A B

ENEN

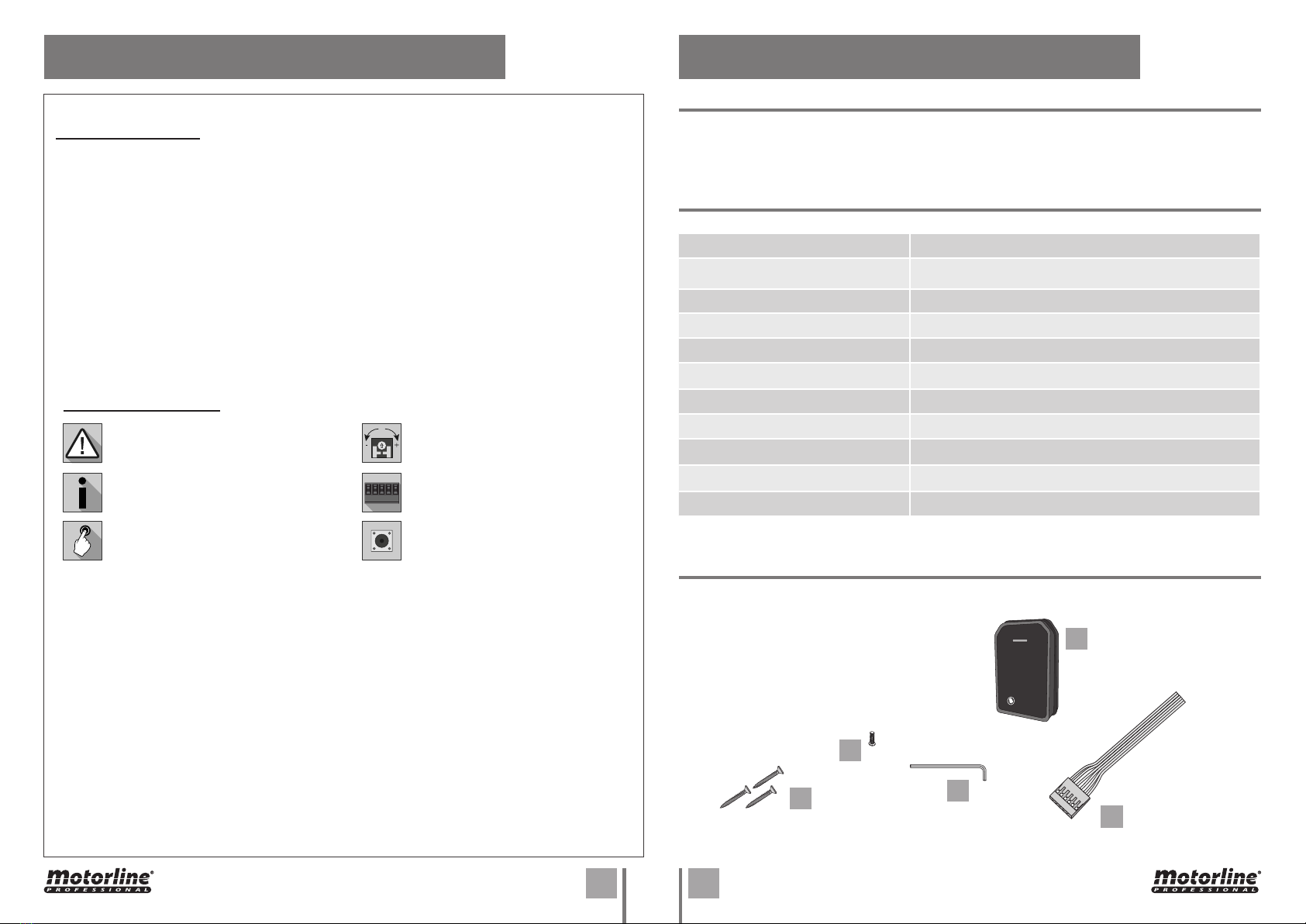

01. SAFETY INSTRUCTIONS

ATENÇÃO: GENERAL WARNINGS

•This manual contains very important safety and usage information.

very important. Read all instructions carefully before beginning the

installation/usage procedures and keep this manual in a safe place

that it can be consulted whenever necessary.

•This product is intended for use only as described in this manual. Any

other enforcement or operation that is not mentioned is expressly

prohibited, as it may damage the product and put people at risk

causing serious injuries.

•Thismanualis intendedfirstlyforspecialized technicians, anddoes not

invalidate the user’s responsibility to read the “User Norms” section in

order to ensure the correct functioning of the product.

•The installation and repair of this product may be done by qualified

and specialized technicians, to assure every procedure are carried

out in accordance with applicable rules and norms. Nonprofessional

and inexperienced users are expressly prohibited of taking any action,

unless explicitly requested by specialized technicians to do so.

•Installations must be frequently inspected for unbalance and the

wear signals of the cables, springs, hinges, wheels, supports and other

mechanical assembly parts.

•Do not use the product if it is necessary repair or adjustment is

required.

•When performing maintenance, cleaning and replacement of parts,

the product must be disconnected from power supply. Also including

any operation that requires opening the product cover.

•The use, cleaning and maintenance of this product may be carried

out by any persons aged eight years old and over and persons whose

physical,sensorialormentalcapacitiesarelower,orbypersonswithout

any knowledge of the product, provided that these are supervision

and instructions given by persons with experienced in terms of usage

of the product in a safe manner and who understands the risks and

dangers involved.

This product is certified in accordance with European

Community (EC) safety standards.

This product complies with Directive 2011/65/EU of the

European Parliament and of the Council, of 8 June 2011, on

the restriction of the use of certain hazardous substances

in electrical and electronic equipment and with Delegated

Directive (EU) 2015/863 from Commission.

(Applicable in countries with recycling systems).

This marking on the product or literature indicates that the

product and electronic accessories (eg. Charger, USB cable,

electronic material, controls, etc.) should not be disposed

of as other household waste at the end of its useful life. To

avoid possible harm to the environment or human health

resulting from the uncontrolled disposal of waste, separate

these items from other types of waste and recycle them

responsibly to promote the sustainable reuse of material

resources. Home users should contact the dealer where

they purchased this product or the National Environment

Agency for details on where and how they can take these

items for environmentally safe recycling. Business users

should contact their vendor and check the terms and

conditions of the purchase agreement. This product and

its electronic accessories should not be mixed with other

commercial waste.

This marking indicates that the product and electronic

accessories (eg. charger, USB cable, electronic material,

controls, etc.) are susceptible to electric shock by direct or

indirect contact with electricity. Be cautious when handling

theproductandobserveallsafetyprocedures inthismanual.