Komfovent UVS 120H User manual

EN

FIRE DAMPER UVS 120H (Two-Bladed design)

Installation manual

SIA KOMFOVENT reserves the right to make changes without prior notice

Fire damper UVS120 H (Two-Bladed design) ∙ Installation manual ∙ 21-01

2

CONTENT

1. FIRE DAMPER DESIGN AND DIMENSIONS ....................................................................................................................................................3

2. INSTALLATION METHOD EXAMPLES ...............................................................................................................................................................5

2.1. Installation in a solid wall ..................................................................................................................................................................................5

3. SAFETY REQUIREMENTS .........................................................................................................................................................................................6

4. INSTALLATION STEPS ...............................................................................................................................................................................................7

4.1. Signalling devices (switches) installation instructions for fire dampers UVS-H .........................................................................11

5. PERIODICAL INSPECTIONS ................................................................................................................................................................................13

5

6

7

8

9

11

10

9

1

4

2

3

SIA KOMFOVENT reserves the right to make changes without prior notice

Fire damper UVS120 H (Two-Bladed design) ∙ Installation manual ∙ 21-01 3

1. FIRE DAMPER DESIGN AND DIMENSIONS

1 – casing, 2 – blade, 3 – opening device with spring, 4 – intumescent seal, 5 – handle attaching screw,

6 – spring washer, 7 – handle of the opening device, 8 – microswitch cap, 9 – PUSH button mechanism (replacing part),

10 – screw, 11 – Fuse element 70˚

The rectangular fire damper UVS120H is an emergency application type damper having two synchronously moving

blades.

A A

H

1

H

B 54.2

400 L

166,4

L

SIA KOMFOVENT reserves the right to make changes without prior notice

Fire damper UVS120 H (Two-Bladed design) ∙ Installation manual ∙ 21-01

4

Fire damper UVS-120H main sizes (EIS 90)

1050 ÷ 1600

200 H = 240, H1 = 180, L = 0

250 H = 290, H1 = 230, L = 0

300 H = 340, H1 = 280, L = 0

350 H = 390, H1 = 330, L = 0

400 H = 440, H1 = 380, L = 0

450 H = 490, H1 = 430, L = 15

500 H = 540, H1 = 480, L = 40

550 H = 490, H1 = 430, L = 65

600 H = 640, H1 = 580, L = 80

650 H = 690, H1 = 630, L = 115

700 H = 740, H1 = 680, L = 140

750 H = 790, H1 = 730, L = 165

800 H = 840, H1 = 780, L = 190

850 H = 890, H1 = 830, L = 215

900 H = 940, H1 = 880, L = 240

950 H = 990, H1 = 930, L = 265

1000 H = 1040, H1 = 980, L = 290

Bnom

Hnom

200 ÷ 1000

1050 A = 505, B = 1090

1100 A = 530, B = 1140

1150 A = 555, B = 1190

1200 A = 580, B = 1240

1250 A = 605, B = 1290

1300 A = 630, B = 1340

1350 A = 655, B = 1390

1400 A = 680, B = 1440

1450 A = 705, B = 1490

1500 A = 730, B = 1540

1550 A = 755, B = 1590

1600 A = 780, B = 1640

Hnom

Bnom

Handle in open

position

Blade in open

position

A-A

B+60mm

H+60mm

400

3

1

2

140

115+10

0

A

A

SIA KOMFOVENT reserves the right to make changes without prior notice

Fire damper UVS120 H (Two-Bladed design) ∙ Installation manual ∙ 21-01 5

2.1. Installation in a solid wall

2. INSTALLATION METHOD EXAMPLES

EIS 90.

1. Solid wall (made of concrete, bricks,

or aerated concrete blocks, masonry

650 kg/m³, minimum 115 mm thick).

2. Plaster / mortar (e.g. Knauf MP75L or

analogue).

3. Fire damper UVS.

Anchor screws

(according wall material)

Opening dimension

SIA KOMFOVENT reserves the right to make changes without prior notice

Fire damper UVS120 H (Two-Bladed design) ∙ Installation manual ∙ 21-01

6

3. SAFETY REQUIREMENTS

The local regulations for health and safety at work and general safety regulations to be applied.

Personal protective equipment must be worn for such types of work: re damper electrical installation, re damper

mechanical connection to the air duct system (ductwork) and any type of service or maintenance works.

Protective gloves must

be worn

Protective gloves protect

hands against abrasion,

oily environment, sharp

metal parts and contact

with hot surfaces.

Protective industrial

helmet must be worn

Industrial helmets protect

the head against impact

from objects falling from

above, by resisting and

deflecting blows to the

head.

Protective boots must

be worn

Protective boots protect

the foot from falling

objects or compression

and prevent slipping on a

slippery floor.

Incorrect use might

cause dangerous

situations.

It is important to correctly use the re damper in prescribed way only:

• Fire damper is permitted to use in exhaust or supply air systems.

• Not allowed to operate the fire damper if it do not comply with manufacturer’s installation requirements specified in

this instruction.

• Any changes or modifications of the fire damper are strictly prohibited, except for using manufacturer’s provided

replacement parts.

• Qualified staff only are allowed to replace parts or service the fire damper.

L L

H

SIA KOMFOVENT reserves the right to make changes without prior notice

Fire damper UVS120 H (Two-Bladed design) ∙ Installation manual ∙ 21-01 7

H, mm L, mm

450 15

500 40

550 65

600 80

650 115

700 140

750 165

800 190

850 215

900 240

950 265

1000 290

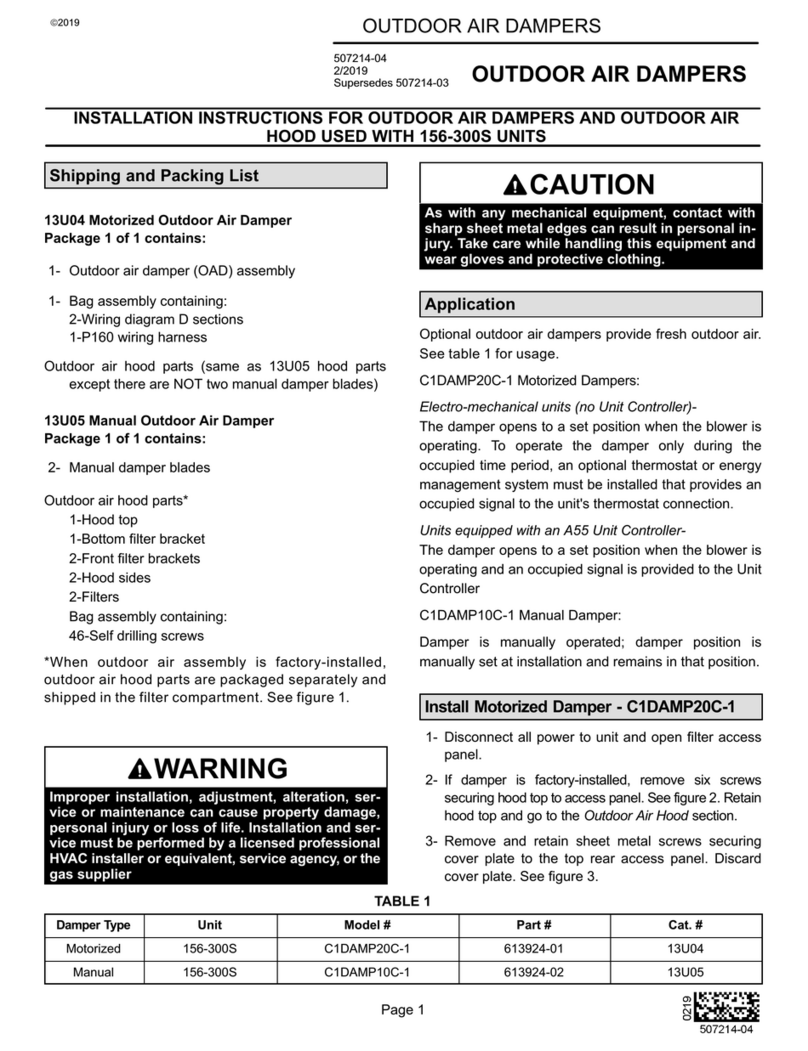

4. INSTALLATION STEPS

Before starting installation process any re damper shall be inspected for damages by responsible person!

The installation process must include the following steps:

1. Check if the blade is closing and opening without additional resistance by pressing “Push’ button several times. If

sticking occurs, lubricate rotation and sliding points as shown below using a suitable amount of grease:

2. Please consider that fire damper has exposition of the blade into the duct within a certain distance in either direction:

≥75

≥200

≥75

B+60 0

+30

H+60 0

+30

SIA KOMFOVENT reserves the right to make changes without prior notice

Fire damper UVS120 H (Two-Bladed design) ∙ Installation manual ∙ 21-01

8

3. Close the blade of a fire damper. If a re damper has been installed with an open blade, this may cause incomplete

closing of the blade or even damage! Blade position can be easily controlled also after installation by referring to

marks located on the casing of locking mechanism:

• The fuse element is single-

use only and should be

replaced after activation.

• The fuse element can be

easily accessible by screwing

out PUSH button screw and

pulling out the thermal

release mechanism.

• In case the fuse element

is melted it can be simply

replaced with a new one.

Blade open

Blade closed

4. Cover the main mechanism (if delivered uncovered) with plastic film or another material to protect it against clogging

with construction dust and materials.

5. Prepare installation opening in the wall in accordance with the prescriptions:

It is highly recommended to install the fire dampers in a way that completely prevents excess load on the

dampers and transfer any load from ducts or supporting constructions!

For solid walls

6. The distance between multiple fire dampers installed close to each other shall not exceed 200 mm, as well as damper

must not be installed closer than 75 mm to the walls, ceiling or other partitions, but it is recommended to leave the

access space to main mechanism at least 300 mm.

8 ... 10 mm

SIA KOMFOVENT reserves the right to make changes without prior notice

Fire damper UVS120 H (Two-Bladed design) ∙ Installation manual ∙ 21-01 9

1050 110 0 1150 1200 1250 1300 1350 1400 1450 1500 1550 1600

200 21.1 21.9 22.5 23.3 23.9 24.7 25.3 26.1 26.7 27. 5 28.1 28.8

250 23.1 23.9 24.6 25.3 26.1 27.1 27.7 28.5 29.3 30.0 30.8 31.6

300 25.0 25.9 26.6 27.3 28.3 29.5 30.0 32.9 33.8 34.6 35.4 36.2

350 27.0 27.9 28.7 31.9 32.8 33.7 34.6 35.4 36.3 37.2 38.1 39.0

400 31.1 32.1 33.0 34.0 34.9 36.0 36.9 37.9 38.8 39.8 40.7 41.7

450 33.1 34.2 35.1 36.2 37.2 38.3 39.3 40.3 41.3 42.4 43.3 44.4

500 35.0 36.2 37.2 38.4 39.4 40.5 41.6 42.7 43.8 44.9 45.9 47.1

550 37.0 38.2 39.3 40.5 41.6 42.8 43.9 45.0 46.2 50.6 51.8 52.9

600 38.9 40.1 41.3 42.6 43.7 45.0 49.4 50.7 51.8 53.1 54.3 55.5

650 40.9 42.1 43.4 44.8 49.7 51.0 51.7 53.1 54.3 55.6 56.9 58.1

700 42.8 44.1 48.7 50.1 51.4 52.8 54.0 55.5 56.7 58.1 59.4 60.8

750 44.8 49.3 50.7 52.1 53.5 54.9 56.3 57.8 59.2 60.6 62.0 63.4

800 49.8 51.3 52.7 54.2 55.7 57.2 58.6 60.2 61.6 63.1 64.5 66.0

850 51.5 53.1 54.7 56.2 57.8 59.2 60.9 62.6 64.1 65.6 67.1 68.7

900 53.2 54.9 56.5 58.1 59.8 61.2 63.2 65.0 66.5 68.1 69.6 71.3

950 55.0 56.7 58.4 60.2 61.9 63.3 65.5 67.3 69.0 70.6 72.2 74.0

1000 56.7 58.6 60.4 62.2 64.0 65.4 67.8 69.7 71.4 73.1 74.7 76.6

Bnom

Hnom

Note: for installation of a damper into a wall axle of the blade should be positioned horizontally only! Blade of a damper always has to be

placed INSIDE the supporting construction. Main mechanism can be used as a guide to find right damper’s position:

Recommended distance between supporting construction (wall or

ceiling) edge and main mechanism of the fire damper is 8 to 10 mm.

It is extremely important that the blade is positioned into the

supporting construction, if possible closer to its center.

Red duct tape can be used as a guide to identify fire damper’s blade

position.

It is important to select only appropriate fastening for fire damper supporting based on its weight, kg:

Please be advised, that after installation of the damper periodical inspections will be held in accordance with p. 4 and it is necessary to

ensure access to the main mechanism of a fire damper.

SIA KOMFOVENT reserves the right to make changes without prior notice

Fire damper UVS120 H (Two-Bladed design) ∙ Installation manual ∙ 21-01

10

7. Fill in the gap between the casing and supporting construction with prescribed type of the filler and let the filler dry

out completely.

8. Visually check that fire damper is securely installed into the supporting construction, check if the fuse element and

levers system are undamaged and check if the blade is closing and opening properly by pressing “Push’ button

several times. The blade must be fully closed and no seizing should be observed.

9. When fire damper is fully installed and verified, make sure it is left in its normal working position with blade OPEN.

10. Please consider that all EU working safety and Fire safety standards must be observed during the installation

process.

11.

End position microswitches is an additional option that can be used to identify the blades position from a distance.

For each position of the blade (OPEN / CLOSE) one end switch is needed. Meaning in total it will be two end

position switches for one fire damper. It is easy to mount end positions switches on fire dampers with plastic

actuation mechanism – only one additional plastic part must be installed. This plastic part comes as a set with the

switches.

SIA KOMFOVENT reserves the right to make changes without prior notice

Fire damper UVS120 H (Two-Bladed design) ∙ Installation manual ∙ 21-01 11

Installation steps:

4.1. Signalling devices (switches) installation instructions for re dampers UVS-H

If fire damper is additionally completed by one or two signaling devices (microswitches) and switch cam, simple

installation of the parts is required:

Switch cam – 1 pc. Microswitch – 1 or 2 pcs.

1. Unscrew damper’s handle holding screw DIN 912,

then remove handle and cap.

2. Place switch cam to

the axis and one or

two microswitches

to the indicated

positions. Make sure

that the cam ledge

pushes the microswi-

thes’ metal plate.

3. Place

switch cam

and handle

back and

screw in

DIN 912

screw.

4. Connect microswitches to designed way. Each

microswitch has NC (normally closed), NO (nor-

mally open) and C (common) poles. Connection

scheme using signaling device:

Using an appropriate tool (e.g. pliers), GENTLY

fold the metal plate as shown:

ACTION SHOULD BE TAKEN IF THE CAM DOESN’T PUSH

THE METAL PLATE:

Avoid to fold the plate too hard so it can be broken!

C NO NC

3-30 V

C NO NC

3-30 V

Each microswitch has NC (normally closed), NO

(normally open) and C (common) poles. Connection

scheme using signaling device is shown

Tool:

3-5°

Screw:

DIN 912 M6x10

1

2

3

NC

NO

COM

Normally Closed

Normally Open

Common

SIA KOMFOVENT reserves the right to make changes without prior notice

Fire damper UVS120 H (Two-Bladed design) ∙ Installation manual ∙ 21-01

12

IF ANY OF THE FOLLOWING ISSUES OBSERVED AFTER THE FIRE DAMPER INSTALLATION, IT IS STRICTLY PROHIBITED

TO ACCEPT IT INTO OPERATION:

• INSPECTION HATCH OF THE FIRE DAMPER IS INACCESSIBLE;

• BLADE OF THE FIRE DAMPER IS BLOCKED IN OPEN POSITION;

• CASING OF THE FIRE DAMPER HAD BEEN DAMAGED OR SKEWED DURING INSTALLATION PROCESS;

• THE FIRE DAMPER IS FITTED WITHOUT OBSERVING THE REQUIREMENTS OF THIS INSTRUCTION;

• FASTENERS USED DURING INSTALLATION PROCESS BLOCK CLOSING OF THE FIRE DAMPER BLADE;

• GAPS BETWEEN CASING OF THE FIRE DAMPER AND THE SUPPORTING CONSTRUCTION REMAIN UNFILLED;

• THE DAMPER IS INSTALLED REMOTELY FROM THE WALL OR CEILING;

• CONSTRUCTION WASTE OR DUST SHOULD NOT BE LEFT ON THE SURFACES OF THE DAMPER;

• ACTUATOR IS DISCONNECTED OR MOUNTED LOOSE ON SHAFT;

• WIRES RUN THROUGH THE FIRE DAMPER.

SELF-TEST IS REQUIRED AFTER THE COMPLETION OF THE FIRE DAMPER INSTALLATION!

SIA KOMFOVENT reserves the right to make changes without prior notice

Fire damper UVS120 H (Two-Bladed design) ∙ Installation manual ∙ 21-01 13

5. PERIODICAL INSPECTIONS

It is a mandatory requirement of EN 15650:2010 standard that all fire dampers must be checked at least twice a year.

Below is Komfovent recommended maintenance inspection checklist.

Year of inspection Year 1 Year 2 Year 3 Year 4 Year 5

Date of inspection 01.01.21

Inspected by

Installation date:

RECORDS OF THE FIRE DAMPER

PERIODICAL INSPECTIONS

Checked by / date:

Accepted by / date:

Fire damper ref. No. FD25

Location Kitchen 21

Damper type and size UVS90H-1200x1000

Mounted in wall (w) or slab (s) thickness W115

Access to the damper compliant Yes

Installation in acc. to manufacturer’s instructions Yes

Correct operation of the fire damper Yes

Damper cleanness (accumulated dust, grease) No

Lubricate all moving Parts (done/not done) Yes

Damper condition (corrosion, rust) No

Fusible link or thermosensor was replaced No

Damages or modifications No

Blade and sealing material are undamaged Yes

Wiring of the end switches is undamaged and connected Yes

Wiring of the actuator is undamaged and connected NA

Pass / fail blade drop test Pass

End switches indicate blade closing Yes

Fire damper left in OPEN position Yes

Year of inspection

1x

2

3

4

5

Comments

www.komfovent.com

Fire damper UVS120 H (Two-Bladed design) ∙ Installation manual ∙ 21-01

SIA KOMFOVENT

Bukaišu iela 1, LV-1004 Riga, Latvia

Tel. +371 24 66 4433

info.lv@komfovent.com

Table of contents

Other Komfovent Fire And Smoke Damper manuals

Popular Fire And Smoke Damper manuals by other brands

NuTone

NuTone RDM2 installation guide

MAT

MAT Roto-Twist RT-150 Series Installation & operation instructions

Emerson

Emerson Enardo EN FVFA Series instruction manual

NuTone

NuTone RDFUWT installation guide

EKOVENT

EKOVENT EKO-RBG1 Installation and maintenance instructions

Schako

Schako BKA-EN Installation, mounting and operating instructions