1

•

TIRE RESERVE LOAD

This

table

lists

the tire size designations recommended by the manufacturer for use on the vehicles

to

which

it

applies,

with

the recommended inflation pressure for maximum

lo

ading and the

ti

re reserve load

~

percentage

for

each

of

the tires listed. The tjre reserve load percentage

indic

ated is met

or

exceeded by

V Ieach vehicle

to

which

the table applies.

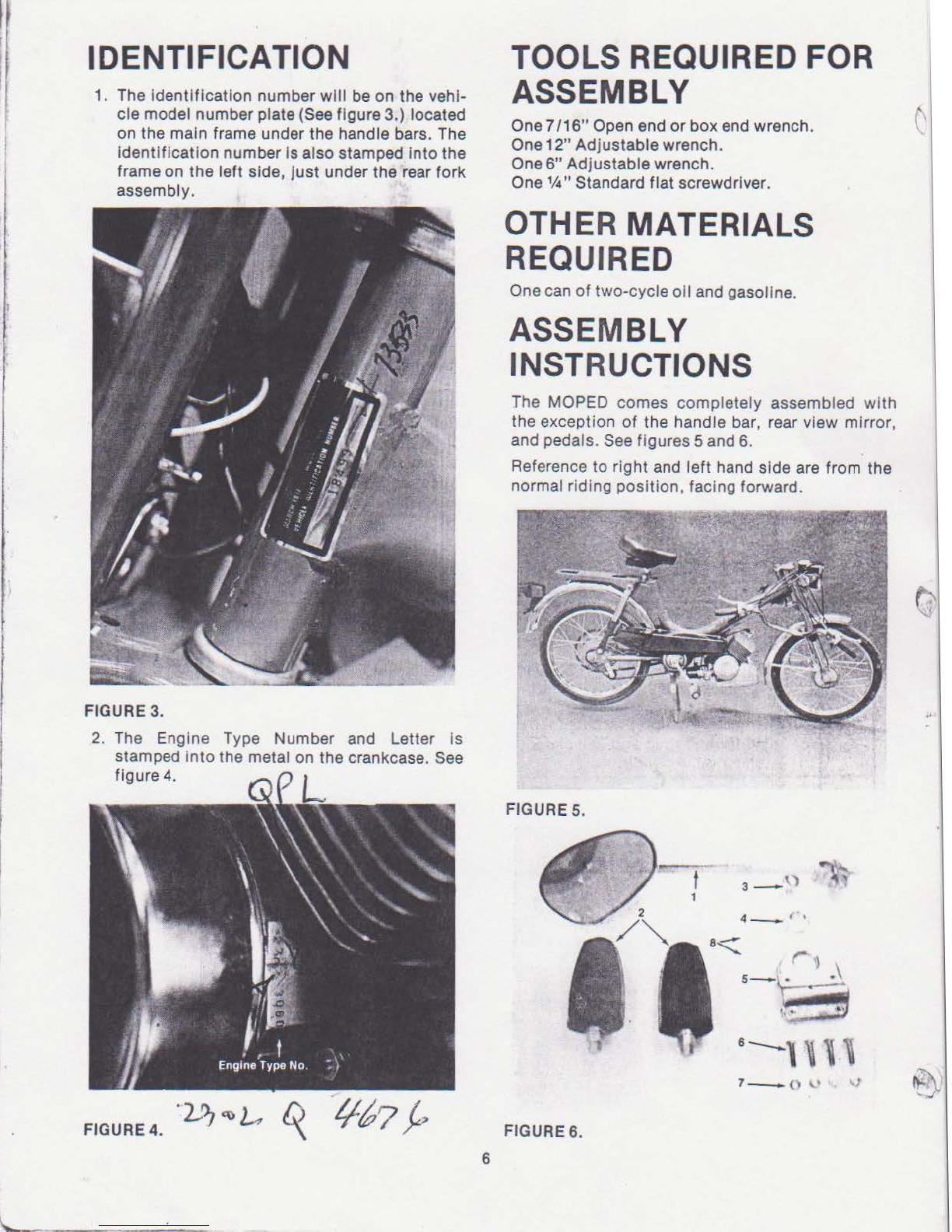

Descript

ion

of

Vehicles

to

Which

theTableApplies:

_

A

:....:..:..:.

II

_

M

_

o

_;

d_e

_

l

s

_

of

.:...

'_;'

M

~

O

.:...

P

-=

E

:..::

O

_"

_

__

_ _

_____

_

R

ecommended Tire Size Designations 2-

1/4-17

R

ecommended.Cold

Inflation

Pressure Front 25

PSI

for Maximum Loaded VehicleWeight Rear 32

PSI

*The difference, expressed as a percentage

of

tire load rating, between (a) the load rating

of

a tire at the

vehicle manufacturer's recommended inflation pressure at the maximum loaded vehicle weight and (b) the .

load imposed

upon

the tire by thevehicle at that

condition

.

WARNING. Failure

to

maintain the recommended tire

inflation

pressure

or

to

increase

tire

pressure as

recommended when operating at maximum loaded vehicle weight, or loading the vehicle beyond the

capacities specified on the tire placard affixed

to

the vehicle, may result in unsafe operating conditions due

to

premature tire failure, unfavorable handling characteristics, and excessive tire wear. The tire reserve

load percentage

is

a measure

of

tirecapacity,

not

of

vehiclecapacity. Loading beyond the specified vehicle

capacity may result In failure of thevehicle components.

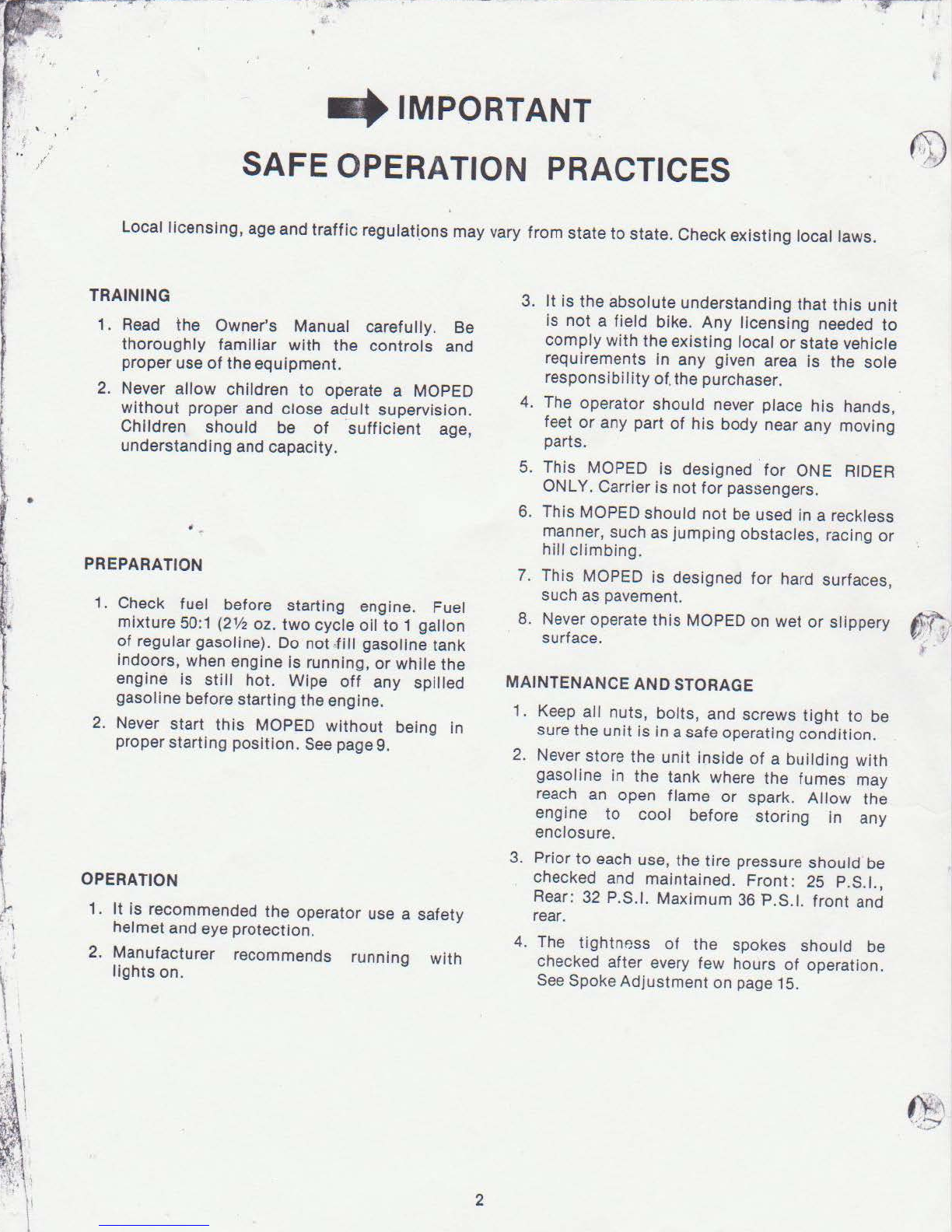

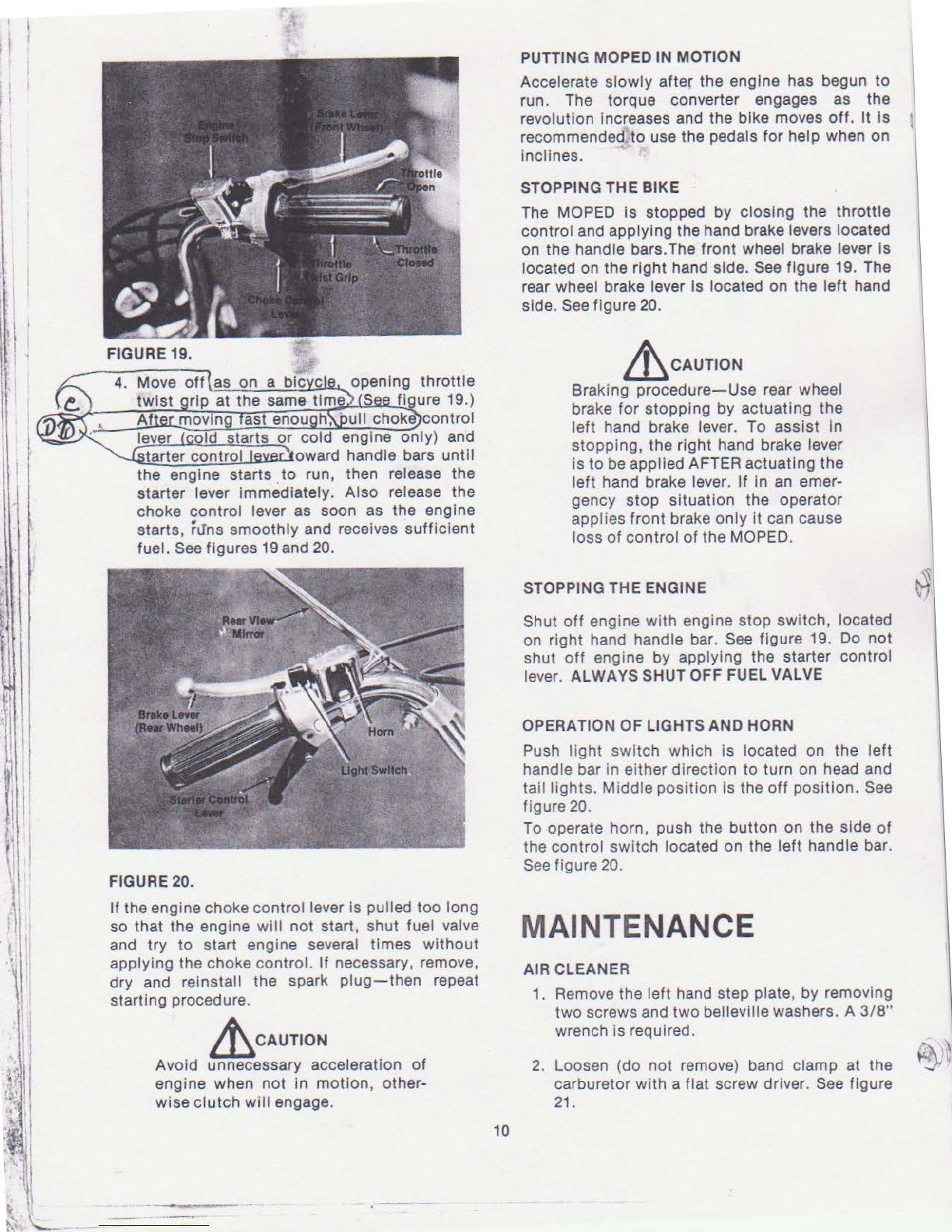

ACCELERATION

AND

PASSING ABILITY

This figure indicates passing times and distances that can be met

or

exceeded by the

vehicles

to

which

it

applies

in

the situation diagrammed below. '

The

low

speed pass assumes an initial speed

of

20 MPH and a

limiting

speed

of

35 MPH.

The high speed pass assumes an initial speed

of

50 MPH and a

limiting

speed

of

80 MPH.

NOTI

Cl:

The

information

presented represents results obtainable by skilled drivers under

. controlled road and vehicle

conditions

and the information may not be correct

·

;;

under other

conditions.

l

Descripllon

of

vehicles

to

which this tableapplies:

All

Mo

dels of "MO

PED

"

LOWfSPEED PASS SUMMARY TABLE:

1,500

FEE

T 46 SECONDS

HIGJ-tSPEED PASS FEET SECONDS NOT CAPABLE

LOW SPEED

INITIAL SPEED: 20 MPH LIMITING

SP

EED: 35 MPH

I TOTAL PASSING DISTANCE FEET I

TOTAL PASSING TIME SECONDS

············

·

················

·

···············

-

~

140o

••

•

•••••••••

••

••

••

••••••

•

-·~

1+

40+1

55 TRUCK CONSTANT 20 MPH

HIGH SPE

ED

(MOPED NOT CAPABLE)

INITIALSPEED: 50 MPH LIMITING

SP

EED: 80 MPH

I

~

TOTAL PASSING DISTANCE FEET I

l TOTAL PASSING TIME SECONDS

·····························

·

······

·

·

·······

· · ·

······

·

······~

~

100

~

c::::J···

····

······

·

····

··

········-~~~

100

~

55TRUCK CONSTANT50 MPH

5