FG036- park n ride prover RevA18 09-01-18

Avoid stopping machine with dough left in the pockets as after a time it will adhere to the

pockets and cause the machine to malfunction.

ALWAYS CHECK THE POCKETS FOR ADHERING DOUGH AND REMOVE AS SOON

AS POSSIBLE. DO NOT WAIT FOR DAILY CLEANING IF IN DOUBT.

ISOLATE MACHINE FROM THE POWER SUPPLY BEFORE CLEANING.

ensuring the dough sensor and reflector are clean.

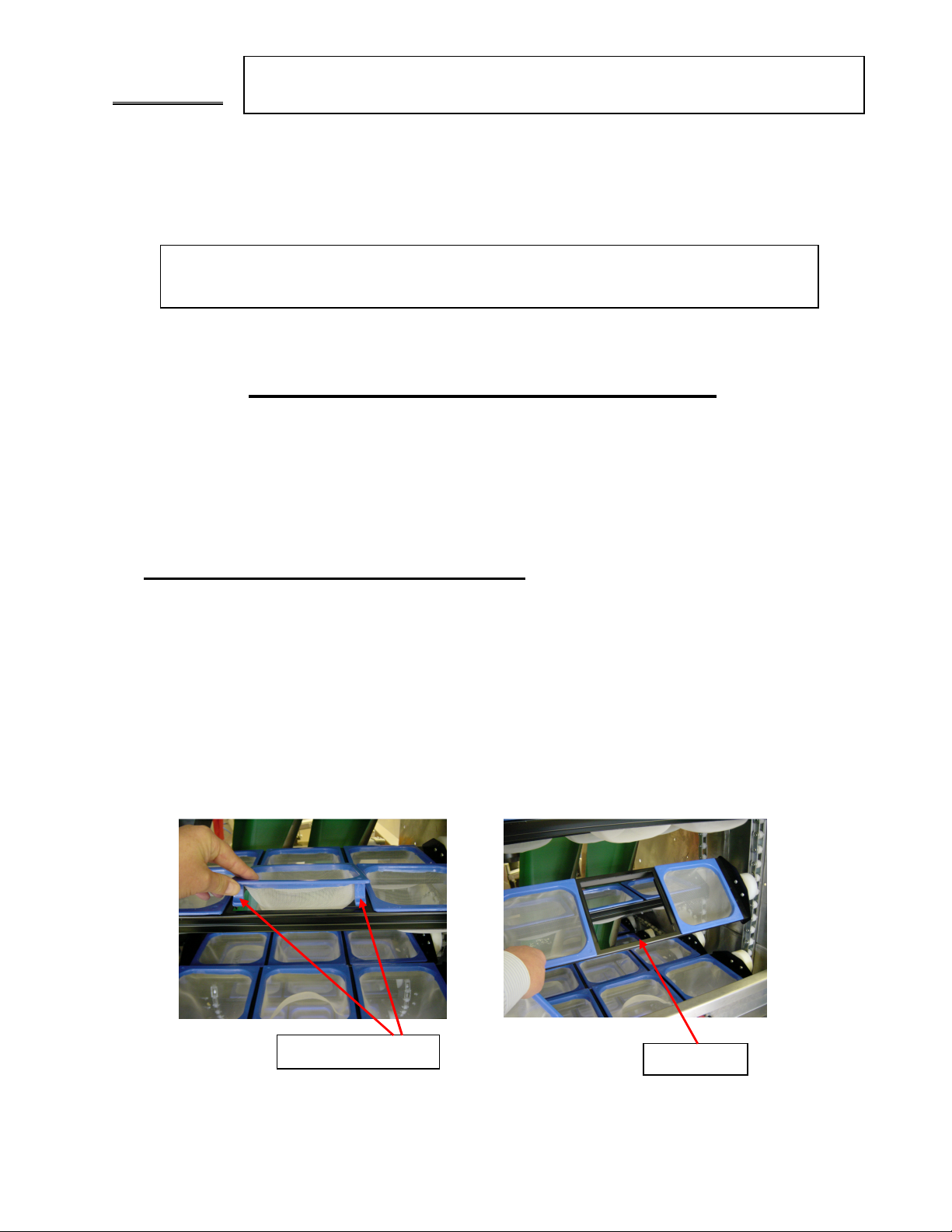

2. Remove drive box drawer (1) and cleaning door (2).

3. Withdraw the plastic trays and remove dough. Wash thoroughly, dry and replace.

4. Wipe over drawer and door and replace.

5. Remove clear transfer window (3). Wash and dry.

6. Wipe the window fixing channels and replace window.

7. Open main overhang door (4) and check for fallen pieces of dough inside. Brush rear of

door and close.

8. Brush conveyor (5) (if fitted) and wipe clean the metalwork paying attention to the chute

areas and inner sides.

9. Remove the moulder from position and clean the conveyor chute (6) inside and out paying

attention to edges, corners and the window area.

10. Wipe over the control panel (7) with a damp cloth (do not allow moisture to enter the

panel). Pay attention to the switch area removing any residue. (do not use a knife).

7.0 CLEANING

DAILY

KEEP WATER AWAY FROM THE MAIN CONTROL PANEL

AND ELECTRICAL CONNECTION SOCKETS.