Morgan MEDesign BASIC-ONE CSA-UL Manual

December 2015 Version 2.2

98/37/EC

89/336/EEC

73/23/EEC

93/42/EEC

Manual Covers Models:

BASIC-ONECSA - UL

BASIC-ONE

Maintenance ~ Service Manual

!

!

Morgan MEDesign

, Inc. - Maintenance ~ Service Manual BASIC-ONE -

2005 Page 1

MAINTENANCE GUIDELINES

It is the responsibility of the user to perform periodic maintenance

procedures to insure that your table remains in optimum service for many

years. The factory recommendation is towards a twelve week cycle of

attention. The procedure should only take a small amount of time and is

quite straight-forward. During the maintenance procedure take care to detach

the table from the mains power supply whilst cleaning and re-attach the table

for the portions of the procedure that involve table movements.

Do not access any the internal cavities of any control box or electrical

assembly. Do not reach under the table top during any motion instigated by

the controller(s). Do not sit or lay on the table during the procedures.

MAINTENANCE PROCEDURES

1. Unplug or disconnect the table from the AC mains.

2. Starting from the base of the unit examine all harnesses and wires for

evidence of cracking, insulation displacement, fraying or other loss.

Determine the seriousness of any such damage and consider

replacement parts.

3. Check the integrity of fasteners that keep wires and cables in place.

4. Check that bolts, nuts, thumbscrews, screws and other hardware

items are secure.

5. Undo the locking mechanisms on the wheels and move the table

upon the floor in all four directions to insure mobility of the wheel

casters. Relock in position.

6. Note any lubricant leakages or stains that may have arisen onto or

from bearing surfaces.

7. Using a cloth and an industrial cleaner containing alcohol wipe down

surfaces which may have received patient exposure and/or contact.

Wipe down all horizontal surfaces twice.

8. Insure that all labels are firmly in place and are not starting to be

frayed or faded. If found, replace such labels with ones ordered from

the manufacturer.

9. Using a commercial vinyl cleaner and/or preservative clean and

cosmetic the vinyl top. Use the cleaner on all exposed sides insuring

that all elements of grease and grime are removed. Take care to

include seams and cracks, sides and every surface that can be

reached by a cloth held in the hand.

10. Wipe down the power cord using a damp cloth or sponge. Let dry.

11. Reconnect the table to AC mains.

12. Using the provided control unit(s) translate the table through all

its movements, taking each movement in sequence. Do not activate

simultaneous movements. Retain the UP-DOWN movement, if

provided, as the last procedure.

13. Listen for unusual noises during the operation of the table. Note any

clicks, snaps or loud scratching, scraping, growling or other noises.

14. Wait 5 minutes for the safety circuits that monitor duty cycle to

re-sync. This is an internal feature and is related to power cycles

in each motor assembly.

15. Check under the table base for captive debris and in general

examine the control and movement rods for evidence of

lubrication leaks.

16. If provided, fill out the Maintenance Schedule.

Morgan MEDesign

, Inc. - Maintenance ~ Service Manual BASIC-ONE -

2005 Page 2

MAINTENANCE SCHEDULE

EL HORARIO DE MANTANIMIENTO

RECEIVED

RECIBIDO

+ 1 YEAR

+ 2 YEARS

+ 3 YEARS

+ 4 YEARS

+ 5 YEARS

___-200__

___-200__

___-20___

___-20___

___-20___

___-20___

ADHERENCE TO ACCESS PROHIBITED NOTICES

Control electronics are provided in a sealed enclosure. It is imperative that only

AUTHORIZED PERSONS familiar with the working voltages and safety regulations of such

devices attempt to access the control console interior. The following label warning must be

observed and any unauthorized access immediately cancels the warranty.

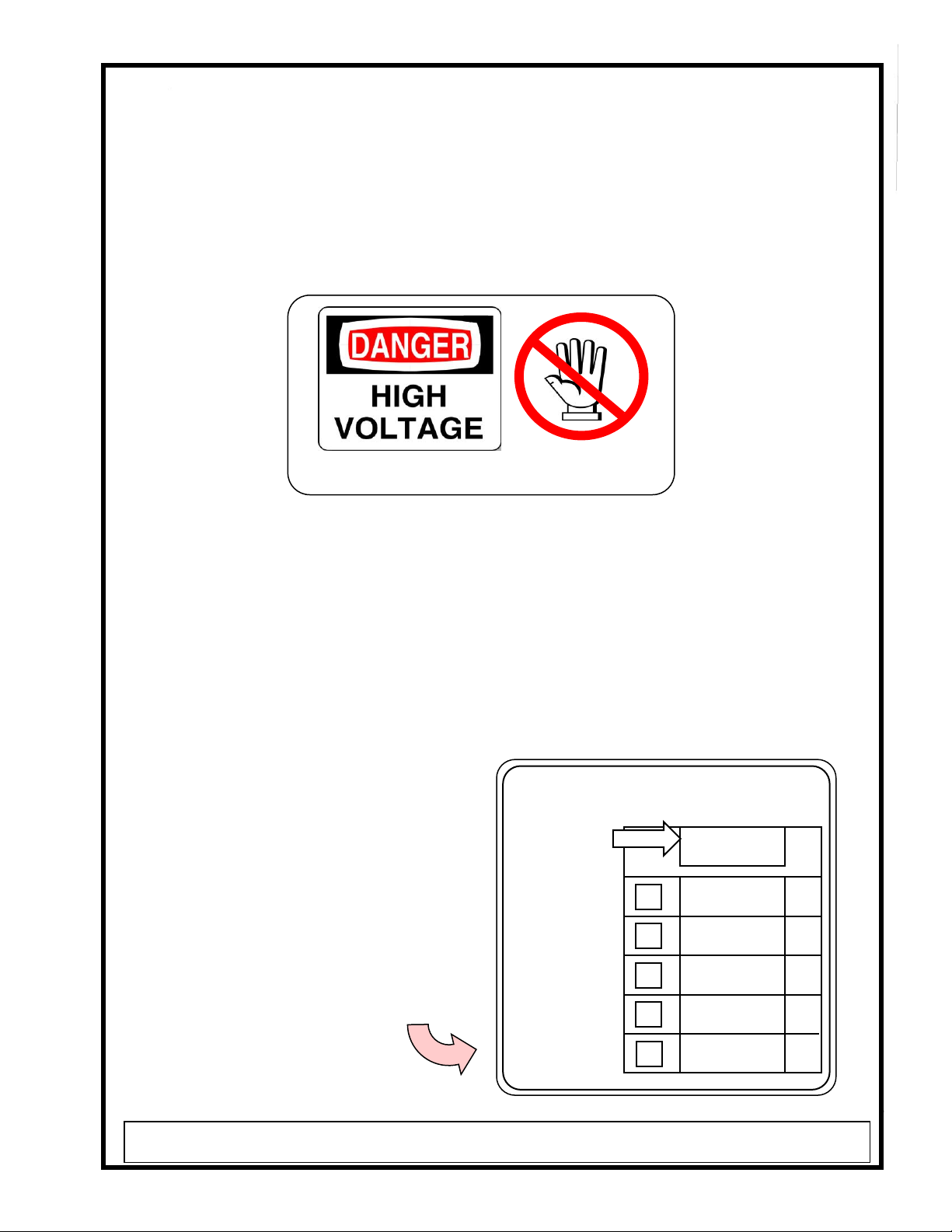

OPTIONAL MAINTENANCE SCHEDULE AND INSPECTION

When your table was received we recommend that you immediately date the optional

Maintenance Schedule that may have been provided on the base. Optionally use the chart

below or make a copy to keep with your table. It is the responsibility of the user to have annual

inspections and cleaning of the table to continue the validation of the warranty. This process

includes a visual inspection of all moving components and joints and the cleaning of all patient

contact surfaces. Examine the soft control tubes leading to the hand controller for kinks or

cracks. Insure that all electrical cords are not worn or frayed. Remove any grease or soil from

surfaces that may be contacted by patient or user. Check that all fasteners

are secure. Make sure all labels are in

place and continue to be visible.

HARNESS TO HAND CONTROL

ELECTRICAL WIRING

FASTENERS

COSMETIC SURFACES

CLEAN MATS, ACCESS AREAS

LABELS IN PLACE

When the inspection is complete initial the

MAINTENANCE SCHEDULE, check the

small box and insert the inspection date.

AUTHORIZED ACCESS ONLY

Morgan MEDesign

, Inc. - Maintenance ~ Service Manual BASIC-ONE -

2005 Page 3

REMOVING PARTS

NOTE: Repair or service that involves diagnostic removal of

components violates the warranty of this equipment, unless

performed by an authorized representative of Morgan

MEDesign

, Inc. Contact Morgan MEDesign

for details,

concerns or questions.

The removal of parts within the service-able parts of this equipment requires

special consideration. Following are some guidelines.

1. Attention to cosmetic surfaces is mandatory. Be careful not to scrape or

dent any of the surfaces or finishes that appear through-out the equipment.

The attachment hardware has been selected to have nick and burr free edges

and such edges and surfaces should remain after your service. Use new

tools and handle them with care.

2. All repair or component removal is to be performed with all power

disconnected.

3. All electrical repair is to be performed by credentialed persons within the

knowledge of such repair possessing permission to proceed. High voltages

may be present and adherence to the safety warnings is mandatory. Such

repair is at the risk of the instigator and Morgan MEDesign, Inc. holds it-self

clear and harmless for actions that result during and after such procedures.

4. All removed attachments must be placed back into their original positions.

Careful mechanical detailing and matching of tolerance parts have resulted in

mandated placements that must remain after the procedure.

5. All safety labels must remain in place during and after the procedures.

Should the process destroy or deface a label a new one is to be obtained

from Morgan MEDesign, Inc.

6. Do not attempt to repair any module within this equipment that has been

manufactured by another company and used as a sub-assembly. This

includes, but is not limited to, modules built by FAIRCHILD, RENTEC,

MAGNETIC, CORCOM or other manufacturer as evidenced by their label or

logo appearing on the sub-assembly. These modules are repaired by

replacing them with another from Morgan MEDesign, Inc. Do not attempt to

contact these vendors in the service of their modules as in most cases special

versions of their product have been used in the manufacture of your

equipment and are unique to the Morgan MEDesignapplication.

Morgan MEDesign

, Inc. - Maintenance ~ Service Manual BASIC-ONE -

2005 Page 4

Morgan MEDesign

, Inc. - Maintenance ~ Service Manual BASIC-ONE -

2005 Page 5

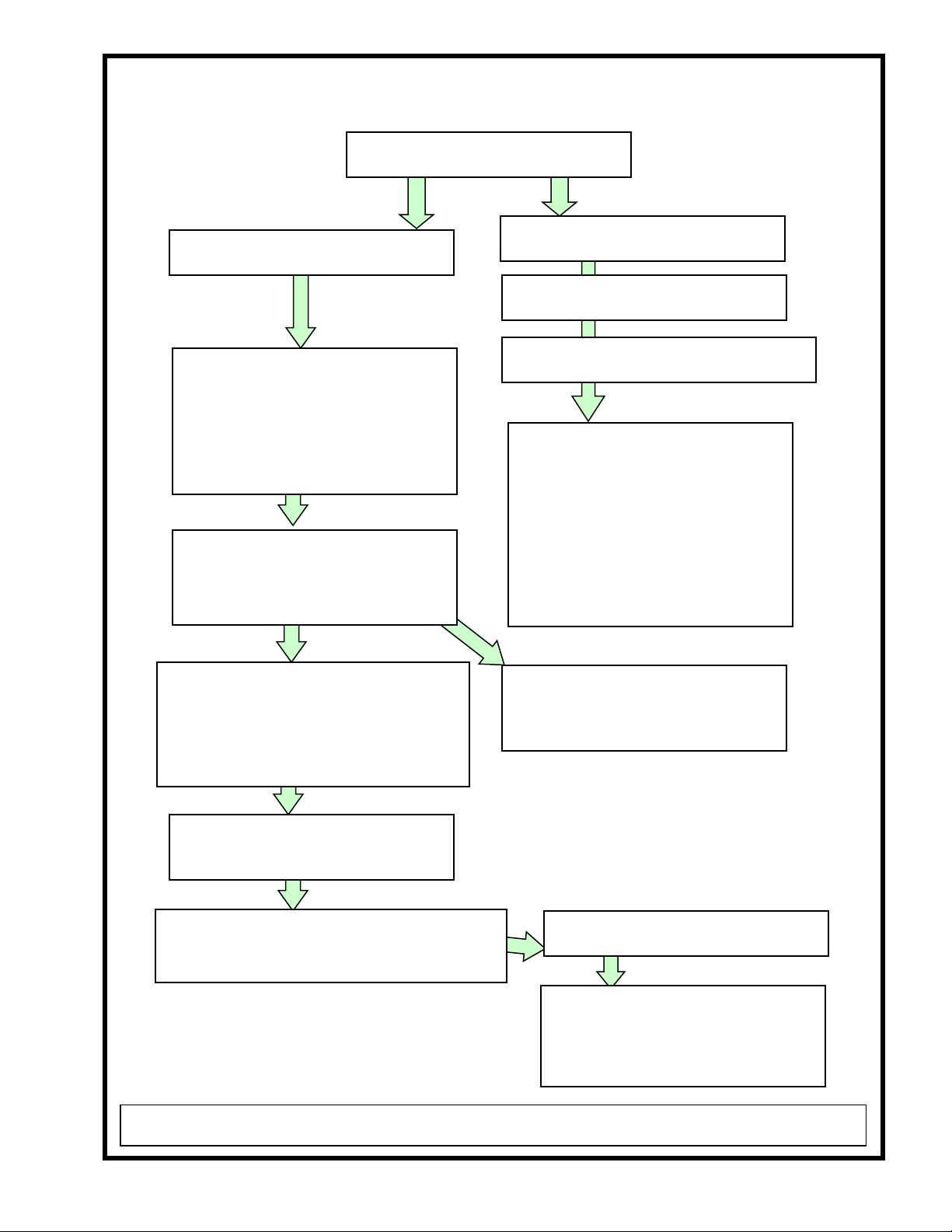

DIAGNOSTICS

NO TABLE MOVE-MENTS

GREEN STATUS LIGHT ON?

NO STATUS LIGHTS ON?

CHECK CIRCUIT BREAKER

NO TABLE MOVEMENTS ?

REPLACE AND SECURE KOM POWER

and HAND CONTROLLER CABLES

CHECK AC POWER CORD, MAINS

MONITOR CIRCUITS are O.K.

FILTER is O.K.

FAIRCHILD MONITOR is O.K.

LINE VOLTAGE is O.K.

+12 VOLT SUPPLY is O.K.

Unit is not receiving AC power

and the fault may be due to wiring

inside the base assembly. This

may been in the FILTER or at the

terminal strips. Gain access to the

inner BASE wiring and refer to

the SCHEMATIC. Establish

where power loss occurs.

CHECK KOM POWER CORD

Remove cord from KOM BOX at

connector and use volt meter to

validate AC volts on plug.

AC ABSENT = BASE wiring of

KOM POWER CORD is faulted

or terminal strip connection fault.

AC THERE = Possible KOM BOX

failure or HAND CONTROLLER

failure or loose connector at KOM

POWER CABLE or CONTROLLER

CABLE

CHECK HAND CONTROLLER

CONNECTION SECURE?

Consider replacement of KOM

POWER CONTROL BOX and

perhaps HAND CONTROLLER

Morgan MEDesign

, Inc. - Maintenance ~ Service Manual BASIC-ONE -

2005 Page 6

DIAGNOSTICS

PARTIAL TABLE MOVE-MENTS

GREEN STATUS LIGHT ON?

ALARM LIGHTS ON?

REPLACE AND SECURE KOM

POWER and HAND

CONTROLLER CABLE

IF PROBLEM PERSISTS-

CHECK AFFECTED MOTOR

CHECK AC MAINS

There may be weak AC voltages

present affecting the motor drives.

The STATUS lights will indicate the

voltage condition, refer to the

OPERATION MANUAL.

MONITOR CIRCUITS are O.K.

FILTER is O.K.

FAIRCHILD MONITOR is O.K.

LINE VOLTAGE is O.K.

+12 VOLT SUPPLY is O.K.

POSSIBLE OVERHEATED MOTOR

The motor drives have a duty cycle and when

this is exceeded will self-protect with a

thermal electrical breaker. WAIT 10

MINUTES and TRY OPERATION AGAIN

Possible KOM BOX failure or

HAND CONTROLLER

failure or HAND CONTROLLER

CABLE failure. Check for secure

connection.

WAIT 10 MINUTES MORE, if NO

OPERATION consider to REPLACE

the AFFECTED MOTOR

If MOTOR is O.K. consider

replacing KOM BOX or HAND

CONTROLLER

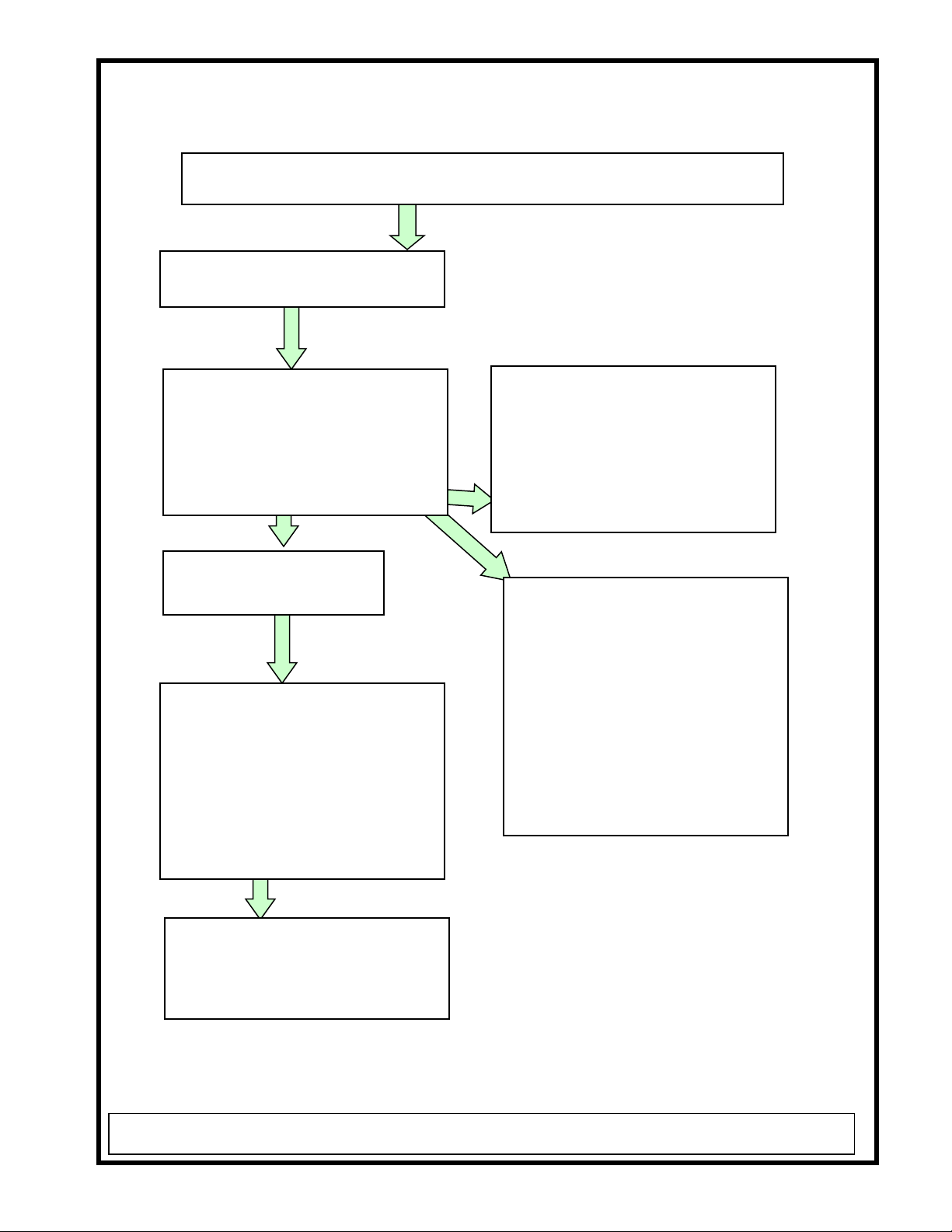

DIAGNOSTICS

ALARM STATUS LIGHT CONDITION

ALL MOTIONS WORK WELL

RE-POWER THE EQUIPMENT

Watch the STATUS lights

Do all three lights, POWER,

TROUBLE and ALARM

illuminate for 5 seconds when you

first power the equipment?

YES NO

There may be a loose or defective

bulb in the socket. The bulb that

isn’t illuminating is the culprit.

Remove the lens cap and correct

the situation which may include

bulb replacement. Look in the

OPERATION MANUAL.

CHECK AC MAINS for

under or over voltage.

AC O.K. = Possible wiring fault

in the BASE. This may also

indicate a failed RENTEC or

FAIRCHILD monitoring module.

Replacement of the MONITOR

STRIP may be necessary, the

assembly that carries both of these

modules.

Gain access to the BASE wiring.

Check all wires to and from the

RENTEC and FAIRCHILD

monitors to be secure.

Morgan MEDesign

, Inc. - Maintenance ~ Service Manual BASIC-ONE -

2005 Page 7

Gain access to the BASE wiring.

Check all wires to and from the

RENTEC and FAIRCHILD

monitors to be secure.

This may also indicate a failed

RENTEC or FAIRCHILD

monitoring module. Replacement

of the MONITOR STRIP may be

necessary, the assembly that

carries both of these modules.

DIAGNOSTICS

NOISY MOTOR

GREEN STATUS LIGHT ON?

ALARM STATUS LIGHTS ON?

Consider to

REPLACE MOTOR

CHECK AC MAINS for low voltage

MONITOR CIRCUITS are O.K.

FILTER is O.K.

FAIRCHILD MONITOR is O.K.

LINE VOLTAGE is O.K.

+12 VOLT SUPPLY is O.K.

Is the MOTOR OVERHEATED?

NO YES

WEIGHT TOO GREAT?

NO Check limits.

All MOTOR mechanical

connections secure and in place?

YES

Morgan MEDesign

, Inc. - Maintenance ~ Service Manual BASIC-ONE -

2005 Page 8

POSSIBLE OVERHEATED MOTOR

The motor drives have a duty cycle and

when this is exceeded will self-protect

with a thermal electrical breaker. WAIT

10 MINUTES and TRY OPERATION

AGAIN

WAIT 10 MINUTES MORE,

if NO OPERATION consider

to REPLACE the AFFECTED

MOTOR

Subassembly Component List –BASIC-ONE™

The following parts are used in the assembly of this equipment. Many components are

built on a custom basis and may or may not be available on a quick request. Contact

Morgan MEDesign®for the status of the desired item. Morgan MEDesign®reserves

the right to substitute or change a component or the availability of a component at any

time.

Part Number

Components Description Quantity Per

___________________________________________________________________________

BASIC ONE TABLE BASIC ONE Procedure Table

AV-PB LARGE ASSY LARGE PILLOW BLOCK 1.000

ASSEMBLY

JAR-CAS 5-50 LOCKING CASTER LOCKING 5-50MG213GD 4.000

APSL FGOALP025213GDD

MAG-EHA1321B3ON-000 6 Button Hand Control Wired 1.000

with holder * DC

MAG-KOM14020A-000 KOM BOX KOM14-020A-000 1.000

LG BOX WITH CORD 140360

HOSPITAL CORD

MAG-MAX10C100 MAX10-C100295A0A1MO-000 1.000

DC TILT 100mm stroke *LAT.

1500N

MAG-POWER CABLE DB-9 Cable * DB-9 POWER CABLE 1.000

FOR KOM BOXESWITH HUBBLE

PLUG END

MAG-TLG10AA21 2 Stage DC Lift Motor 1.000

200mm stroke 4000N *

MMI20041 BASE ASSY BASE ASSEMBLY 1.000

BASIC 1

MMI63002 Clamp Disk * 4.000

VP-20041-13 COVER-R ABS COVER RIGHT SIDE 1.000

3/16 X 35 X 11.43-BLACK

Morgan MEDesign

, Inc. - Maintenance ~ Service Manual BASIC-ONE -

2005 Page 9

Subassembly Component List –BASIC-ONE™ (continued)

VP-20041-14 COVER-L ABS LEFT SIDE COVER 1.000

3/16 X 35 X 11.438-BLACK

MMI20030-3 BASIC 1 TOP PLATE 1.000

17 X 22 ALUM PLATE

KAISER

HANDLE PUSH BAR MMI20046 HANDLE PUSH BAR 1.000

BASIC ONE -120 WALL X 1

X STEEL TUBING

MMI20042 #2 BRKT ASS #2 BRKT ASSY 1.000

BASIC ONE

MMI20043 LAT BRKT LAT BRACKET ASSY 1.000

MMI20031-4R 1.7 X 20 CLAMP BARS RIGHT 1.000

BASIC ONE

MMI20031-4L 1.7 X 20 CLAMP BARS LEFT 1.000

BASIC ONE

AV-SM/LG PB ASSY SMALL PILLOW BLOCK ASSY 1.000

MMI20044 TREN/LAT BR TREN/LAT BRACKET ASSY 1.000

GASKET-20045 MOTOR GASKET 20045 1.000

1/16 ABS PLASTIC GASKET

7.75 X 7.75 W/ 4 HOLES

MMI20047-1" RISER 1" RISER BLOCK 1.000

5.75 X 5.75 X 1"

MCM-9688K281 PLUG-NYLON SNAP IN UNVENTE 2.000

13/16 ID X 1 1/32 HEAD

MAG-MAX30A12335 CURL MAX30A120335AOA1-00-000 1.000

DC Tilt Motor, 8000N-CURLY

CORD 120mm stroke * TREND

WASHERS-20046-2 1/4 X 1.0 X 3.75 6.000

PUSH BAR WASHER FOR HANDLE

MCM-SEAL TAPE 1/2" MCM-9477K21-VALUE-SEAL 0.060

EXPANDED PIPE GASKET TAPE

MCM-74125K73 SNAP IN DUST TIGHT GRIP 1.000

FITTING 5/8 HOLE

MMI20041-DECK COVER BASIC DECK COVER FRONT & B 1.000

20041-11- & 20041-12

Morgan MEDesign

, Inc. - Maintenance ~ Service Manual BASIC-ONE -

2005 Page 10

Subassembly Component List –BASIC-ONE™ (continued)

FWS-20041-16 COVER SEAM 1/8 X 2 X 20 3/4 1.000

1/8 X 2 X 20 3/4

WHEEL ABRAIDED/ SANDBLAST

MMI20048-1 MONITOR AND STATUS ASSEMBLY 1.000

MMI20048-2 RED STATUS LIGHT ASSEMBLY 1.000

MMI20048-3 YELLOW STATUS LIGHT ASSEMBLY 1.000

MMI20048-4 GREEN STATUS LIGHT ASSEMBLY 1.000

E-20048-5 AC INPUT CORD ASSEMBLY for BASIC ONE 1.000

E-20048-6 EMERGENCY SWITCH HARNESS for BASIC NE 1.000

E-20048-7 KOM CORD HARNESS for BASIC ONE 1.000

E-ALLIED315-0009 EMERGENCY SWITCH ACTUATOR with CLAMP 1.000

E-ALLIED677-0156 CIRCUIT BREAKER, 16 amp 1.000

E-HS1138LIQTIGHT LIQUID TIGHT (LPT) 3/8 NPT Grey Pass-through 2.000

CSA-MANUAL-BASIC-OPERATING OPERATION MANUAL, BASIC-ONE 1.000

CSA-MANUAL-BASIC-MAIN + SERVICE SERVICE MANUAL, BASIC-ONE 1.000

E-ALLIED937-9615 BULBS, 6 volt, (Spare –shipped with unit) 3.000

CSA/CEKIT-MANUAL+BULB KIT, OPERATION MANUAL 1.000

plus 6 volt spare BULB

Morgan MEDesign

, Inc. - Maintenance ~ Service Manual BASIC-ONE -

2005 Page 11

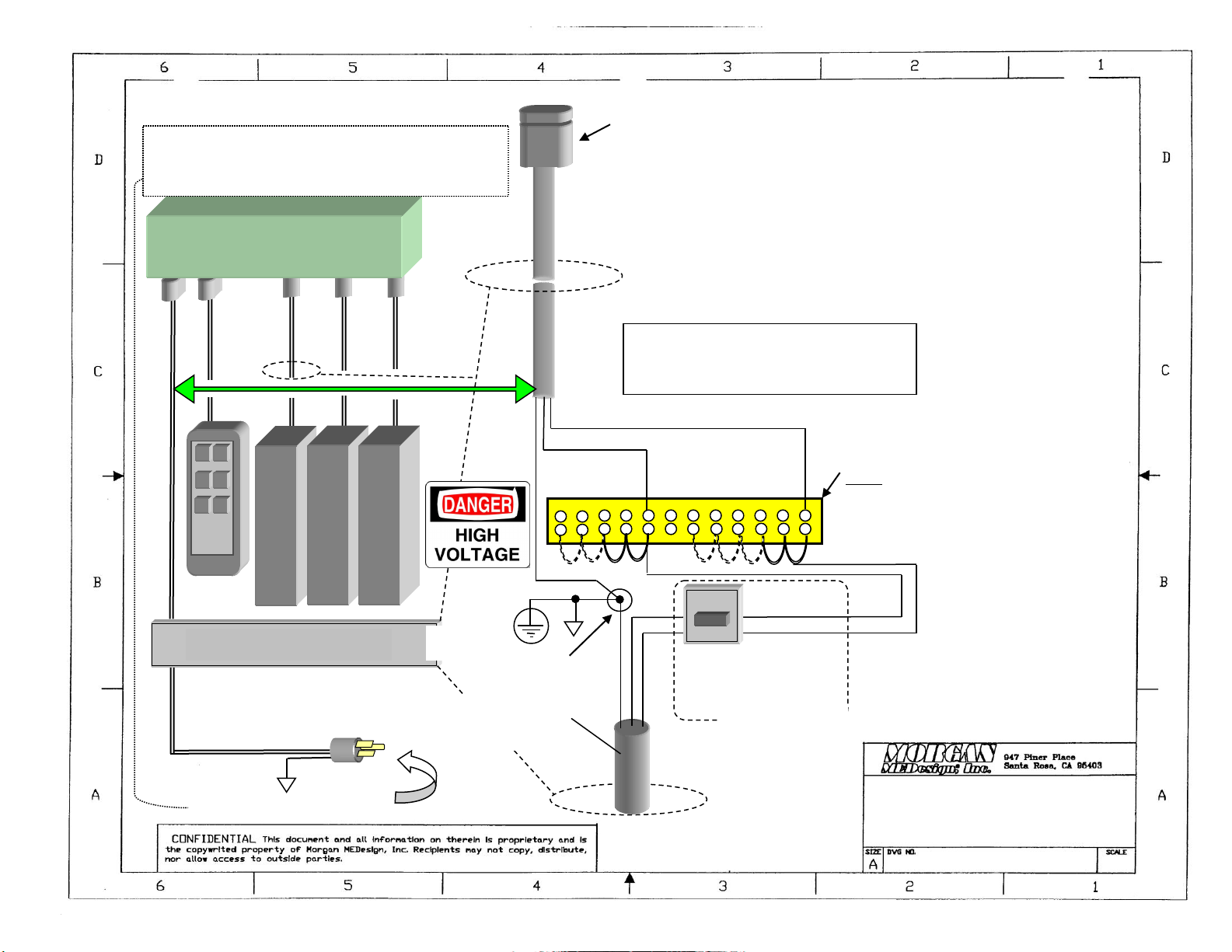

BASIC-ONE PICTORIAL PARTS

IDENTIFICATION DIAGRAM

This diagram depicts parts common to both

UL and CSA-CE versions of this equipment

Morgan MEDesign

, Inc. - Maintenance ~ Service Manual BASIC-ONE -

2005 Page 12

Morgan MEDesign

, Inc. - Maintenance ~ Service Manual BASIC-ONE -

2005 Page 13

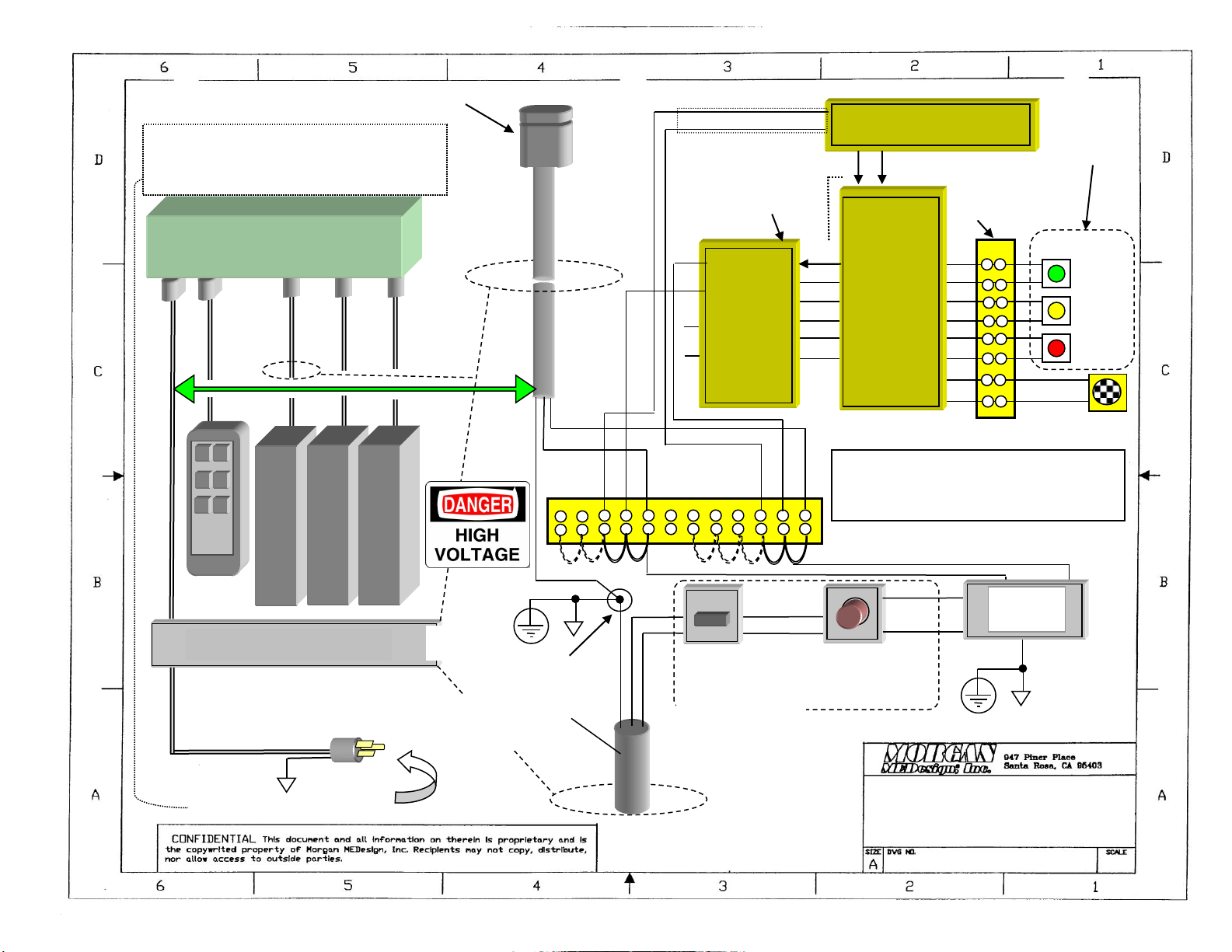

SCHEMATICS FOR BASIC-ONE FOLLOW;

NEXT 4 PAGES

If more detail is necessary contact

Morgan MEDesign, Inc.

Schematic AC 120 V Model

BASIC-ONE –(UL- 544)

90001-01

AC INPUT

AC INPUT 120 VAC, 60 HZ

12 11 10 9 8 7 6 5 4 3 2 1

TERMINAL STRIP S1

NOTE:

MAY HAVE ANY NUMER OF

TERMINALS DEPENDING ON

APPLICATION

DUAL CIRCUIT

BREAKER 16A

ON LID COVER, BASE

POWER CABLE TO “MAGNETICS” “KOM” SERIES POWER CONTROLLER

LEGEND-

W = WHITE WIRES - NEUTRAL - COMMON

B = BLACK WIRES –HOT –ACTIVE PHASE

G = GREEN AND GROUND WIRES

BLOCK DIAGRAM

CHASSIS

CONNECTION

G B

W

W

B

HOLE IN LID

OF BASE

HOLE IN LID OF BASE

B

W

G

WITHIN BASE

LIFT MOTOR

TREND MOTOR

R/L TILT MOTOR

AC CONTROL 1 2 3

KOM CONTROLLER

IN

OUT

OUT

IN

TYPES OF KOM CONTROL UNITS

KOM 14-020A-000 5 PORT, 3 PORTS USED

KOM 33-020A-000 3 PORT, ALL PORTS USED

W

B

HOLE

MAINS, LINE IN, 3 WIRE,

PROTECTIVE GROUND

HOSPITAL GRADE

ON FRONT PANEL

Schematic AC 220 V Model

BASIC-ONE –(UL- 544)

90001-02

AC INPUT

AC INPUT 220 VAC, 60 HZ

12 11 10 9 8 7 6 5 4 3 2 1

TERMINAL STRIP S1

NOTE:

MAY HAVE ANY NUMER OF

TERMINALS DEPENDING ON

APPLICATION

DUAL CIRCUIT

BREAKER 16A

ON LID COVER, BASE

POWER CABLE TO “MAGNETICS” “KOM” SERIES POWER CONTROLLER

LEGEND-

W = WHITE WIRES - NEUTRAL - COMMON

B = BLACK WIRES –HOT –ACTIVE PHASE

G = GREEN AND GROUND WIRES

BLOCK DIAGRAM

CHASSIS

CONNECTION

G B

W

W

B

HOLE IN LID

OF BASE

HOLE IN LID OF BASE

B

W

G

WITHIN BASE

LIFT MOTOR

TREND MOTOR

R/L TILT MOTOR

AC CONTROL 1 2 3

KOM CONTROLLER

IN

OUT

OUT

IN

TYPES OF KOM CONTROL UNITS –220 V

KOM 14-020A-000 5 PORT, 3 PORTS USED

KOM 33-020A-000 3 PORT, ALL PORTS USED

W

B

HOLE

MAINS, LINE IN, 3 WIRE,

PROTECTIVE GROUND

HOSPITAL GRADE

ON FRONT PANEL

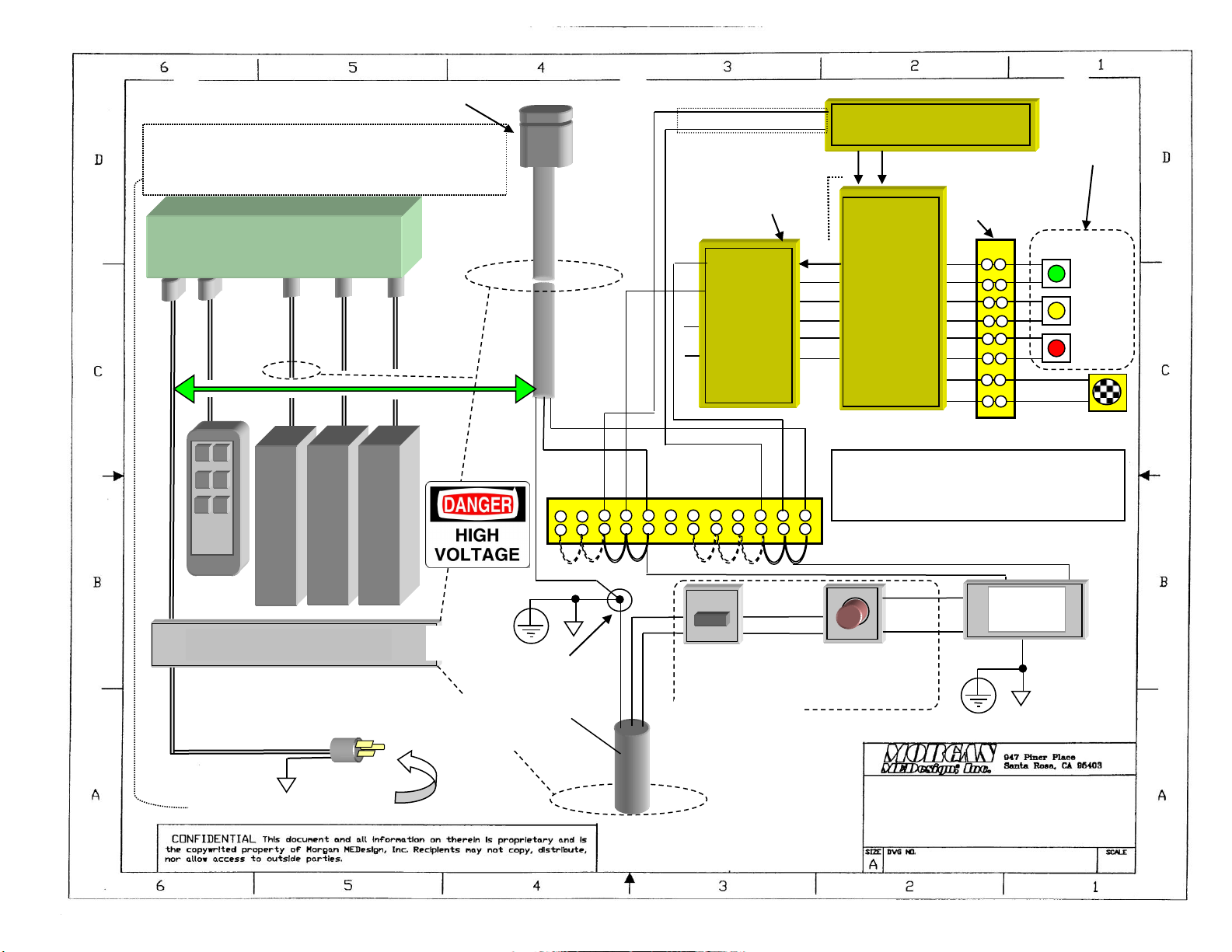

Schematic AC 120 V Model

BASIC-ONE –(UL- CSA)

90001-03

AC INPUT

AC INPUT 120 VAC, 60 HZ

12 11 10 9 8 7 6 5 4 3 2 1

TERMINAL STRIP S1

DUAL CIRCUIT

BREAKER 16A

ON LID COVER, BASE

POWER CABLE TO “MAGNETICS” “KOM” SERIES POWER CONTROLLER

LEGEND-

W = WHITE WIRES - NEUTRAL - COMMON

B = BLACK WIRES –HOT –ACTIVE PHASE

G = GREEN AND GROUND WIRES

BLOCK DIAGRAM

CHASSIS

CONNECTION

G B

W

W

B

HOLE IN LID

OF BASE

HOLE IN LID OF BASE

B

W

G

WITHIN BASE

LIFT MOTOR

TREND MOTOR

R/L TILT MOTOR

AC CONTROL 1 2 3

KOM CONTROLLER

B

IN

OUT

OUT

IN

TYPES OF KOM CONTROL UNITS

KOM 14-020A-000 5 PORT, 3 PORTS USED

KOM 33-020A-000 3 PORT, ALL PORTS USED

EMERGENCY STOP

SWITCH

LINE

FILTER

CORCOM 50-60 HZ

15EHT1

B

B

G

W

W

ALARM

TROUBLE

POWER

AUDIO

ALARM

RENTEC

STATUS

MONITOR

POW+

POW-

TROB+

TROB-

ALRM+

ALRM-

BP+

BP-

V+

NH-OK

NL-OK

NS1-OK

NS2-OK

OV

LINE

NEUT

SENS1

SENS2

0V +12V

12 POWER SUPPLY- 2 AMP

UL LISTED CSA, CE

1

2

3

4

5

6

3

4

5

6

7

8

1

2

3

4

5

6

8

10

2 1

VERSION

FOR 120V

V+5

NH-OK

NL-OK

NS1-OK

NS2-OK

OV

UL LISTED

MID400

TERMINAL STRIP

FOR WIRE ATTACH

ONLY, WIRE

COLORS ARE COLOR

OF INDICATOR

RED

BLACK

W

W

B

B

HOLE

B

W

ITEMS IN YELLOW ON SEPARATE STRIP

ON

FRONT

PANEL

MAINS, LINE IN, 3 WIRE,

PROTECTIVE GROUND

HOSPITAL GRADE

ON FRONT PANEL

MONITOR ASSEMBLY IS MMI-20048-01

Schematic AC 220 V Model

BASIC-ONE –(UL- CSA)

90001-04

AC INPUT

AC INPUT 220 VAC, 60 HZ

12 11 10 9 8 7 6 5 4 3 2 1

TERMINAL STRIP S1

DUAL CIRCUIT

BREAKER 16A

ON LID COVER, BASE

POWER CABLE TO “MAGNETICS” “KOM” SERIES POWER CONTROLLER

LEGEND-

W = WHITE WIRES - NEUTRAL - COMMON

B = BLACK WIRES –HOT –ACTIVE PHASE

G = GREEN AND GROUND WIRES

BLOCK DIAGRAM

CHASSIS

CONNECTION

G B

W

W

B

HOLE IN LID

OF BASE

HOLE IN LID OF BASE

B

W

G

WITHIN BASE

LIFT MOTOR

TREND MOTOR

R/L TILT MOTOR

AC CONTROL 1 2 3

KOM CONTROLLER

B

IN

OUT

OUT

IN

TYPES OF KOM CONTROL UNITS - 220 V

KOM 14-020A-000 5 PORT, 3 PORTS USED

KOM 33-020A-000 3 PORT, ALL PORTS USED

EMERGENCY STOP

SWITCH

LINE

FILTER

CORCOM 50-60 HZ

15EHT1

B

B

G

W

W

ALARM

TROUBLE

POWER

AUDIO

ALARM

RENTEC

STATUS

MONITOR

POW+

POW-

TROB+

TROB-

ALRM+

ALRM-

BP+

BP-

V+

NH-OK

NL-OK

NS1-OK

NS2-OK

OV

LINE

NEUT

SENS1

SENS2

0V +12V

12 POWER SUPPLY- 2 AMP

UL LISTED CSA, CE

1

2

3

4

5

6

3

4

5

6

7

8

1

2

3

4

5

6

8

10

2 1

VERSION

FOR 220V

V+5

NH-OK

NL-OK

NS1-OK

NS2-OK

OV

UL LISTED

MID400

TERMINAL STRIP

FOR WIRE ATTACH

ONLY, WIRE

COLORS ARE COLOR

OF INDICATOR

RED

BLACK

W

W

B

B

HOLE

B

W

ITEMS IN YELLOW ON SEPARATE STRIP

ON

FRONT

PANEL

MAINS, LINE IN, 3 WIRE,

PROTECTIVE GROUND

HOSPITAL GRADE

ON FRONT PANEL

MONITOR ASSEMBLY IS MMI-20048-01

Table of contents