Part # 910-850 910-855 -1- Modified 03/18

Coolant Reroute Kit

Installation Instructions

For 1994-1997 Miata 1.8L

PART # 910-850 and 910-855

Tools required:

• Timing Light

• Jack, jack stands, wheel chocks

• Phillips Head and Flathead Screwdrivers

• ¼" Ratchet

• " Ratchet

• 10mm Socket

• 12mm Socket

• 19mm Deep Socket

• " Deep Socket

• " Socket

• 5mm Allen Wrench

• 10mm Wrench

• 12mm Wrench

• 22mm or " Wrench

• Thread Sealant

• Razor blade or similar gasket scraper

• Radiator Hose Cutter

• Telescoping mirror (recommended)

• Spill-Free Funnel such as Lisle 24680 (recommended)

• Torque Wrench ¼" (recommended)

• Cooling System pressure tester (recommended)

Kit number 910-855 does not include an EGR

tube, EGR block off plate or block off nut. 910-855

is intended for an individual who has already done

away with the EGR system.

If your car presently has a working EGR system,

we recommend returning this kit and purchasing

Coolant Reroute Kit part# 910-850 which includes

a compatible EGR tube.

Removing the EGR tube and blocking off the ports

will turn the “Check Engine Light” on.

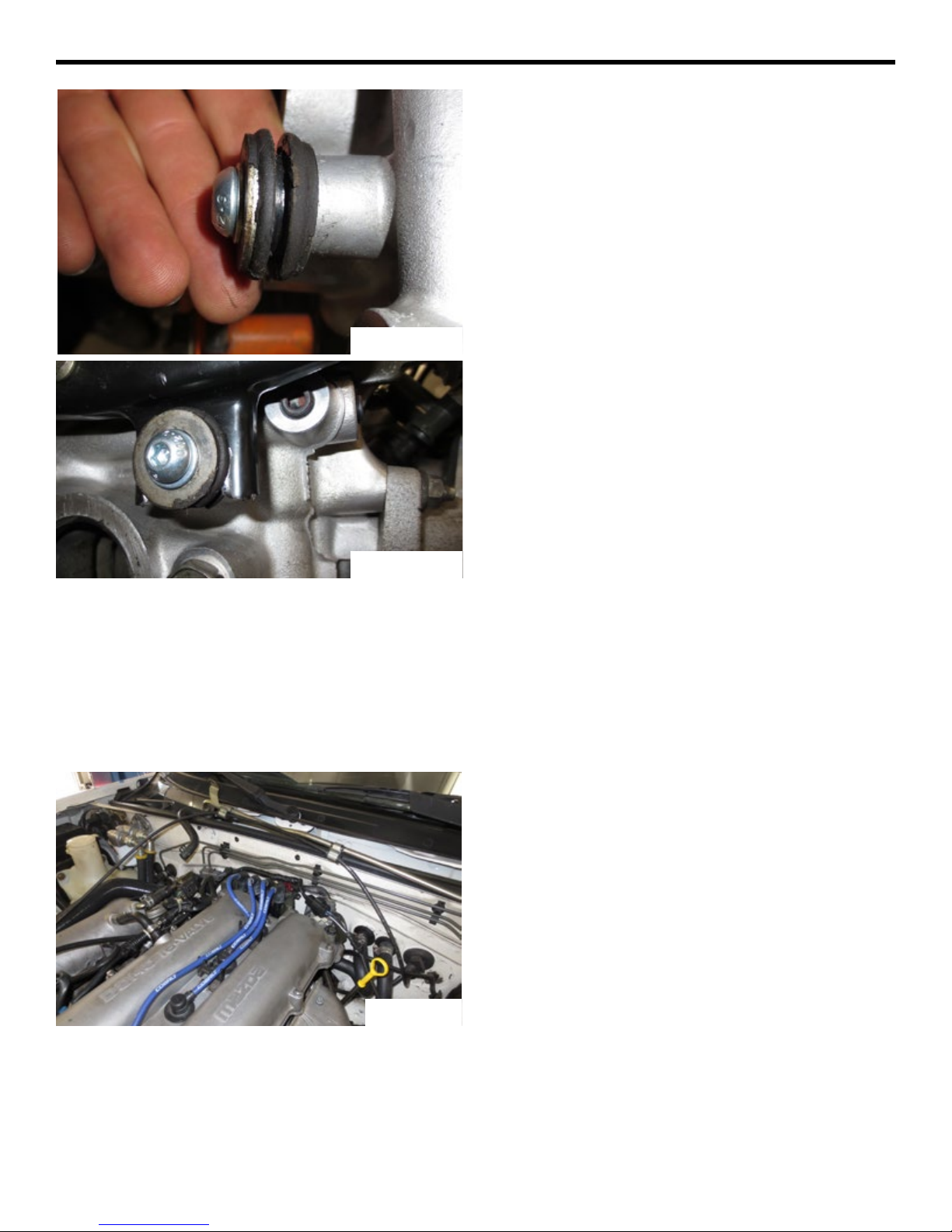

Notes: The stock coolant routing on the Mazda 1.8L

engine leaves much to be desired. Since the 1.8L

was originally developed for light-duty transverse-

mounted front wheel drive applications, little thought

was given to the rear-wheel drive Miata. Coolant

flows from the water pump at the front, through

passages in the engine to the rear of the cylinder

head. Some coolant can exit at the rear of the engine

but only through the small heater hose leading to the

heater core, a major flow restriction. The majority of

the coolant has to reverse direction and travel back

through the block again to exit at the thermostat at

the front of the engine; transferring unwanted heat

back into the block on the way. As a result of this

inefficient design, the rear cylinders run hotter than

the front. This can lead to a hotter running engine and

premature failures of the rear cylinders. The design is

especially problematic when a Miata is driven hard on

the track or modified for increased power output.

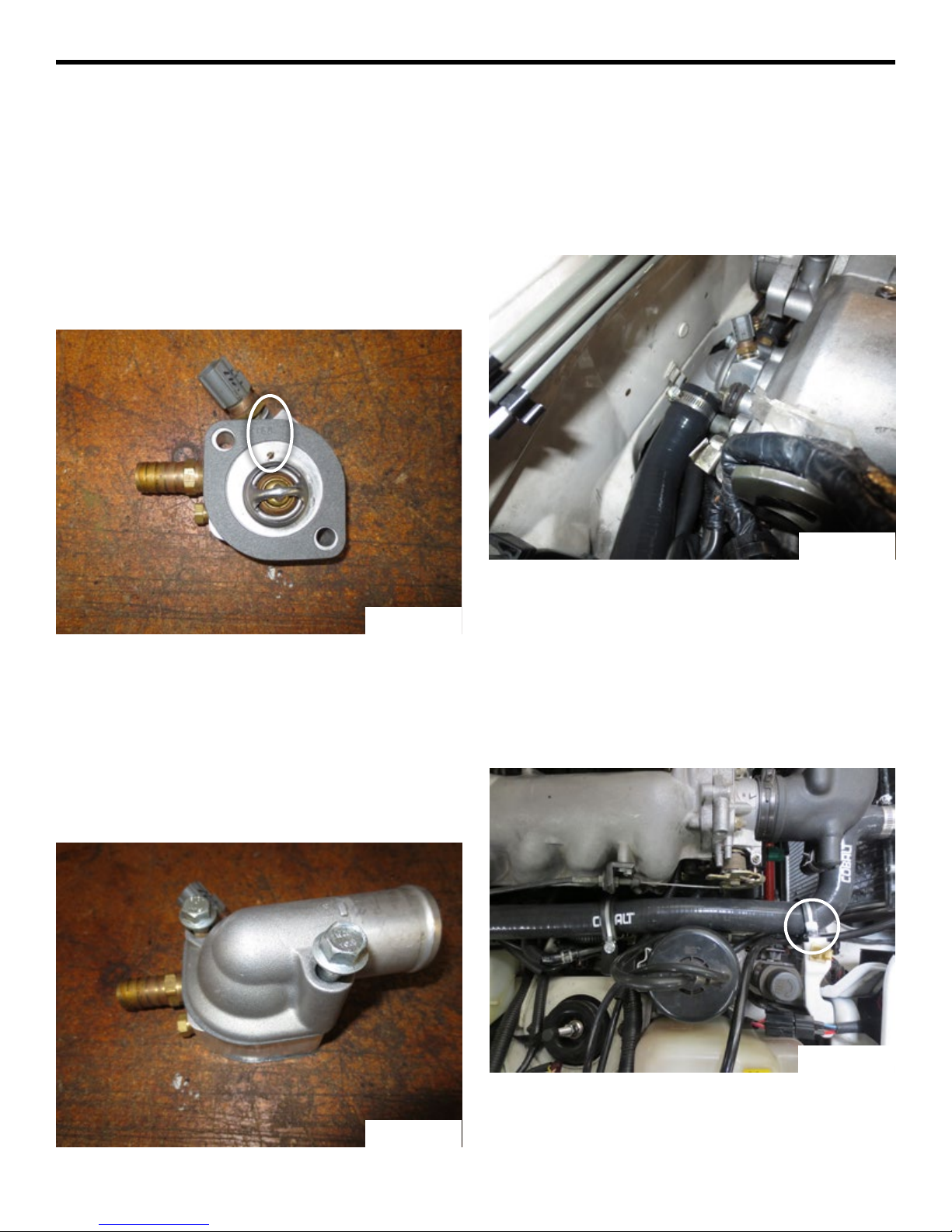

This kit will relocate the thermostat from the front of

the engine to the rear, thereby allowing coolant to

flow more efficiently one direction through the block.

The full-size radiator hose outlet at the rear of the

engine ensures maximum coolant flow is directed out

of the engine to the radiator. This helps to keep all

cylinders at a more uniform lower temperature.