Table of Contents

410-MAN Page 3 of 105

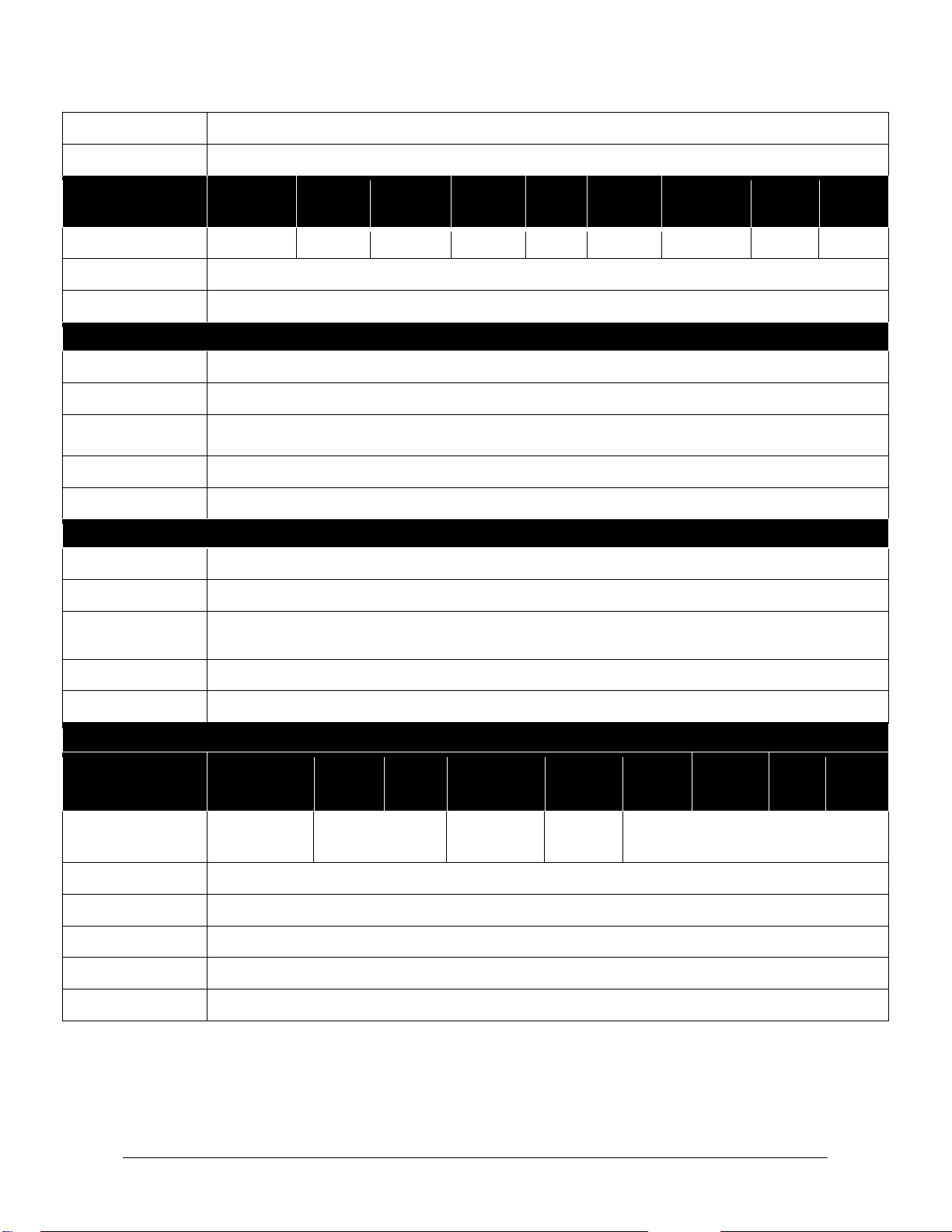

Table of Contents

Table of Contents ....................................................................................................... 3

Introduction............................................................................................................... 5

Warranty Registration and Warranty Certificate Request...................................................5

Scope and Audience.....................................................................................................5

Safety and Warnings.....................................................................................................5

Accessing Product Documentation.................................................................................6

Service........................................................................................................................6

Chapter 1. Overview .......................................................................................... 7

1.1 Specifications.........................................................................................................8

1.2 System Description...............................................................................................11

1.3 Models ................................................................................................................12

1.4 Product Features...................................................................................................17

Chapter 2. Safety.............................................................................................. 19

Chapter 3. Hardware Overview........................................................................ 23

3.1 Key Components ..................................................................................................24

3.2 Typical Functional Description...............................................................................28

3.3 Theory of Operation..............................................................................................31

Chapter 4. Installation...................................................................................... 33

4.1 Delivery Space Requirements.................................................................................34

4.2 Site Considerations ...............................................................................................42

4.3 Delivery and Handling...........................................................................................45

4.4 Storing the System................................................................................................54

Chapter 5. Operation ....................................................................................... 56

5.1 Starting the Unit ...................................................................................................57

Chapter 6. Maintenance ................................................................................... 60

6.1 Safety Precautions.................................................................................................61

6.2 Preventative Maintenance......................................................................................63

6.3 FRU Replacement.................................................................................................67

6.4 Calling for Service................................................................................................73

6.5 Customer Service and Support................................................................................73