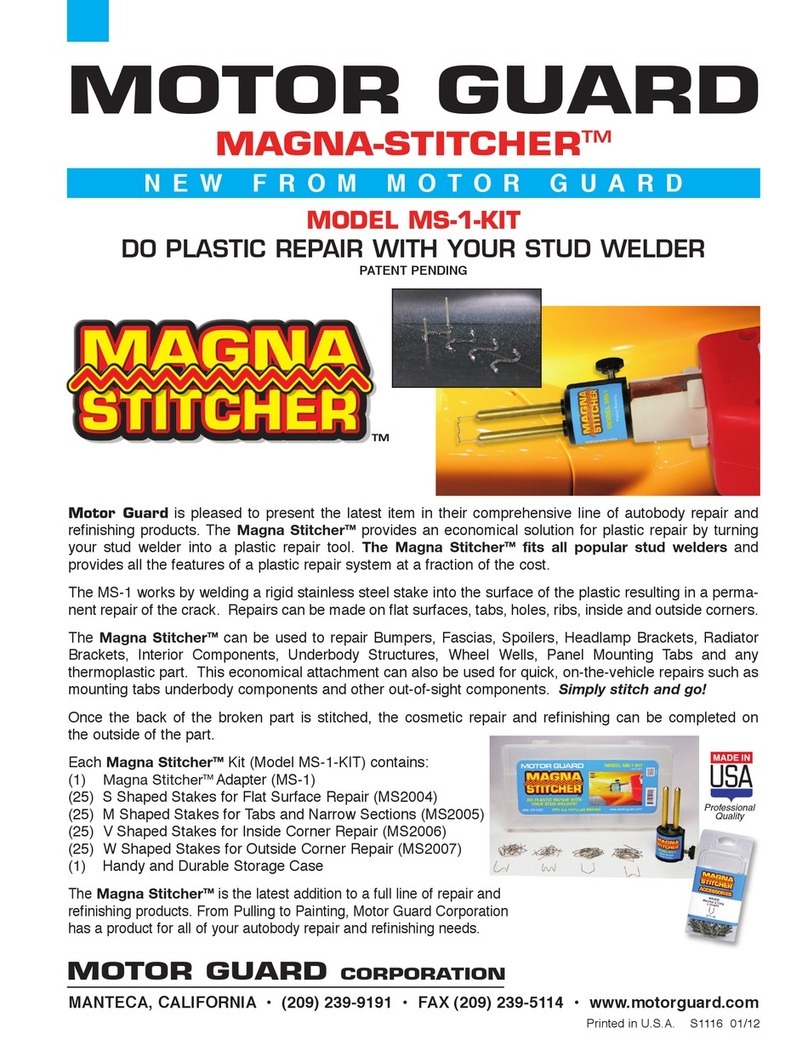

MAGNA-STITCHERTM

INSTRUCTIONS

Plastic Repair Kit

Model MS-1-KIT

Patent Pendin

*WARNING: Read and understand all instructions before attempting to operate tool.

Failure to follow instructions may result in electric shock, fire and/or serious

personal injury.

Review and follow all instructions for your electric stud welder.

If you do not have the original instructions for your stud welder, contact the

manufacturer for a replacement copy.

IMPORTANT SAFETY INSTRUCTIONS

*8

To reduce the risk of serious

injury and/or property damage,

observe all warnings and

instructions while operating the

tool. Keep work area clean and well

lit. Maintain tool in top condition and

obtain service from manufacturer if

tool malfunctions. Use only

accessories and replacement parts

that are provided by the

manufacturer.

Stud welder must be connected

to a properly grounded outlet

installed in accordance with all local

codes and ordinances. Never

remove the grounding prong or

modify the plug in any way. Do not

use adapter plugs. Consult an

electrician if you are in any doubt as

to whether the plug is properly

grounded. Avoid bodily contact with

grounded surfaces.

=!

A

Always wear proper personal

protection when operating welder.

A full face shield per ANSI Z87.1-

2003 standard is required at all times

to protect face and eyes against

injury from flying parts. Adequate

gloves and clothing are required to

reduce the risk of burns. Allow parts

to cool before handling.

Do not operate tool in explosive

atmospheres, such as in the

presence of flammable liquids,

gases or dust. Welders create

sparks which may ignite dust or

fumes. Use in well ventilated areas

only. Welders generate heat which

can ignite surrounding materials

causing fires.

SAVE THESE INSTRUCTIONS

IF YOU HAVE ANY QUESTIONS ABOUT THE OPERATION OF PRODUCT CALL TOLL FREE

800-227-2822

8:00 am to 5:00 pm - Pacific Time - Monday through Friday