FG079 OMEGA plus inc wirecut QUICKSTART RevA22 13-08-22

SAFETY

1Never use a machine in a faulty condition and always report any damage.

2Only trained engineers may remove parts that need a tool to remove them.

3Always ensure hands are dry before touching any electrical appliance

(including cable, switch and plug).

NEVER move machinery by pulling on the power cords or cables.

4Ensure that the floor area around the OMEGA is clean to avoid slipping –

especially if carrying heavy hopper and template components to and from the machine.

5All operatives must be fully trained.

Use of the machine can prove dangerous if:

the machine is operated by untrained or unskilled staff

the machine is not used for its intended purpose

the machine is not operated correctly

All safety devices applied to the machine during manufacture and the

operating instructions in the cd manual are required to operate this

machine safely. The owner and the operator are responsible for operating

this machine safely.

6People undergoing training on the machine must be under direct supervision.

7Do not operate the machine with any panels or guards removed.

8No loose clothing or jewellery should be worn while operating the machine.

9Switch off power at the mains isolator when machine is not in use and before

carrying out any cleaning or maintenance.

10 The bakery manager or the bakery supervisor should carry out daily safety checks.

11 Do not operate machine without a hopper, a template and guard fitted correctly.

12 Due to the essential requirement for handling heavy components during cleaning, it is

recommended that protective footwear be worn when carrying out such procedures.

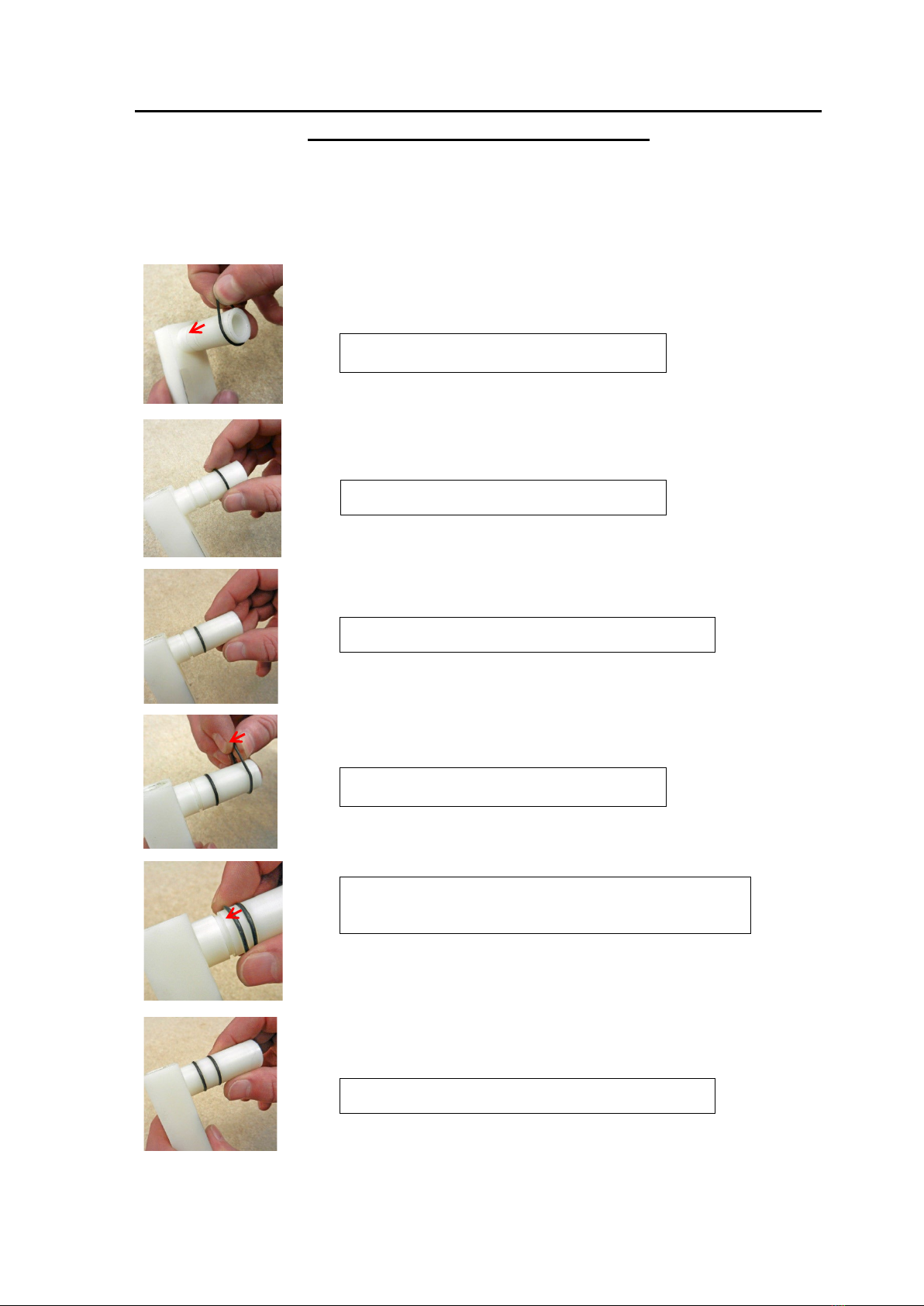

(11) HOPPER TEMPLATE AND

GUARD FITTED

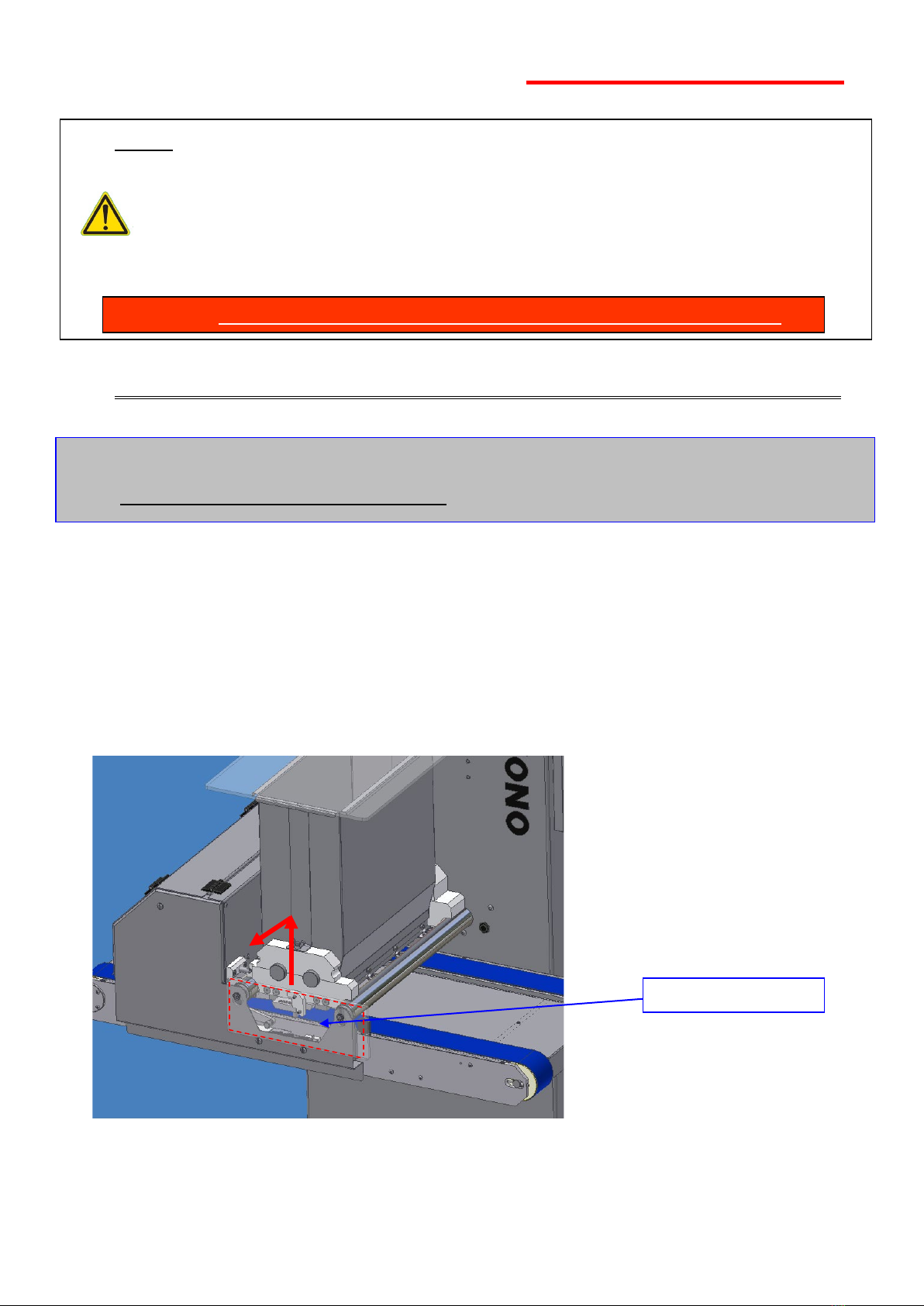

ALL CLEANING AND MAINTENANCE OPERATIONS MUST BE MADE

WITH MACHINE DISCONNECTED FROM THE POWER SUPPLY.

The use of templates and/or accessories not produced or supplied by MONO

Equipment will invalidate the machine’s warranty