3

Warning

●Before operating this instrument, familiarize yourself with all instructions outlined

in this manual.

●The instrument must only be used by suitably trained competent parsons.

●Always check to make sure that the function switch is set to the proper position.

●When making measurements, use CAUTION as dangerous voltages may be

present in normally safe areas.

●When making measurements, do not touch any conductive parts of the

equipment under test. For safe operation, the use of rubber insulation glove

is recommended.

●The instrument should not be used if any part of the instrument is damaged.

The CT sensor must be good order with no broken or cracked insulation.

●To avoid electrical shock, use CAUTION when working above 60V DC or 25V

AC rms. Such voltages pose a shock hazard.

●Do not disassemble the CT sensor or instrument.

●Do not remove the stopper in normal operation, it may cause the serious

problem of the instrument.

POSSIBLE ELECTRICALSHOCK

●If excessive current is applied to the CT sensor, the instrument will be heated

and damaged. Use the instrument within the rated current.

●This instrument is designed to measure the grounding line of arrester, do not

measure the live power line.

●Do not use the instrument, if any part of the CT sensor is damaged.

●Do not measure the uninsulated conductor.

4

3. SPECIFICATIONS

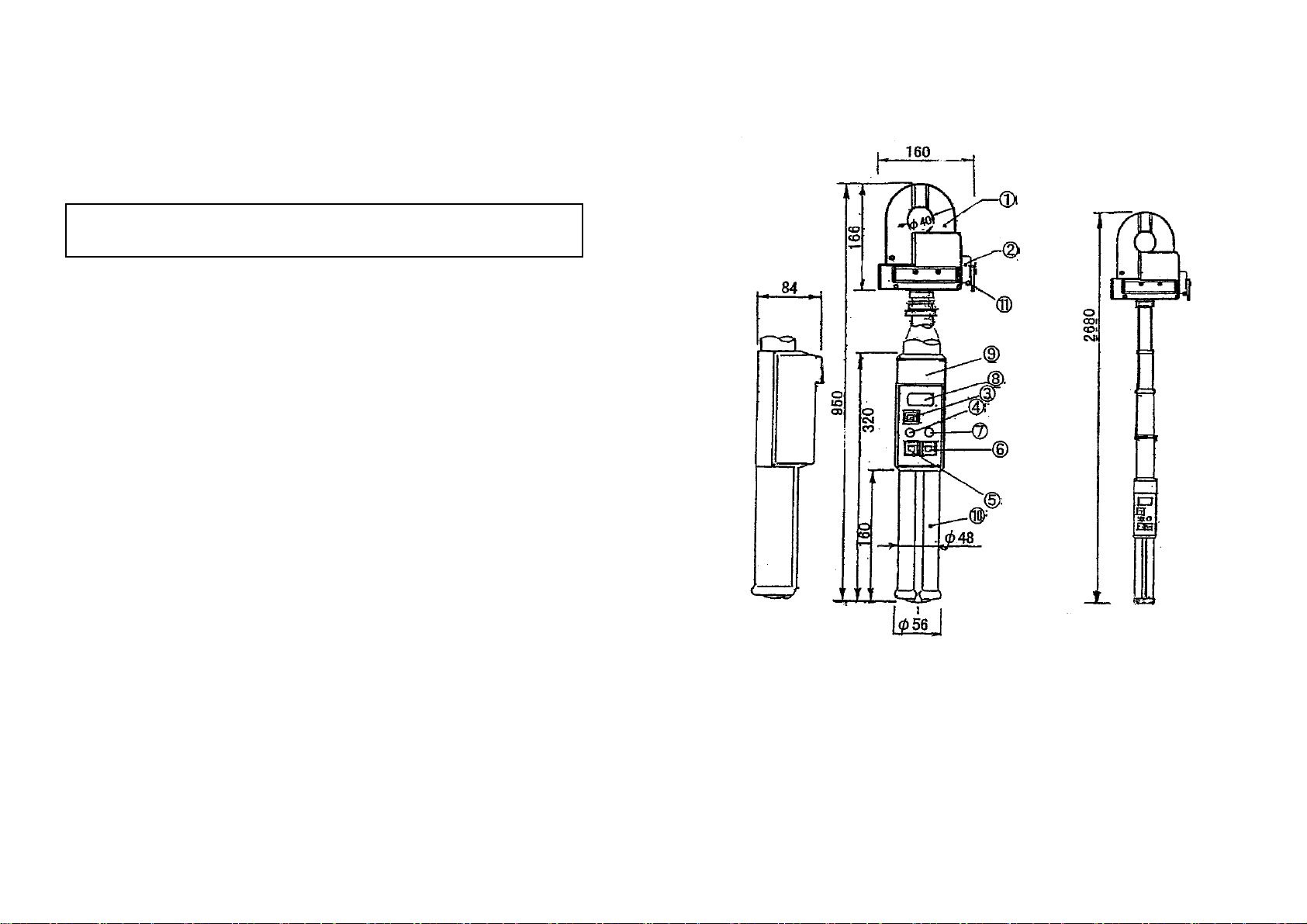

CT Sensor

CT max. opening size : φ37mm

Opening/closing of the jaw : Motor operation

Withstanding voltage : AC 2300V, 1 minute (between the core of CT and CT

outer case)

Measuring and display unit

Measuring function : Leakage current, harmonic current (Fundamental & 3rd

harmonics)

A/D converstion : Dual slope integration mode

Measuring range : AC 0-300μA/3mA/30mA(3range manual)

Input frequency : 45-60Hz (Fundamental frequency)

AC conversion : AC coupled true rms responding

Display : LCD, max. 3200 count

Sampling : 2 times/sec.

Over indication : “OL” mark on LCD

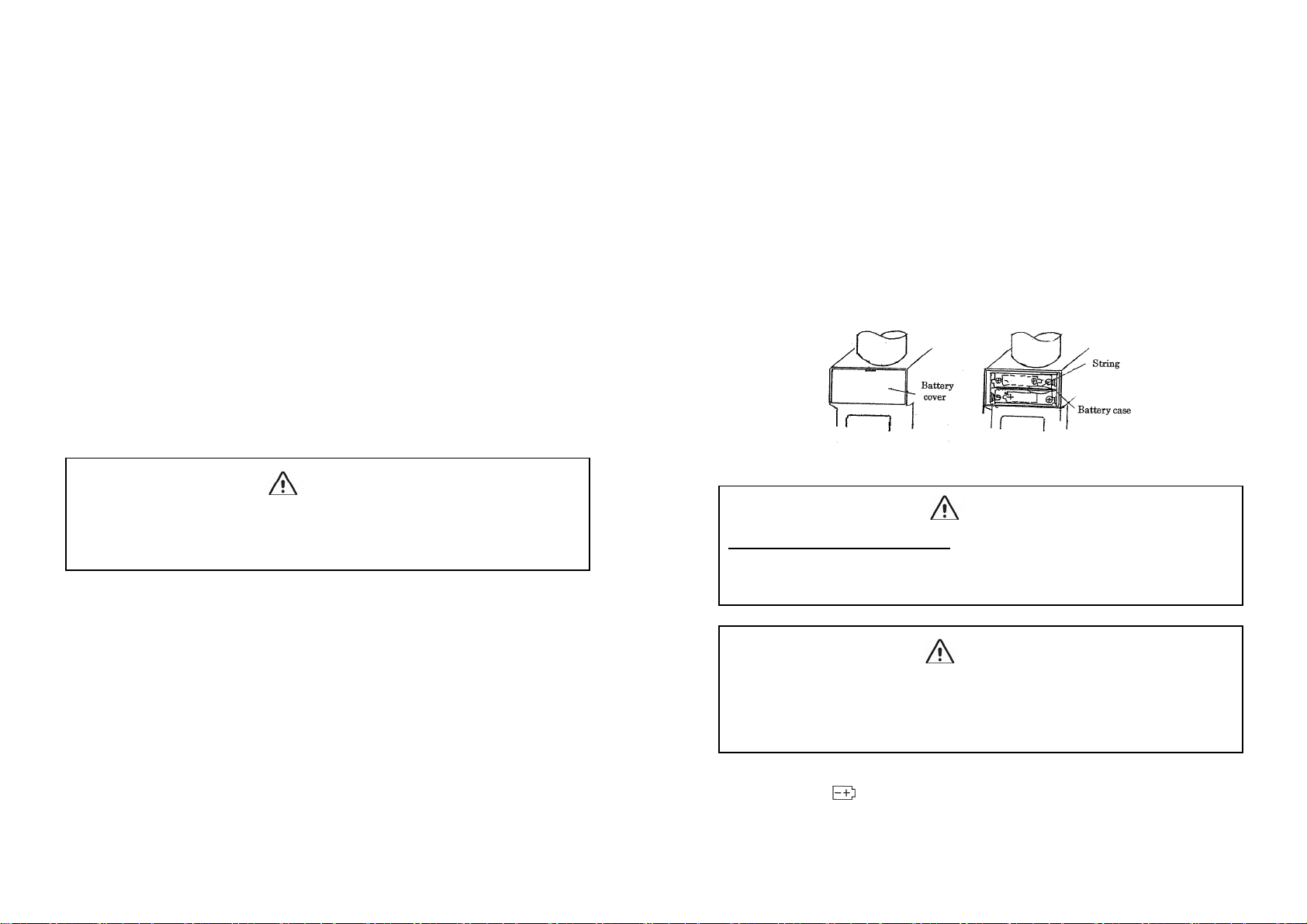

Low battery indication : “ ” mark on LCD

Data hold indication : “DH” mark on LCD

Auto power off function : Approx.10 minutes later after power on

Power supply : AAsize alkaline battery × 4

Limitation of circuit voltage : Less thanAC500Vrms

Operating temperature : 0-40℃, less than 80%RH

(Without condensation)

Storage temperature : -10~60℃, less than 70%RH

(Without condensation)

Dimensions : 160(W)×950(L)×84(D)(When retracted)

: 160(W)×2680(L)×84(D)(When stretched)

Weight : Approx.2.6kgs

AC Current

Accuracy (23℃±5℃, less than 80%RH)

Range Resolution Accuracy(45~65Hz) Max. input Current

300μA 100nA(0.1μA) ±1.2%±8digit

40Arms

3mA 1μA(0.001mA)

30mA 10μA(0.01mA)

Crest factor : <3 (0-50% of the range)

<2 (50-100% of the range)