MPW MED. INSTRUMENTS MPW-54s User manual

20054.EN rev.11

USER MANUAL

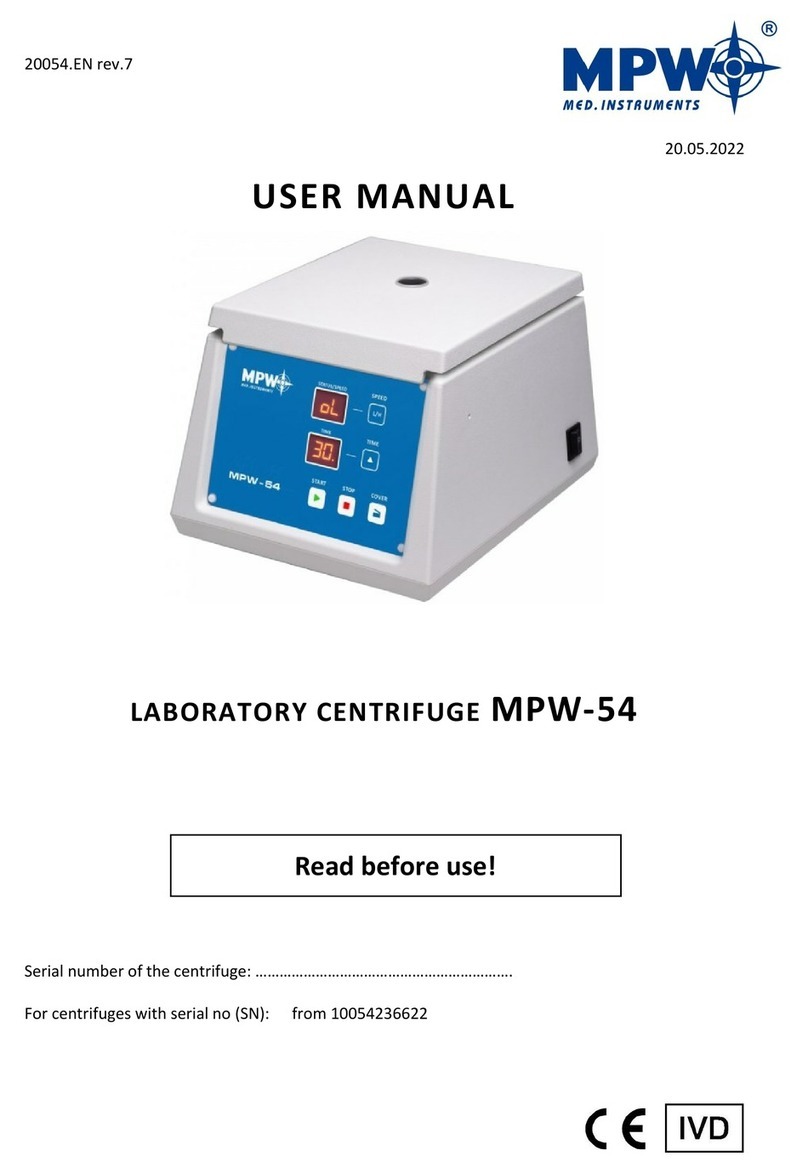

MPW-54

MPW-54s

Read before use!

Serial number of centrifuge: ……………………………………………………….

For centrifuges with serial no (SN):

MPW-54

10054237122 –…

MPW-54s

10054s000123 –…

2

This manual was prepared with special care. MPW MED. INSTRUMENTS may change the

manual at any time and without notice because of improvements, typographical errors, or

improvements to facilities

All rights reserved. No part of this User Manual may be modified, distributed, published, or

reproduced without the prior permission of MPW MED. INSTRUMENTS.

You can find the current version of the user manual on our website under:

www.mpw.pl DOWNLOAD section (one should choose demanded language version of website).

3

Content

1. Symbols used in the manual and on the device .....................................................................................4

1.1. Markings on the device.......................................................................................................................... 4

2. Application............................................................................................................................................ 5

3. Technical specification .......................................................................................................................... 6

3.1. Environmental conditions ...................................................................................................................... 6

4. Installation ............................................................................................................................................ 7

4.1. Unpacking............................................................................................................................................... 7

4.2. The contents of the package.................................................................................................................. 7

4.3. Consumable Materials ........................................................................................................................... 7

4.4. Location.................................................................................................................................................. 8

4.5. Current protection ................................................................................................................................. 8

5. Safety notes .......................................................................................................................................... 9

5.1. General remarks..................................................................................................................................... 9

5.2. Placing the rotor and accessories in the centrifuge ............................................................................... 9

5.3. Filling tubes .......................................................................................................................................... 10

5.4. Filling the rotor..................................................................................................................................... 10

5.5. Safety hints........................................................................................................................................... 11

5.6. Operating conditions............................................................................................................................ 12

5.7. Equipment life...................................................................................................................................... 12

5.8. Work safety .......................................................................................................................................... 13

5.9. Residual risk ......................................................................................................................................... 13

5.10.Obligation to report a serious device incident..................................................................................... 13

6. Product description ............................................................................................................................. 14

6.1. Product Design and Appearance.......................................................................................................... 14

6.2. Name plate........................................................................................................................................... 15

6.3. Control device ...................................................................................................................................... 15

6.4. Set up parameters................................................................................................................................ 15

6.5. Safety features ..................................................................................................................................... 15

6.6. Increase in temperature....................................................................................................................... 16

7. Centrifuging......................................................................................................................................... 16

7.1. Control panel........................................................................................................................................ 16

7.2. HOLD mode .......................................................................................................................................... 16

7.3. End of the centrifuging......................................................................................................................... 16

7.4. Signaling states of centrifuge ............................................................................................................... 17

8. Maintenance ....................................................................................................................................... 18

8.1. Cleaning of the centrifuge.................................................................................................................... 18

8.2. Maintenance of centrifuge elements................................................................................................... 18

8.3. Sterilization .......................................................................................................................................... 20

8.4. Autoclaving........................................................................................................................................... 20

8.5. Chemical resistance.............................................................................................................................. 22

9. Troubleshooting .................................................................................................................................. 23

9.1. Emergency cover release ..................................................................................................................... 23

10.Guarantee ........................................................................................................................................... 24

11.Transport and storage ......................................................................................................................... 24

11.1.Transport and storage conditions ........................................................................................................ 24

11.2.Disposal................................................................................................................................................ 25

12.List of changes in the manual .............................................................................................................. 25

13.Manufacturer’s info............................................................................................................................. 26

Distributor’s info....................................................................................................................................... 26

14.Annexes............................................................................................................................................... 26

A. Additional accessories

B. Declaration of conformity (CE, ROHS 2)

C. Declaration of decontamination (repair / return)

D. Nomogram RPM / RCF

4

1. Symbols used in the manual and on the device

Symbol

Explanation

WARNING!

Warning of potential injury or health risk

DANGER!

Risk of electric shock with potential for severe injury or death as a consequence

DANGER!

Biohazard with potential for risk to health or death as a consequence

DANGER!

Risk of explosion with potential for severe injury or death as a consequence

Symbol identifying a medical device for in vitro diagnostic use

CE mark

Symbol informing about the method of disposal

Please read the instruction manual before you start working with the device

Manufacturer's data

1.1. Markings on the device

Symbol

Explanation

Location

Information about the

direction of rotation of the

rotor

Under the centrifuge

lid

Reminder for proper rotor

maintenance and

Information about correct

and incorrect filling of

rotors

Under the centrifuge

lid

5

Information about the

place of danger

On the side of the

centrifuge next to the

emergency opening of

the lid

Information reminding

about the proper

tightening of the rotor

Under the centrifuge

lid

2. Application

▪The MPW-54/MPW-54s centrifuge is a bench-top non-automatic laboratory centrifuge.

▪The device is intended for In Vitro Diagnostics (IVD). This means that it is an in vitro

diagnostic medical device - in accordance with the Regulation of the European Parliament

and of the Council (EU) 2017/746 of 5 April 2017 on in vitro diagnostic medical devices and

repealing Directive 98/79/EC and Commission Decision 2010 /227/EU.

▪The centrifuge is used to separate aqueous solutions and suspensions of samples with a

density not higher than 1.2g/cm3 taken from human, animal and plant organisms into

components of different densities under the influence of centrifugal force, in order to

provide information about their biological state and to other analytical work.

▪The design of the centrifuge ensures ease of use, safe operation and a wide range of

applications in medical, biochemical and other analysis laboratories.

▪The centrifuge is not biotight, therefore, when centrifuging preparations that require

biotightness, containers and rotors with a biotightness certificate should be used.

6

3. Technical specification

manufacturer

"MPW MED. INSTRUMENTS" SPÓŁDZIELNIA PRACY,

Boremlowska 46 Street, 04-347 Warsaw

type

MPW - 54

MPW –54s

cat. no (REF)

10054/

2-56

10054/1-

56/100

10054/1-

56/110

10054/1-

56

10054/1-

56/127

10054/

2-56/S

10054/1-

56/100/S

10054/1-

56/110/S

10054/1-

56/S

10054/1-

56/127/S

mains voltage

(L1+N+PE)

230V

100V

110V

120V

127V

230V

100V

110V

120V

127V

±10%

±5%

±10%

±5%

frequency

50/60Hz

connected load

(max)

65W

overcurrent

protection

fuse WTA-T 2A 250V

capacity (max)

120ml

speed –RPM

(L) 3500, (H) 5800

(L) 1000, (H) 3500*

force –RCF

1137, 3122

93, 1137

kinetic energy

(max.)

550 J

running time

01:00 30:00 [min., s] (step 1min.)

short-time

operation mode

–SHORT

no

continuous

operation mode

–HOLD

yes

Protection

degree

(according to

PN-EN 60034-

5:2021-01)

IP 20

electromagnetic

compatibility

according to EN 61326-2-6:2006

height (H)

180 mm

width (W)

220 mm

depth (D)

270 mm

height with

open lid(Hoc)

367 mm

noise level

≤ 56 dB

weight of

centrifuge 230V

approx. 4,2 kg

weight of

centrifuge 120V

approx. 4,2 kg

*- It is possible to change the speed Hand Lin the range from 500 to 5800 RPM

3.1. Environmental conditions

▪The device may only be used indoors.

▪The permissible ambient temperature is 2°C to 40°C.

▪Maximum allowed relative humidity 80% at temperature up to 31°C decreasing linearly to

50% relative humidity at 40°C.

▪The mains voltage fluctuations must not exceed ± 10% of the nominal voltage.

▪Maximum altitude 2,000 m above sea level.

▪Overvoltage category II.

▪Pollution degree 2.

7

4. Installation

4.1. Unpacking

Open the package. Remove the box containing the accessories. Take out centrifuge from the

container. Keep the box and packing materials in case of service shipping

4.2. The contents of the package

4.2.1. MPW-54

Name

Quantity

(pcs)

Cat No.

Centrifuge MPW-54

1

10054/2-56 or

10054/1-56 or

10054/1-56/100 or

10054/2-56/110 or

10054/2-56/127

(depending on the power supply

variant)

Rotor fixing screw

1

17168

Rotor key

1

17099T

Key for emergency cover release

1

17162

Power cord 230V/120V

1

17866/17867

Fuse WTA T2A 250V

2

17859

Petroleum jelly 20ml

1

17201

User manual

1

See page 1

4.2.2. MPW-54s

Name

Quantity

(pcs)

Cat No.

Centrifuge MPW-54s

1

10054/2-56/S or

10054/1-56/S or

10054/1-56/100/S or

10054/2-56/110/S or

10054/2-56/127/S

(depending on the power supply

variant)

Rotor fixing screw

1

17168

Rotor key

1

17099T

Key for emergency cover release

1

17162

Power cord 230V/120V

1

17866/17867

Fuse WTA T2A 250V

2

17859

Petroleum jelly 20ml

1

17201

User manual

1

See page 1

4.3. Consumable Materials

Only original MPW buckets can be used! One should use tubes which dimensions, and

durability is proper! Using of tubes from other companies should be consulted with

manufacturer of centrifuge. In the centrifuge, disinfectants and cleaning agents

generally used in medical care should be used (e.g., Aerodesina-2000, Lysoformin

3000, Melseptol, Melsept SF, Sanepidex, Cutasept F).

8

4.4. Location

▪The device should be lifted from below near its feet and placed directly on a

suitable laboratory table.

▪The centrifuge should be set so that access to the power switch is not difficult.

▪Do not place the centrifuge near heaters and avoid direct sunlight.

▪The table on which the centrifuge is placed should be stable and have a flat,

leveled top.

▪A protection zone of at least 30 cm on all sides should be provided around the

centrifuge. The ambient temperature for normal operating conditions of the

centrifuge is given in section Environmental conditions.

▪When changing the place from cold to warm, water condensation inside the

centrifuge will occur. It is important to allow sufficient time for drying before

restarting the centrifuge (minimum 4 hours).

▪The supply voltage must match the voltage specified on the rating plate.

Laboratory centrifuges by "MPW MED. INSTRUMENTS" are devices with a basic

safety class and have a three-wire connection cord with a plug resistant to

dynamic loads.

▪The power socket should have a protective pin.

▪It is recommended to install an emergency switch located far from the

centrifuge near the exit from the room or outside the room.

▪Before switching on, check if the centrifuge is properly connected to the

power supply.

▪Only the power cord recommended by the manufacturer may be used.

4.5. Current protection

The centrifuge is equipped with thermal current protection. Fuse is situated in the

plug-in socket unit at back wall of the centrifuge.

9

5. Safety notes

5.1. General remarks

▪The laboratory centrifuge may be operated only by qualified laboratory personnel,

after reading the operating manual.

▪The operating instructions are part of the product.

▪The operating manual should always be kept in the vicinity of the centrifuge.

▪The centrifuge cannot be operated contrary to its purpose.

▪If the centrifuge is used in a manner inconsistent with the manufacturer's

guidelines, the safety of its use may be impaired.

▪For centrifugation in the centrifuge, only containers and inserts provided in the list

of equipment and centrifuge tubes, the diameter, length and strength of which are

appropriate, should be used. The use of test tubes not included in the list should be

agreed with MPW MED. INSTRUMENTS or its authorized representatives.

▪Pay attention to the quality and appropriate thickness of the glass test tubes walls.

Glass tubes should be centrifuge tubes, and their use in the centrifuge should be

made dependent on the following guidelines:

glass tubes

max RCF

in angular rotors

5-10 ml

3000 x g

30-100 ml

spinning not allowed

▪Weighing the filled test tubes into the rotor is recommended. This will allow to

minimize the differences in mass between them, and as a result to avoid the

negative impact of vibrations on the engine suspension and to reduce noise levels

during the operation of the centrifuge.

5.2. Placing the rotor and accessories in the centrifuge

▪Connect the centrifuge to the power supply (mains socket at the back of the

centrifuge).

▪Turn on the centrifuge (switch on the side of the centrifuge).

▪Open the cover of the centrifuge by pressing the COVER key. Before installing the

rotor, check that the rotating chamber is free from any contamination. If there is

dust, glass splinters, liquid residues, etc., remove them.

▪The rotor can fall if not handled properly, therefore it should always be handled and

placed in the centrifuge using both hands.

▪Place the rotor on the motor axis by sliding it onto the cone as far as it will go

(keeping the coaxiality between the rotor and the motor axis).

▪Screw the screw fixing the rotor into the motor axis (clockwise), and then tighten it

firmly with the rotor key.

▪Fill the rotor with containers / hangers / test tubes according to recommendations in

section Filling the rotor.

▪In order to replace the rotor, first remove the tubes and containers from it, unscrew

the screw fixing the rotor with the enclosed rotor key, counterclockwise, then using

both hands, grab the rotor on opposite sides and remove it from the motor axis.

▪Install another rotor as described above instructions.

10

5.3. Filling tubes

▪Fill test tubes outside the centrifuge.

▪If the manufacturer of the test tube has not specified the maximum level, fill the

test tubes so that the centrifuged substance does not run out of the vessel during

centrifugation. To do this, use the formula below:

5.4. Filling the rotor

CAUTION!

▪Angle rotors must be used with a suitable cover which must be screwed securely

onto the rotor. The rotor and the cover are marked with the same catalog number

(REF) to eliminate the risk of incorrect selection when you have several types of

rotors.

▪Check that the impeller is seated correctly and firmly bolted to the motor shaft.

▪Do not exceed the maximum rotor load (information is provided on the rotor).

An example of the marking on the angular rotor:

MAX. 24x2,4g - means the possibility of placing 24 test tubes in the rotor, each

weighing 2.4 g.

▪To ensure symmetrical loading, insert test tubes of the same type and weight in

pairs into opposite openings of the rotor. If reduction inserts are used, they should

also be placed in the holes opposite to each other in pairs of the same type.

Centrifugation force

centrifuged substance

A

C

B

A–internal tube diameter

B–tube height

C–max liquid level

11

Examples of correct and incorrect arrangement of test tubes in the rotor:

5.5. Safety hints

ROTOR MAINTENANCE

▪In order to increase the durability of gaskets, threaded places, rotor pins,

undercuts for pins in containers, they must be cleaned, and then it is necessary to

lubricate them with the technical petroleum jelly supplied with the device (catalog

number 17201).

▪Use only accessories that are in good technical condition.

HU EQUIPMENT MAINTENANCE

▪Make sure the sealing rings (rubber) are lightly coated with grease to maintain

tightness. Use high vacuum silicone grease, eg type "C" by LUBRINA.

HAZARDOUS MATERIALS

▪Infectious materials should be centrifuged only in containers / rotors with covers.

▪It is not allowed to centrifuge toxic or infectious materials if the rotor or test tube

seal is damaged.

▪Appropriate disinfection procedures should always be carried out, if hazardous

substances have contaminated the centrifuge or its accessories.

EXPLOSIVE, FLAMMABLE MATERIALS

▪It is not allowed to centrifuge explosive and inflammable materials.

▪Do not centrifuge substances that could create a potentially explosive atmosphere

as a result of the high energy supply during centrifugation.

▪The centrifuge must not be used in an explosive atmosphere.

▪It is not allowed to centrifuge materials that may generate flammable or explosive

mixtures when exposed to air.

12

5.6. Operating conditions

START-UP

▪Before switching on the device, carefully read all sections of this manual in order

to ensure the correct operation of the device and to avoid damage to the device

or its accessories.

CENTRIFUGAL SUBSTANCES

▪Rotors are designed for centrifuging liquids with an average density of 1.2 g / cm3

or less. This applies to centrifugation at maximum speed. If liquids with a higher

density are to be used, be sure to enter the density value in the PARAM /

DENSITY tab in order to reduce the available spin speed.

5.7. Equipment life

▪Each spin cycle in which the rotor has accelerated and decelerated is considered a

duty cycle, independent of speed and duration.

▪Do not use the equipment after the allowable after the maximum service life - 5

years.

GENERAL REMARKS

▪Only original equipment of centrifuges and spare parts should be used.

▪In case of a malfunction of the centrifuge, the MPW MED factory service should

be used. INSTRUMENTS or its authorized representatives.

▪It is not allowed to start the centrifuge if it is not installed correctly or the rotor

and accessories are not properly mounted.

▪The centrifuge must not be transported with the rotor installed on the motor

shaft.

▪Fill the rotor equipment to the same weight in order to prevent unbalance of the

centrifuge (point Filling the rotor).

13

5.8. Work safety

The centrifuge should be inspected by an authorized service at least once a year (after the warranty

period). Special circumstances, e.g., corrosive environment, may be the reason for more frequent

checks. Tests should end with issuing a validation protocol, which specifies checking the technical

condition of a laboratory centrifuge.

It is recommended to create a document that records all repairs and inspections. This document

should be kept in the place where the centrifuge is used.

CONTROLS CONDUCTED BY THE OPERATOR

▪The operator must pay attention to the fact that the parts of the centrifuge,

important from the safety point of view, are not damaged. This remark applies to:

▪Centrifuge accessories, especially structural changes, corrosion, initial cracks,

abrasion of metal parts.

▪Bolted connections.

▪Inspection of rotor and container seals, if any. Particular attention should be paid to

rubber elements (seals). In the event of any damage or visible structural changes,

they should be immediately replaced with new ones.

▪Control of the performance of annual post-warranty inspections of the technical

condition of the centrifuge.

▪During centrifugation, it is not allowed to lift, shift the centrifuge or rest on it.

▪During centrifugation one must not stay in the safety zone, i.e., 30 cm distance

around the centrifuge, nor leave any objects, e.g., glass vessels, inside this zone.

▪It is not allowed to put any objects on the centrifuge.

OPENING THE COVER DURING SPINNING

▪It is not allowed to use the emergency cover opening during centrifuging, because it

may result in loss of health or life.

HANDLING OF ROTORS

▪It is not allowed to use accessories (rotors, lids, containers, hangers and round

carriers) with signs of corrosion or other mechanical damage.

▪It is not allowed to centrifuge substances of high corrosive aggressiveness, which

may damage the materials and reduce the mechanical properties of rotors, buckets

and round carriers.

▪It is not allowed to centrifuge rotors with removed or loose covers.

5.9. Residual risk

The centrifuge is built according to the state-of-the-art and the recognized safety regulations.

Nevertheless, still remain some level of residual risk due to improper operation and malfunctions. It

is possible to decrease residual risk by strictly applying user manual conditions and correcting

malfunction which could threaten safety, immediately.

5.10. Obligation to report a serious device incident

Any serious incident related to the device should be reported to the manufacturer and the

competent authority of the Member State where the user or patient resides.

14

6. Product description

6.1. Product Design and Appearance

The new generation of laboratory centrifuges "MPW MED. INSTRUMENTS" is equipped with

modern microprocessor controllers, very durable and quiet brushless asynchronous motors and

equipment that meets modern user requirements. The centrifuge has a rigid self-supporting

structure. The housing is made of ABS plastic. The cover is mounted on metal hinge axes, and from

the front it is closed with an electromagnetic lock blocking the possibility of opening during spinning.

The centrifugation chamber is made of plastic.

1Centrifuge lid

2Inspection glass (is used to control the rest condition of the rotor)

3Emergency cover release

4Name plate

5Control panel (display and control of the centrifuge operation)

6Main’s switch

7Centrifuge power socket (with fuse socket)

Fig.1. Front and rear view of the MPW-54/MPW-54s centrifuge

1

2

3

4

7

6

5

15

6.2. Name plate

The data concerning the device should be read from the rating plate located on the rear wall of the

centrifuge (the picture below is an example).

1Centrifuge model

2Catalog number

3Maximum speed

4Rated voltage

5Maximum rated power

6Kinetic energy

7Serial number

8Approval marks and symbols (exsplained

in chapter 1)

9Rated frequency

10 Minimum speed

11 Manufacturer's logo

12 Manufacturer's information

13 Current protection

14 Density of centrifuged substance

15 QR code for serial number

16 Date of production

6.3. Control device

The microprocessor control unit of the centrifuge ensures broad possibilities of providing,

realisation and reading of work parameters.

6.4. Set up parameters

Data setting and read-out system forms hermetically closed keyboard with distinctly accessible

operation points. Easily readable display signalling time to end of centrifuging and set mode of

speed. It makes easy for the operator to the registration status of the device.

Control system provides possibility of:

▪set up speed mode

H –high speed,

L –low speed.

Speed values are given under "Technical specification".

▪set up time of centrifuging in the range 1÷30 min or hold time mode.

6.5. Safety features

Cover lock

The centrifuge can be started only with properly closed cover. While the cover can be

opened only after stopping the rotor. In case of emergency opening of the cover during operation,

the centrifuge will be immediately switched-off and the rotor will brake till complete stopping.

Rest state inspection

Opening of the centrifuge’s cover is possible only with the rotor in the state of rest.

1

2

3

4

5

6

9

10

8

11

12

15

16

7

13

14

16

6.6. Increase in temperature

In uncooled centrifuges, the temperature in the rotor chamber, rotor and sample can increase to

above 40°C, based on the run time, g-force (rcf)/speed and ambient temperature.

7. Centrifuging

Power switching ON/OFF is carried out with master switch situated on the side wall of the centrifuge.

All settings on the centrifuge are done by means of the control panel.

7.1. Control panel

The control panel (equipped with membrane keyboard) placed on the front casing serves the

purpose of controlling centrifuge operation. STATUS/SPEED display show information about state of

centrifuge (left side) and speed mode (right side). TIME display show information about time remain

to the end of centrifuging.

Fig.4 Control panel

Buttons application:

►

START

Start of centrifuging

STOP

Cancel of centrifuging

COVER

Open the lid

▲

TIME

Set up runtime (in 1 minute step)

L/H

SPEED

Change speed mode

7.2. HOLD mode

HOLD mode

continuous mode (centrifuging until pressing STOP)

▪In order to run the HOLD mode, set the time value to - -

7.3. End of the centrifuging

WAYS OF FINISH THE CENTRIFUGING

▪After reaching the preset working time centrifuging is stopped.

x1

▪Before the expiry of the set time, you can interrupt the cycle by pressing the

STOP

17

7.4. Signaling states of centrifuge

▪Cover is locked

▪Cover is open

▪Rotor is running (speed is increasing or constant) –mark

turn counter-clockwise

▪Rotor is running (breaking) –mark turn clockwise

▪Rotor is running, time is counting –dot next to time

indication is blinking

▪Cycle cancelled or end of centrifuging –a dot next to the

time indication stops flashing, after braking the rotor, four

short beeps are issued

▪Centrifuging in high rotational speed

18

▪Centrifuging in low rotational speed

Centrifuge has memory for remembering the last settings even after turning off and turn on the

centrifuge.

8. Maintenance

8.1. Cleaning of the centrifuge

▪Pull the mains plug before cleaning.

▪Before any cleaning or decontamination process other than that is

recommended by the manufacturer, the user has to ask the manufacturer if the

planned process does not damage the device

▪For cleaning, water with soap or other water-soluble mild detergent shall be used.

▪One should avoid corrosive and aggressive substances.

▪It is prohibited to use alkaline solutions, inflammable solvents or agents containing

abrasive particles.

▪Do not lubricate the centrifuge motor shaft.

▪The unused centrifuge should have cover opened.

Once a week

Using wiping cloth, remove condensate or residues of the products from the rotor

chamber.

Once a month

▪Check the condition of the rotor mounting screw thread. If damaged, it must be

replaced.

▪Check the centrifuging chamber whether it is damaged. In case of damage, it

cannot be longer put into operation. Notify authorized service workshop.

8.2. Maintenance of centrifuge elements

▪In order to increase the durability of threaded places, they should be lubricated

with technical petroleum jelly.

▪Make sure that the sealing rings (rubber) are covered with a thin layer of

technical petroleum jelly in order to maintain tightness (catalog number 17201

- element of basic equipment).

Cleaning of the equipment

▪In order to ensure safe operation, one shall carry out in regular way periodical

maintenance of the accessories.

▪Rotors, buckets, and round carriers have to withstand high stresses originating

from the centrifugal force. Chemical reactions as well as corrosion (combination of

variable pressure and chemical reactions) can cause destruction of metals. Hard to

observe surface cracks increase gradually and weaken material without visible

symptoms.

▪In case of observation of surface damage, crevice, or other change, as well as the

corrosion, the given part (rotor, bucket, etc.) shall be immediately replaced.

19

▪The rotor, including the fixing screw, buckets and round carriers must be regularly

cleaned to prevent corrosion.

▪Cleaning of the accessories shall be carried out outside of the centrifuge once

every week or still better after each use. For cleaning them one should use neutral

agent of pH value 6÷8. It is forbidden to use alkaline agent of pH > 8. Then, those

parts shall be dried using soft fabric or in the chamber drier at ca. 50°C.

▪Angle rotor should be placed on a fabric with holes facing down, for effective

drying.

▪Do not use bleach on plastic parts of the rotor.

▪In this way, the useful service life of the device is substantially increased and

susceptibility to corrosion is diminished. Accurate maintenance increases the

service life as well and protects against premature rotor failures.

▪Do not use bleach on plastic parts of the rotor.

▪According to laboratory standards, minimize the immersion time in each solution.

▪Especially prone to the corrosion are parts made of aluminium.

▪Corrosion and damages resulting from insufficient maintenance could not be

subject of claims lodged against the manufacturer.

▪The unused rotor should have the lid removed.

HS accessories maintenance (HU):

▪Check the general condition of seals.

▪Make sure that rubber O-rings are lightly coated with silicone grease. Use high

vacuum grease, e.g., type „C” by LUBRINA.

▪In order to maintain hermetic sealing, it is recommended to replace the sealing

rings after each autoclaving.

▪Store hermetically sealed rotors and buckets with the lids removed.

20

8.3. Sterilization

Plastics - legend to abbreviations

PS

polystyrene

ECTFE

ethylene/chlorotrifluoroethylene

SAN

styrene-acrylonitrile

ETFE

ethylene/tetrafluoroethylene

PMMA

polymethyl methacrylate

PTFE

polytetrafluoroethylene

PC

polycarbonate

FEP

tetrafluoroethylene/perfluoropropylene

PVC

polyvinyl chloride

PFA

tetrafluoroethylene/perfluoroalkylvinylether

POM

acetal polyoxymethylenel

FKM

fluorcarbon rubber

PE-LD

low density polyethylene

EPDM

ethylene propylene diene

PE-HD

high density polyethylene

NR

natural rubber

PP

polypropylene

SI

silicon rubber

PMP

polymethylpentene

One can use all standard disinfectants. Centrifuges and devices are made of different materials, one

should consider their variety.

radiation β

radiation γ

25 kGy

C2H4O

(ethylene oxide)

formalin,

ethanol

PS

●

○

●

SAN

○

●

●

PMMA

●

○

●

PC

●

●

●

PVC

○

●

●

POM

●

●

●

PE-LD

●

●

●

PE-HD

●

●

●

PP

●

●

●

PMP

●

●

●

ECTFE, ETFE

○

●

●

PTFE

○

●

●

FEP, PFA

○

●

●

FKM

○

●

●

EPDM

○

●

●

NR

○

●

●

SI

○

●

●

●

may be used

○

cannot be used

In the centrifuge, disinfectants and cleaning agents generally used in medical care should be used

(e.g., Aerodesina-2000, Lysoformin 3000, Melseptol, Melsept SF, Sanepidex, Cutasept F).

8.4. Autoclaving

▪Rotors, buckets, and round carriers can be sterilized in autoclave with temperature 121°C

during 20 min (215 kPa), unless otherwise specified in the OPTIONAL ACCESSORY.

▪During sterilization (autoclaved) by means of steam one should consider temperature

resistance of individual materials.

▪Deformation of the accessories (carriers or lids made of plastic) may occur during autoclaving.

▪Do not autoclave disposable materials (e.g., tubes, cyto-container).

▪The life of the accessory depends on the frequency of autoclaving and use.

▪Autoclaving reduces lifespan of plastic components. They should be replaced if any signs of

damage are visible, including a change in colour or shape or when leakage etc.

▪Pressure in closed containers can cause plastic deformation or explosion.

▪Prior to autoclaving the rotors and accessories, thoroughly wash and rinse with distilled water.

▪Never exceed the permissible autoclaving temperature and time.

This manual suits for next models

11

Table of contents

Other MPW MED. INSTRUMENTS Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

TOSOH BIOSCIENCE

TOSOH BIOSCIENCE Phenyl-5PW instruction manual

Crono

Crono Five Short Instruction

Thermo Scientific

Thermo Scientific Orion COD165 user guide

JUMO

JUMO CEROS S01 M Interface description

Nickel-Electro

Nickel-Electro Clifton 1000ER Series manual

GREINER

GREINER Bio-One Sapphire MaxiPette Operation manual