CONTENTS

Safe Operation Practices

.....

......

...

......

2

Index and

Know

Your

MOPED

...

.

...

..

......

. 3 Exploded View for Fork and Handle Bar

.......

18

Parts

List

for

Fork and Handle Bar

.....

.

.....

.19

Cons

umer

Information

....

.

..

.......

.....

...

4 Exploded View

for

Main Frame

.....

...

..

...

..

20

Tire Reserve Load

..........................

5 Parts

List

fo

r Main Frame

................

21, 22

Identification

..........

. .

................

..

6 Exploded View

for

Torque Converter

..........

23

Assembly

Instructions

..

.

......

.

.........

.

..

6

Prepare

for

Operation

......

.

................

8

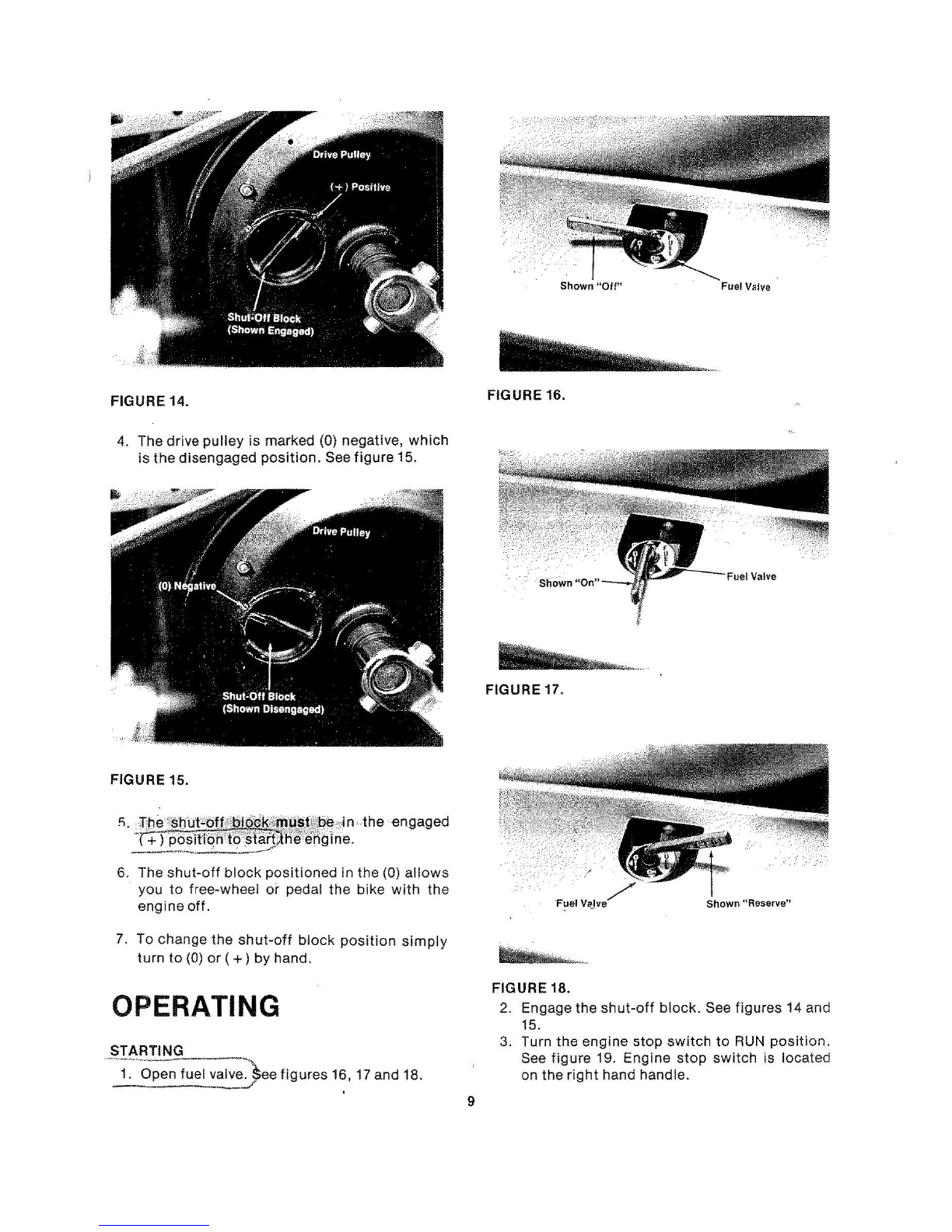

Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Maintenance . .

....

.

....

.

....

..

...

. .

..

..

...

10

Exploded View and Parts

List

for

Front Wheel 24

Exploded View and Parts

List

for

Rear Wheel .

..

25

E

xploded

View and Parts

List

for

Controls

.....

26

E

xploded

View and Parts

List

for

Engine

....

27-31

Adjustments

....

..

..

.

...........

.........

.13 Parts Ordering Procedure

...........

BackCover

Wiring

Diagram

...

.

....

. .

....

..

.........

..

.

17

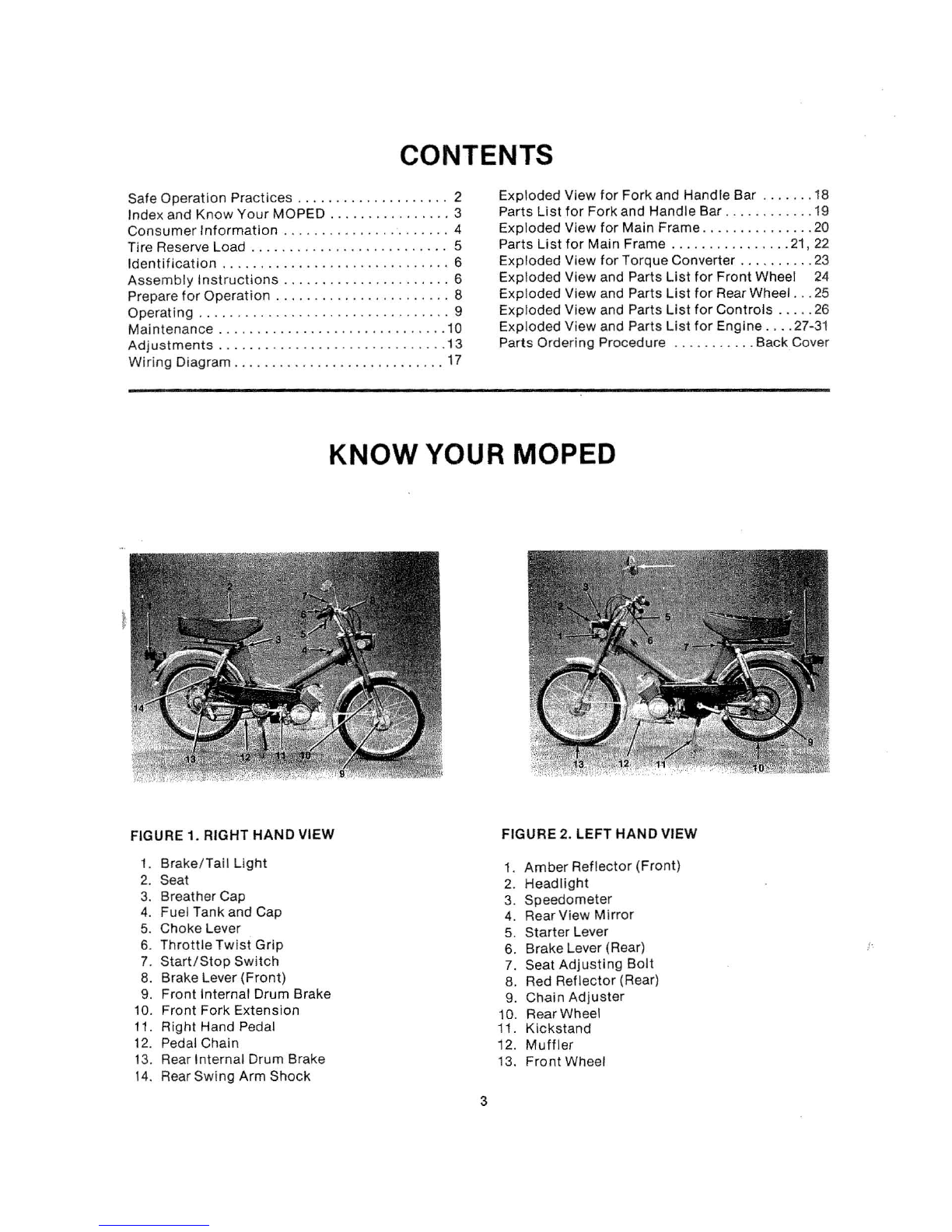

KNOW YOUR MOPED

FIGU

RE

1. RIGHT

HAND

VI

EW FIGURE 2. LEFT

HA

ND VIEW

1. Brake/Tail

Light

1.

Amber

Reflector (Front)

2. Seat 2. Headlig

ht

3. Breather Cap

3.

Speedometer

4. Fuel Tank and Cap 4. Rear View

Mirror

5. Choke Lever 5. Starter Lever

6.

Throttl

e

Twist

Grip 6. Brake Lever (Rear)

!'

7.

Start/Stop

Switch

7.

Seat

Adjusti

ng

Bolt

8. Brake Lever

(Front)

8.

Red Reflector (Rear)

9.

Front

Internal Drum Brake 9. Chain

Adjuster

10. Front Fork Extension 10. Rear Wheel

11.

Right

Hand Pedal 11.

Kickstand

12. Pedal Chain 12.

Muffler

13. Rear Internal Drum Brake 13.

Front

Wheel

14

. Rear

Swing

Arm Shock

3