MOTO GUZZI V7 Cafe Classic Guide

Other MOTO GUZZI Motorcycle manuals

MOTO GUZZI

MOTO GUZZI NORGE GT 8V User manual

MOTO GUZZI

MOTO GUZZI Le mans 1000 User manual

MOTO GUZZI

MOTO GUZZI GRISO 850 2007 Guide

MOTO GUZZI

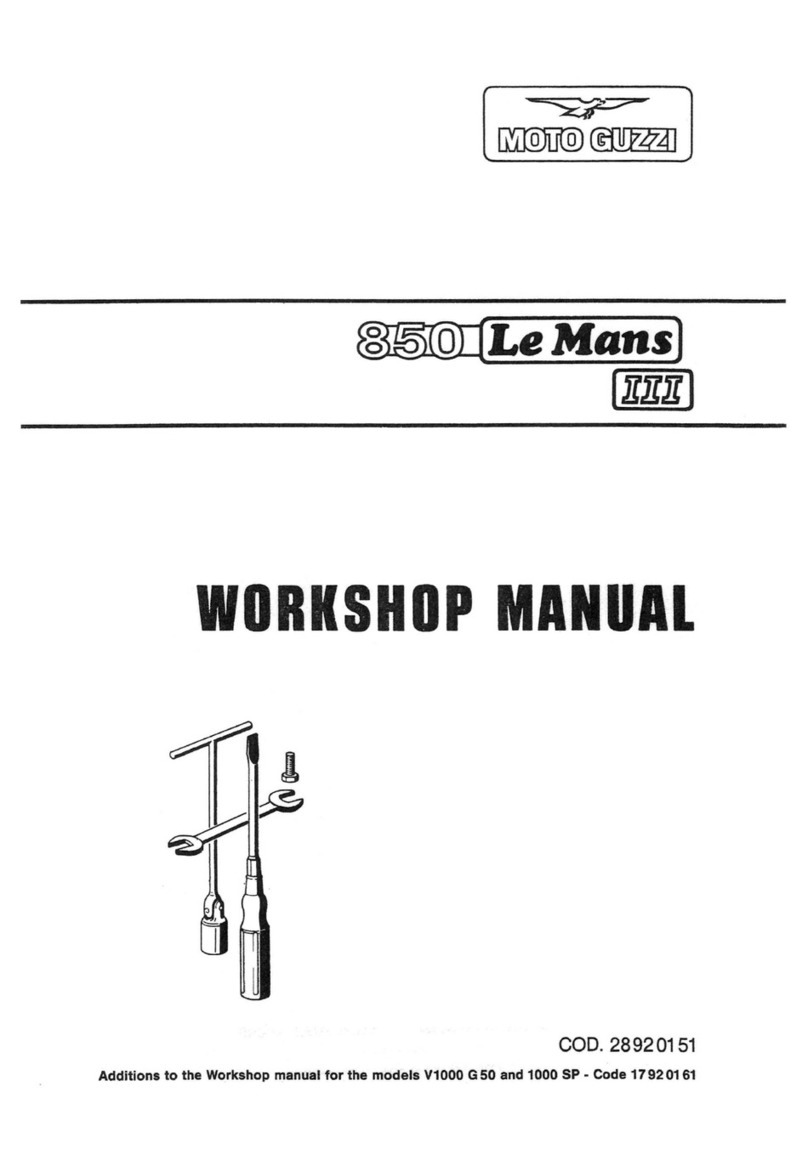

MOTO GUZZI 850 Le Mans III Instruction manual

MOTO GUZZI

MOTO GUZZI 1993 Strada 1000 Instruction manual

MOTO GUZZI

MOTO GUZZI Robin User manual

MOTO GUZZI

MOTO GUZZI 850-T User manual

MOTO GUZZI

MOTO GUZZI V1000 G5 User manual

MOTO GUZZI

MOTO GUZZI V11 SPORT MY 2003 User manual

MOTO GUZZI

MOTO GUZZI V7 II ABS Guide

MOTO GUZZI

MOTO GUZZI V85 TT Guide

MOTO GUZZI

MOTO GUZZI V1000 G5 Instruction manual

MOTO GUZZI

MOTO GUZZI V750 IE Mounting instructions

MOTO GUZZI

MOTO GUZZI V7 III Special User manual

MOTO GUZZI

MOTO GUZZI NORGE GT 8V User manual

MOTO GUZZI

MOTO GUZZI V 7 CAFE CLASSIC User manual

MOTO GUZZI

MOTO GUZZI California 1100 User manual

MOTO GUZZI

MOTO GUZZI BREVA V1100 Guide

MOTO GUZZI

MOTO GUZZI California II Instruction manual

MOTO GUZZI

MOTO GUZZI nevada User manual

Popular Motorcycle manuals by other brands

MV Agusta

MV Agusta Brutale 675 Workshop manual

APRILIA

APRILIA RSV MILLE - PART 1 1999 User manual content

Royal Enfield

Royal Enfield Himalayan 2018 owner's manual

SSR Motorsports

SSR Motorsports Lazer5 owner's manual

KTM

KTM 85 SX 19/16 owner's manual

Beta Motorcycles

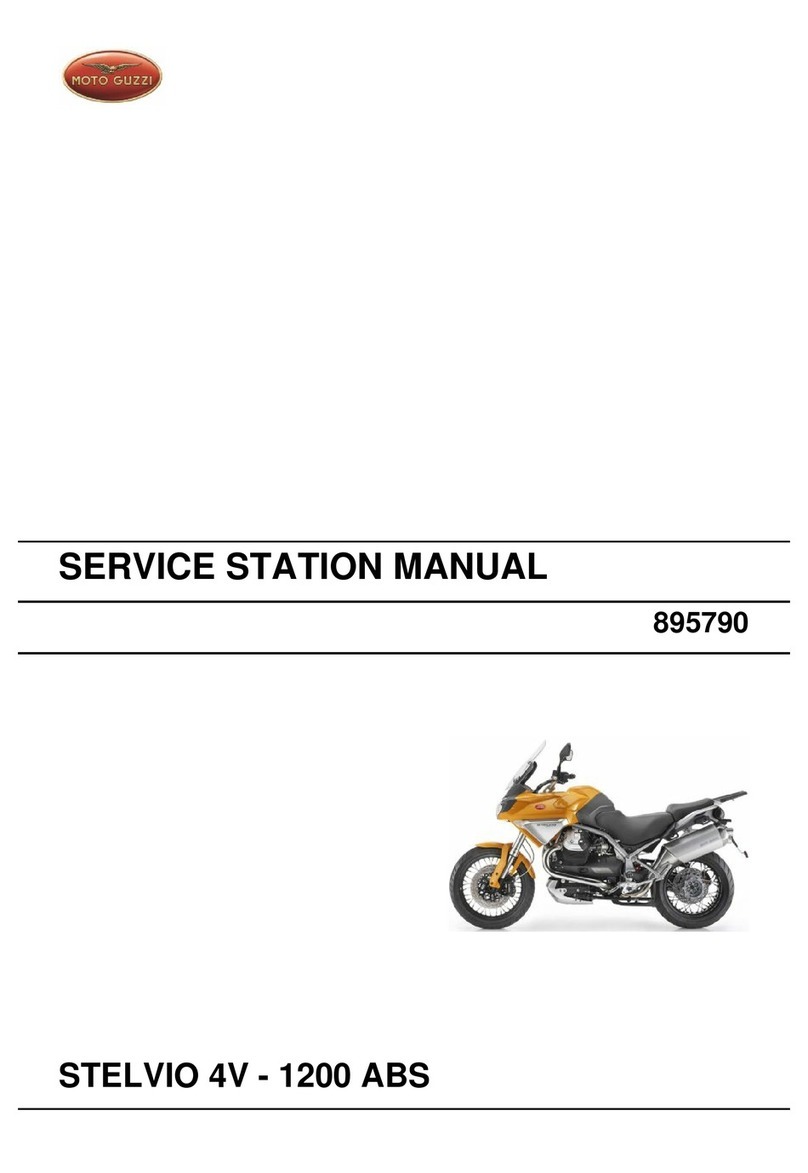

Beta Motorcycles XTRAINER 250 2T EUROPA 2022 manual