10

REV: 04_07_2022

www.montanarigiulio.com

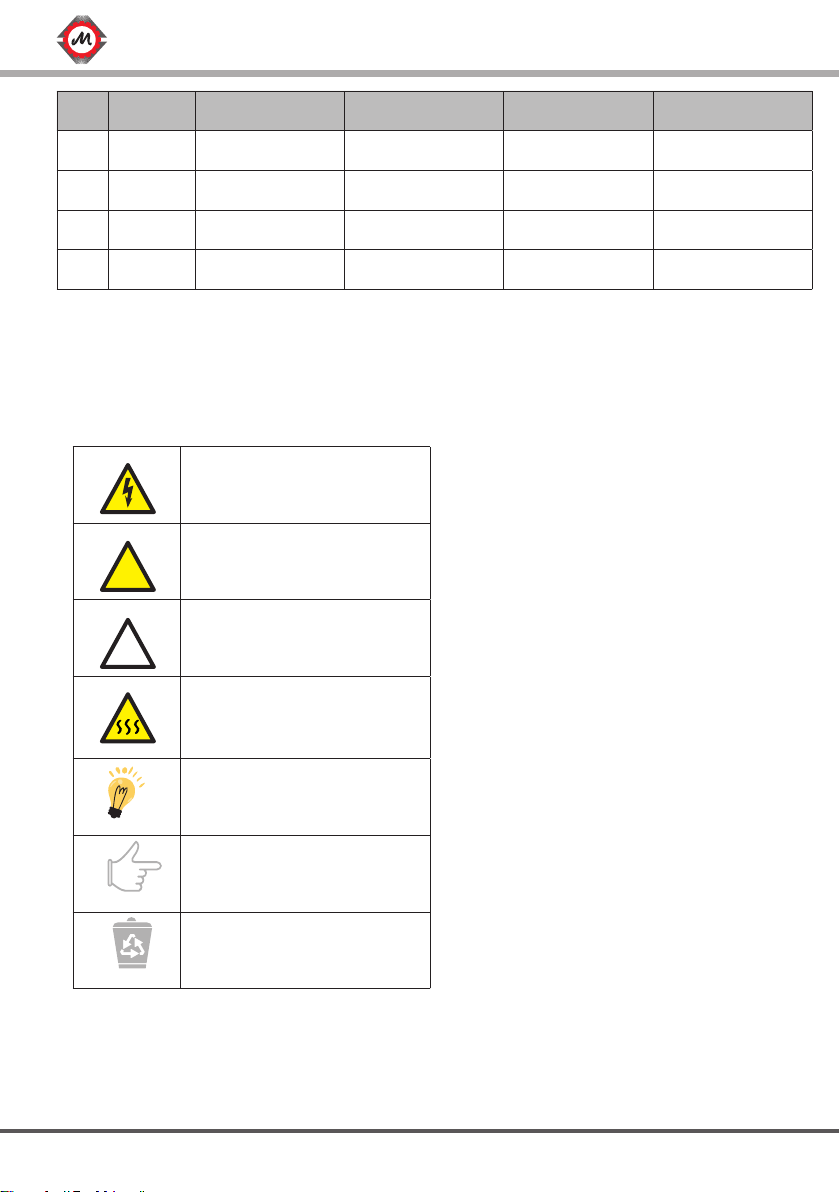

GEARLESS MACHINE TECHNICAL CHARACTERISTICS: MGS19M - MGS19L

Tab. 2

Tab. 3

MGS19M Type Pn

Speed Vn Cn In Cmax Imax EMF Poles F Rs Ls Static

Load IDuty

Cycle Weight

Motor code kW [RPM] [V] [Nm] [A] [Nm] [A] [V∙s/

rad] [N°] [Hz] [Ω] [mH] [Kg] [kg∙m2] [Kg]

MGS19150482B200 MGS19M 0,7 48 210 140 6,5 190 9 18 16 6,4 6,9 27 1500 0,04 180S/H 40% 102

MGS19152393B200 MGS19M 1,41 96 210 140 9,5 220 16 18 16 12,8 3,7 27 1500 0,04 180S/H 40% 102

MGS19153203B200 MGS19M 2,2 150 210 140 12 220 20 6 16 20 2,2 17,5 1500 0,04 180S/H 40% 102

MGS19155103B200 MGS19M 3,5 239 210 140 17,5 220 28 4 16 31,9 1,1 8,3 1500 0,04 180S/H 40% 102

MGS19152393B200 MGS19M 3,5 239 360 140 9,5 220 16 18 16 31,9 3,7 27 1500 0,04 180S/H 40% 102

MGS19153203B200 MGS19M 4,7 320 360 140 12 220 20 6 16 42,7 2,2 17,5 1500 0,04 180S/H 40% 102

MGS19155103B200 MGS19M 7,48 510 360 140 17,5 220 28 4 16 68 1,1 8,3 1500 0,04 180S/H 40% 102

MGS19L Type Pn

Speed Vn Cn In Cmax Imax EMF Poles F Rs Ls Static

Load IDuty

Cycle Weight

Motor code kW [RPM] [V] [Nm] [A] [Nm] [A] [V∙s/

rad] [N°] [Hz] [Ω] [mH] [Kg] [kg∙m2] [Kg]

MGS19221603B400 MGS19L 1,67 80 210 200 10 320 16 11 16 10,7 3,8 32,4 2200 0,09 180S/H 40% 132

MGS19222393B400 MGS19L 2,09 100 210 200 13 320 22 8 16 13,3 2,2 18,6 2200 0,09 180S/H 40% 132

MGS19223203B400 MGS19L 3,35 160 210 200 17 320 27 6 16 21,3 1,4 12 2200 0,09 180S/H 40% 132

MGS19225103B400 MGS19L 5 239 210 200 24 320 39 4 16 31,9 0,69 5,8 2200 0,09 180S/H 40% 132

MGS19221603B400 MGS19L 3,35 160 360 200 10 320 16 11 16 21,3 3,8 32,4 2200 0,09 180S/H 40% 132

MGS19222393B400 MGS19L 5 239 360 200 13 320 22 8 16 31,9 2,2 18,6 2200 0,09 180S/H 40% 132

MGS19223203B400 MGS19L 6,7 320 360 200 17 320 27 6 16 42,7 1,4 12 2200 0,09 180S/H 40% 132

MGS19225103B400 MGS19L 10,7 510 360 200 24 320 39 4 16 68 0,69 5,8 2200 0,09 180S/H 40% 132

MGS19M

MGS19L