4

c) Choose suitable positions for installing the motoscope rally and the speedometer sensor.

Attach the motogadget mounting bracket to your vehicle or make your own bracket. Attach the

speedometer senor bracket.

d) Decide at which point all wires will be brought together in order to connect the motoscope mini

with the power supply, speedometer sensor, ignition signal cable and the push button. Make

sure there is sufficient space for the connections.

e) Mount the instrument, the speedometer sensor and the push button to the vehicle.

f) Locate “switched plus” on the wiring of your vehicle by using a voltmeter (“switched plus”

means electricity only flows when ignition is switched on). Connect the delivered cable fuse to

switched plus and route a wire from the other end of the fuse to the chosen terminal point.

g) Remove ground cable from battery terminal.

i) Connect all wires which meet in the terminal point (motoscope, power supply, speed sensor,

ignition coil and push button) according to the circuit diagram provided in the appendix. Use

the delivered connector kit for easy unplug of the instrument if necessary.

j) Re-connect vehicle battery and switch ignition on.

k) Navigate to the setup menu (see Chapter 12) and adjust all necessary parameters for engine

speed, the rev. counter scale and the speedometer.

l) Ride carefully and slowly for a while and check the speedometer. If you do not detect any

electrical or mechanical problems continue the test drive.

6 General safety instructions for mounting and connection

•Disconnect vehicle battery prior to installation.

•In the interest of your own and other peoples’ safety attach all parts securely to your vehicle.

•Make sure that your vehicle is equipped with interference suppressing spark plugs and

connector cables! Use of the motoscope rally with non-suppressed ignition systems can

lead to serious damage of the device.

7 Installation

To ensure correct fastening two metric fastening screws must be used (M3). In order to avoid

distortions of the thread, the fastening bolts must be screwed into the instrument casing to a

minimum depth of 3 mm and a maximum depth of 5 mm. Choose screws that fit to the mounting

bracket. We also recommend the use of additional washers and screw adhesive (e.g. Loctite

medium-strength). Furthermore, the maximum torque applied to the M3 fastening screws must

not exceed 4 Nm.

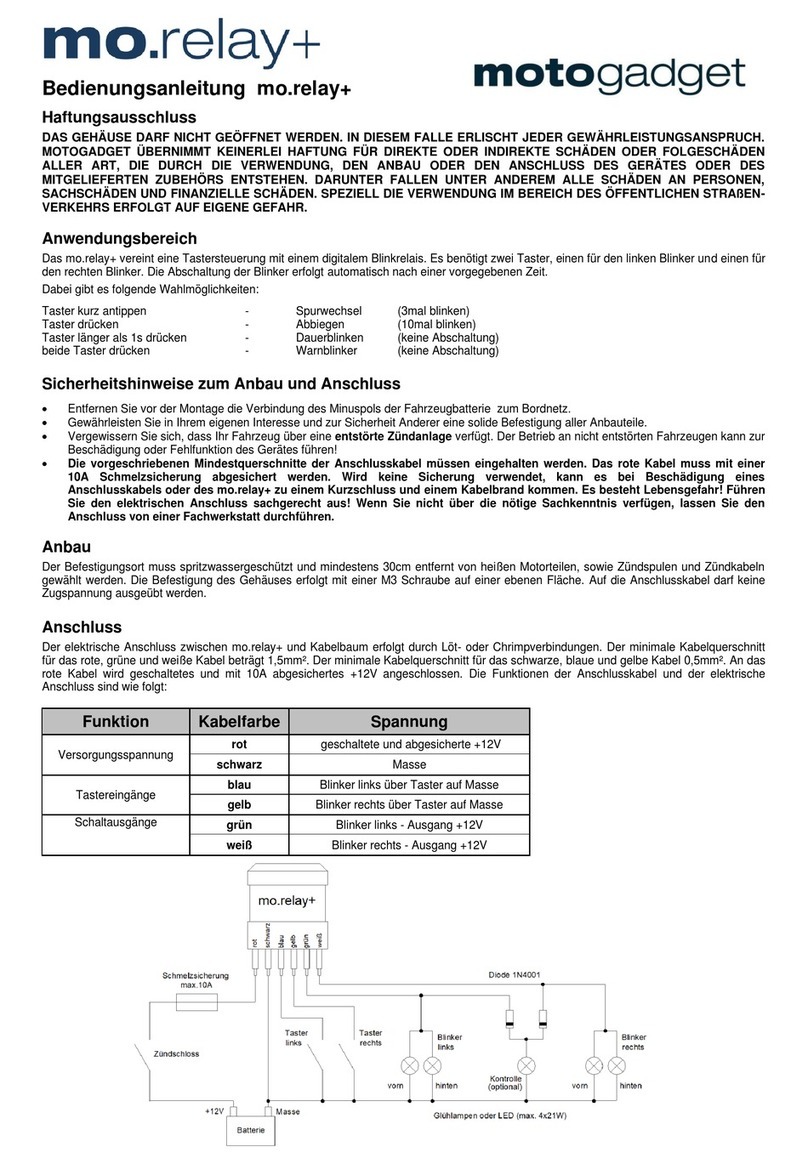

8 Connecting

8.1 Recommendations for wiring

Before connecting wires look for suitable cable paths. The cables should be as far away as

possible from hot engine parts. Look for a suitable place to connect wires and plugs. Similar

connection points can already be found at the headlights, underneath the gas tank or at the dash

board. Make sure you take note of required lengths of cables before cutting them to fit. It is

important to consider the full lock of the handlebars as well as pitch of the front and rear

suspension. All wires should be free of kinks and should not be subject to any pull and should be

well isolated especially in places of mechanical wear. We recommend solder joints. For securing

wires we recommend cable ties made from plastic.