MOPEC BF840 Room Filtration Module

MOPEC BF840 PAGE 10

CLEANING AND MAINTENANCE

EVALUATING FILTERS FOR REPLACEMENT

The filters in your BF840 unit contain activated charcoal and alumina pellets

impregnated with potassium permanganate, KMnO4, which is a fast oxidizer.

Formaldehyde passing through the filter is converted to carbon dioxide and water.

The filter’s life depends entirely on the amount of formaldehyde fumes passing

through the filter.

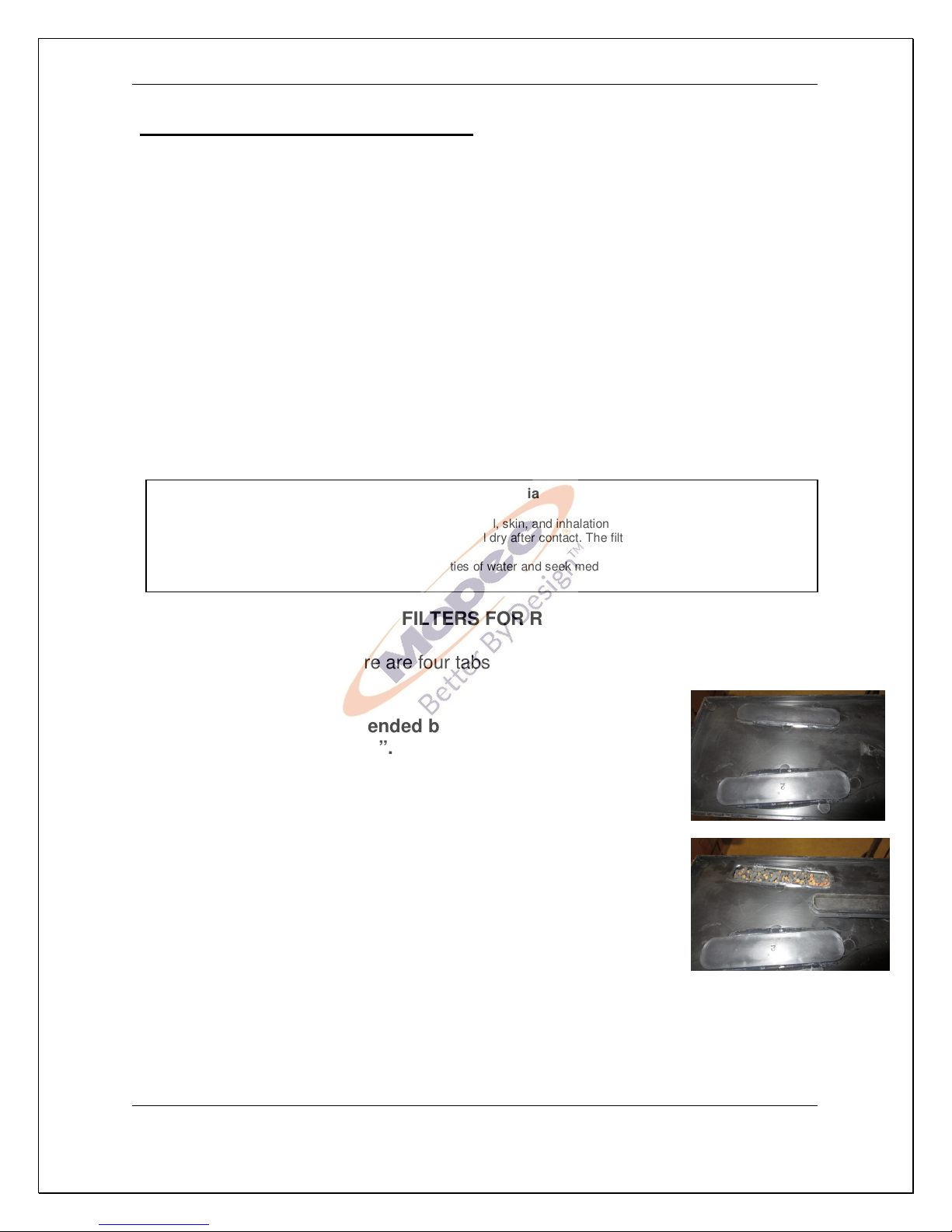

The pellets are bright purple when new and become dark brown when spent. Once the

inner part of the pellet is brown it is totally spent and must be replaced. This chemistry is

very effective and essentially removes all formaldehyde as long as there is active KMnO4

available. The efficiency drops off as the filter media approaches its maximum capacity.

The last 15-20% capacity will exhibit some pass through of formaldehyde.

PROCEDURE - EVALUATING FILTERS FOR REPLACEMENT

On one side of the filter there are four tabs which can be opened to allow pellets to be

removed. (see photo)

Eye protection is recommended based on the

above “Health Hazard Data”.

The usefulness of the filter is approximately 80% diminished

when the purple color first disappears from the core.

To determine when the KMnO4has been exhausted, remove a

pellet and slice it in half. Place the sliced pellet(s) on a paper

towel and add a few drops of water. The water running off the

pellet(s) should be initially purple and then turn a deep iodine

color. If no purple coloration is present, the KMnO4is totally

spent.

When the purple color first disappears from the core of the pellet as described above,

the rate at which formaldehyde is removed from the air stream is slowed considerably.

(See Summary On Following Page)

Alumina Permanganate Filter Media

Effects of Exposure – The filter media is non-toxic upon oral, skin, and inhalation exposure and is non-irritant of the

skin. Breathing of dust may cause sneezing. Skin may feel dry after contact. The filter media is an eye irritant.

Emergency Treatment – Flush eye with large quantities of water and seek medical attention.