T H E W O R L D P O W E R I N A N C H O R I N G S Y S T E M S

HANDY HINTS

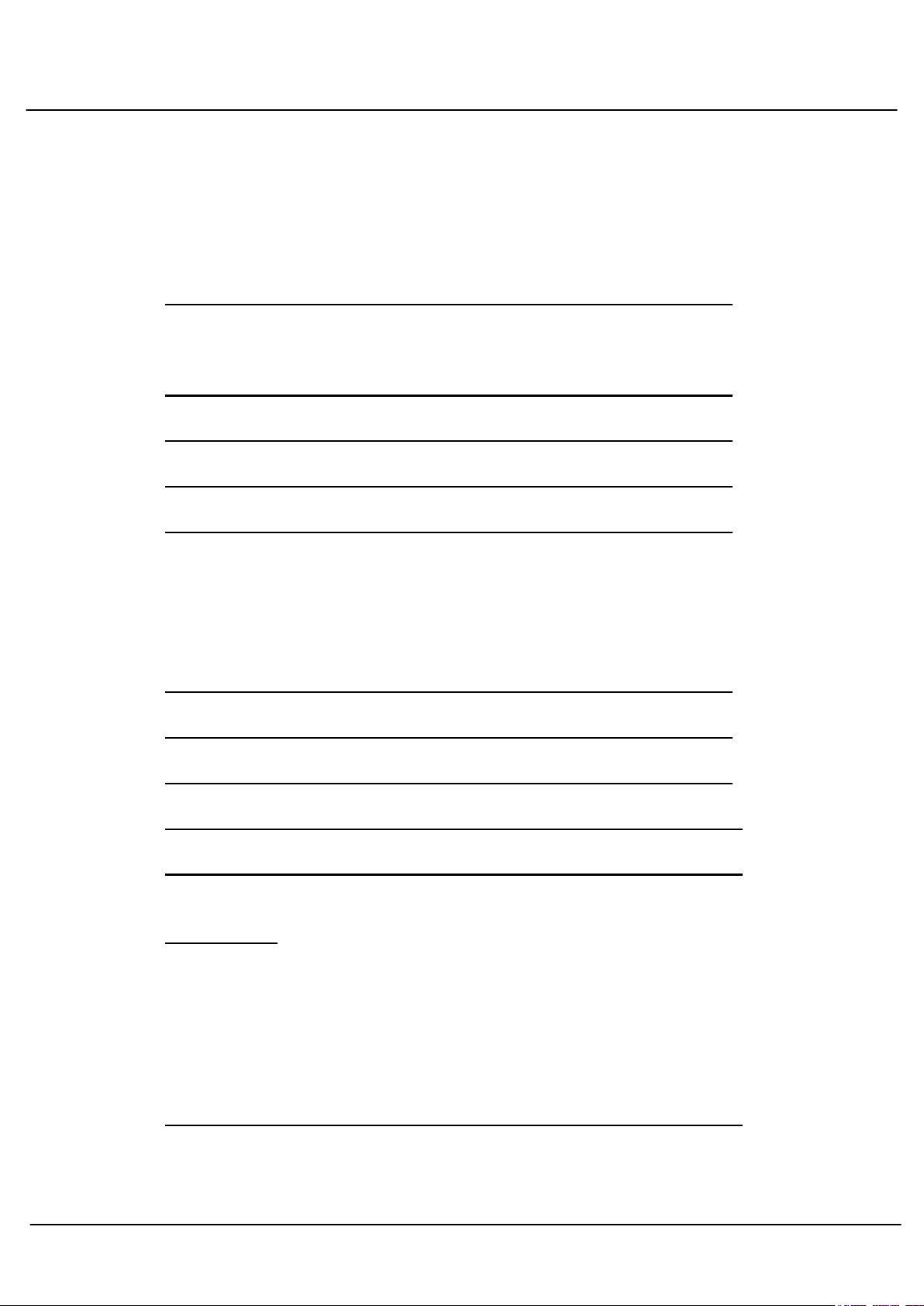

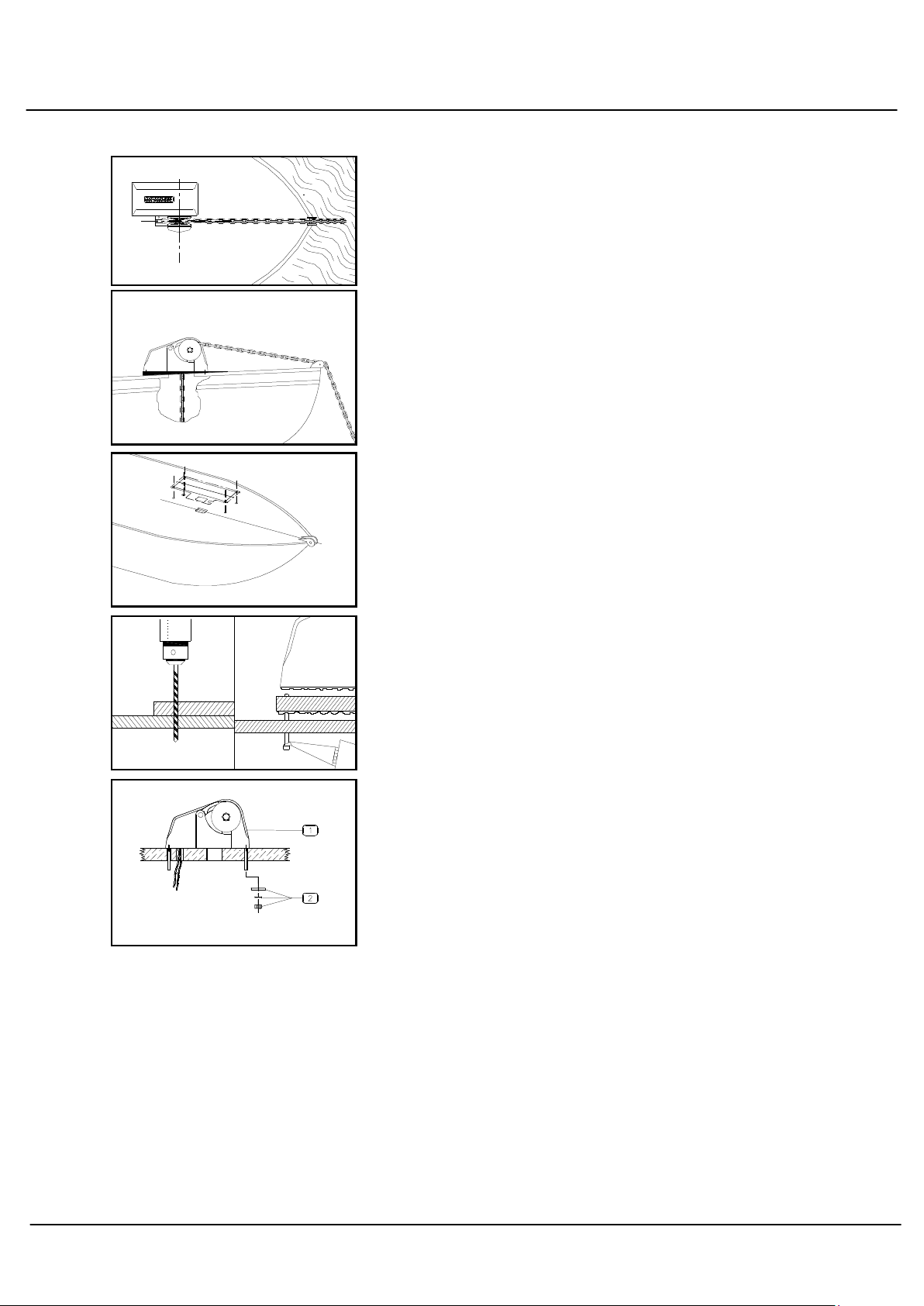

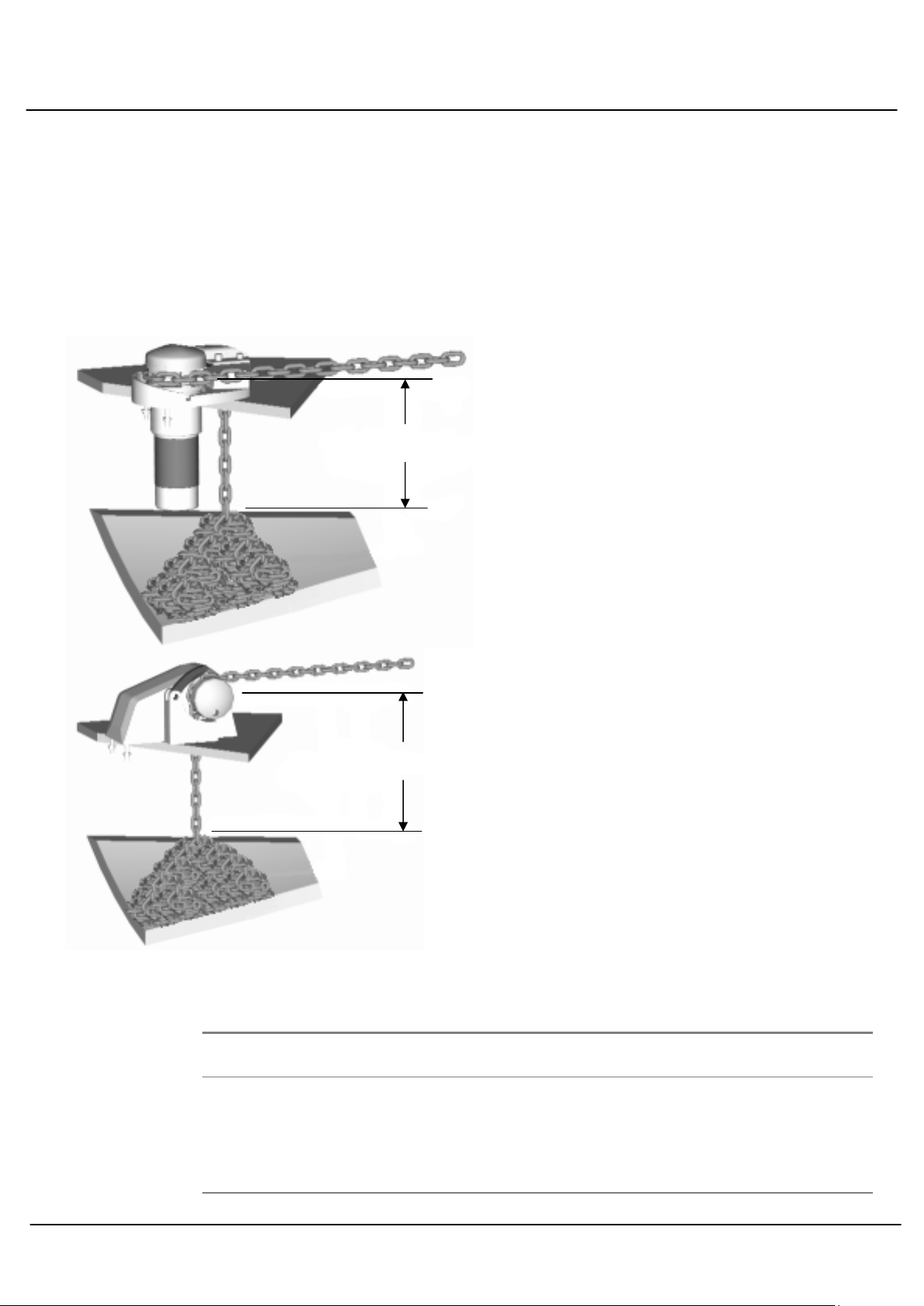

It is a common mistake to locate the windlass too far forward, or too close to the bulk head,

where there is insufficient room for chain and anchor stowing. The chain fail position should

be in the centre of the chain locker. If the chain falls alongside a bulkhead or onto the stem it

will pyramid and jam.

If the chain falls into an undesirable position, a metal tube can be fitted under the hawser to

redirect the chain to a preferred position. This pipe should be at least ½ times the diameter

of the chain. It should also have as much vertical angle as possible. Position the windlass in

the best location with the chain hawser facing forward. Ensure sufficient room to run electric

cables to the windlass. Follow the instructions on page 4 including underdeck stiffening, deck

camber, alignment, mounting blocks and sealing procedures. The gearbox and motor can

be located in one of 22 positions.

ELECTRICAL

See Wiring Diagrams for wiring instructions.

A c rcu t breaker

must be f tted to ensure warranty

. If the windlass is overloaded or stalled the

circuit breaker automatically cuts off power to the windlass and protects the wiring and

motor. The circuit breaker should not be used as an isolating switch.

Deck Sw tches

are best located out to either port or starboard or directly behind the windlass

in a position where it can be easily reached with your foot or knee, preferably where you can

view the anchor and chain coming aboard

.

Isolat ng Sw tch

should be fitted in an accessible position for safety, ideally close to the

battery or switches. The isolating switch is not a circuit breaker

.

Batter es

are best located as close to the windlass as possible. If located within 7m (23') use a

cable of min 36sqmm, 8mm(5/ 6") core. For longer runs, 9- 7m (30'-55') use 50 sqmm, 0-

2mm (3/8" -7/ 6") core. The larger the cable, the greater voltage is delivered to the motor

and overheating will not occur. Small diameter cables drop voltage considerably

.

Rotat on

:

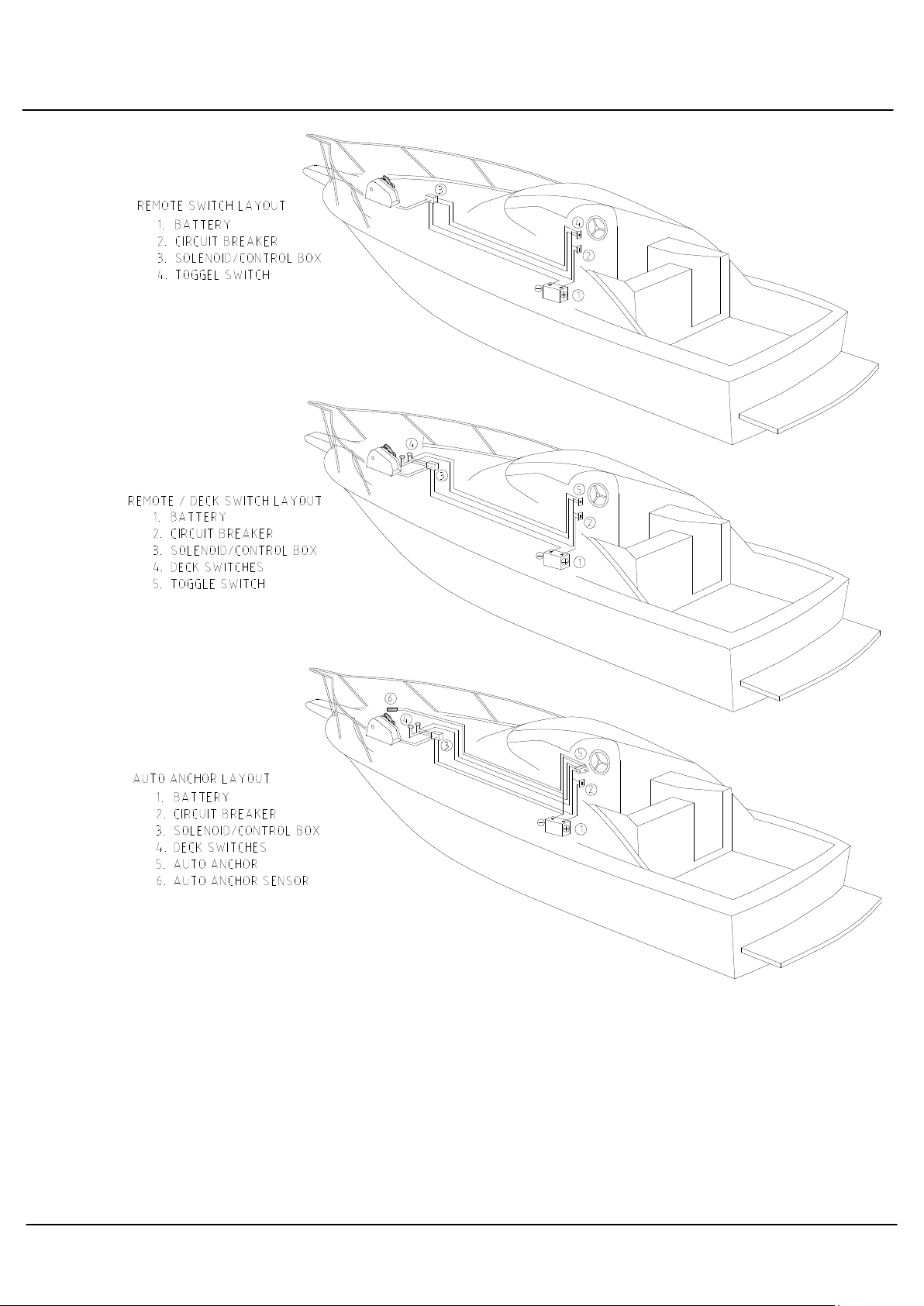

Windlasses may be wired for single or dual direction, using single or dual deck

switches for raising or lowering. Alternatively a remote control solenoid packages with Toggle

Switch, Hand Pendant or Auto Anchors are available

.

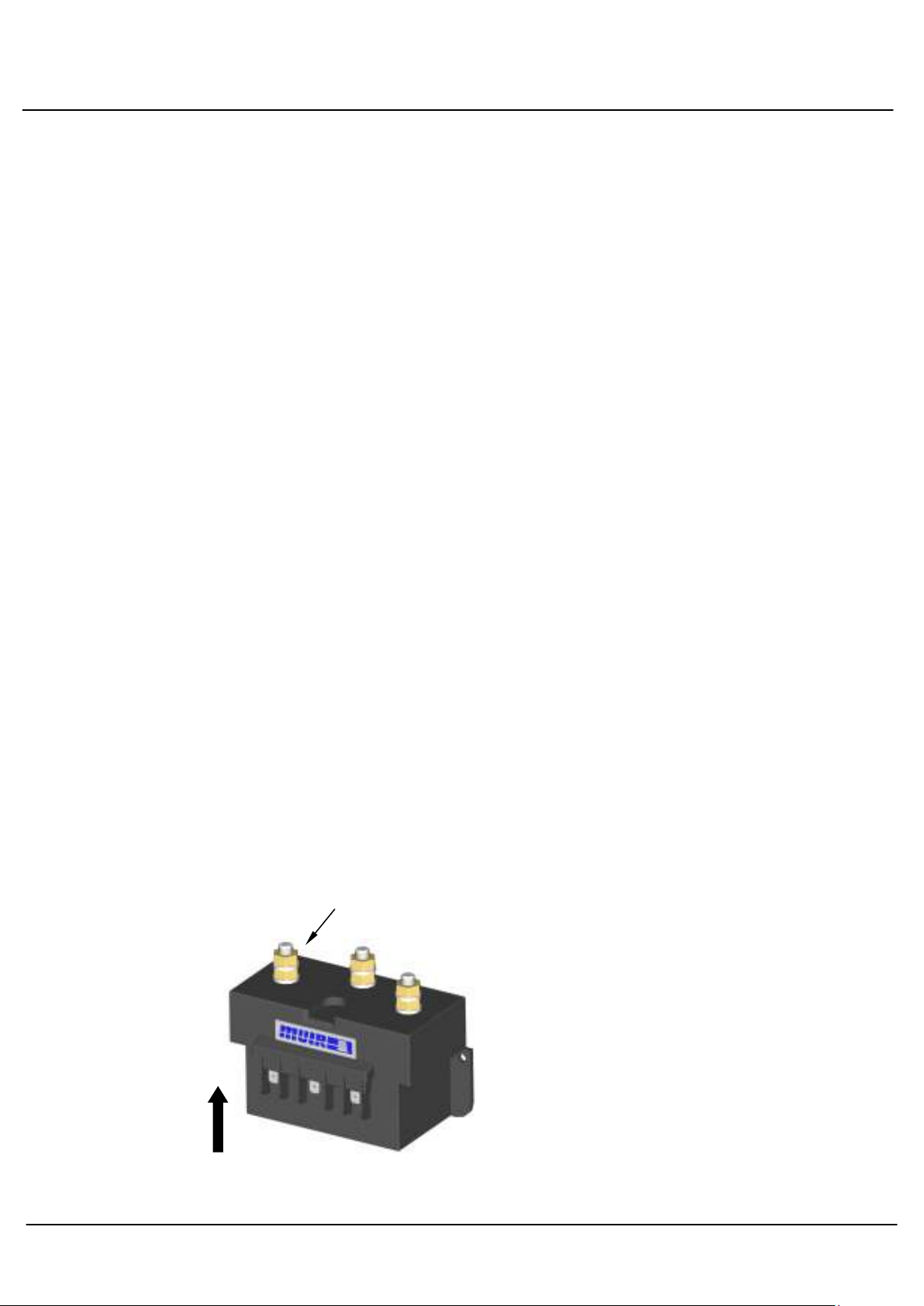

Th s way up

3 POLE

Soleno d Installat on

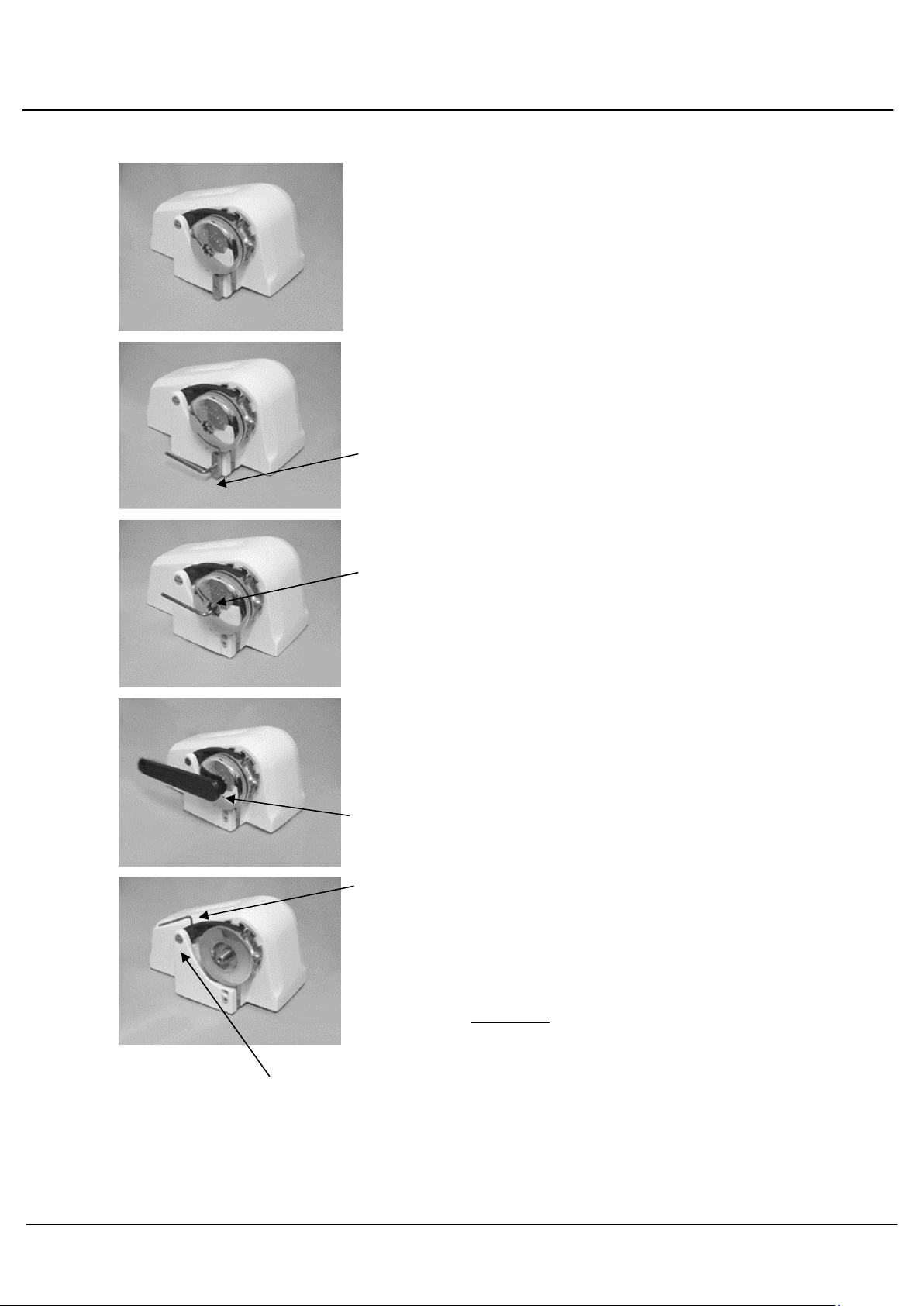

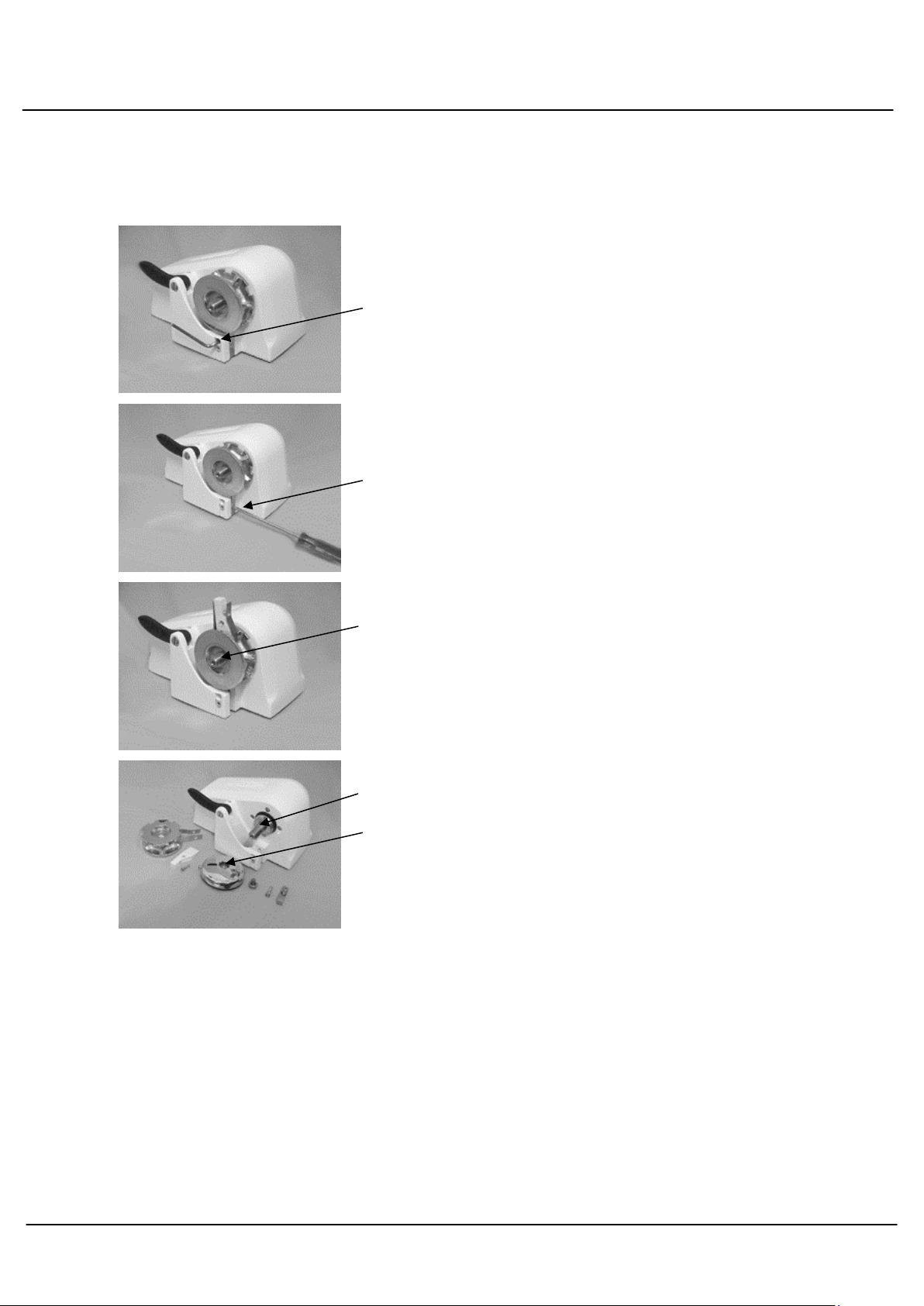

We recommend that the solenoid is

installed in an upright position, and in

close proximity to the electric motor of

the capstan. The solenoid must not be

installed in chain locker. It should be

located in dry area only.

For wiring information, please refer to the

appropriate wiring diagram listed in the

table below.