Page | 5 V102020-01

POWER-ON & SETUP

Confirm all electrical connections have been completed and the sensor is in its proper mounting location.

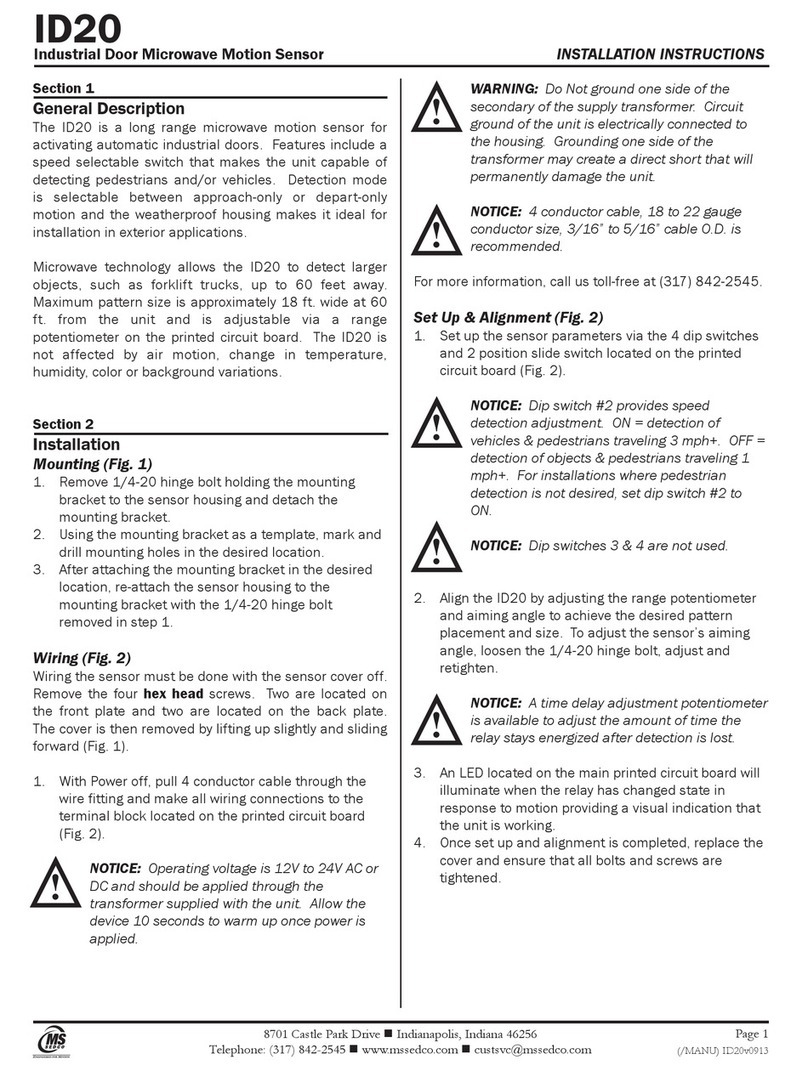

Apply low voltage power to the sensor. Do not ground the secondary side of the transformer.

Observe the LED indication at the top of the sensor –the following

should occur:

oThe sensor shall blink green 3 times once power has been

applied

oThe sensor LED changes to a solid green indicating sensor is

ready for setup and alignment.

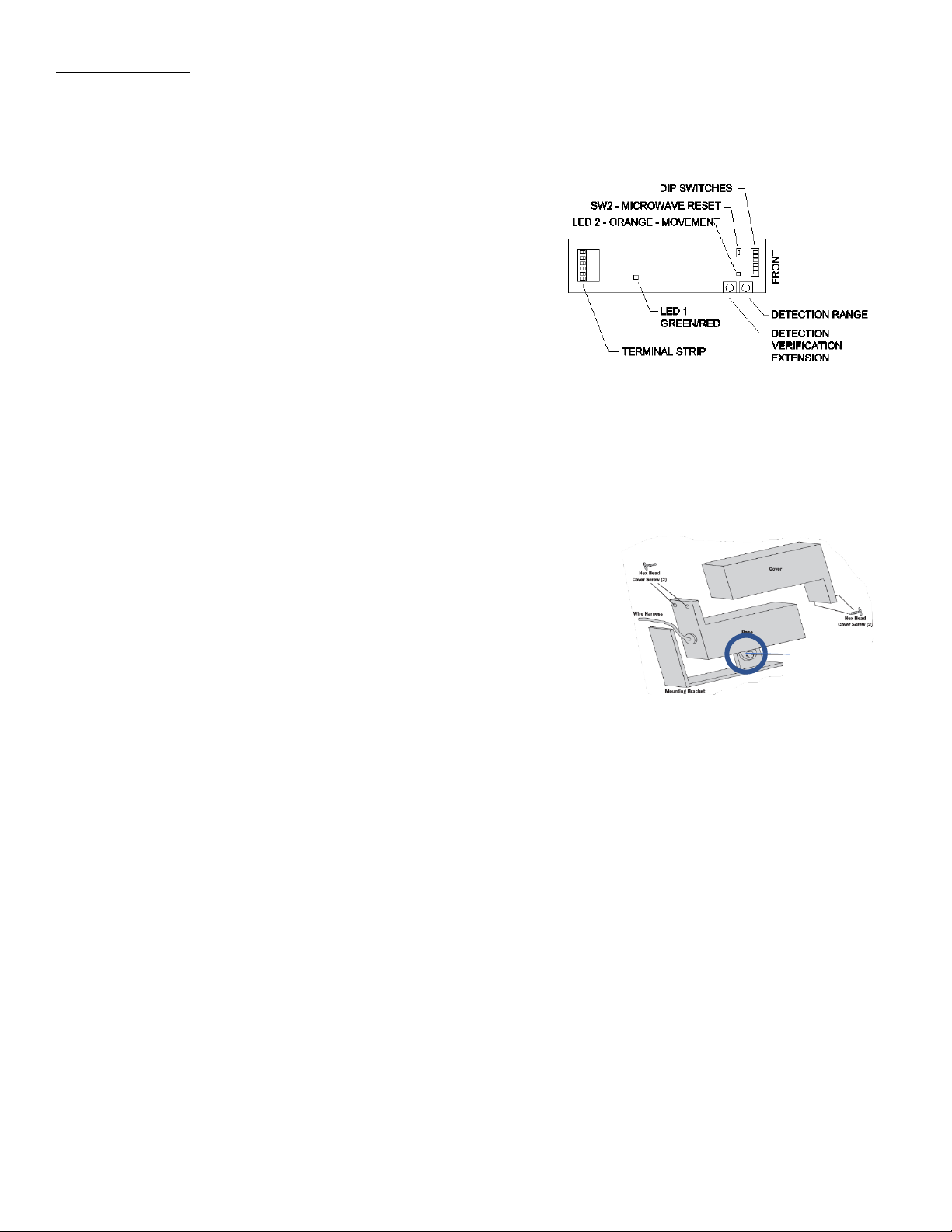

To simplify the initial walk-test of the detection zone, check to

ensure the potentiometer for the “Detection Verification Extension”

is set at its minimum value –all the way counter-clockwise.

To determine the detection zone, walk in and out of the targeted detection zone and note the trigger points of the area so

it can be mapped out on the sidewalk.

oNote: The sensor will detect human movement in a direction defined by the value of dipswitch #1.

oIf the sensor is set to uni-directional mode, it will only detect movements of a frontal approach to the sensor.

If the sensor is set to bi-directional, it will detect movements toward the

sensor from any direction.

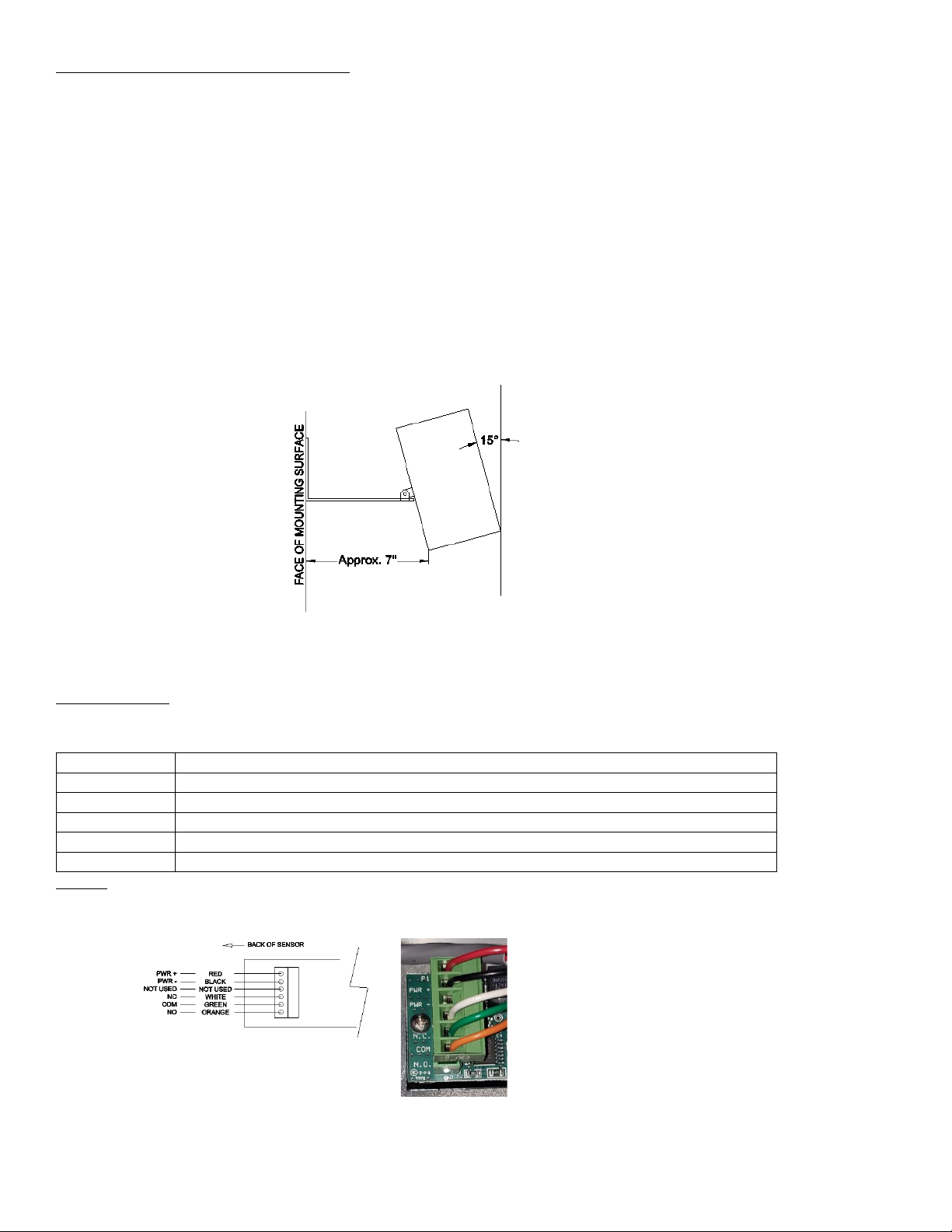

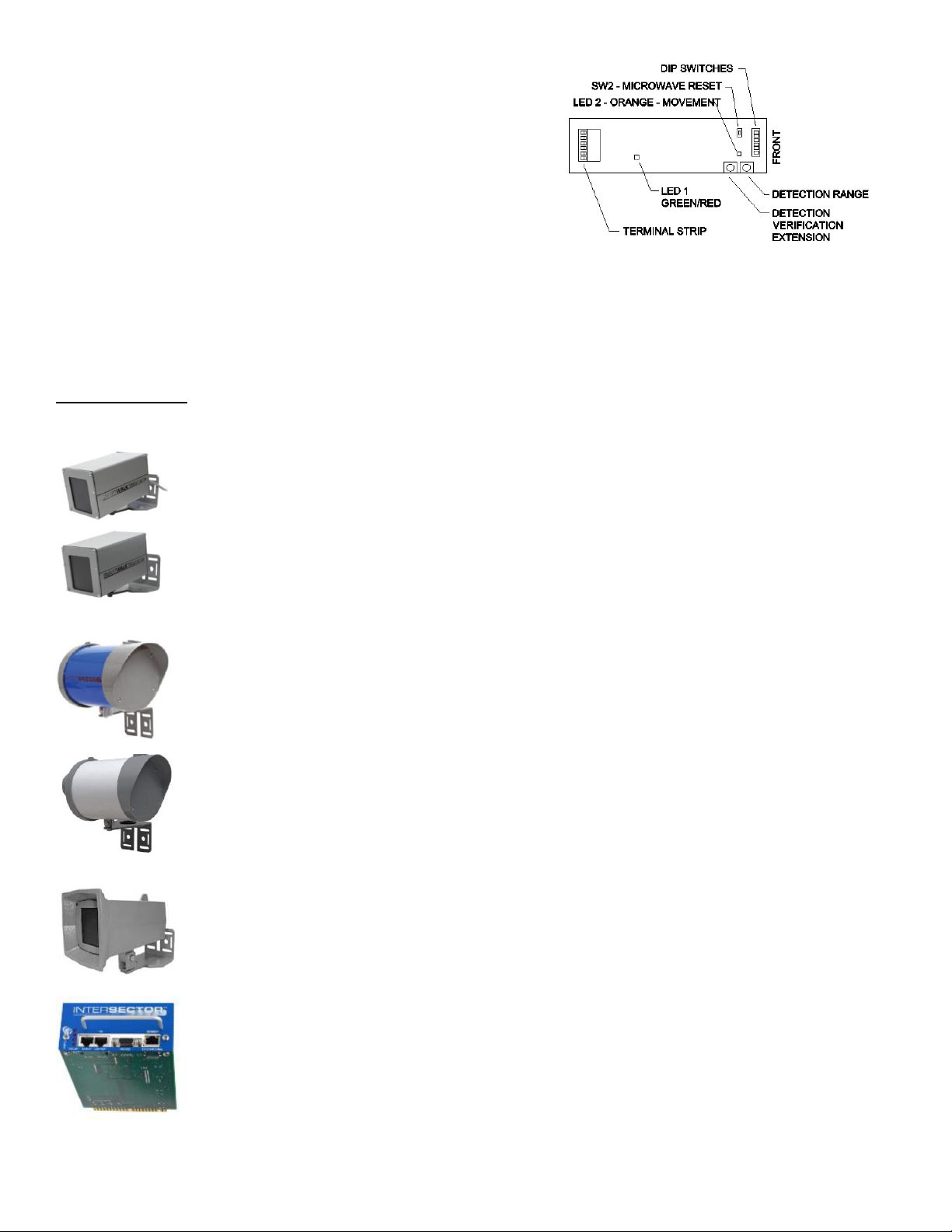

If the position of the targeted detection zone is incorrect for the application,

re-aim the sensor for better alignment to the intended area of detection. This

can be done by loosening the hinge bolt of the sensor to adjust angle, or by

loosening the bracket attachment screws to for lateral adjustment. Make the

proper adjustments and then re-tighten the hardware.

HELPFUL HINTS:

oRemember to walk-test the entire targeted detection zone , mapping out the zone to ensure it is providing

adequate detection coverage.

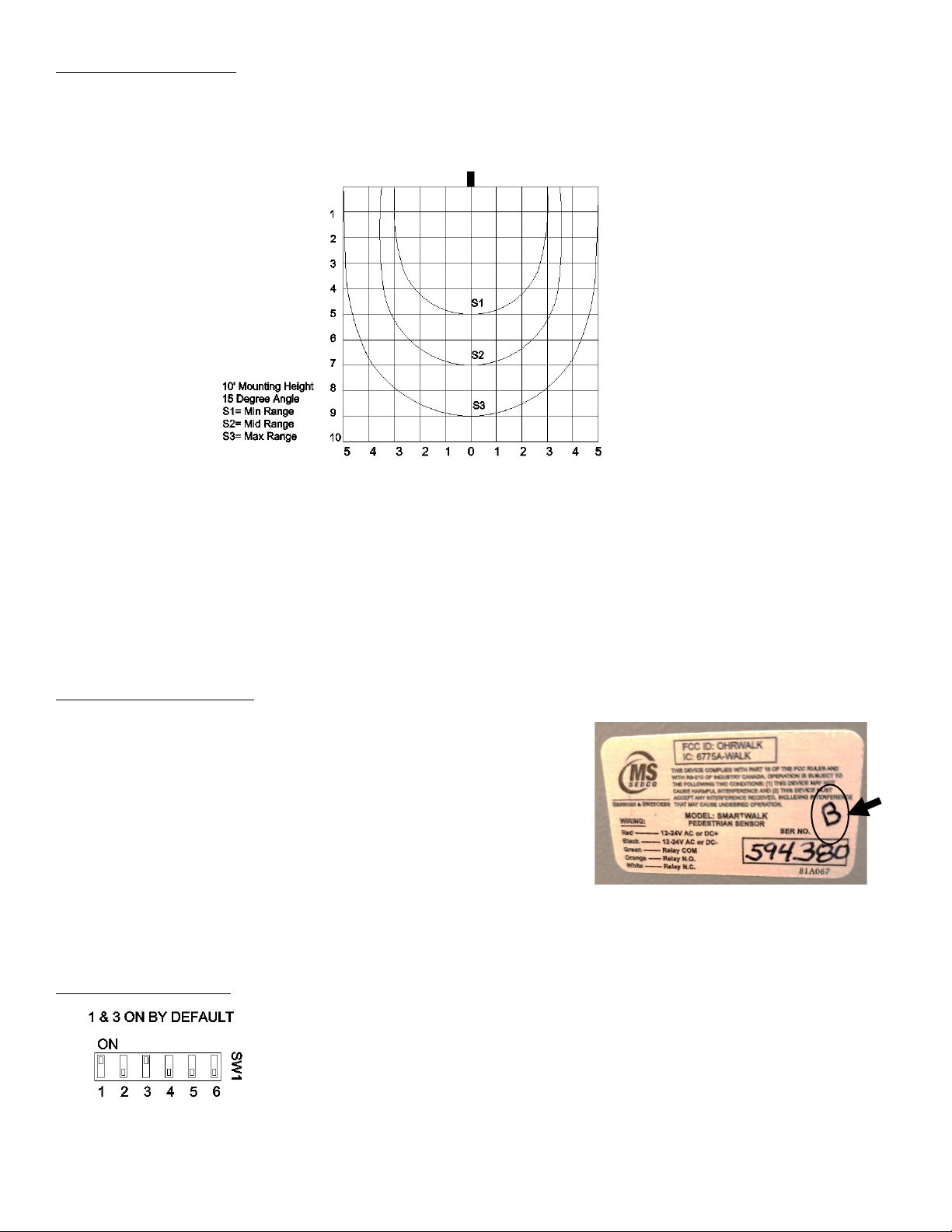

oThe “Range” adjustment potentiometer can be used to effectively enlarge or reduce the detection zone. By

default, the range is at its maximum setting.

oHigher mounting heights equate to larger detection zones. As such, if the sensor must be mounted higher than 10’

due to obstructions on the pole, such as signage, it will require more care in the setup to try and eliminate un-

wanted detections from peripheral movements on the sidewalk or even cars passing through the intersection near

the curb. If the sensor is unable to perform sufficiently at the higher height, a lower mounting position may be

necessary.

oWhen the sensor is configured for uni-directional detection, it will require more of a frontal approach to the sensor

to achieve detection in the targeted detection zone. As one progressively moves off center from a frontal approach

to a side or rear approach, the sensor will eventually no longer detect you. If detection from any direction is

desired, set dipswitch #1 to bi-directional detection.