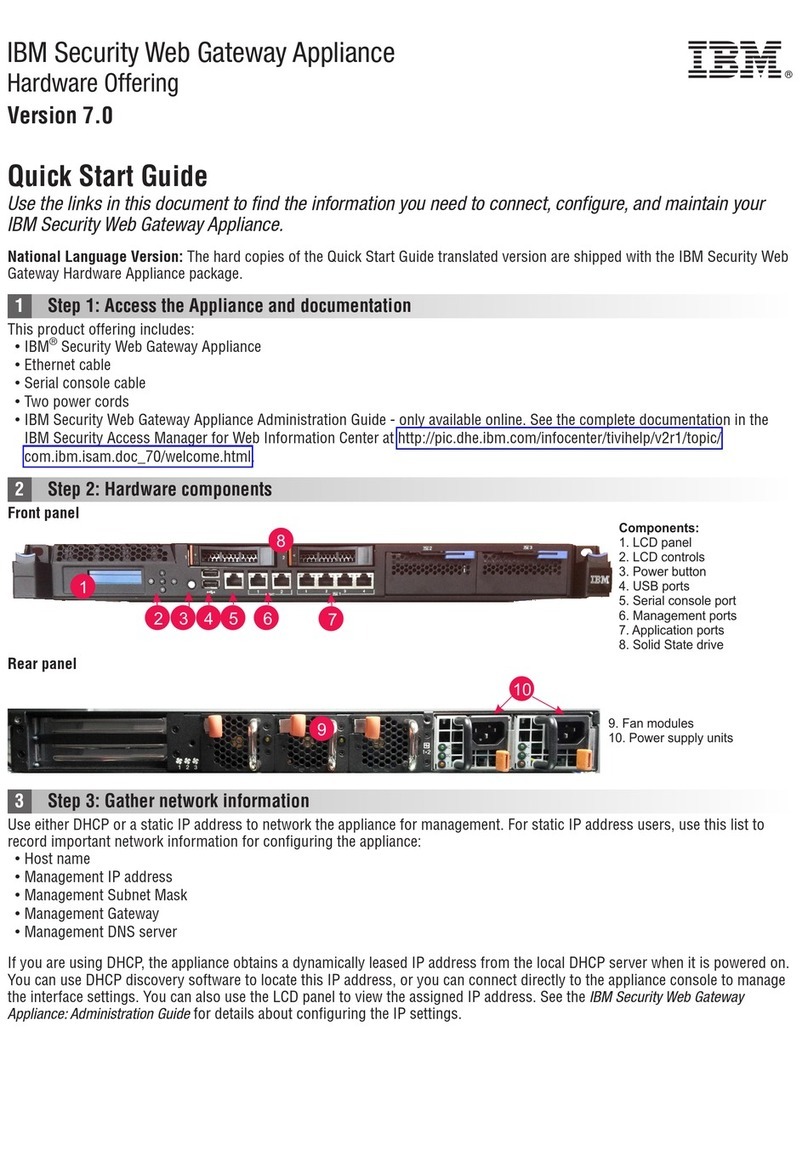

MANAGE SENSOR NETWORKS

To view or edit information about your wireless sensor network(s), select the Networks box

in the account overview page.

The following network list page allows you to edit details, create new sensor tetworks, and

manage wireless gateways and sensors for your network(s). Find the network you wish to

modify in the list and select it to be taken to to the network edit page.

The network edit page will give the option of

changing the name of your network, enable

notications, enable holding, and review the

Install Tech Access Cut-off Date.

Remember, you must press the “Save”

button after making any changes in this

section.

Below this section is a list of sensors and

gateways attached to the account. Choosing

the icon of a trashcan beside each sensor

will delete it from the network. Selecting

the icon directly above the sensor section

will allow new devices to be added to the

network. Review the steps on registering a

new device on page 3 of this user guide.

Note: A sensor or gateway cannot be recovered once it

has been deleted from the network. It is reccomended that

you export a sensor’s data history before clearing it from

the list.

PAGE 14 PAGE 15