13/11/14 M2-5 (TS)_EN

ENGLISH

ENGLISH

REV.0-01/18

M

2.5

SAFETY RULES

ENGINE DRIVEN WELDERS

GENERAL SAFETY INSTRUCTIONS

+ NOTE: the information contained in this manual are

subject to change without notice.

The instructions in this manual are intended as indicative only.

It is the responsibility of the owner/operator to evaluate risks

and potential damages in relation to the use of the product in

the specic conditions of application. Remember that the non

observance of the indications of this manual may result in da-

mage to people or things.

In all cases, however, it is understood that the use shall be in

compliance with the applicable laws/regulations.

• Before operating the machine, read carefully the safety in-

structions contained in this manual and other manuals sup-

plied (engine, alternator, etc.).

• All operations, handling, installation, use, maintenance, re-

pair should be carried out by authorized and qualied per-

sonnel.

• When operating, wear personal protective equipment (PPE):

footwear, gloves, helmet, etc..

• The owner is responsible for maintaining the equipment in

safe conditions.

Use only in perfect technical conditions

The machinery or equipment must be used in perfect tech-

nical condition. Remove immediately any defects that may

affect the safe conditions of use.

• Before starting to use this equipment it is important to take

knowledge of all the controls of the machine, all its functions

and its correct installation in order to avoid accidents to pe-

ople and damage to the machine itself. In particular, it is

important to know how to stop the equipment quickly in case

of emergency.

• Do not allow the use of the machine to people unless pre-

viously instructed with all the information for a proper, safe

use.

• Forbid the access in the operational area to non authorized

personnel, children and pets so as to protect them from pos-

sible injury caused by any part of the machine.

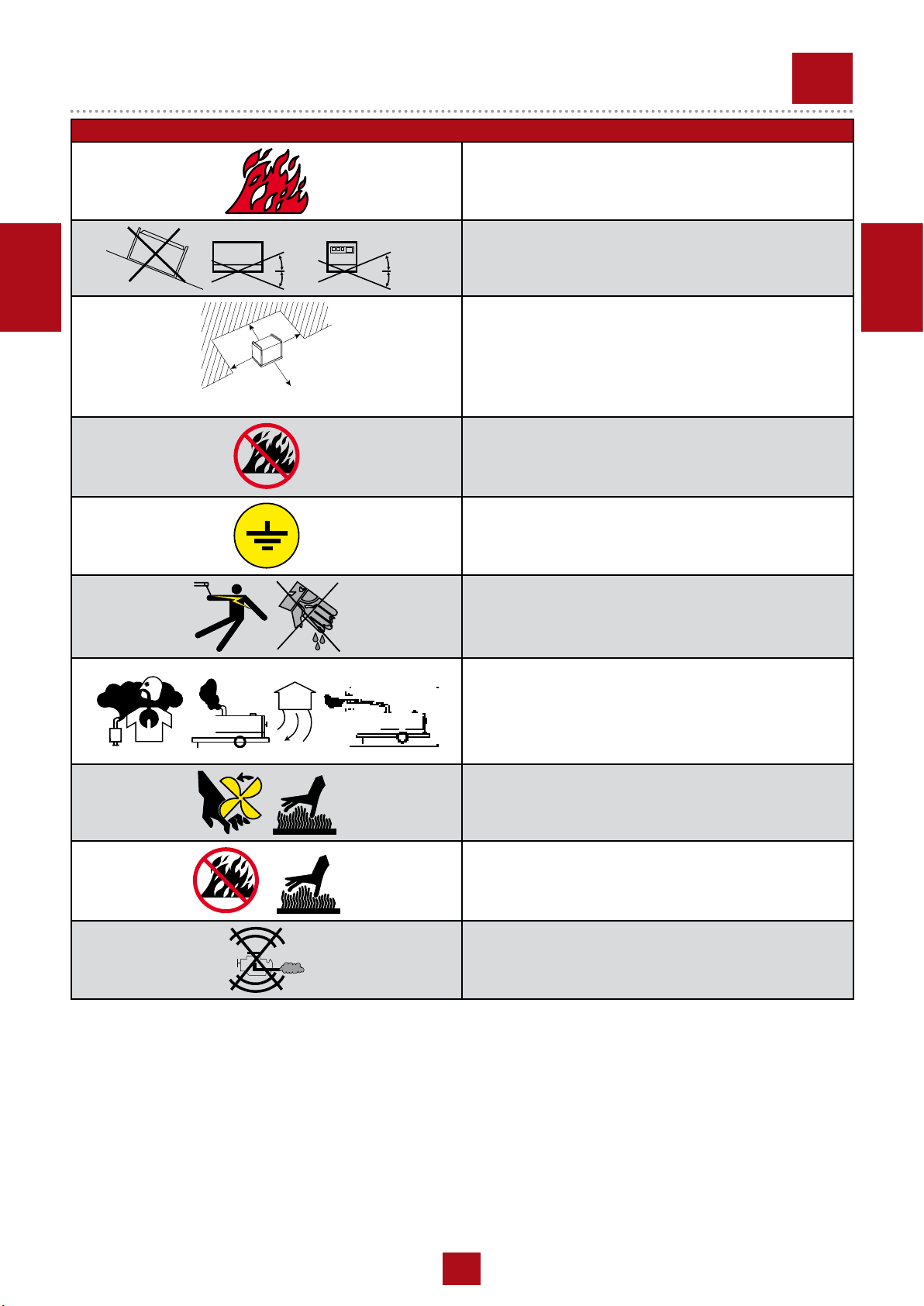

SAFETY PRECAUTIONS DURING HANDLING AND TRAN-

SPORTATION

• Lift the machine using only the points allocated for this fun-

ction.

The lifting eye (or eyes) and the correct positioning of the

forks of the forklift are marked with specic adhesives.

• Clear the operational area of possible obstacles and all un-

necessary personnel.

• Always use lifting equipment properly sized and controlled

by enabled bodies.

• It is forbidden to set on the frame of the equipment objects

or accessories that alter weight and center of gravity and

cause stresses not foreseen to the lifting points.

• Do not submit the machine and the lifting equipment to

swinging or shock which may transmit dynamic stress to the

structure.

Equipments with trailers or site tows

• Never drag the machine without trailer (or site tow)

• Check for a correct assembly of the machine to the towing

device.

• Always make sure that the hook of the vehicle is suitable for

towing of the total mass of the trailer.

• Do not tow the trailer if the coupling devices are worn or

damaged.

• Check for proper tire pressure.

• Do not replace the tires with types different from the original

ones.

• Check that the brakes and the optical signaling of the trailer

are working properly.

• Verify that the bolts of the wheels are in place and well

tightened.

• Do not park the machine (on trailer or site tow) on a steep

slope.

For the stops, not followed by a work session, always enga-

ge the parking brake and / or block the wheels by means of

wheel chocks.

• Do not tow the trailer on bumpy roads.

• Do not exceed the maximum permissible speed on public

roads of 80 km/h with the trailer, in any case comply with the

legislation applicable in the country of use.

• Do not use the site tow on public roads, this is intended for

use only in private and delimited areas. The maximum per-

mitted speed is 40 km/h on smooth surfaces (asphalt or con-

crete), adapt in each case the speed to the type of ground.