MRF TS36 User manual

COPYRIGHT © 2021

MESSER REPAIR AND FABRICATING, LLC

SAUK CENTRE, MN

PRINTED IN USA

ALL RIGHTS RESERVED

OPERATOR’S MANUAL

Tree Scoop

Model TS36, TS48

Serial Number 12921-

Manual# 96385 JUNE 2021 ENGLISH

2

Introducon

Using This Manual

The term loader is used in this manual to refer to a skid steer loader.

Your loader operator’s manual contains instructions to safely operate the

loader. Anyone who operates a loader with this attachment installed must

rst read, understand and follow the instructions in the loader operator’s

manual.

This manual contains instructions to safely operate and service the

attachment. Anyone who operates or services the attachment must rst

read, understand and follow the instructions in this manual.

Additional operating or servicing information for the attachment may be

provided online, in video, or in other publications. This additional infor-

mation does not replace, and is not a substitute for reading and following,

the instructions in this manual.

The safety alert symbol is shown in WARNING statements to alert users

to hazards which could cause death or injury. Carefully read and follow

the messages.

IMPORTANT notices alert users to instructions which, if not followed,

could result in damage. Carefully read and follow the messages.

There may be times when the attachment and loader shown in this man-

ual may not be your exact model. The model shown will be close enough

to your attachment or loader to accurately convey the information.

The most current information available is included in this manual. The

publisher may revise this manual at any time and is not required to notify

users of revisions.

Replacement Manuals

Be sure to include this operator’s manual if you sell or transfer owner-

ship of the attachment.

Contact Messer Repair and Fabricating, LLC for a printed manual, or

nd a downloadable manual on our website.

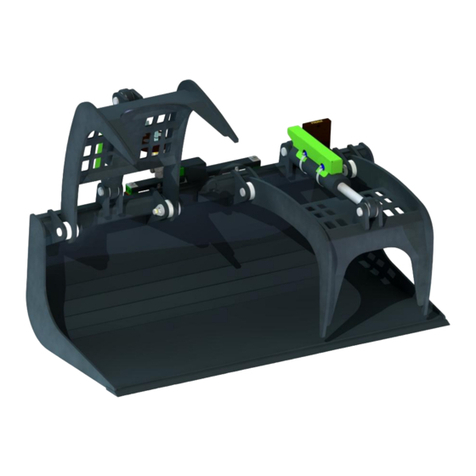

Using This Aachment

The attachment is designed to move trees and perennials, and can also be

used for digging and trenching.

The attachment is designed for installation on a full-size loader.

The manufacturer reserves the right to make improvements, and to dis-

3

Introducon

continue or change specications, models or design without notice and

without incurring obligation.

Loader Compability

Conrm your loader’s Rated Operating Capacity (ROC) in the loader

operator’s manual. Conrm your attachment’s ROC in Specications in

this manual.

Do not install the attachment on the loader if the combined weight of

the attachment and attachment load will exceed the loader ROC during

operation because this may cause diculty in controlling the loader or

may cause loader damage.

Do not exceed the attachment’s ROC because this may damage the

attachment.

Product Misuse

Product misuse can cause accidents, injury and death.

The manufacturer of the attachment is not responsible for any harm or

injury resulting from product misuse.

Product misuse includes operating or servicing the attachment without

following the instructions in this manual, using the attachment in any

way for which it was not designed, and modifying the attachment.

Modicaons

Do not modify the attachment in any way.

Manufacturer Contact

Call Messer Repair and Fabricating, LLC at (833) 352-3477, or see us at

www.messerrepair.com.

4

Product Idencaon

Idencaon Numbers

Record your product information to provide when you contact the dealer

or manufacturer.

Tree Scoop

Model TS36, TS48

Serial Number 12921-

Serial Number Locaon

Purchase Date

Dealer

Dealer Phone

Model

Serial #

5

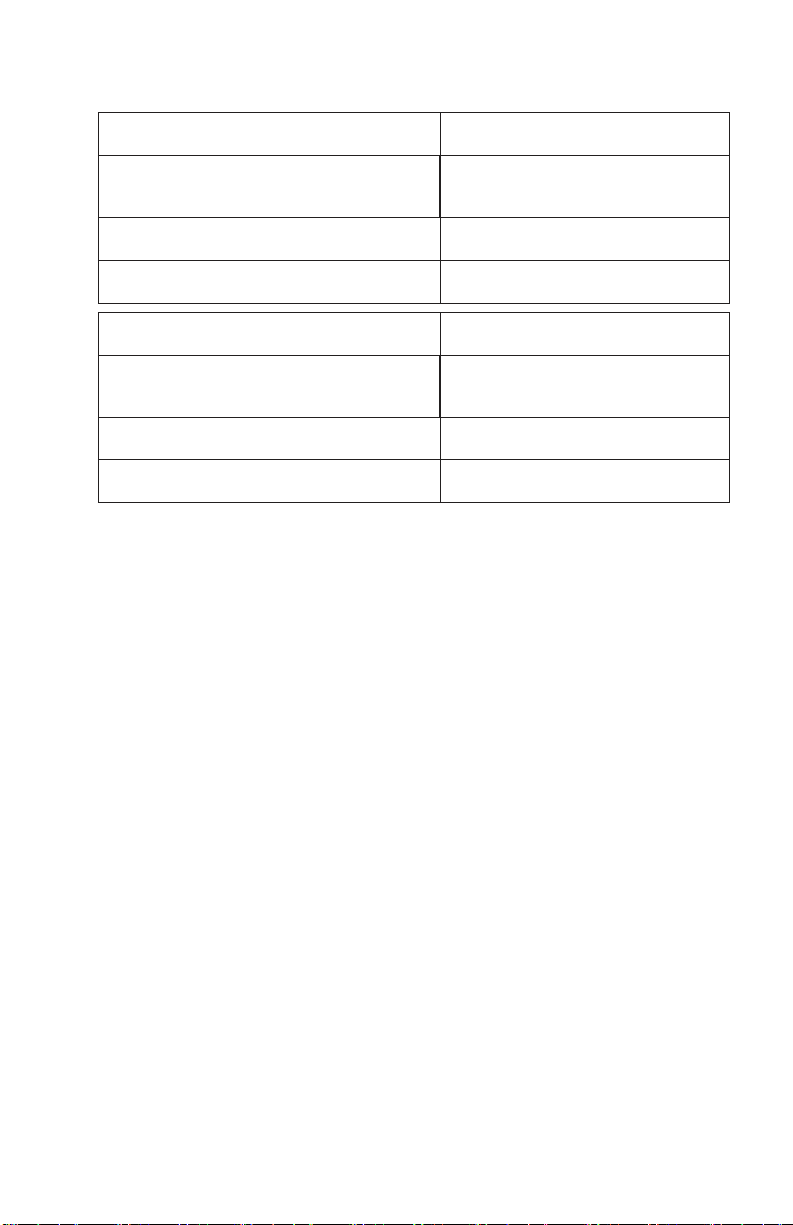

Specicaons

Model TS36

Length x Width x Height 99 x 114 x 51 cm

(39 x 45 x 20 in.)

Weight 107 kg (235 lbs.)

Rated Operang Capacity 1361 kg (3000 lbs.)

Model TS48

Length x Width x Height 122 x 122 x 69 cm

(48 x 48 x 27 in.)

Weight 170 kg (375 lbs.)

Rated Operang Capacity 1814 kg (4000 lbs.)

6

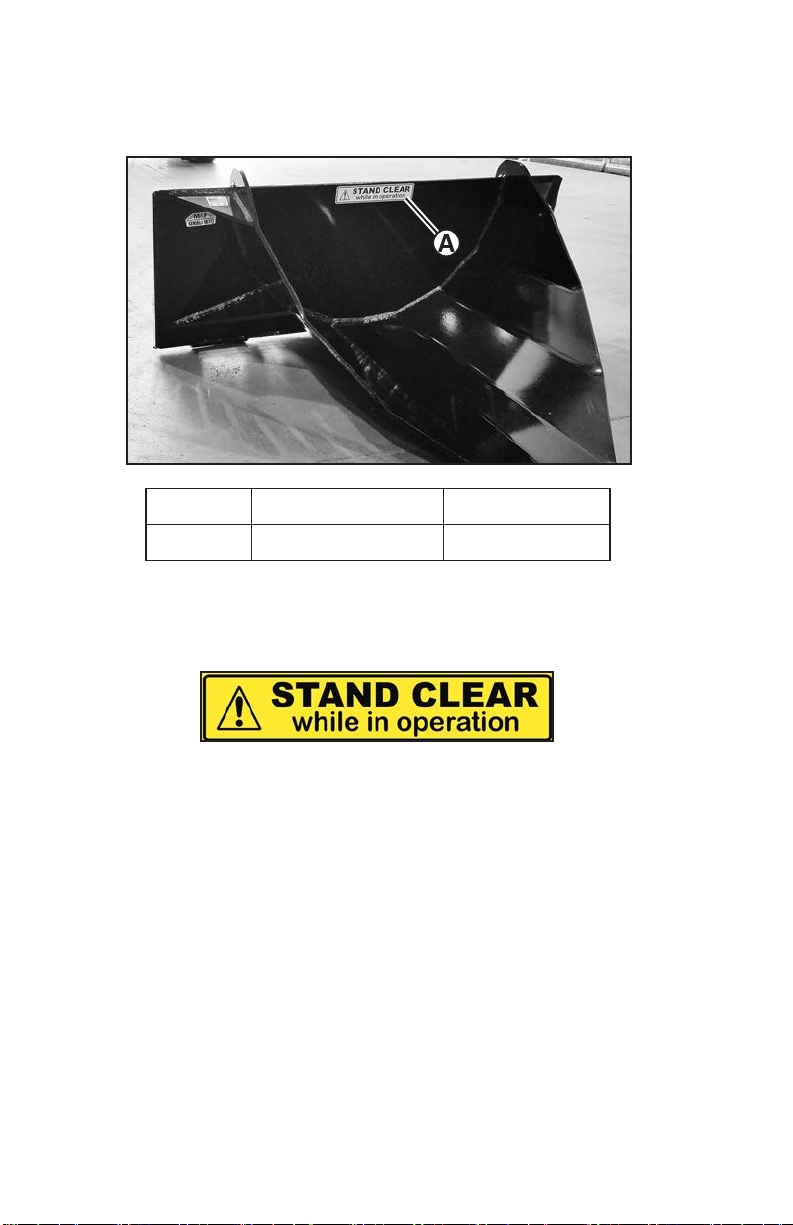

Safety Decals

Decal Locaons

Locaon Descripon Part Number

A Stand Clear Decal 96138

STAND CLEAR DECAL 96138

STAND CLEAR WHILE IN OPERATION

7

Wear Protecve Equipment

• Wear gloves to protect hands from burns if hydraulic couplers be-

come hot during operation.

• Never wear sandals or other light footwear when operating or servic-

ing the attachment. Wear protective footwear when handling blades

or heavy parts.

• Do not wear loose tting clothing which may become entangled

when operating or servicing the attachment.

Parking Safely

1. Follow the instructions in the loader operator’s manual to park the

loader safely.

2. Fully lower the attachment to level ground.

3. Stop the loader engine and remove the key from the switch.

4. Do not leave the loader operator seat until the engine and all other

moving loader and attachment parts have stopped.

5. Follow the instructions in the loader operator’s manual to exit the

loader safely. Use the attachment step area if one is provided.

Operang Aachments Safely

• Do not allow anyone to operate the attachment unless they have rst

read and understood the loader and the attachment operator’s manu-

als.

• Do not allow anyone to operate the attachment unless they have rst

read and understood the safety and warning decals on the loader and

on the attachment.

• The attachment owner is responsible for training others to safely

operate the attachment, and is responsible for any injuries or harm

which occurs while the attachment is being operated.

• If an area to step on the attachment has been provided, be sure to use

it when entering and exiting the loader.

• Before operating, replace any worn or damaged safety decals.

• Before operating, thoroughly inspect the attachment to be sure all

hardware (bolts, nuts, etc.) is installed and tightened.

• Before operating, thoroughly inspect the attachment to be sure it is

Safety

8

Safety

in working order. If the attachment is damaged or otherwise not in

working order, do not operate until it has been repaired by a qualied

technician.

• Before raising or lowering the attachment be sure the area is clear of

bystanders.

• Do not operate the loader or the attachment if you are under the

inuence of alcohol, drugs, or medications which may cause drows-

iness.

• Do not allow children to operate the loader or the attachment.

• Do not allow anyone who has not been trained to operate the loader

or the attachment.

• Never allow riders on the attachment.

• Keep hands, feet or other objects away from underneath the attach-

ment while operating.

• Fully lower the attachment to level ground when you are done oper-

ating.

• Never leave the attachment unattended while in a raised position.

• When transporting the attachment installed on the loader, travel at a

slower speed to maintain control.

Servicing Safely

• Disconnect the attachment hydraulic hoses from the loader before

servicing. Do not service the attachment when the hydraulic hoses

are installed on the loader.

• Remove the attachment from the loader before servicing when in-

structed to do so in this manual.

• Do not allow anyone to service the attachment unless they have rst

read and understood the loader and the attachment operator’s or

service manuals.

• Do not allow anyone to service the attachment unless they have rst

read and understood the safety and warning decals on the loader and

on the attachment.

• The attachment owner is responsible for training others to safely

service the attachment, and is responsible for any injuries or harm

which occurs while the attachment is being serviced.

9

Safety

• Before inspecting or servicing the attachment, follow the Parking

Safely instructions in this manual and disconnect the attachment

hydraulic hoses from the loader.

• Always securely block the attachment to prevent accidental release

of the lifting mechanism when inspecting or servicing the attach-

ment.

Hydraulic Fluid Safety

• Read and understand the hydraulic safety information in the loader

operator’s manual before operating or servicing the attachment.

• Use cardboard or a board when you check for a leak.

• Fluid in hydraulic hoses is under extreme pressure. If uid is injected

into your skin seek medical treatment immediately.

• Do not handle any hydraulic components until pressure has been

relieved from the system.

• Disconnect the attachment hydraulic hoses from the loader before

inspection or service.

• Inspect attachment hydraulic hoses and hose shields for damage or

wear before attaching to the loader.

Safety Decals

Safety decals may be installed on the attachment to warn users of safety

hazards:

• DANGER decals provide warnings about hazardous situations which

will result in death or serious injury if not avoided.

• WARNING decals provide warnings about hazardous situations

which could result in death or serious injury if not avoided.

• CAUTION decals provide warnings about hazardous situations

which could result in injury if not avoided.

Read and understand all safety decals before operating or servicing the

attachment.

See the Safety Decal Location illustration in this manual to conrm

where decals are installed on the attachment.

Safety decals which are missing, worn or faded must be replaced. Re-

placement safety decal part numbers are included in this manual. Contact

the attachment manufacturer for replacement decals.

10

Installing the Aachment

1. Follow the instructions in the loader operator’s manual to install the

attachment and exit the operator station safely.

2. Fully lower the loader lift arms.

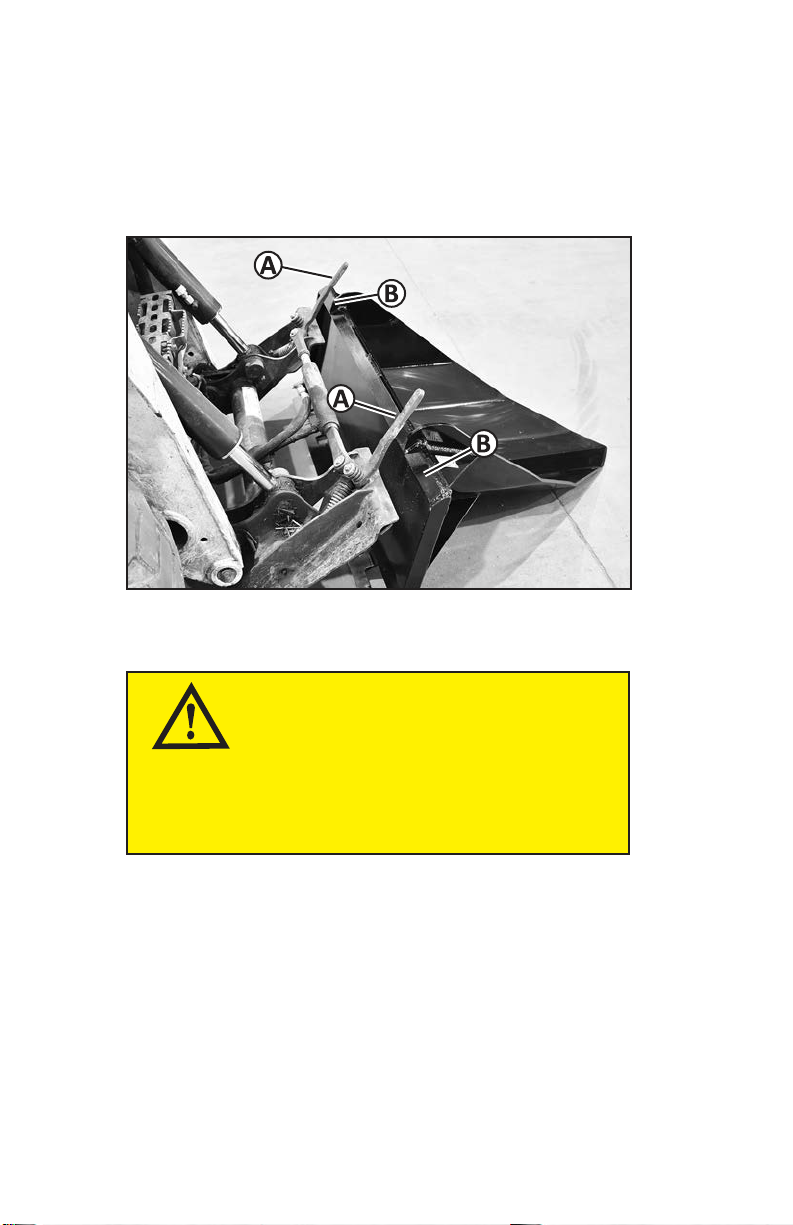

3. Move the loader attaching plate levers (A) to the unlocked (up) posi-

tion either manually or by using the loader controls.

IMPORTANT

AVOID DAMAGE!

Aaching plate levers may be damaged if they

strike the aachment. Be sure the aaching plate

levers do not hit the aachment during installaon.

4. Tilt the loader attaching plate forward, and drive the loader forward

until the top edge of the loader attaching plate is under the top ange

(B) of the attachment mounting frame.

5. Raise the loader lift arms slightly until the attaching plate is fully

seated under the top ange.

6. Tilt the attaching plate backward to raise the front of the attachment.

Installing and Removing

11

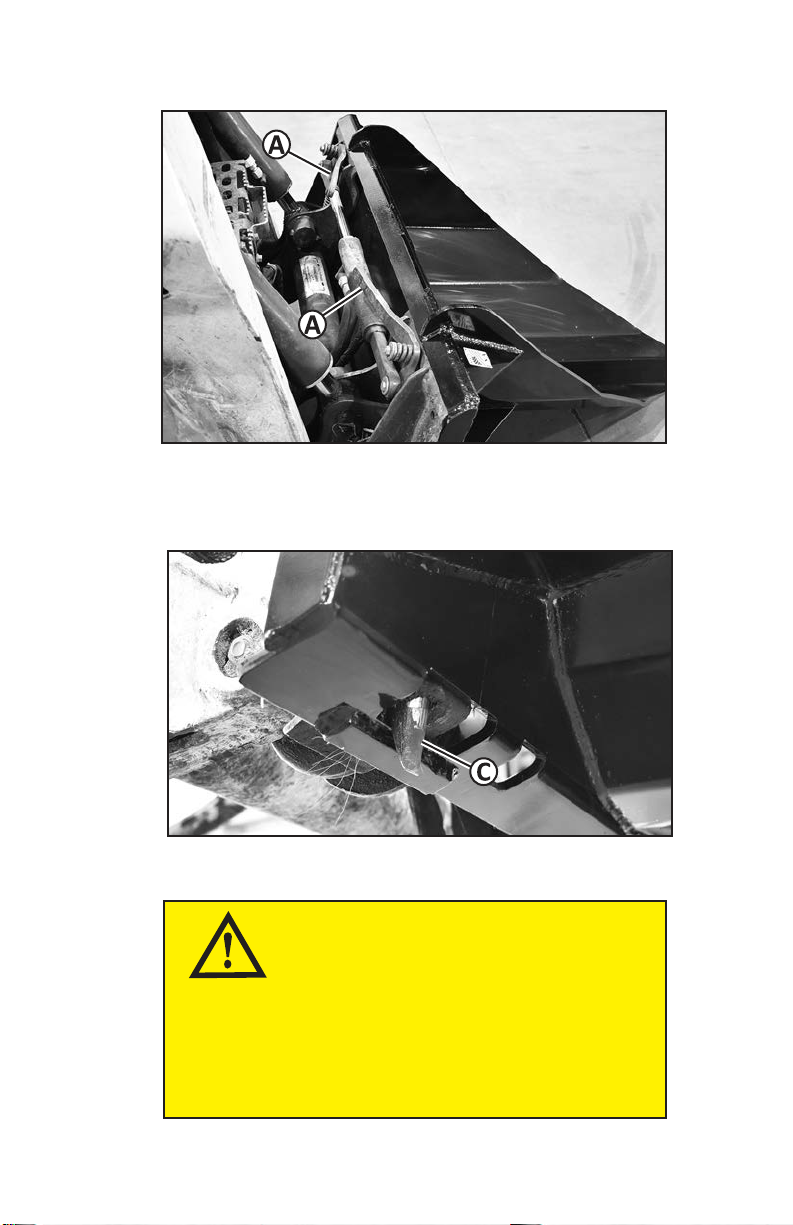

7. Move the loader attaching plate levers (A) to the locked (fully down)

position either manually or by using the loader controls.

8. Park the loader. (See Parking Safely in this manual.)

Picture Note: Wedge on right side of attachment shown. Check the

wedges or pins on both sides of the attachment.

Installing and Removing

IMPORTANT

AVOID DAMAGE!

The aachment may come o the loader if it is

not secured to the aaching plate. The aaching

plate pins or wedges must be extended into the

aachment with the levers fully down.

12

9. Check to be sure the loader attaching plate pins or wedges (C)

extended into the holes in the bottom of the attachment mounting

frame. If not, move the loader attaching plate levers to the unlocked

(up) position and repeat installation.

Removing the Aachment

1. Follow the instructions in the loader operator’s manual to remove the

attachment and exit the operator station safely.

2. Fully lower the loader lift arms and the attachment to level ground.

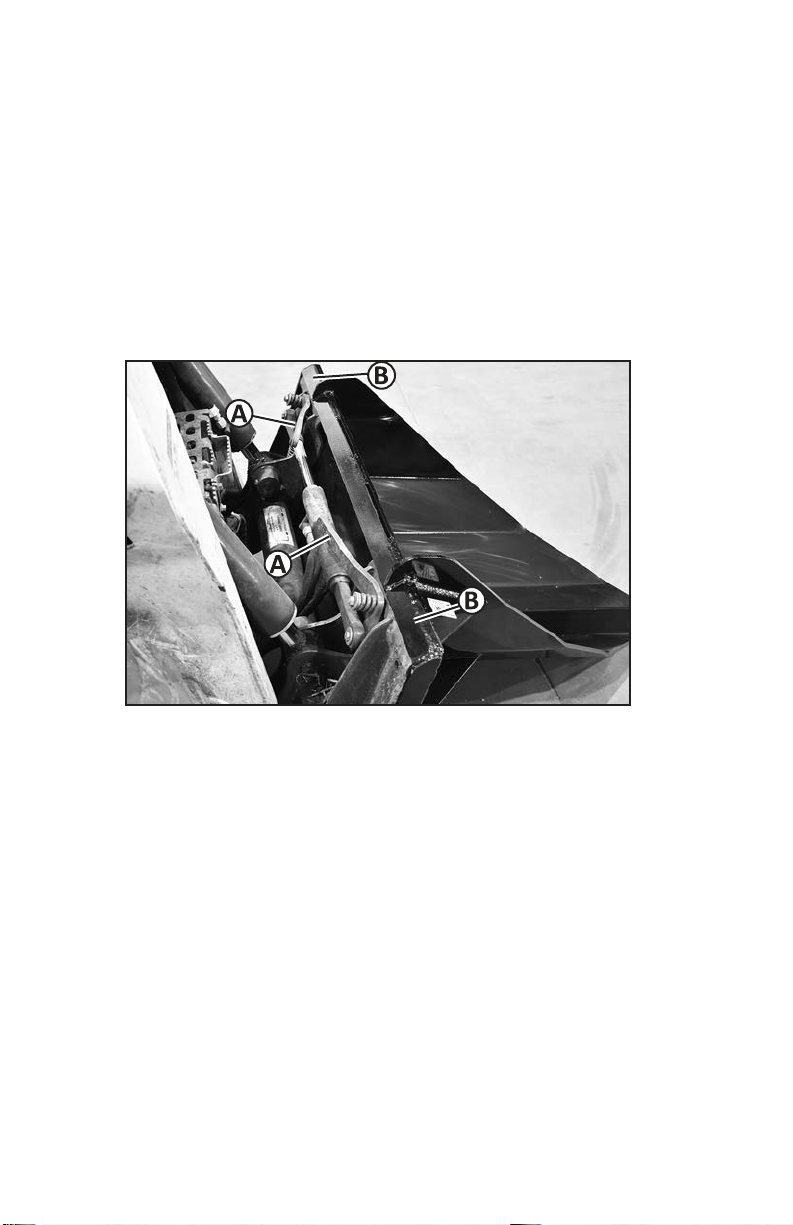

3. Move the loader attaching plate levers (A) to the unlocked (up) posi-

tion as shown either manually or by using the loader controls.

4. Tilt the loader attaching plate forward slightly and drive the load-

er backward until the top edge of the attaching plate clears the top

ange (B) of the attachment mounting frame.

Installing and Removing

13

Pre-Operaon Inspecon

Before starting operation, inspect the area you will be operating in and

inspect the attachment.

Inspect the Work Area

1. Conrm the area is clear of bystanders including animals. Establish

a safety zone by keeping bystanders and animals beyond a 100 foot

radius around the attachment when operating.

Inspect the Aachment

1. Inspect the attachment to be sure it is in working order. If the attach-

ment is damaged or not in working order, do not operate until it has

been repaired by a qualied technician.

Theory of Operaon

The loader’s hydraulic controls are used to raise and tilt the Tree Scoop

for digging and trenching.

Operaon

1. Follow the instructions in the Installing and Removing section to

install the attachment.

2. Park the loader. (See Parking Safely in this manual.)

3. Perform the pre-operation inspection.

Moving Trees and Bushes

1. Raise and tilt the attachment, forcing the sharpened edge into the

ground to dig under tree and bush roots.

2. Approach the tree or bush from all four sides to dig completely

around it.

3. Tilt the attachment back to lift material from the ground and trans-

port the load to the unloading area.

4. Keep the attachment lowered as close to the ground during transport

as possible.

Operang

14

Operang

Trenching

1. Raise and tilt the attachment, forcing the sharpened edge into the

ground.

2. Tilt the attachment back to lift material from the ground and trans-

port the load to the dumping area.

3. Keep the attachment lowered as close to the ground during transport

as possible.

Transporng the Aachment

On the Loader

Check to be sure the attachment is correctly installed on the loader before

hauling the loader on a trailor or truck. Follow all loader, truck or trailer

operator’s manual instructions to safely haul the loader.

Hauling the Aachment

Follow all truck or trailer operator’s manual instructions to securely fas-

ten the attachment to the truck or trailer with straps or chains.

15

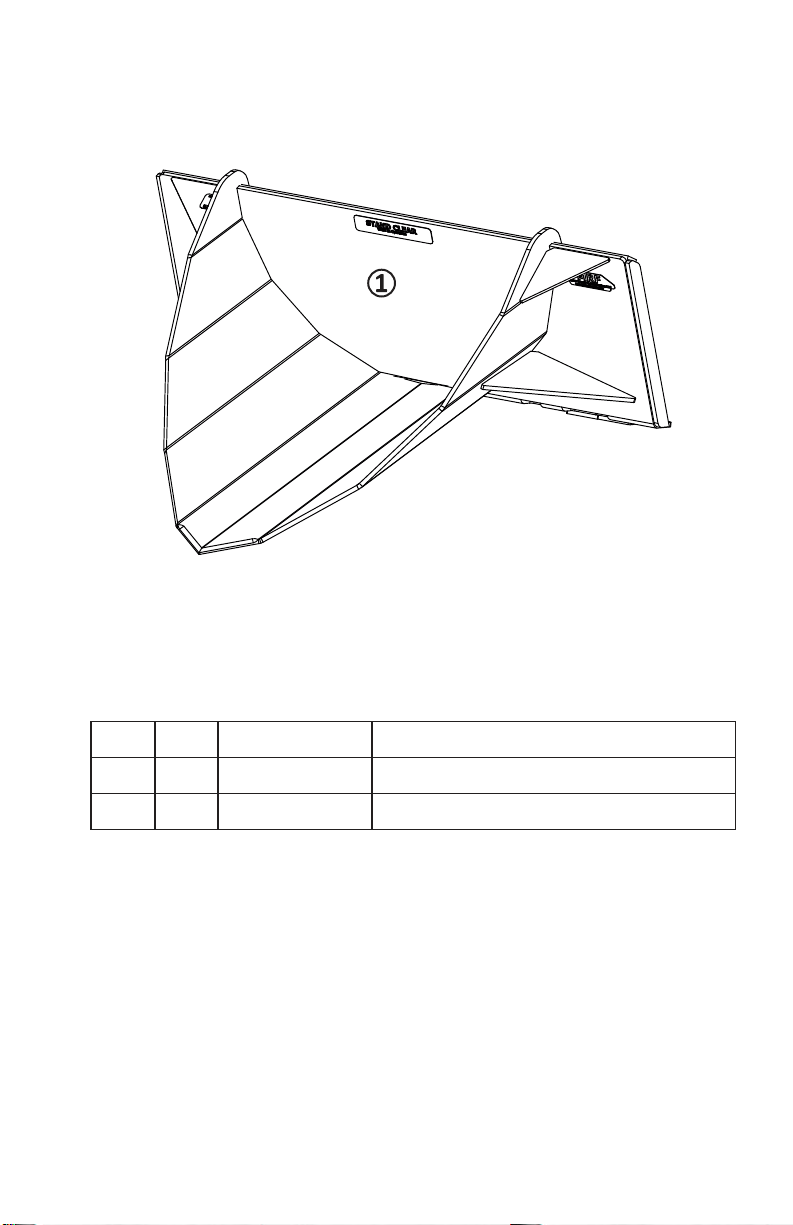

Replacement Parts

Replacement Parts

Contact Messer Repair and Fabricating, LLC for replacement parts.

Part numbers may change without notice.

Item Qty. Part Number Part Descripon

1 11063-P TS36 Body

10107-P TS48 Body

16

MESSER REPAIR & FABRICATING, LLC

Limited Warranty and Terms and Conditions of Sale

The following limited warranty, and terms and conditions of sale (the “Limited

Warranty”) apply to all equipment, products, parts, and goods (any of the forego-

ing are referred to herein as “Equipment”) sold by Messer Repair & Fabricating,

LLC (“Messer”):

1. Covers All Equipment. Each purchase of Equipment by a purchaser is ex-

pressly made conditional on purchaser’s assent to the terms and conditions in this

Limited Warranty.

2. Limited Warranty. Messer warrants that for a period of 24 months from the

date of purchase, the Equipment will remain free from defects in material and

workmanship under normal use and proper maintenance. Messer’s obligation un-

der the warranty shall be limited to the repair or replacement (at Messer’s option)

of the Equipment. Notwithstanding the foregoing, if the Equipment is used for

commercial purposes or is rented or leased out by the purchaser, then, the forego-

ing warranty shall only be for a period of 180 days and not 24 months.

3. No Warranty For Equipment Components From Third Parties. Notwithstand-

ing the limited warranty terms set forth above, MESSER OFFERS NO WAR-

RANTY WHATSOEVER WITH RESPECT TO ANY COMPONENTS OF THE

EQUIPMENT MADE OR PROVIDED TO MESSER BY OTHER MANUFAC-

TURERS, PRODUCERS, OR SELLERS (the “Purchased Components”). The

sole and exclusive warranty for each the Purchased Components shall be limited

to the express written warranty with respect to the Purchased Component as pro-

vided by the manufacturer, producer, or seller of such Purchased Component.

Messer’s responsibility and liability for the Purchased Components shall be lim-

ited to the assignment of the Purchased Components’ express written warran-

ties applicable to the Purchased Components. Purchased Components include,

without limitation, the following: axles, tires and rims; trailer hitch components

and jacks; hydraulic pumps, motors, cylinders and components; and bales spears,

pallet tines, and bucket teeth.

4. No Other Warranties. THE FOREGOING REPAIR AND REPLACEMENT

OBLIGATIONS IN SECTION 2 ARE IN LIEU OF ALL OTHER WARRAN-

TIES, LIABILITIES AND OBLIGATIONS, INCLUDING ALL WARRANTIES

OF MERCHANTABILITY, OF FITNESS FOR A PARTICULAR PURPOSE

OR OTHERWISE, EXPRESSED OR IMPLIED IN FACT OR BY LAW, AND

STATE MESSER’S ENTIRE AND EXCLUSIVE LIABILITYAND PURCHAS-

ER’S EXCLUSIVE REMEDY FOR ANY CLAIM IN CONNECTION WITH

THE SALE AND PURCHASE OF EQUIPMENT (AND ALL COMPONENTS

THEREOF), THEIR DESIGN, SUITABILITY FOR USE, INSTALLATION OR

OPERATIONS.

Warranty

17

5. Location of Warranty Repairs. All warranty repairs pursuant to this Limited

Warranty shall be made at Messer’s corporate manufacturing plant, or other loca-

tion as determined by Messer, at its discretion. Purchaser shall be responsible for

and pay for any transportation expenses necessary for Limited Warranty repairs.

6. Limited Warranty Voidable. The limited warranty herein is void and deemed

waived if the purchaser fails to give written notice to Messer of any alleged defect

under the limited warranty herein within 20 days of its discovery; or (a) purchaser

or parties other than Messer or its authorized representatives attempts to remedy

or x the alleged Equipment defects; or (b) purchaser has used the Equipment for

purposes it was not intended to be used for; or (c) purchaser has not operated the

Equipment in a manner consistent with Messer’s instructions for the Equipment;

or (d) the Equipment has been modied, altered, abused, or misused; or (e) the

Equipment has been damaged pursuant to accident, re, ood, or other Act of

God.

7. No Consequential Damages. IN NO EVENT SHALL MESSER BE LIABLE

FOR ANY DIRECT, INDIRECT, SPECIAL OR CONSEQUENTIAL DAMAG-

ES WHATSOEVER, AND MESSER’S LIABILITY, UNDER NO CIRCUM-

STANCES, WILL EXCEED THE PRICE PAID FOR THE EQUIPMENT FOR

WHICH LIABILITY IS CLAIMED.

8. Governing Law. This contract shall be governed by the laws of the State of

Minnesota.

9. Arbitration. Any controversy or claim arising out of or relating to the limited

warranty provided herein, or any alleged breach thereof, shall be settled exclu-

sively by arbitration in accordance with the Rules of the American Arbitration As-

sociation, and judgment upon the award rendered by the arbitrator may be entered

in any court having jurisdiction thereof. The arbitration shall be conducted in

Minneapolis, MN, by one arbitrator selected by Messer and Purchaser, or, if they

cannot agree, the President of the American Arbitration Association.

Rev. 7-20

Warranty

18

19

20

This manual suits for next models

1

Table of contents

Other MRF Tractor Accessories manuals

Popular Tractor Accessories manuals by other brands

Grouser Products

Grouser Products Ag Pro Plus HD Owner's manual & parts book

CAEB

CAEB USA custom MOUNTAINPRESS 550TPL Assembly instructions

Digga

Digga SKID HOE Operator's & parts manual

Homestead

Homestead Independence HI-I-LR-48 Operator's manual

Kubota

Kubota AP-SSP1572 Operator's manual

Raven

Raven AutoBoom Rogator 54 Series 1997+ installation manual