7

MUELLER®SUPER CENTURION®3 0 FIRE HYDRANT

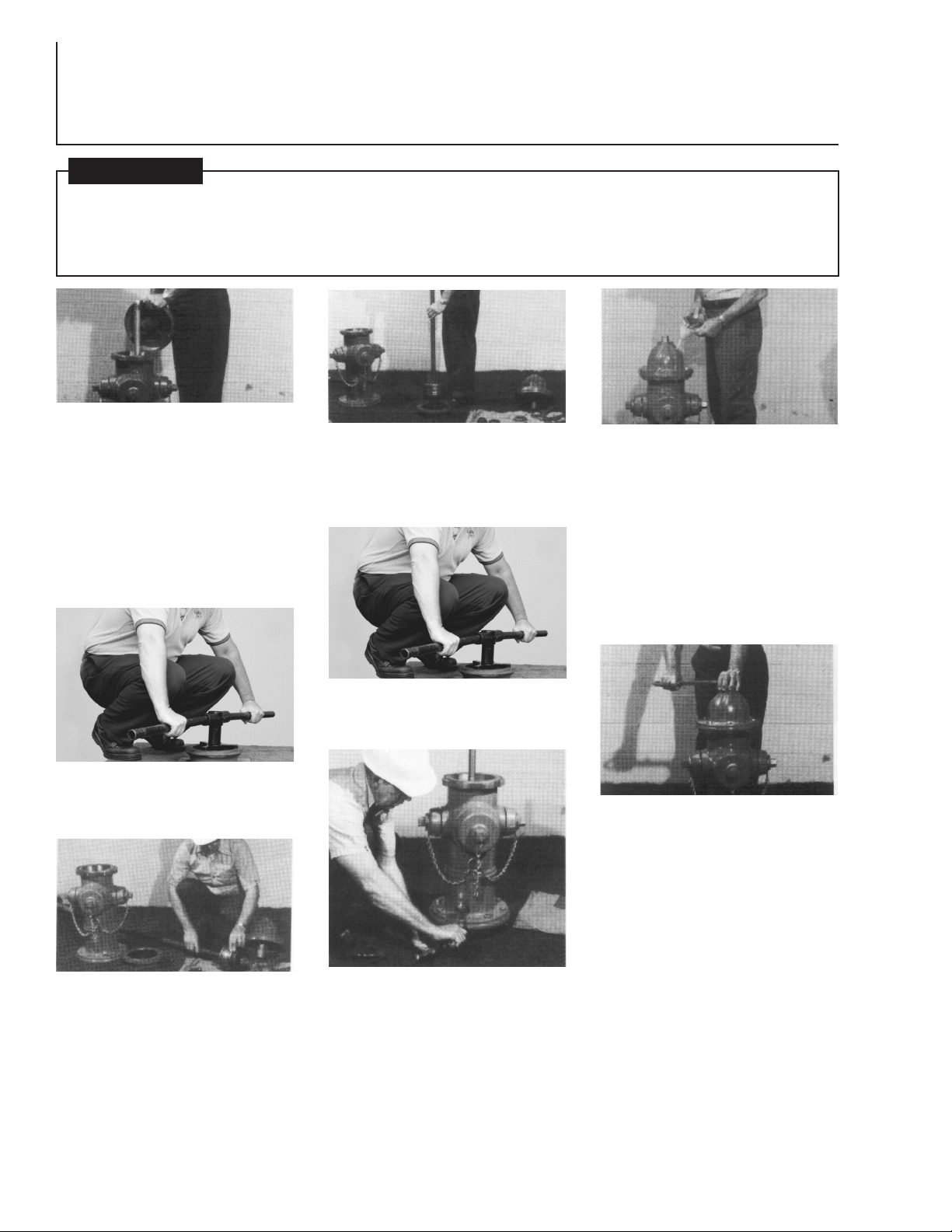

Remove Main Valve rom Lower Barrel Flange

CAUTION: Always fill the il reserv ir

with the b nnet installed, the hydrant

in its n rmal upright p siti n, and the

main valve fully cl sed. If the hydrant

is filled with lubricant under any ther

circum stances, excess lubricant can

ver fill the b nnet and create a pres -

sure l ck. This c uld result in damage

t the seals r b nnet, r prevent

pr per hydrant perati n.

1. Remove Hold Down Nut, Thrust Bearing, and

Operating Nut rom Bonnet. Lubricate Brass

Sleeve and slide over threaded stem end to

prevent O-ring damage. Unbolt and remove

Bonnet. Remove Sa ety Flange Bolts and Sa ety

Flange. Remove Upper Barrel. Remove Upper

Stem and Stem Coupling rom Lower Stem. Slide

slotted end o Wrench over Lower Stem. Align

holes in Wrench and Stem and attach Wrench to

Stem with Clevis Pin. Lower Support Arm onto the

Flange o Lower Barrel and tighten Thumb Screw

(to hold Main Valve in closed position). Shut o

water at Gate Valve.

5. Tighten Main Valve to 200 t-lbs. Turn on

water at the Gate Valve and remove Wrench

rom Stem by removing Clevis Pin.

8. Tighten Bonnet Bolts. Unscrew one Hose

Nozzle Cap slightly to bleed air. Open Hydrant

ully. Tighten the Hose Nozzle Cap when water

starts lowing and check all lange connections

or leaks. Turn Operating Nut to ully closed

position and remove Hose Nozzle Cap to allow

Barrel to drain. Replace Nozzle Cap.

9. Turn Operating Nut in closing direction to

make sure Main Valve is closed tightly, then

turn in opening direction approximately 1/4

turn to relieve tension on operating

mechanism.

2. Remove Main Valve Assembly by turning

Wrench counter-clockwise and li t out Wrench,

Lower Stem, Main Valve Assembly and Seat

Ring rom Hydrant Barrel as a unit.

6. Reassemble Upper Stem to Lower Stem.

Place Upper Barrel in place and reassemble

Sa ety Flange.**

4. Lower Main Valve Assembly and care ully

thread Seat Ring into the base o the Hydrant

hand-tight. Raise the Main Valve leaving about

1/2” o play between the Main Valve and Seat.

Lower Support Arm onto Flange o Lower

Barrel and tighten Thumb Screw.

3. Straighten stainless steel Lock Washer,

unscrew Cap Nut and remove Washer, Stem

Seal, Lower Valve Plate, Main Valve and Seat

Ring. Clean, inspect and replace any damaged

parts. (Main Valve can be reversed to provide

new seal.) Replace Drain Valve Facings. Inspect

and lubricate Top and Bottom Seat Ring O-

rings (replace i necessary). Lubricate all

threaded sur aces and reassemble. With Cap

Nut tightened to 100 t-lbs on 5 1/4” Hydrant,

or 75 t-lbs on 4 1/2” Hydrant, bend edges on

stainless steel Lock Washer over one lat on the

Lower Valve Plate and one lat on the Cap Nut.

7. Check Bonnet O-ring** or proper position and

condition. Attach the Brass Sleeve to Upper Stem

and lubricate outside to protect O-ring Seals rom

thread damage. Place Bonnet onto Upper Barrel

and assemble Bonnet Bolts only hand-tight.

Remove Brass Sleeve. Reassemble Operating Nut,

Thrust Bearing (re er to pg 1 or correct assembly),

and Hold Down Nut*. Be sure O-ring Seals are in

good condition at thread shoulder on outside o

Hold Down Nut and on inside where contact is

made with Operating Nut. Remove Oil Filler Plug

in side o Bonnet. Pour MUELLER Hydrant

Lubricant into Oil Reservoir until it is level with Oil

Filler Plug Hole. Replace Oil Filler Plug.

Bef re rem ving any b lt(s) h lding the hydrant t gether, shut ff gate valve t is late hydrant fr m main water s urce.

L sen (d n t rem ve) ne n zzle cap tw turns and check f r water under pressure inside hydrant – bleed ff any pressure,

then rem ve n zzle cap c mpletely. Open hydrant main valve c mpletely. A c ntinu us fl w f water, n matter h w slight,

indicates hydrant is n t pr perly is lated fr m the main water supply, and that pr blem must be c rrected bef re any

hydrant disassembly can pr ceed. Disassembly f hydrant with pressurized water acting against the main valve c uld result

in unexpected ejecti n f hydrant parts, debris r high-pressure water stream, which c uld cause seri us b dily injury.

! WARNING

*TIGHTEN HOLD DOWN NUT TO 200-300

FT-LBS OF TORQUE. IF TORQUE WRENCH IS

NOT AVAILABLE, USE A 3 LB HAMMER TO

STRIKE THE END OF THE A-311 WRENCH

FIRMLY TWO TIMES TO ASSURE THE NUT IS

PROPERLY TIGHTENED.

**TO DETERMINE CORRECT O-RINGS FOR

BONNET AND GROUND LINE FLANGES,

WHICH ARE SIMILAR IN APPEARANCE: SMALLER

DIAMETER O-RING IS USED AT BONNET

FLANGE; LARGER AT GROUND LINE FLANGE.