11

Finishing the wings

! Glue the end caps onto the 1/8” balsa ailerons. Align the ailerons with the trailing edges of the

wings. The notch cut for the control horn is on the side closest to the fuselage. Note that each

aileron is tapered to fit with the trailing edge. Sand a 45 degree bevel into the front edge of the

ailerons. Note that the way you angle the bevel determines if it is a right or left aileron. The bevel

should be such that the aileron touches the wing at the top, not bottom.

! Paint or cover the ailerons.

! Use 3/4” packaging tape for the hinges. Once the tape is applied, you can strengthen the tape bond

with some thin CA by flowing it into the tape joint. The CA will wick into the balsa. Be certain

not to glue the aileron to the trailing edge.

! Feed the wings through the holes cut in the sides of the fuselage and join the left and right spars.

Ensure the wing is straight and then glue the inner spar seam with CA, or, if you want removable

wings, bolt the two spars together with the supplied 4-40 bolt.

! Insert the control horns into the notches in the aileron so the horn is angled towards the leading

edge of the wing. Glue into place with CA.

Tail Assembly

! The tail assemblies are made up from the 3/32” laser cut sheet. Lay the plans out on a flat

worktable and tape them down, and then lay a sheet of wax paper over the plans. This will protect

the plans from the glue. The pieces of balsa are positioned over the plans and glued together. .

Build one part at a time, removing only that part from the balsa sheet so that you don’t mix the

parts up. Assemble each half of the elevator and then join them with the 1/8” x 2.75” hardwood

dowel.

! Sand a 45 degree bevel in the leading edge of the rudder. Also sand a 45 degree bevel in the

trailing edges of the horizontal stabilizer.

! Paint the tail assemblies if desired.

! The vertical stabilizer rests on the rear fuselage top. Insert the tabs of the stabilizer into the

notches in the back of the fuselage. Ensure the stabilizer sits at a 90 degree angle to the fuselage

and glue into place.

! Face the elevator so that the trailing edge faces the front of the plane and insert it into the slot cut

in the fuselage. Once it is centered, rotate it around to face the correct direction and push it back

towards the rear. Insert the horizontal stabilizer into the fuselage slot. Be certain you have both

assemblies in place before gluing the horizontal stabilizer to the fuselage.

! The edges of the stabilizer must be equidistant from the fuselage. Once satisfied with the

alignment, glue into place with some thin CA. Ensure no glue touches the elevator.

! Use 3/4” packaging tape for the hinges. Align the elevator with the horizontal stabilizer and tape

into place. You can reinforce the tape joint like you did with the ailerons.

! Insert the plywood control horn into the elevator and glue into place with thin CA. The horn is

attached to the top of the elevator.

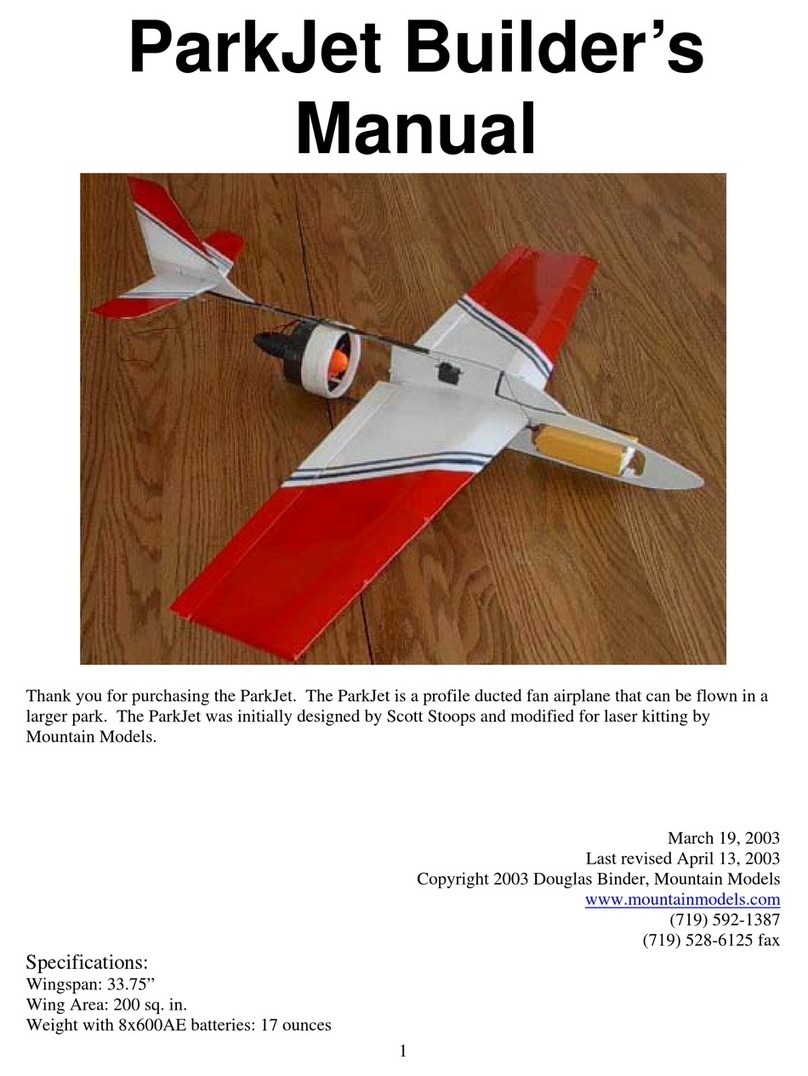

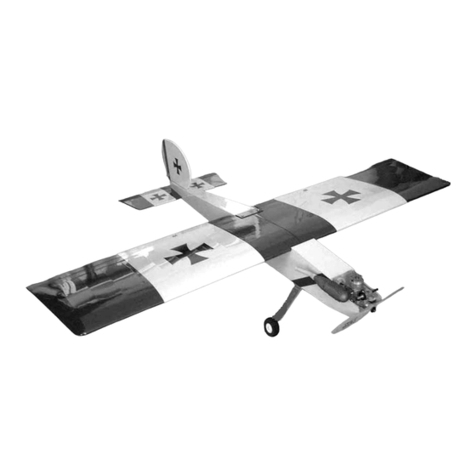

! Shape the tail wheel wire as shown in the picture. The first bend will create the axle. The second

bend will go over the edge of the wheel, with the third bend running parallel with the wire

between the first and second bends.