MP3 WXH Series User manual

CIRCULAR SERIES WXH - 1500Pa

Cert. N° 1812-CPR-1189

Technical Manual

English

WXH

SINGLE COMPARTMENT

SMOKE CONTROL DAMPER

2

Smoke damper

rev 21-10

Description

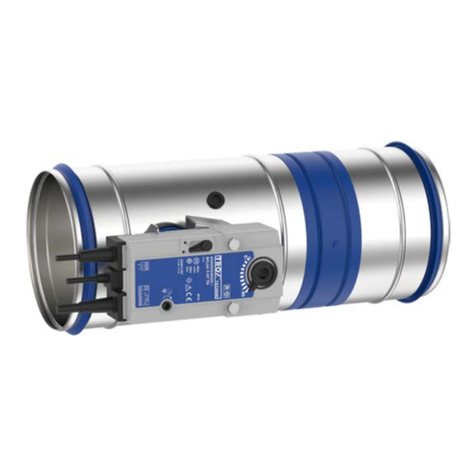

Damper WXH is a single compartment smoke control damper; It’s a device which can be open or closed

to control the ow of smoke and hot gasses into, from or within a duct for use in single compartment

applications at elevated temperatures (600°C), which may be associated with smoke control ducts to

EN1366-9:2008.

The function of the single compartment smoke control damper is to concentrate the fan pressure in the

smoke reservoirs involved in the re scenario.

The damper casing is made of galvanized steel with EPDM connection with leakage class C according with

EN1751.

The damper has two dierent motorized versions depending on the relay response required: type AA

(Automatic Activation) and type MA (Manual Activation, with re rated motor covering box). The smoke

damper is CE marked according to EN12101-8, tested according to EN1366-10 and classied according to

EN13501-4. The damper is suitable for vertical and horizontal installation in single compartment smoke

duct evacuation systems with maximum temperature of 600°C for 2 hours with smoke leakage class S at

1500Pa negative pressure.

Declaration of performance

The damper is CE marked with the declaration of performance according to EN12101-8 as a circular smoke

control damper single compartment with CPR nr. 1812-CPR-1189.

Manufacturer of the smoke damper:

MP3 S.r.l., via G. La Pira 9, 35012 Camposampiero (PD), Italy

Intended use

The damper is a part of a smoke and re protection system that is designed to reach the following targets:

• Extract smoke for 2 hours during the re

• Reduce temperatures during the re

• Opens the blade and remove heat and smoke from a compartment in re

• Closes the blade to prevent the spread of heat and smoke to a safe compartment

• Create an non-smoke layer

• Protect the property

This damper represents a part of the smoke and re protection project whose main purpose is to be

WXHU AA WXHU MA

3

Smoke damper

rev 21-10

installed in single compartment smoke ducts to concentrate all the depression of the smoke extraction

fan in the smoke reservoirs actually aected by the presence of smoke. This re protection project shall be

designed by a re expert. The products used in system should not be larger than dimension Ø 630.

Testing and classication

The WXH single compartment smoke control dampers have been tested connected to single compart-

ment circular ducts and ttings belonging to the Lindab (www.lindab.com) smoke and heat exhaust

ventilation system.

WXH smoke control dampers have two relay response options: type AA (Automatic Activation) and type

MA (Manual Activation).

In accordance with EN12101-8:2011 WXH single compartment smoke control dampers have been subjec-

ted to the following tests:

- Opening and closing cycles according to EN1366-10:2011+A1:2017: 10000 cycles at nominal operating

supply, 100 cycles at nominal operating supply -10%, 100 cycles at nominal operating supply +15%.

- Blade and casing ambient leakage according to EN1751:2014 with pressure from -2000Pa to +2000Pa

obtaining the classication in class 2 for the air tightness of the blade and class C for the air tightness of

the casing.

- Extraction system ambient leakage according to EN1366-10:2011+A1:2017 with pressure -1500Pa (level

3).

- 600°C temperature resistance according to EN1366-10:2011+A1:2017 with pressure -500Pa (level 3)

for 120 minutes with damper installation both horizontal and vertical and with blade rotation axis both

horizontal and vertical.

The re classication obtained according to EN13501-4:2016 is:

According to the classication obtained, according to Tables 1 and 3 (level 3) and according to paragraph

6.3.2.2 of EN1366-10:2011+A1:2017 it is allowed to use single compartment smoke control dampers WXH:

- In single compartment smoke exhaust ventilation system;

- In general HVAC systems as well as a smoke control system;

- With depression for smoke exhaust up to -500Pa;

- With pressure at ambient temperature from -1500Pa to +500Pa.

E I t Ved ho i o S Operating pressure C MA/

AA

Single/

multi

E6oo - 120 ved hod i o S -1500 Pa to 500 Pa 10000 MA single

E6oo - 120 ved hod i o S -1500 Pa to 500 Pa 10000 AA single

According to par. 9.7.1 of EN1366-10:2011+A1:2017, single compartment smoke control dampers may be

applied to ducts that have been tested to EN 1366-9, constructed from materials of the same density as

those tested or of the same material with a greater density or thickness.

Single compartment smoke control dampers may be applied to builders work (created on site) ducts,

concrete or aerated concrete ducts and walls, provided that the single compartment smoke control

damper has been tested on a duct or in a wall constructed from materials of lower density and thickness

(e.g. boards or sheet steel), provided that the concrete/aerated concrete construction has a thickness that

complies with the supporting construction information shown in EN 1363-1 and EN 1366-2 for the time

period of classication required. Correct re resisting fasteners to suit the materials shall be used.

4

Smoke damper

rev 21-10

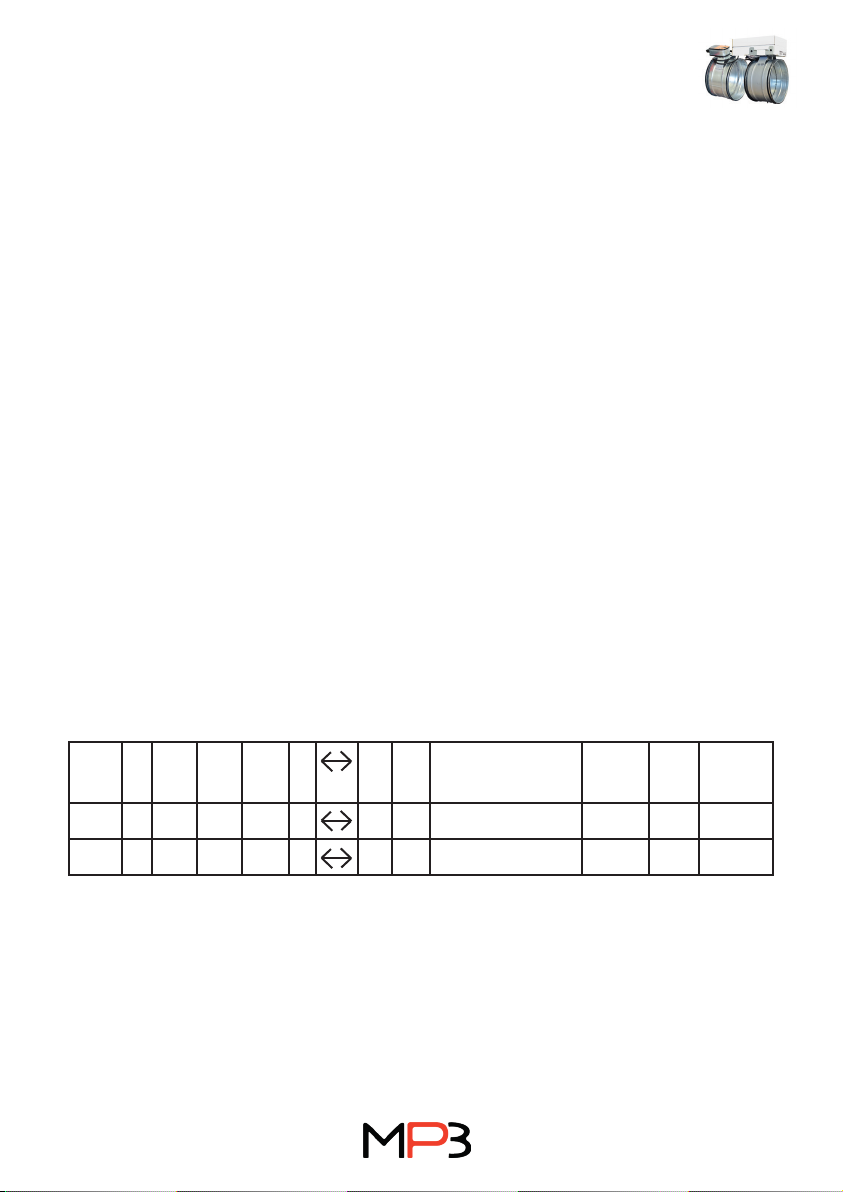

Dimension

Ød

nom

l

mm

Type AA Type MA

a

mm

m

kg

a

mm

m

kg

100 100 250 3,2 376 5,7

125 100 250 3,4 376 5,9

160 100 250 3,6 376 6,1

200 100 250 3,9 376 6,4

250 100 270 4,5 379 7,0

315 100 270 5,2 379 7,7

355 100 270 5,5 379 8,0

400 100 290 6,8 399 9,3

450 100 290 8,1 399 10,6

500 115 298 9,5 407 12,0

560 115 298 11,0 407 13,5

630 115 298 12,5 407 15

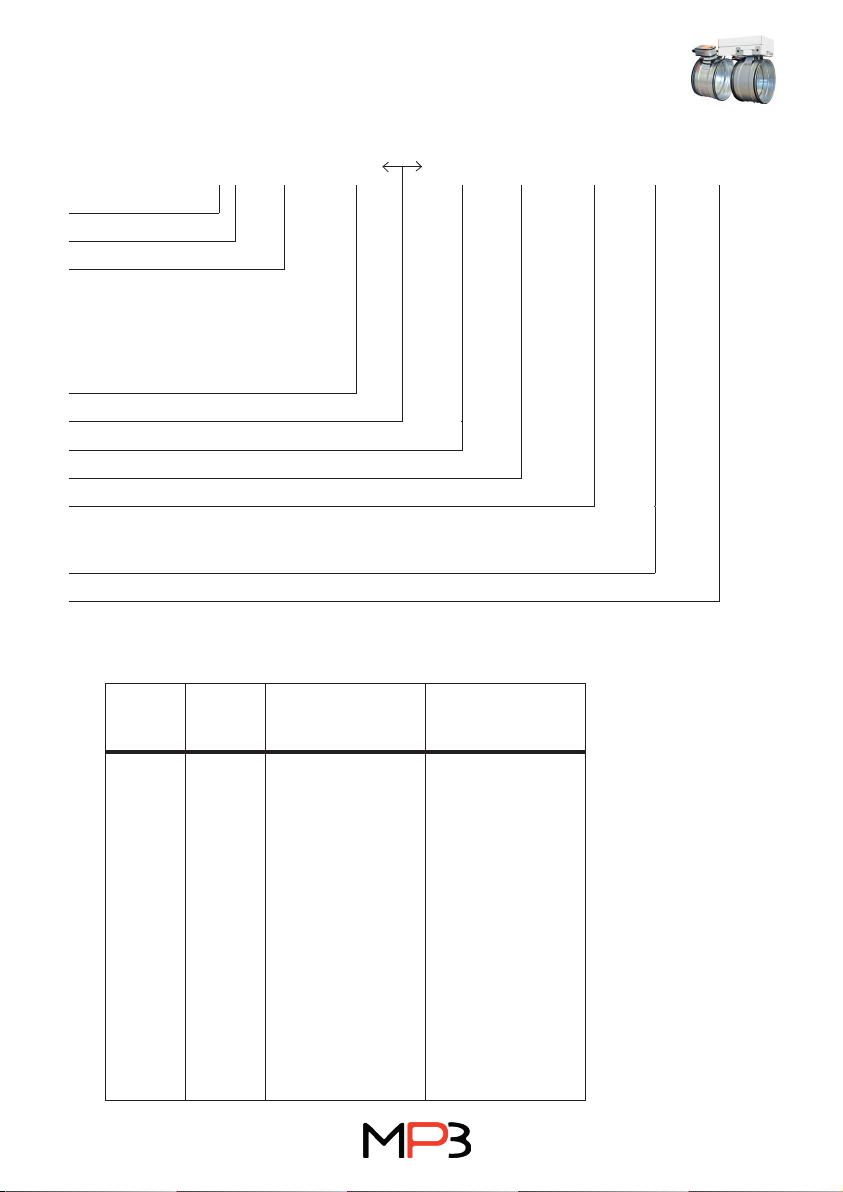

Classication details

E600 120 (ved,hodi S 1500Pa C10000 AA single

E = integrity

Temperature

Time

ved = Installation on duct penetrating a

vertical wall

hod = Installation on duct penetrating a

horizontal wall

origin of re is irrelevant

Smoke leakage <5 (m3/h)/m2

Maximum negative pressure

Motor cycles use in combined smoke control and HVAC system

Relay response

Type AA = Automatic Activation

Type MA = Manual Activation

Single compartment

o)

5

Smoke damper

rev 21-10

a

65

l

Ød

94

Type AA Ø 100-630 mm Type MA Ø 100-630 mm

a

133

l

Ød

203

164

Transport and delivery

The transport is performed by common transport means. Components that are free loaded should be

secured in such a way that any deformation and damage to the components will be eliminated. The trans-

port vehicle must be covered to prevent dust, debris and humidity to damage the components.

Components are delivered without an acceptance at a supplier´s as default. If an acceptance at a

supplier´s is required, it is necessary to state this requirement in the orderpurchase contract.

A buyer or his/her representative is obliged in terms of good acceptance to on site check these according

to the delivery documentation. Visible defects and amount shortages are to be noticed in the transporter’s

transport sheet immediately.

Storage

The goods should be stored inside and protected to prevent dust, debris and humidity to damage the

goods.

Before mounting

Before starting the mounting of the damper it is necessary to inspect all components to make sure that

they are correct according to the project documentation and to make sure they have not been damaged

during transport or storage. When handling the products on site it is important to be careful so that they

don’t get damaged and their properties change.

Mounting of the damper should only be done by trained professionals equipped with the correct protec-

tive equipment and tools. The mounting of the damper should always be performed according to valid

documentation from the manufacturer.

The damper should never be used as a supporting part of the building.

In order to achieve a good result, ensure you have:

• A well-organised and protected storage site for components and other parts that are to be assemb-

led.

• A properly planned assembly sequence in accordance with the instructions.

6

Smoke damper

rev 21-10

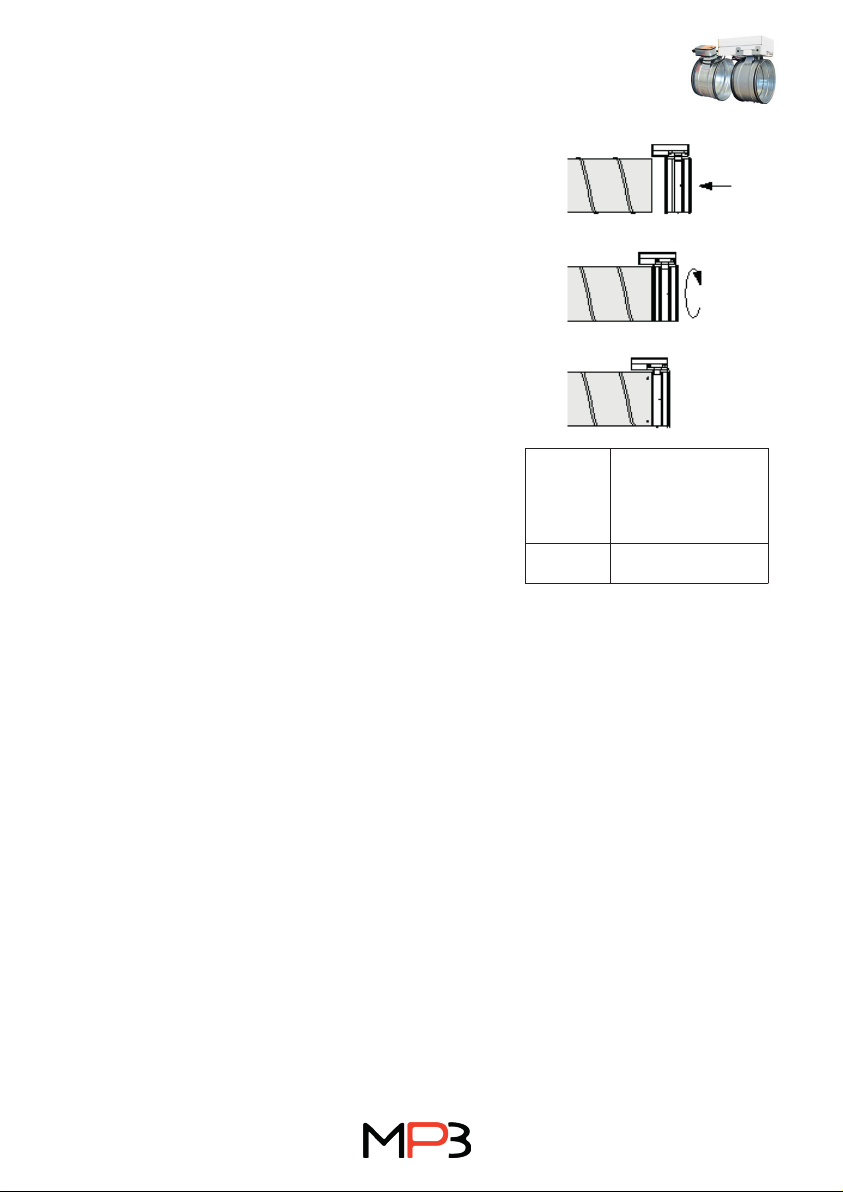

Preparations:

• Cut ducts at right angles.

• Carefully remove any burrs from cut edges. Installation is

easier and the risk of damaging the gasket is reduced if there

are no burrs.

• Cut away the needles created from the fold.

Assembly

• Start by inserting the turned-over edge of the damper into

the duct.

• Check that the rst lip of the gasket is in contact with the

edge of the duct all the way around and sticks straight out so

that the lip is not twisted in one direction or the other.

• Push the end of the damper into the duct. Twisting the

damper slightly aids insertion.

• Secure the damper in the duct using self-tapping screws

Ø4,2×13.

• Fasteners should be positioned on the duct close the damper

(minimum 10-15 mm) to support itself weight and to prevent

damage to the gasket.

• The damper must be installed on certi ed and CE marked

smoke control system.

Ø

nom

Minimum number

of fasteners

required to achieve

sucient strength.

100-630 4

Mounting

Technical data for the motors

BLE motor BLE24 BLE230

Power supply.................................... AC/DC 19.2 28,8 V,

50/60 Hz

AC 198-264 V,

50/60 Hz

Power consumption.......................... 7,5 W 5 W

For wire sizing................................... 9 VA 12 VA

Connection........................................ Cable 1 m, 3×0,75 mm2Cable 1 m, 3×0,75 mm2

Operative angle................................ Max. 90° Max 105°

Torque at rated voltage..................... Min. 15 Nm Min. 15 Nm

Direction of rotation.......................... Selected by mounting L/R Selected by mounting L/R

Position indication............................ Mechanical with pointer Mechanical with pointer

Running time.................................... <30 s for 90° <30 s for 90°

Sound power level........................... Max. 62 dB (A) Max. 62 dB (A)

Protection class................................ III Safety extra-low voltage II totally insulated

Protection type................................. IP 54 IP54

Ambient temperature range.............. -30 to +50°C -40 to + 80°C

Ambient moisture.............................. 95 % RH 95 % RH

7

Smoke damper

rev 21-10

<3° <87°

3S1 S2 S3 S4 S5 S6

2

2

1

1

–+

~

T

<3° <87°

S1 S2 S3 S4 S5 S6

NL1

3

2

2

1

1

Note

Caution: Main power supply voltage!

Parallel connection of several actuators possible.

Power consumption and switching thresholds must

be observed!

Note

Supply via safety isolation transformer!

Parallel connection of several actuators possible.

Power consumption and switching thresholds must

be observed!

2-wire open-close control. The actuator is overload-proof and

can thus remain energized even at the end stops.

Two microswitches with xed settings are installed in the

actuator for indicating the damper end positions. The position

of the damper blade can be read o on a mechanism position

indicator.

The crank handle supplied with the actuator allows it to be

operated manually.

Mode of operation.................................

Signalling .................................................

Manual operation....................................

8

Smoke damper

rev 21-10

Electric cables and system

For Manual Activation version (MA), the electric cables and system must be protected and designed to

have at least 30 minutes circuit integrity.

Operation

All smoke dampers have a electrical actuator. They are designed to be installed indoor in a smoke evacua-

tion and reversable HVAC system.

Before starting the system it is necessary to check the system for damages and that it is consistent to the

re expert design.

Checking and Maintenance

Following features shall be checked up during a revision of the damper at least once every six months:

• All parts are to be installed according to this mounting instruction.

• The damper must not be damaged in any way, the cross-section of the casing, the motor and the

covering box of the motor must not be damaged in any way.

• All connections with the smoke evacuation system are to be tightened and properly connected.

• The ducts connected to the damper must be suspended or supported in order to bear the damper’s

weight too.

• There must not be any ammable bodies on the damper surface and 50 mm away from the system

itself.

Periodic inspection and cleaning

Periodic inspection shall be performed in accordance with the requirements of the law or by the building

regulations or other local regulations.

In the absence of specic regulations (or to their complement), in accordance with point 8.3 of the EN

12101-8 standard, it is recommended to carry out the following controlactivities at intervals of no more

than 6 months: execute an opening and closing test and check the correct movement of the blade and the

correct functioning of the microswitches (limit switches). Blade opening time shall be not more than 60

seconds. Blade closing time shall be not more than 60 seconds.

Together with the control activities, it is recommended to visually verify the absence of corrosion, the

integrity of the electrical wiring and the sealing of the construction support. Damper cleaning is included

in the ordinary maintenance activities of the ventilation ducts. Smoke control dampers can be cleaned

with a dry or wet cloth. In the case of resistant dirt, it is possible to use normal household detergents. If

prescribed for the type of building, it is possible to use disinfectant detergents. The use of detergents or

mechanical abrasive cleaning systems is not permitted. These indications comply with the standards EN

12101-8 annex B and EN 15423 annex C.

9

Smoke damper

rev 21-10

WXHU SAA D00 200

Type

Relay response

Motor type

Dimension Ød

Ordering example

Repair

For safety reasons, repair activities involving re-ghting components must be carried out only by qua-

lied personnel. only original spare parts supplied by the smoke control damper manufacturer must be

used.

A functional test must be performed after each repair.

At the end of the inspection, cleaning or repair operations, check that the smoke control damper is in the

normal operating position. Keep records of all inspections, repair activities, any problems encountered

and their resolution. This practice, even when not mandatory, is very useful in practice.

Disposal

Disposal must be carried out in accordance with national legislation. For electrical and electronic parts

also refer to EU Directive 2011/65

Type WXH Circular smoke damper

Connection U EPDM gasket

Relay Response

SAA Automatic Activation

(Single compartment)

MAS Manual Activation

(Single compartment)

Motor type

V00 Belimo BLE24 V AC/DC

D00 Belimo BLE230 V AC

Dimension XYZ Nominal diameter (mm)

Product code

This manual suits for next models

2

Table of contents

Popular Fire And Smoke Damper manuals by other brands

mercor

mercor mcr FID PRO Series Operation and maintenance manual

Greenheck

Greenheck HPR Series Installation, operation and maintenance manual

Orlaco

Orlaco 0701200 installation manual

Trox Technik

Trox Technik AKK Assembly and operating instructions

TAKACHIHO

TAKACHIHO FYN-M 1 Series manual

BSB

BSB FSD-C Installation, operating, & maintenance instructions