FG038 MK2 Divider RevA19 13-02-19

ELECTRICAL SAFETY AND ADVICE REGARDING

SUPPLEMENTARY ELECTRICAL PROTECTION:

Commercial bakeries, kitchens and foodservice areas are environments where

electrical appliances may be located close to liquids or operate in and around damp

conditions or where restricted movement for installation and service is evident.

The installation and periodic inspection of the appliance should only be undertaken by

a qualified, skilled and competent electrician, and connected to the correct supply

suitable for the load as stipulated by the appliance data label.

The electrical installation and connections should meet the necessary requirements of

the local electrical wiring regulations and any electrical safety guidelines.

We Recommend:

−Supplementary electrical protection with the use of a residual current device

(RCD)

−Fixed wiring appliances incorporate a locally situated switch disconnector to

connect to, which is easily accessible for switching off and safe isolation

purposes. The switch disconnector must meet the specification requirements

of IEC 60947.

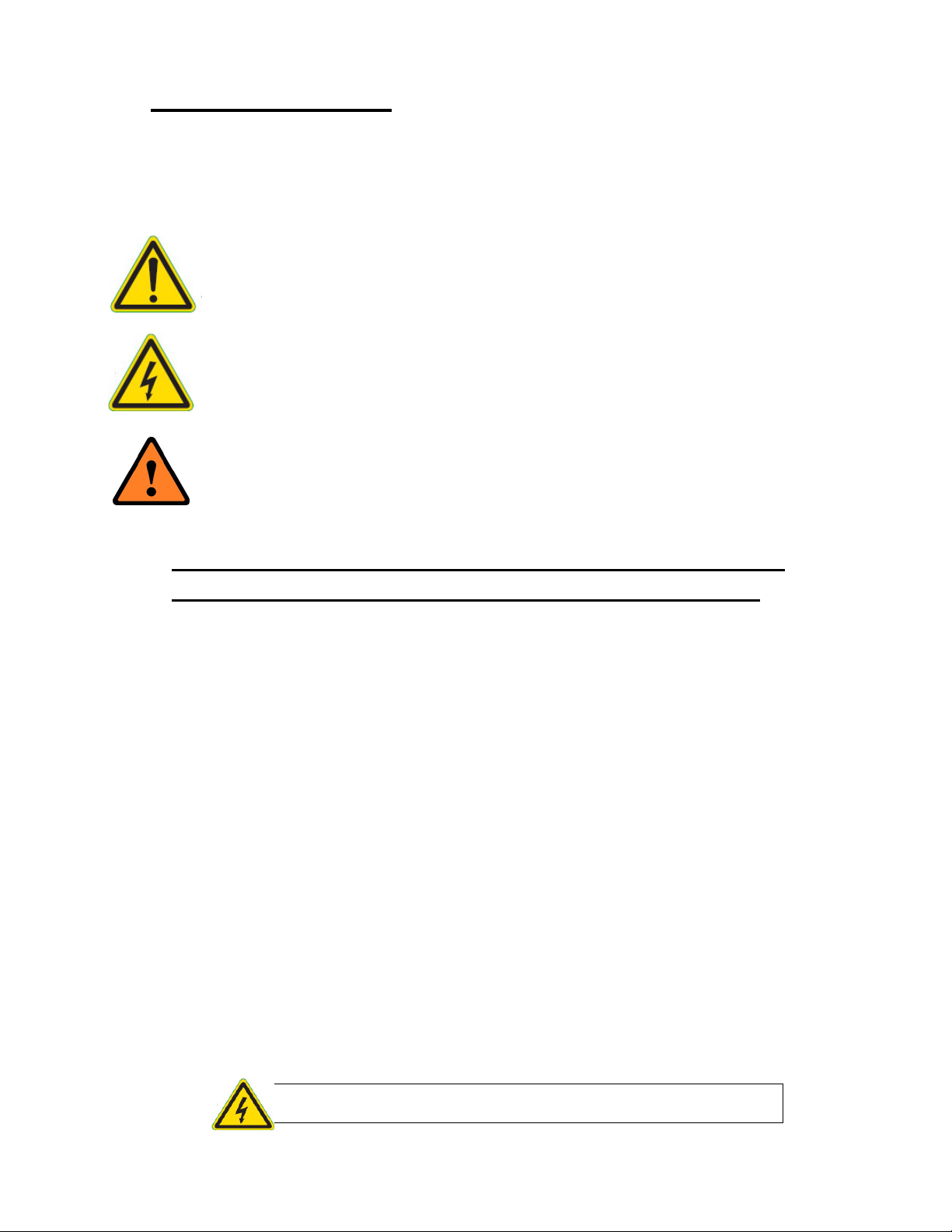

SAFETY SYMBOLS

The following safety symbols are used throughout this product documentation.

Before using your new equipment, read the instruction manual carefully and pay special attention

to information marked with the following symbols.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.WARNING

Indicates a hazardous situation which, if not avoided,

will result in electric shock.

WARNING

Indicates a hazardous situation which, if not avoided,

will result in minor or moderate injury.

CAUTION

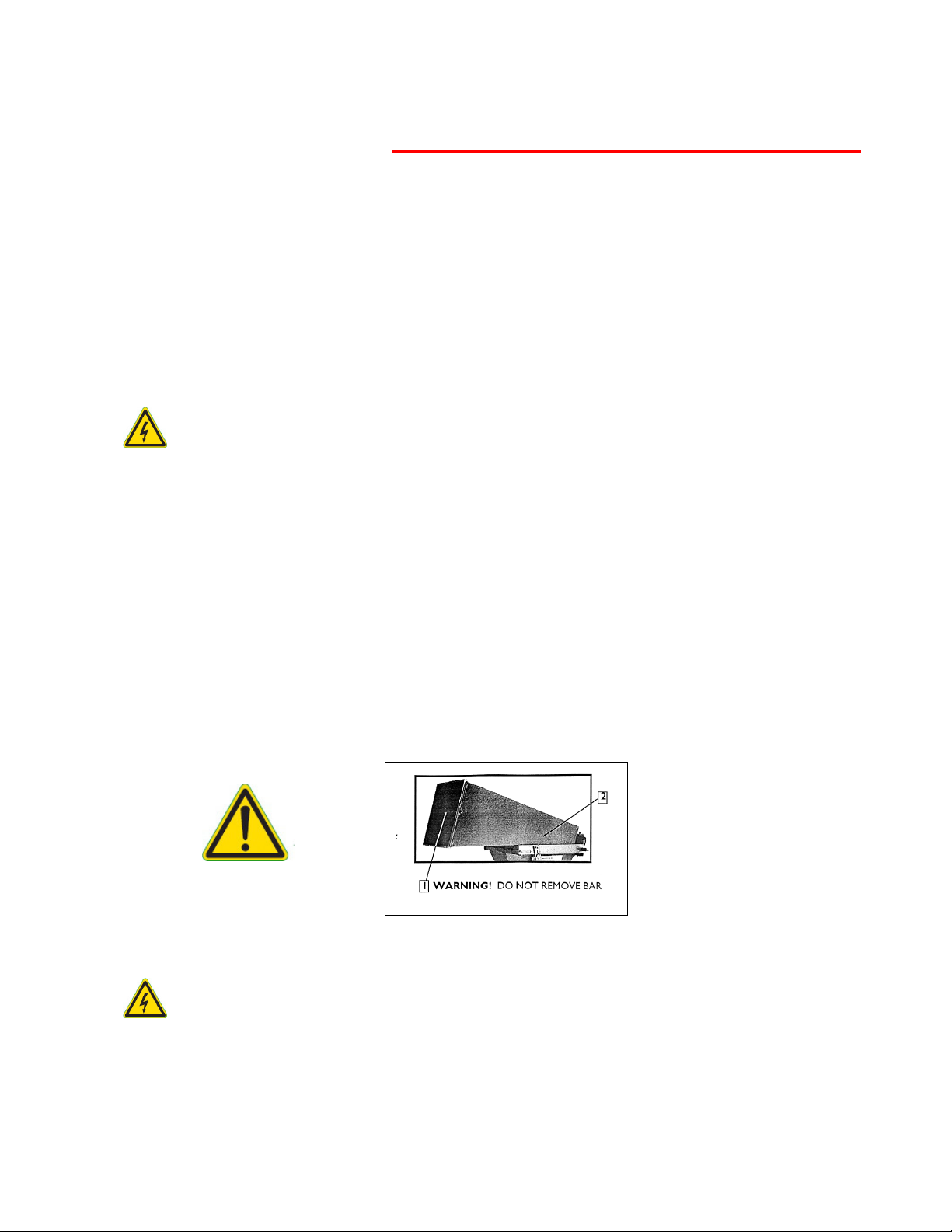

The supply to this machine must be protected by a