1.0 INTRODUCTION

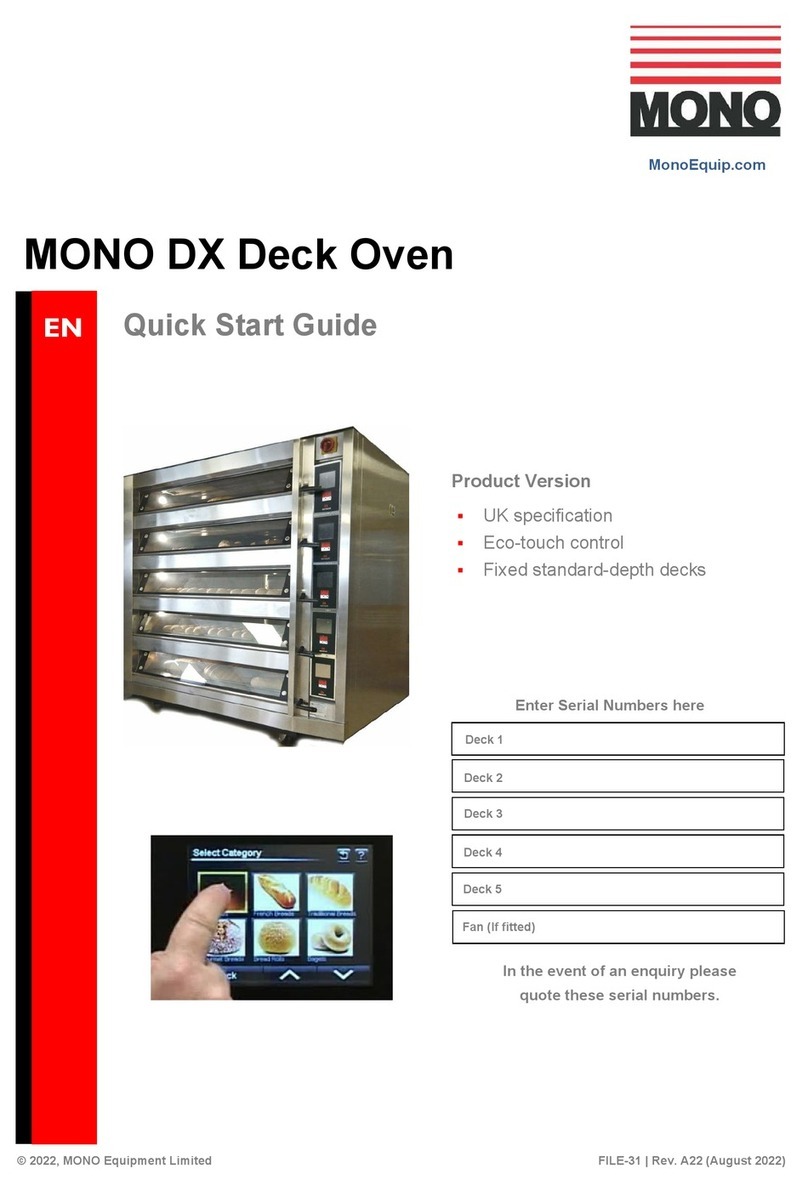

The electric modular Deck Oven is an easy to use practical, good-looking oven,

giving an excellent heat recovery rate and an even bake across a wide range of

bread and confectionery products.

Good looking and totally reliable

Conceived with the no nonsense requirements of both the independent and in-store

baker in mind, and designed to visually please as well as give reliable service for

many years. This oven will more than satisfy the most discerning customer.

Top quality specification

The external and internal contact surfaces are stainless steel.

Each modular deck is fitted with durable reinforced one-piece tiles, and an increase

in high-grade insulation and high temperature ceramic sealant, makes the oven more

efficient.

The oven comes with a patented integral steaming system, which reduces energy

consumption and the overall size of the oven (no drain required). The system

produces real steam with the advantages of spray steam. Pre-steam is also available

to reduce the affects of long loading times.

No drainage is required.

Supplied with an LCD screen. All programmable parameters have separate

indicators for easy programming and extra bake time, if required.

An energy saving 7-day timer is also standard.

The simplified electrical circuits aid reliability with overheat protection (on controllers

and oven) to ensure long life of controllers, all housed in splash-proof electrical

enclosures.

The lights are low voltage, sealed from the chamber and easily accessed from

outside the oven.

Fitted with a choice of hinged easy to clean glazed doors (using low energy-loss

reflective glass for high visibility) or metal doors, means low energy consumption and

the high kW rating gives good recovery.

(0-100% heating available both top and bottom)