v

4-m Tape Placement ...................................................................................................................4-13

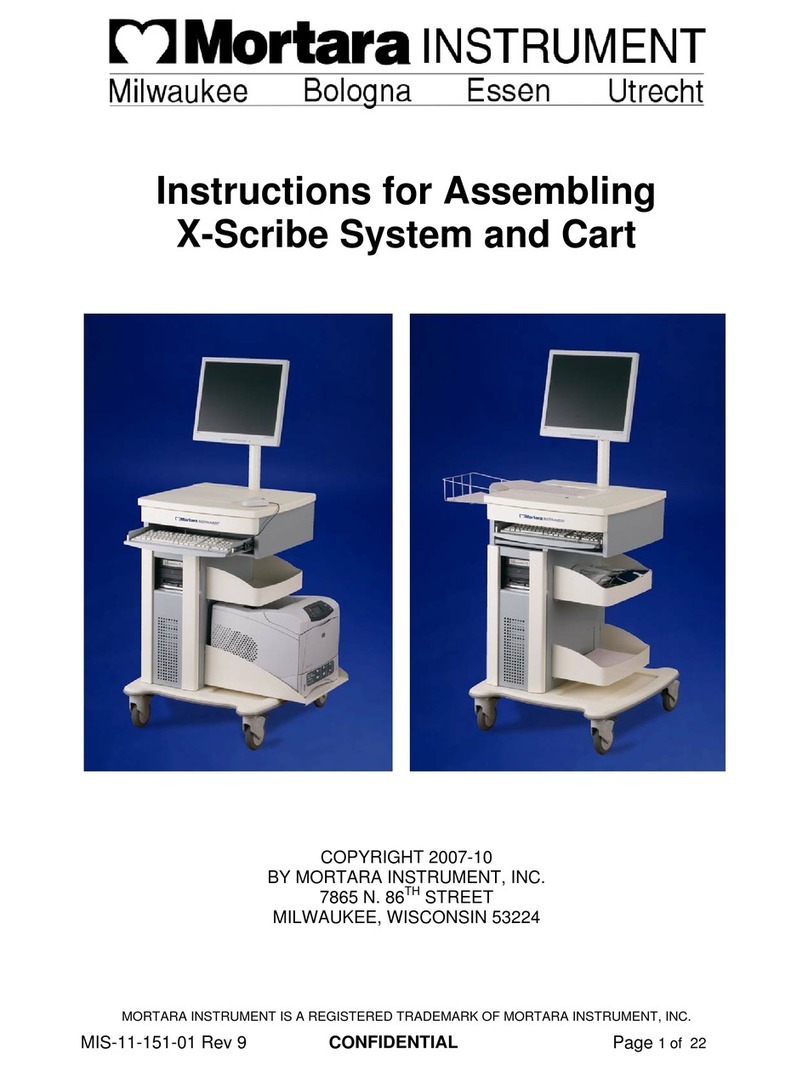

5-a Complete Base Assembly .....................................................................................................5-2

5-b Installing Tie Downs ..............................................................................................................5-3

5-c Labeling and Assembly of Batteries ......................................................................................5-4

5-d Installing Printed Circuit Board .............................................................................................5-5

6-a Complete Writer Assembly ...................................................................................................6-2

6-b Addition of Date Code Label and Bench testing ...................................................................6-3

6-c Installing Printhead and Copper Braid Cable ........................................................................6-4

6-d Installing E-Rings to Cover ...................................................................................................6-5

6-e Installing Main Pivot Shaft ....................................................................................................6-6

6-f Installation of Spring Bar ........................................................................................................6-7

6-g Installing Slider Plate ...........................................................................................................6-8

6-h Installing Alignment Deflector Shaft ......................................................................................6-9

6-i Installing Floating Cover and Grounding Gaskets .................................................................6-10

6-j Detail of Spring .......................................................................................................................6-11

6-k Installing Latch and Springs ..................................................................................................6-12

6-l Installing Slide Shaft, Bearing and Spring .............................................................................6-13

6-m Lower Chassis Complete .....................................................................................................6-14

6-n Completion of Lower Chassis ...............................................................................................6-15

6-o View of Bottom of Paper Trough ...........................................................................................6-16

6-p Installation of 48 Tooth Gear ................................................................................................6-17

6-q Installation of Platen and Gears ............................................................................................6-18

6-r Installation of Motor and Sound Dampeners..........................................................................6-19

7-a Motherboard ..........................................................................................................................7-2

7-b Motherboard 'X-Y' Coordinates .............................................................................................7-3

7-c Installation Details .................................................................................................................7-4

7-d Modification Detail .................................................................................................................7-4

7-e Sheet 1 of Motherboard Schematics ....................................................................................7-6

7-f Sheet 2 of Motherboard Schematics .....................................................................................7-7

7-g Sheet 3 of Motherboard Schematics ....................................................................................7-8

7-h Sheet 4 of Motherboard Schematics ....................................................................................7-9

7-i Sheet 5 of Motherboard Schematics ......................................................................................7-10

7-j Processing Module (MPM) Printed Circuit Board Ref: 26025-005-50....................................7-11

7-k Processing Module Card (MPM) 'X' & 'Y' Coordinates Ref: 26025-005-50 and -51..............7-13

7-l Processing Module (MPM) Printed Circuit Board Ref: 26025-005-51....................................7-14

7-m Sheet 1 of 3 Schematics for MPM Printed Circuit Board Ref: 26025-005-50 and -51.........7-16

7-n Sheet 2 of 3 Schematics for MPM Printed Circuit Board Ref: 26025-005-50 and -51..........7-17

7-o Sheet 3 of 3 Schematics for MPM Printed Circuit Board Ref: 26025-005-50 and -51..........7-18

Table 2 - Default Parameters ......................................................................................................8-6

Table 3 - Lead Fail Test ..............................................................................................................8-9

8-a Measuring Device Forms ......................................................................................................8-13

8-b Chassis Leakage ..................................................................................................................8-14

8-c Patient Sink Current ..............................................................................................................8-15

8-d Patient Source Current ..........................................................................................................8-16

A-a Trace 1 - Noise / Drift Test ...................................................................................................A-1

A-b Trace 2 - 12-Lead Auto ECG ................................................................................................A-2

A-c Trace 3 - Rhythm Strips ........................................................................................................A-3

A-d Trace 4 - Directory ................................................................................................................A-4

A-e Trace 5 - Writer Self Test .....................................................................................................A-5

B-a Modem Module (MMM) 2 MRAM Printed Circuit Board Assembly Ref: 26025-003-50........B-2

B-b Views and Details for Mounting Crystal.................................................................................B-3

B-c Modem Module (MMM) 2 MRAM Board 'X' & 'Y' Coordinates Ref: 26025-003-50...............B-4

B-d Modem Module (MMM) 2 MRAM Schematic Ref: 26025-003-50.........................................B-5

B-e Modem Module (MMM) 16 MRAM Printed Circuit Board Assembly Ref: 26025-003-51......B-6

B-f Installation of C27 and D100..................................................................................................B-7

B-g Installation of R8 and C101...................................................................................................B-7