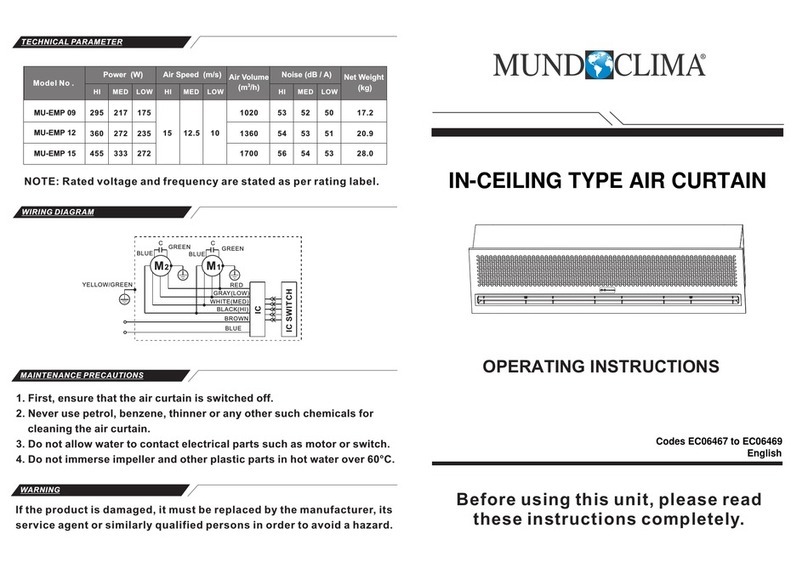

3.6Installation ofdampingdevices

3.6.1Damping devices mustbeprovidedbetweentheunit

and itsfoundation.

By means of the Φ15mm diameter installation holes on the

steel frame of the unit base, the unit can be fastened on

the foundation through the spring damper. See Fig.3-

3(Schematic diagram of installation dimension of the unit)

for details about center distance of the installation holes.

he damper does not go with the unit, and the user can

select the damper according to the relevant requirements.

When the unit is installed on the high roof or the area

sensitive to vibration, please consult the relevant persons

before selecting the damper.

3.6.2Installation stepsofthedamper

Step 1. Make sure that the flatness of the concrete

foundation is within ±3mm, and then place the unit on the

cushion block.

Step 2. Raise the unit to the height suitable for installation

of the damping device.

c. Remove the clamp nuts of the damper.

Step 3. Place the unit on the damper, and align the fixing

bolt holes of the damper with the fixing holes on the unit

base.

Step 4. Return the clamp nuts of the damper to the fixing

holes on the unit base, and tighten them into the damper.

Step 5. Adjust the operational height of the damper base,

and screw down the leveling bolts. ighten the bolts by

one circle to ensure equal height adjustment variance of

the damper.

Step 6. he lock bolts can be tightened after the correct

operational height is reached.

Damping device

Anchor bolt M12

Nut

Ferrol

It is recommended that the damper should be fastened on

the foundation with the provided holes. After the unit is

placed on the foundation, the damper connected with the

unit should not be moved, and the central clamp nut is not

allowed to be tightened before the damper sustains load.

Fig. 3-5

NOTE

4.WATER SYSTEMINSTALLATION

4.1Basicrequirementsofconnection ofchilled

waterpipes

CAUTION

● After the unit is in place, chilled water pipes can be laid.

● he relevant installation regulations should be abided with

when conducting connection of water pipes.

● he pipelines should be free of any impurity, and all chilled

water pipes must conform to local rules and regulations of

pipeline engineering.

● Connection requirements of chilled water pipes

a. All chilled water pipelines should be thoroughly flushed, to

be free of any impurity, before the unit is operated. Any

impurity should not be flushed to or into the heat exchanger.

b. Water must enter the heat exchanger through the inlet;

otherwise the performance of the unit will decline.

c. he inlet pipe of the evaporator must be provided with a

target flow controller, to realize flow-break protection for the

unit. Both ends of the target flow controller must be supplied

with horizontal straight pipe sections whose diameter is 5

times that of the inlet pipe. he target flow controller must be

installed in strict accordance with “Installation & Regulation

Guide for arget Flow Controller” (Figure 4.3~4.4). he

wires of the target flow controller should be led to the

electric cabinet through shielded cable (see Electric

Controlling Schematic Diagram for details). he working

pressure of the target flow controller is 1.0MPa, and its

interface is 1 inch in diameter. After the pipelines are

installed, the target flow controller will be set properly

according to the rated water flow of the unit.

d. he pump installed in the water pipeline system should

be equipped with starter. he pump will directly press water

into the heat exchanger of the water system.

e. he pipes and their ports must be independently

supported but should not be supported on the unit.

f. he pipes and their ports of the heat exchanger should be

easy to disassemble for operation and cleaning, as well as

inspection of port pipes of the evaporator.

g. he evaporator should be provided with a filter with more

than 40 meshes per inch at site. he filter should be

installed near to the inlet port as much as possible, and be

under heat preservation.

h. he by-pass pipes and by-pass valves as shown in Fig.

4-1 must be mounted for the heat exchanger, to facilitate

cleaning of the outside system of water passage before the

unit is adjusted. During maintenance, the water passage of

the heat exchanger can be cut off without disturbing other

heat exchangers.

i. he flexible ports should be adopted between the interface

of the heat exchanger and on-site pipeline, to reduce

transfer of vibration to the building.

j. o facilitate maintenance, the inlet and outlet pipes should

be provided with thermometer or manometer. he unit is not

equipped with pressure and temperature instruments, so

they need to be purchased by the user.

k. All low positions of the water system should be provided

with drainage ports, to drain water in the evaporator and the

system completely; and all high positions should be supplied

with discharge valves, to facilitate expelling air from the

pipeline. he discharge valves and drainage ports should

not be under heat preservation, to facilitate maintenance.

l. All possible water pipes in the system to be chilled should

be under heat preservation, including inlet pipes and flanges

of the heatexchanger

Installation & owner's manual

5

Modular Chiller MUEN-H6