7

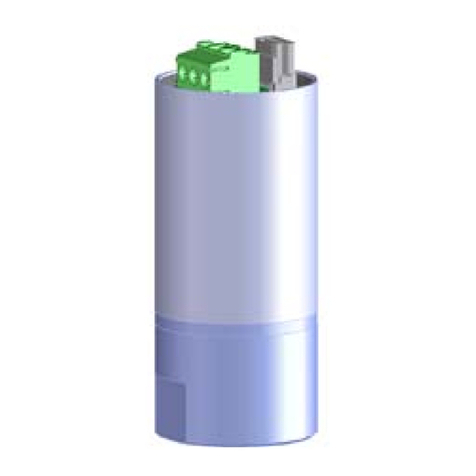

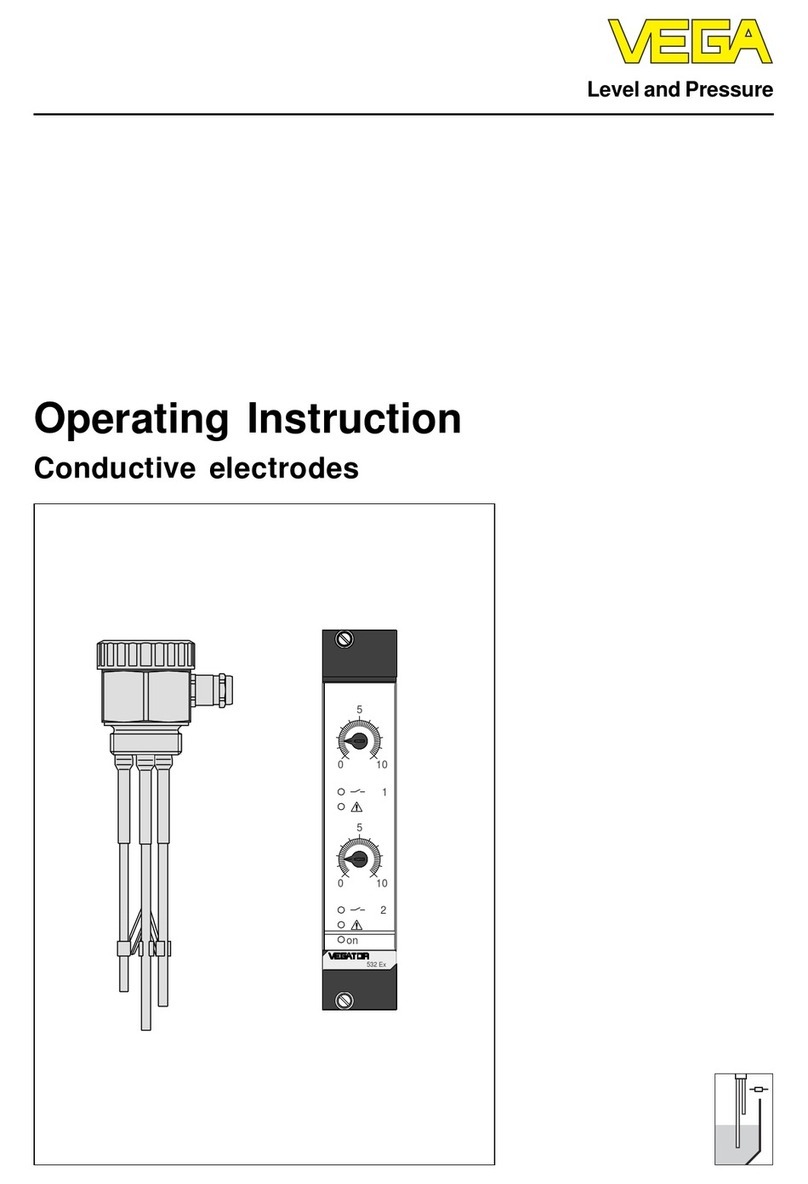

VEGAMET 307 / 308

Adjustment

Empty and full adjustment via the spindle potentio-

meter. The integrated slide clutch avoids overwin-

ding.

Before either adjustment each potentiometer must

be turned by approx. 22 turns clockwise.

In practice 3 versions are possible to carry out the

empty / full adjustment.

a) The level can be set to the required min. level

(= 0%) and max. level (= 100 %)

Empty adjustment

• Set level to the required min. level.

• Adjust the indication of the instrument to 0 % by

the potentiometer for empty adjustment.

Full adjustment

• Set level to the required max. level.

• Adjust the indication of the instrument to 100 %

by the potentiometer for full adjustment.

b) The level in the vessel can be set to the

required min. level (= 0 %), but only to a max.

level < 100 %

Empty adjustment

• Set level to the required min. level.

• Adjust the indication of the instrument to 0 % by

the potentiometer for empty adjustment.

Full adjustment

• Set product to the highest level and check with

dip measure (e.g. 80 %).

• Adjust the indication of the instrument to the

checked value (in the example 80 %) with the

potentiometer for full adjustment.

c) The level in the vessel can be only set to a

min. level of > 0 % and a max. level ≤100 %

Empty adjustment

• Set product to the low level and check with dip

measure (e.g. 20 %)

• Set indication of the instrument to 0 % with the

potentiometer for empty adjustment.

Full adjustment

• Set level to highest possible level and check with

dip measure (e.g. 60 %).

• Calculate the indicated value to be adjusted:

highest level minus lowest level = indicated value

to be adjusted.

In the example: 60 % – 20 % = 40 %.

• Set indication of the instrument to the calculated

value (in the example 40 %) with potentiometer

for full adjustment.

• Set the indication of the instrument to the actual

level (highest level, in the example 60 %) with

the potentiometer for empty adjustment.