MuchMoreWater

Side 9 af 16

Membrane Cleaning

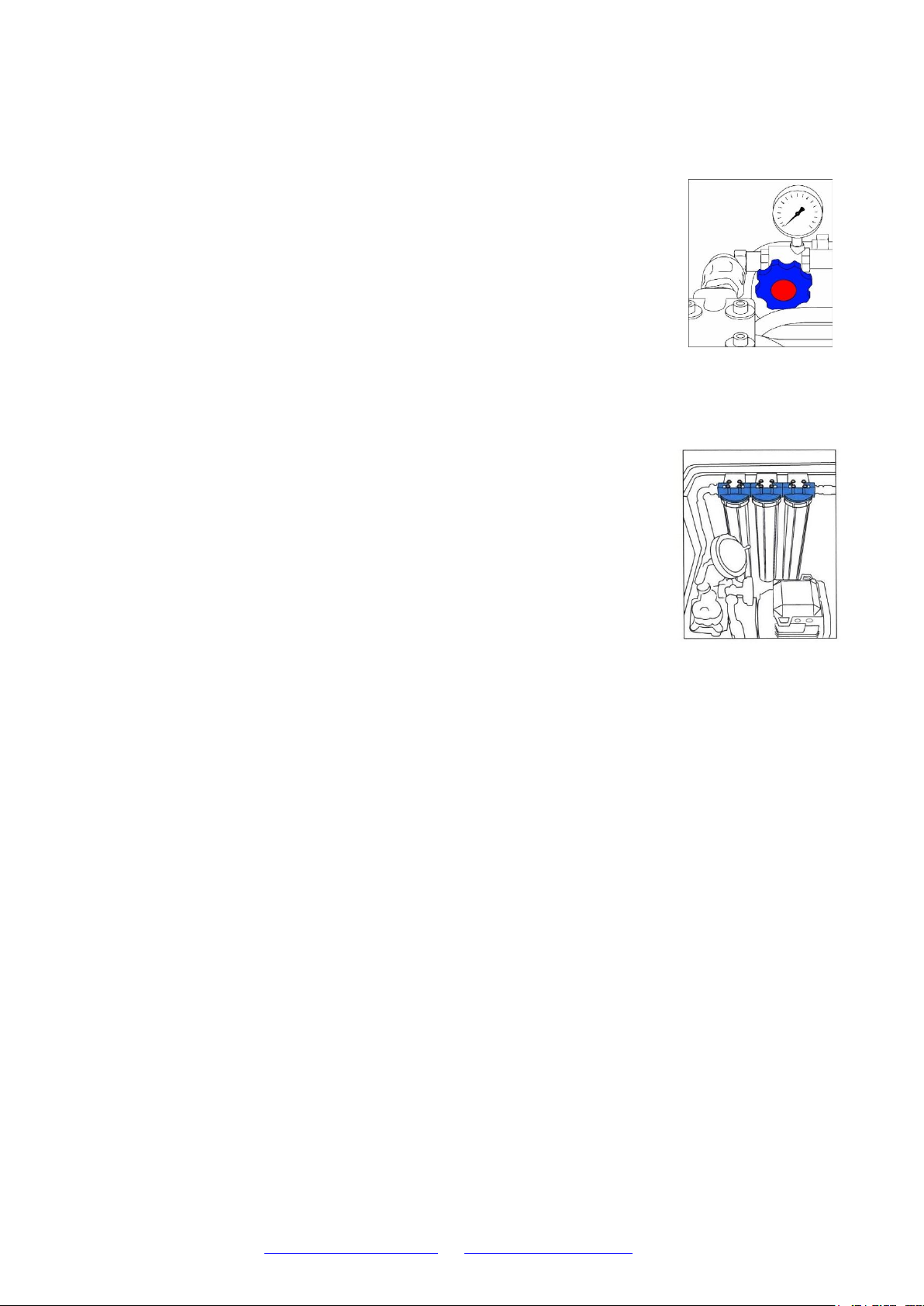

To make sure that the prescribed cleaning fluids are working

correctly, the system must be run with and without pressure,

which means that the blue handle at the main block (see ill.) are

in open position and then turned to closed position.

For cleaning, a clean tank with a capacity of approx. 50 litres must be

used.

Cleaning procedure with Sodium Hydroxide and Nitric Acid

(e.g. Divos 116 and Divos 2)

1. On screw the pre-filters and pull the inside out. Screw the filter

housings on again without the filters in.

2. Pre-rinse with clean water for 10 minutes.

3. Alkali cleaning (DIVOS 116)

Dilute 0.25 liter DIVOS 116 with 50 litres of water in the tank.

Start Bluebox 450 and let the system rinse without pressure

(blue handle in open position = “pressure off”) for 10 minutes.

After that the blue handle are turned to “Pressure on” and the Bluebox 450 must

work at this setting for 30 minutes at 8 bar’s pressure.

4. The system must now rinse with clean water for 10 minutes without pressure, and

then 10 minutes at 8 bar’s pressure.

5. Acid Cleaning (DIVOS 2)

Dilute 0.5 liter DIVOS 2 with 50 litres of water in the tank. Start the Bluebox 450 and

let the system rinse without pressure (blue handle in open pressure = “pressure off”)

for 10 minutes. After that the handles are turned to “Pressure on” and the Bluebox

450 must work at this setting for 30 minutes at 8 bar’s pressure.

6. After 30 minutes have passed, the tubes are placed in the tank, which is now filled

with clean water, and the system has to run for 15 minutes in “Pressure of”. After

that let the pump run for 15 minutes with the blue handle turned to “pressure on” so

that Bluebox 450 is rinsed all the way through.

7. When the cleaning process is finished, it is advisable to place the external hoses in

fresh water and let the Bluebox 450 run for approx. 10 minutes with the blue handle

in the position “Pressure on”.

8. When the cleaning is finished, the system is closed down as described in “Part III –

After using Bluebox 450” (see ill.) and the 3 front-filters has to be changed (see ill.).