MRF TB8X21 User manual

OPERATOR’S MANUAL

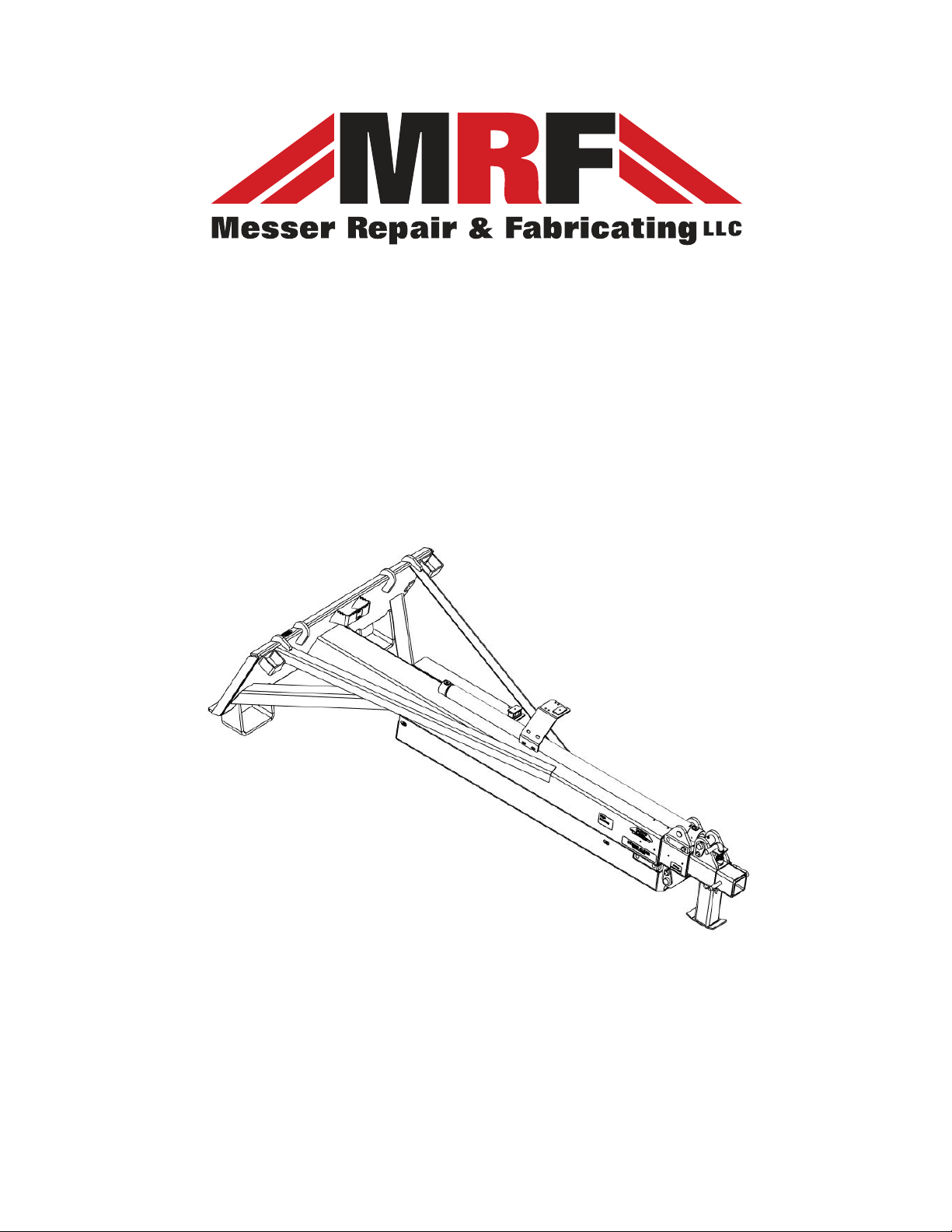

TELESCOPING BOOM

Model TB8X21

Serial Number 14592-

Manual# 96337 AUG 2020 ENGLISH

COPYRIGHT © 2020

MESSER REPAIR AND FABRICATING, LLC

SAUK CENTRE, MN

PRINTED IN USA

ALL RIGHTS RESERVED

2

Using This Manual

The term loader is used in this manual to refer to a skid

steer loader.

Your loader operator’s manual contains instructions to

safely operate the loader. Anyone who operates a loader

with this attachment installed must rst read, under-

stand and follow the instructions in the loader operator’s

manual.

This manual contains instructions to safely operate and

service the attachment. Anyone who operates or services

the attachment must rst read, understand and follow the

instructions in this manual.

Additional operating or servicing information for the

attachment may be provided online, in video, or in

other publications. This additional information does not

replace, and is not a substitute for reading and following,

the instructions in this manual.

The safety alert symbol is shown in WARNING state-

ments to alert users to hazards which could cause death

or injury. Carefully read and follow the messages.

IMPORTANT notices alert users to instructions which, if

not followed, could result in damage. Carefully read and

follow the messages.

There may be times when the attachment and loader

shown in this manual may not be your exact model. The

model shown will be close enough to your attachment or

loader to accurately convey the information.

The most current information available is included in

this manual. The publisher may revise this manual at any

time and is not required to notify users of revisions.

Replacement Manuals

Be sure to include this operator’s manual if you sell or

transfer ownership of the attachment.

Contact Messer Repair and Fabricating, LLC for a

printed manual, or nd a downloadable manual on our

website.

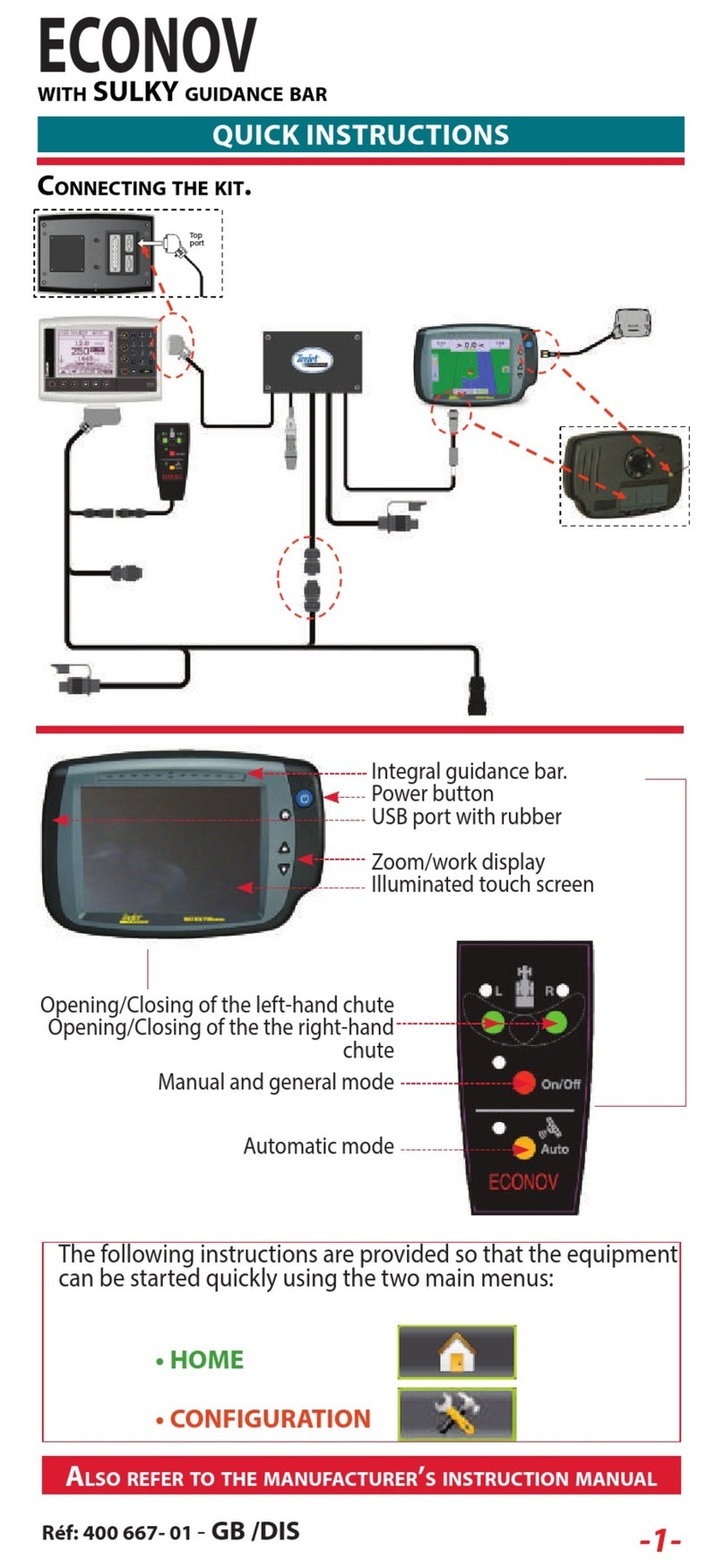

Using This Aachment

The attachment is designed with three telescoping sec-

tions. It is designed for installation of secondary attach-

ments designed by the manufacturer on the end of the

telescoping sections.

The attachment is designed for installation on a full-size

loader, connected to the loader’s front auxiliary hydrau-

lic couplers.

The manufacturer reserves the right to make improve-

ments, and to discontinue or change specications,

models or design without notice and without incurring

obligation.

Loader Compability

Conrm your loader’s Rated Operating Capacity in the

loader operator’s manual. Do not install the attachment

on the loader if it will exceed the Rated Operating Ca-

pacity during operation because this may cause diculty

in controlling the loader or may cause loader damage.

The attachment is designed for use on loaders with a

Rated Operating Capacity of more than 2000 lbs, but not

to exceed 4000 lbs.

Product Misuse

Product misuse can cause accidents, injury and death.

The manufacturer of the attachment is not responsible

for any harm or injury resulting from product misuse.

Product misuse includes operating or servicing the at-

tachment without following the instructions in this man-

ual, using the attachment in any way for which it was not

designed, and modifying the attachment.

Modicaons

Do not modify the attachment in any way.

Manufacturer Contact

Call Messer Repair and Fabricating, LLC at (833) 352-

3477, or visit www.messerrepair.com.

Introducon

3

SpecicaonsIdencaon Numbers

Record your product information to provide when you

contact the dealer or manufacturer.

Telescoping Boom

Model TB8X21

Serial Number 14592-

Serial Number Locaon

Purchase Date

Dealer

Dealer Phone

Model

Serial #

Product Idencaon and Specicaons

Model TB8X21

Overall Width x Height 1.2 x 0.5 m

(46 x 22 in.)

Overall Length (Collapsed) 2.4 m (96 in.)

Overall Length (Extended) 6.5 m (255 in.)

Cylinders 2 x 48 in.

3500 PSI

Weight 295 kg (650 lb.)

4

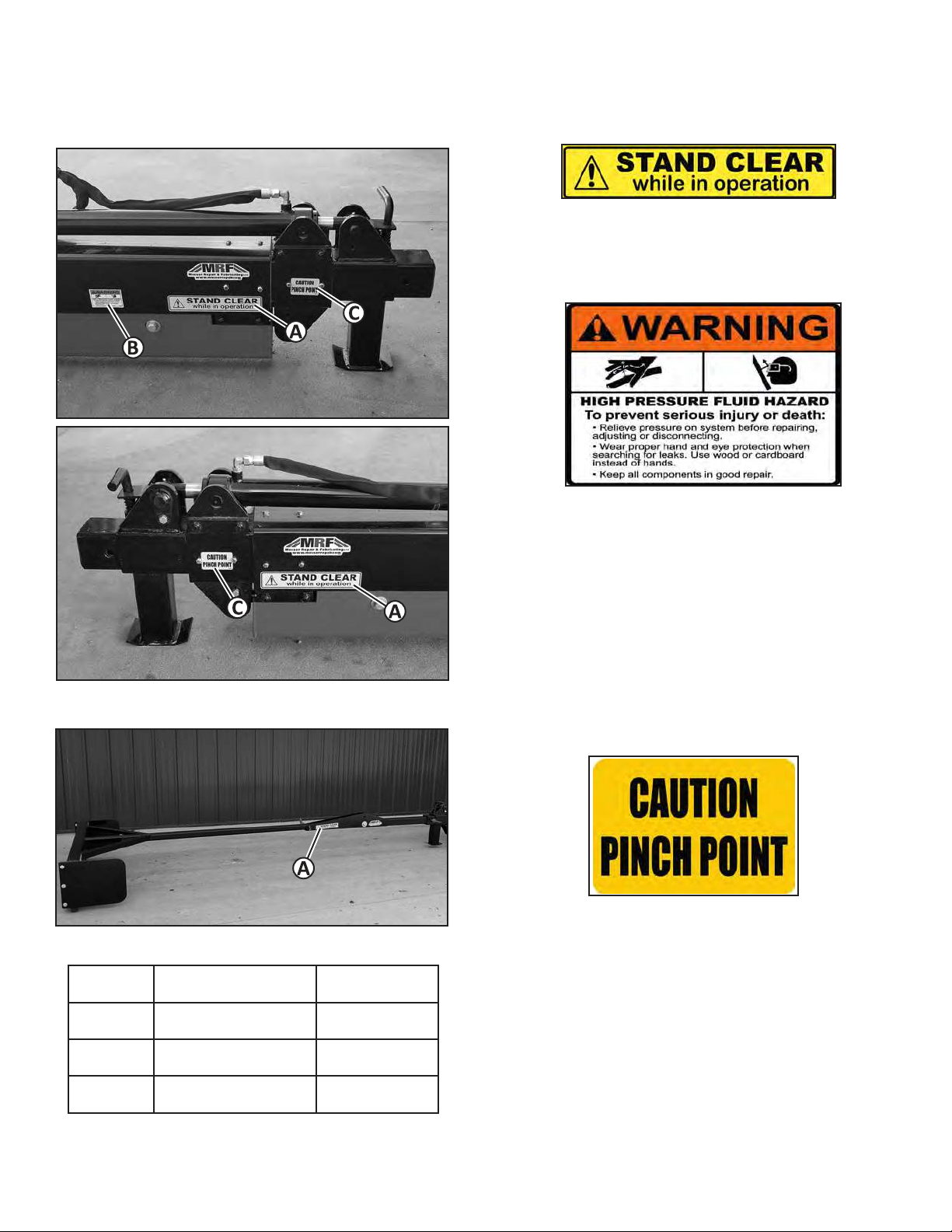

Locaon Descripon Part Number

A Stand Clear Decal 96028

B Warning Decal 96117

C Caution Decal 96109

Safety Decals

Decal Locaons (Telescoping Boom) STAND CLEAR DECAL 96028

STAND CLEAR WHILE IN OPERATION

WARNING DECAL 96117

HIGH PRESSURE FLUID HAZARD

To prevent serious injury or death:

• Relieve pressure on system before repairing, adjust-

ing or disconnecng.

• Wear proper hand and eye protecon when search-

ing for leaks. Use wood or cardboard instead of

hands.

• Keep all components in good repair.

CAUTION DECAL 96109

PINCH POINT

Decal Locaons (Oponal Roof Rake)

5

Wear Protecve Equipment

• Wear gloves to protect hands from burns if hydraulic

couplers become hot during operation.

• Never wear sandals or other light footwear when op-

erating or servicing the attachment. Wear protective

footwear when handling blades or heavy parts.

• Do not wear loose tting clothing which may

become entangled when operating or servicing the

attachment.

Parking Safely

1. Follow the instructions in the loader operator’s man-

ual to park the loader safely.

2. Fully collapse the boom.

3. Fully lower the attachment to level ground.

4. Stop the loader engine and remove the key from the

switch.

5. Do not leave the loader operator seat until the engine

and all other moving loader and attachment parts

have stopped.

6. Follow the instructions in the loader operator’s man-

ual to exit the loader safely. Use the attachment step

area if one is provided.

Operang Safely

• Do not allow anyone to operate the attachment

unless they have rst read and understood the loader

and the attachment operator’s manuals.

• Do not allow anyone to operate the attachment

unless they have rst read and understood the safety

and warning decals on the loader and on the attach-

ment.

• The attachment owner is responsible for training oth-

ers to safely operate the attachment, and is responsi-

ble for any injuries or harm which occurs while the

attachment is being operated.

• If an area to step on the attachment has been provid-

ed, be sure to use it when entering and exiting the

loader.

• Before operating, replace any worn or damaged

safety decals.

• Before operating, thoroughly inspect the attachment

to be sure all hardware (bolts, nuts, etc.) is installed

and tightened.

• Before operating, thoroughly inspect the attachment

to be sure it is in working order. If the attachment

is damaged or otherwise not in working order, do

not operate until it has been repaired by a qualied

technician.

• Before raising or lowering the attachment be sure the

area is clear of bystanders.

• Do not operate the loader or the attachment if you

are under the inuence of alcohol, drugs, or medica-

tions which may cause drowsiness.

• Do not allow children to operate the loader or the

attachment.

• Do not allow anyone who has not been trained to

operate the loader or the attachment.

• Never allow riders on the attachment.

• Keep hands, feet or other objects away from under-

neath the attachment while operating.

• Fully lower the attachment to level ground when you

are done operating.

• Never leave the attachment unattended while in a

raised position.

• When transporting the attachment installed on the

loader, travel at a slower speed to maintain control.

Servicing Safely

• Disconnect the attachment hydraulic hoses from the

loader before servicing. Do not service the attach-

ment when the hydraulic hoses are installed on the

loader.

• Remove the attachment from the loader before ser-

vicing when instructed to do so in this manual.

• Do not allow anyone to service the attachment

unless they have rst read and understood the loader

and the attachment operator’s or service manuals.

• Do not allow anyone to service the attachment

unless they have rst read and understood the safety

and warning decals on the loader and on the attach-

ment.

• The attachment owner is responsible for training oth-

ers to safely service the attachment, and is responsi-

ble for any injuries or harm which occurs while the

Safety

This manual suits for next models

1

Table of contents

Other MRF Tractor Accessories manuals