MotorScrubber

Contents

Thank You For Purchasing 03

Application Details

JET3 04

STORM 05

Know Your Equipment

JET3 06

STORM 07

Preparing Your Machines

Important Information 08

Electrical Connection 08

Battery & Charging Information 09

Water Connection 10

The Handle - Pump Switch 10

Preparing the Chemical 10

Prime the Pump 11

JET3

JET3 12

The Handle - Brush Switch 14

Handle Position 14

Adjusting the Flip Clip 15

Adjusting the JET3 Position 15

Cleaning the JET3 16

Changing a MotorScrubber Brush 17

Removing Dirty Slurry 17

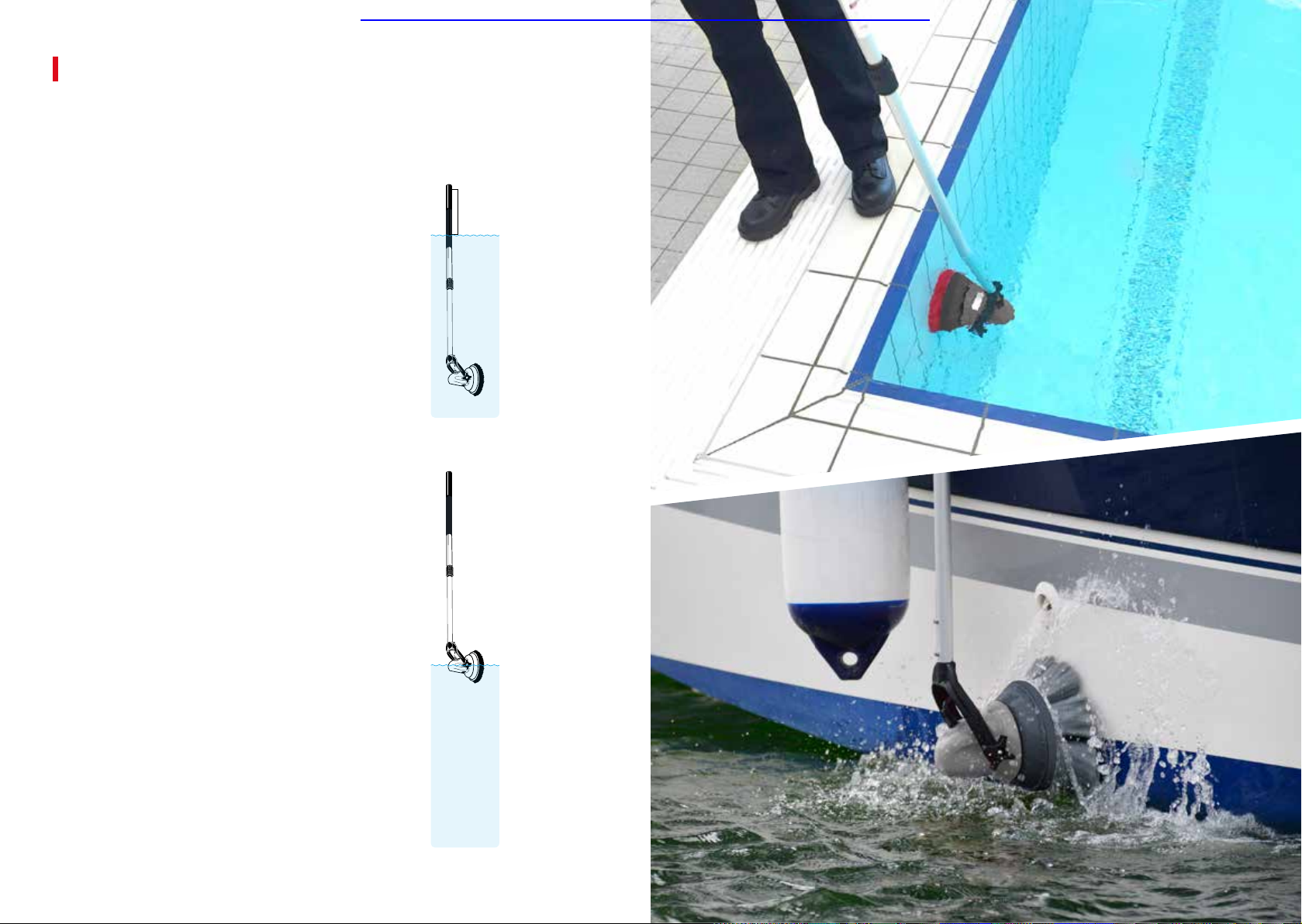

Underwater Use 18

STORM

STORM 20

Disinfecting with STORM 22

Operational Instructions 23

Application Instructions 24

Personal Protective Equipment 25

Complete Parts Breakdown

JET3 26

STORM & Backpack 27

Certicate of Conformity 28

Warranty 29

Safety Instructions 30

Troubleshooting 31

02 03

When using electric

products, basic safety

precautions should

always be followed

to reduce the risk

of electric shock

and personal injury,

including the following:

• Consider your work

area environment.

When using the

MotorScrubber be

aware of overhead

electrical wires.

• MotoScrubber is

powered by DC

current only. Do not

attempt to operate

MotorScrubber with

AC current.

• Always ush out

chemical with clean

water after every use.

• Never pull the

MotorScrubber by

its cord or yank it to

disconnect it from the

battery.

• Keep the cord away

from heat, oil and sharp

edges.

• Keep your

MotorScrubber clean.

(For safer operation,

follow instructions for

attaching accessories.

Keep the upper handle

switch area dry, clean

and free from oil, grease

and water).

• Disconnect the

MotorScrubber when

not in use and when

attaching accessories.

• Inspect for damage

before using

MotorScrubber.

• When servicing, use

only genuine parts and

accessories.

MotorScrubber is a

power tool. As with any

power tool, always use

both hands to ensure

safe operation.

• Ensure you adopt the

correct posture when

using MotorScrubber.

Maintain a straight

back.

• Adjust the position

of the control handle

(see page 14) so your

arm is straight when

holding the handle.

Your back should be

straight at all times.

Save these instructions

for future reference.

Thank you for purchasing

your MotorScrubber

machine.

We hope you enjoy using your MotorScrubber

product, please feel free to leave comments and

feedback at motorscrubberclean.com/support.

PLEASE READ ALL INSTRUCTIONS

Page 12

Page 20

New & Reconditioned Equipment & Parts- www.southeasternequipment.net

New & Reconditioned Equipment - www.southeasternequipment.net