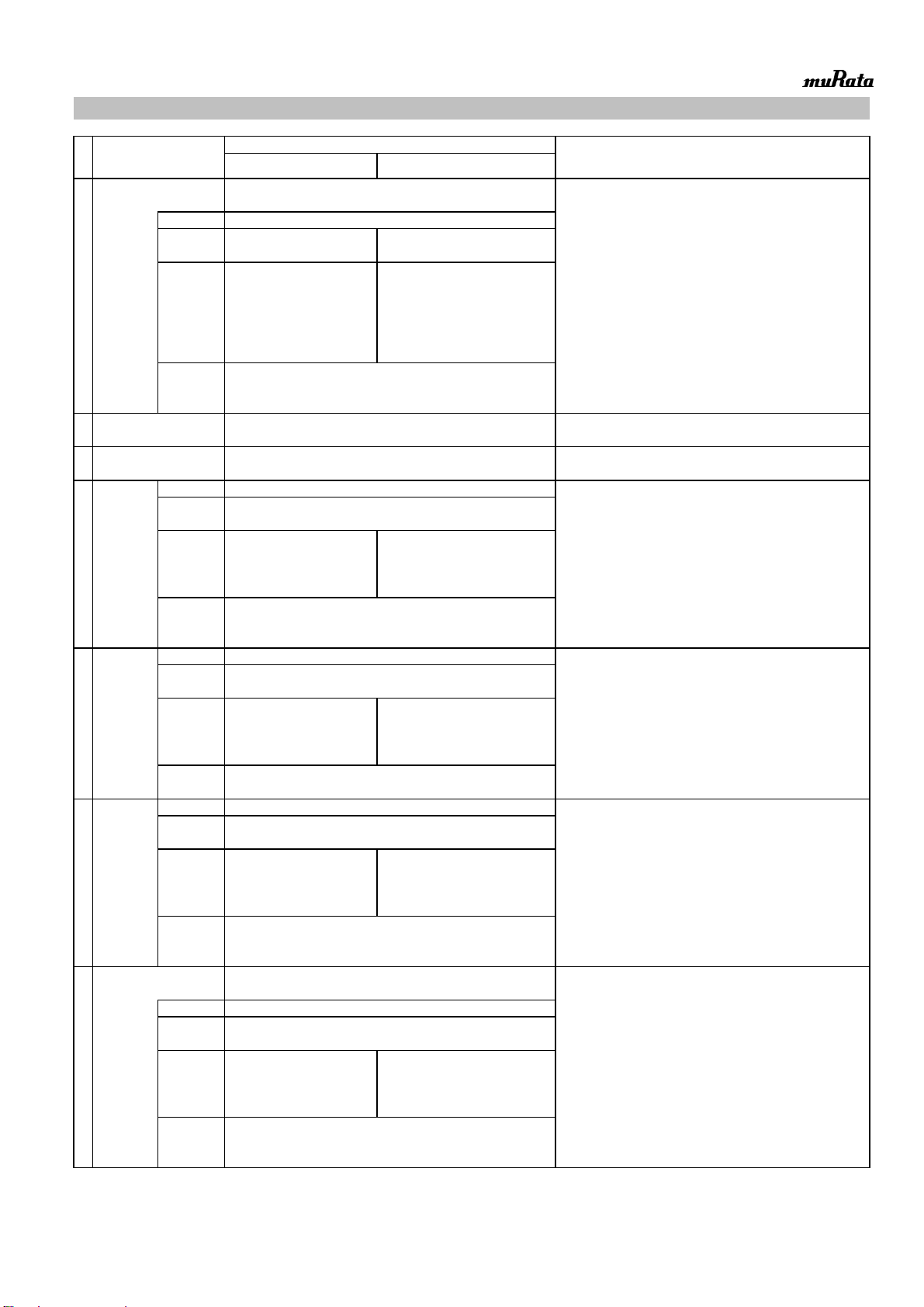

Temperature

Compensating Type

7 Operational Life The measured and observed characteristics should satisfy the

Apply 200% of the rated voltage for 1000±12 hours at 125±3℃

specifications in the following table.

℃(for 5G/L8/R9).

Appearance No marking defects Set for 24±2 hours at room temperature, then measure.

Capacitance Within ±3.0% or ±0.30pF R7/L8/R9: Within ±12.5% The charge/discharge current is less than 50mA.

Change (Whichever is larger)

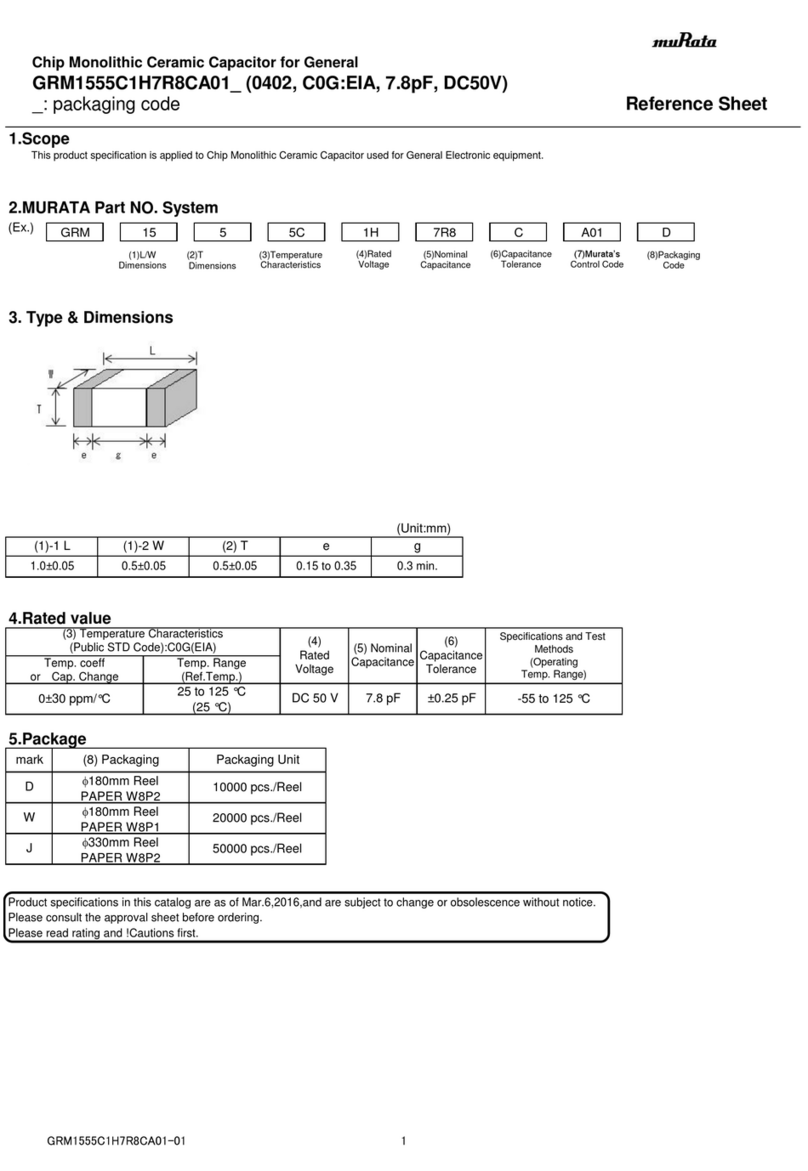

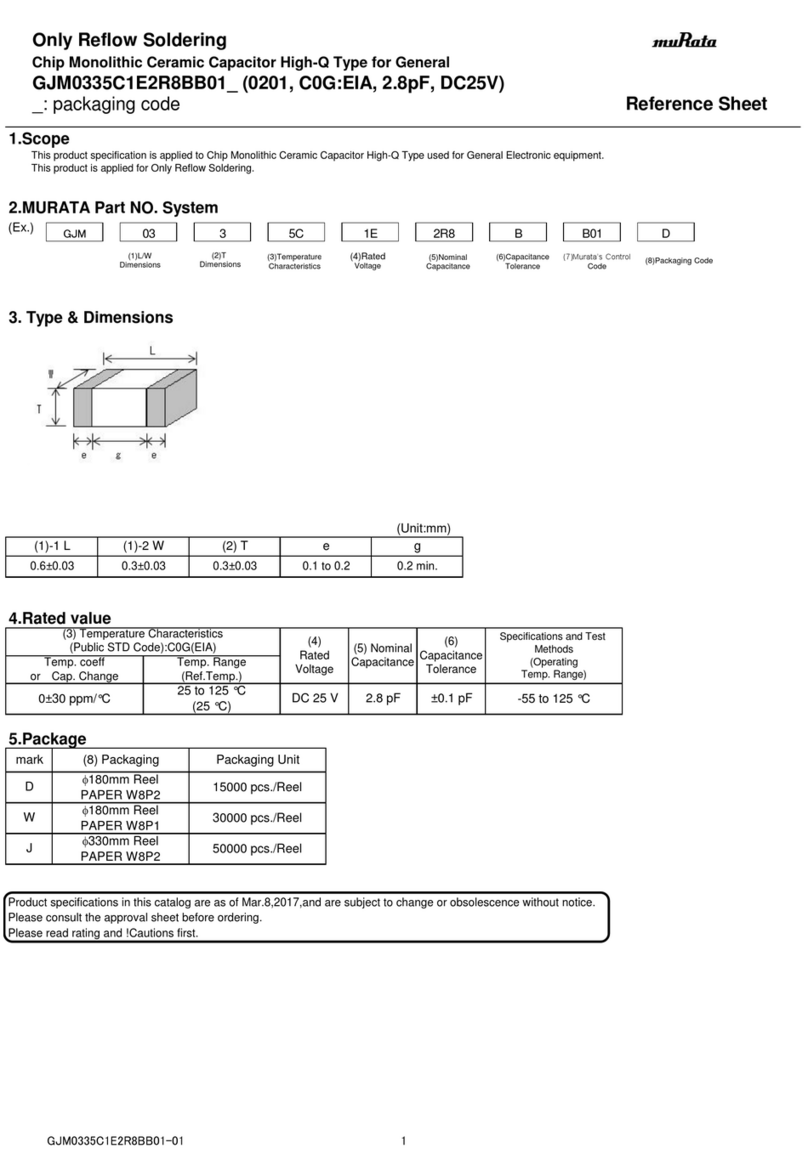

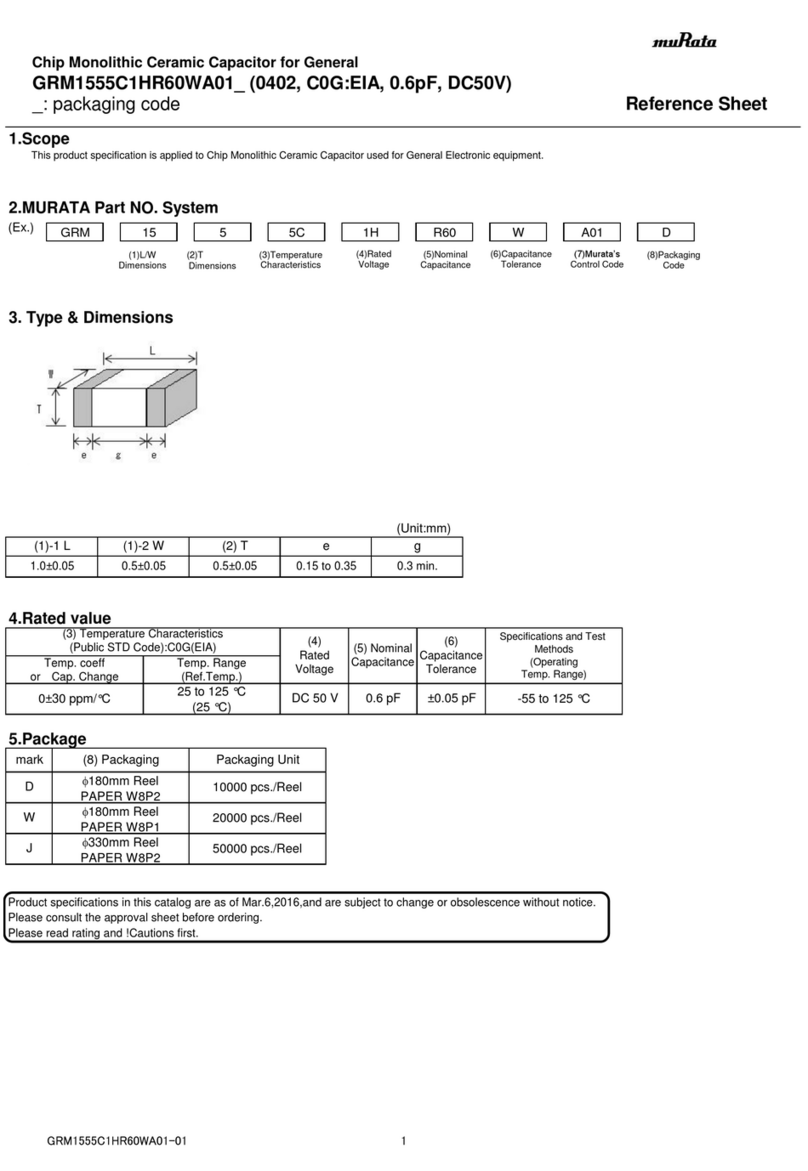

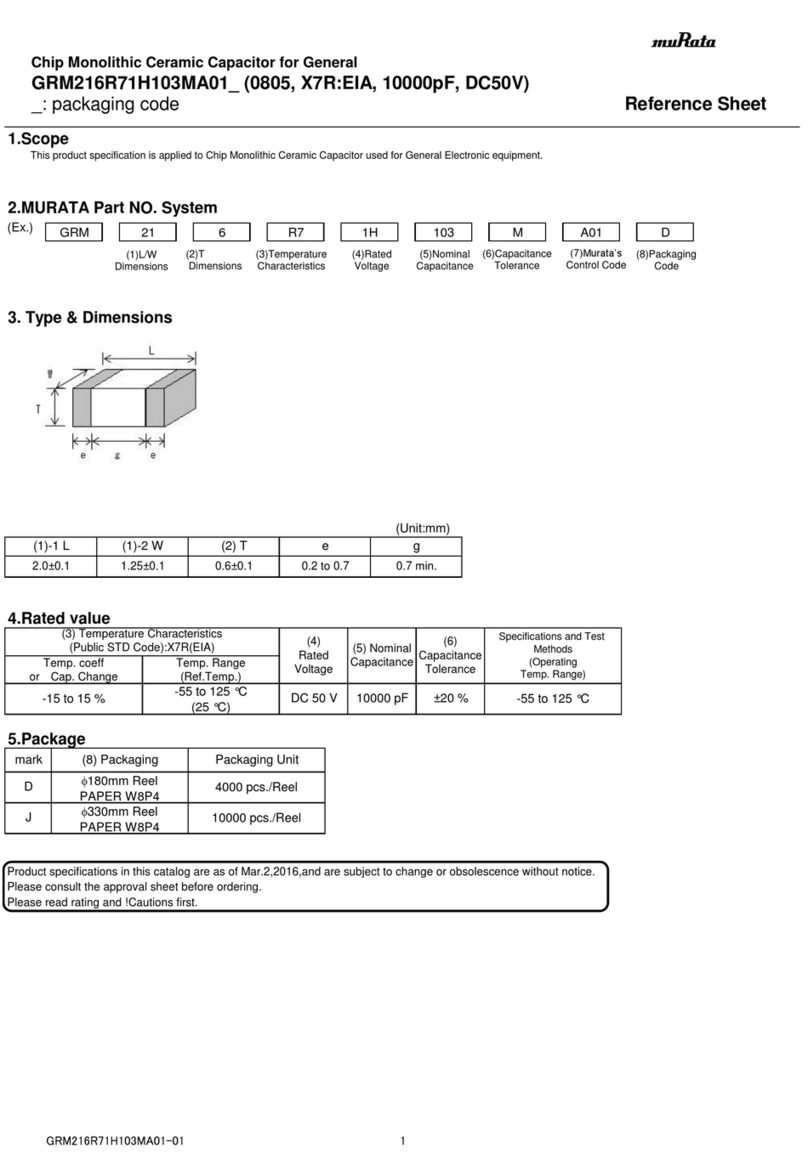

Q/D.F.

30pFmin. : Q≧350 R7/L8 : W.V.: 35Vmin.: 0.035 max.* ・Initial measurement for high dielectric constant type.

10pF and over, 30pF and below: * GCM155R71H 562 to 223: 0.05 max. Apply 200% of the rated DC voltage for one hour at the maximum

Q≧275+5C/2 GCM188L81H221 to 103 : 0.04 max. operating temperature ±3℃. Remove and set for 24±2 hours at

10pFmax.: Q ≧200+10C W.V.: 25Vmax. : 0.05 max. room temperature. Perform initial measurement.

C: Nominal Capacitance(pF) R9 : 0.075max.

I.R.

・F

(Whichever is smaller)

8 External Visual No defects or abnormalities Visual inspection

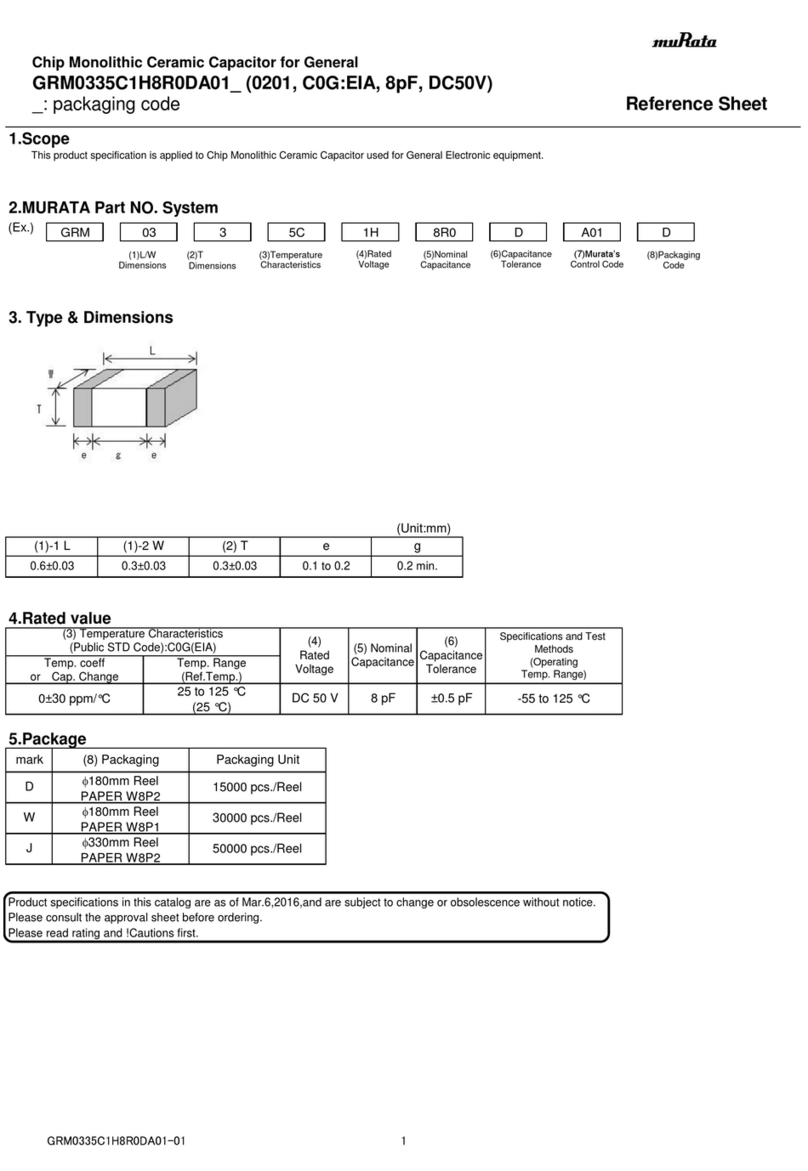

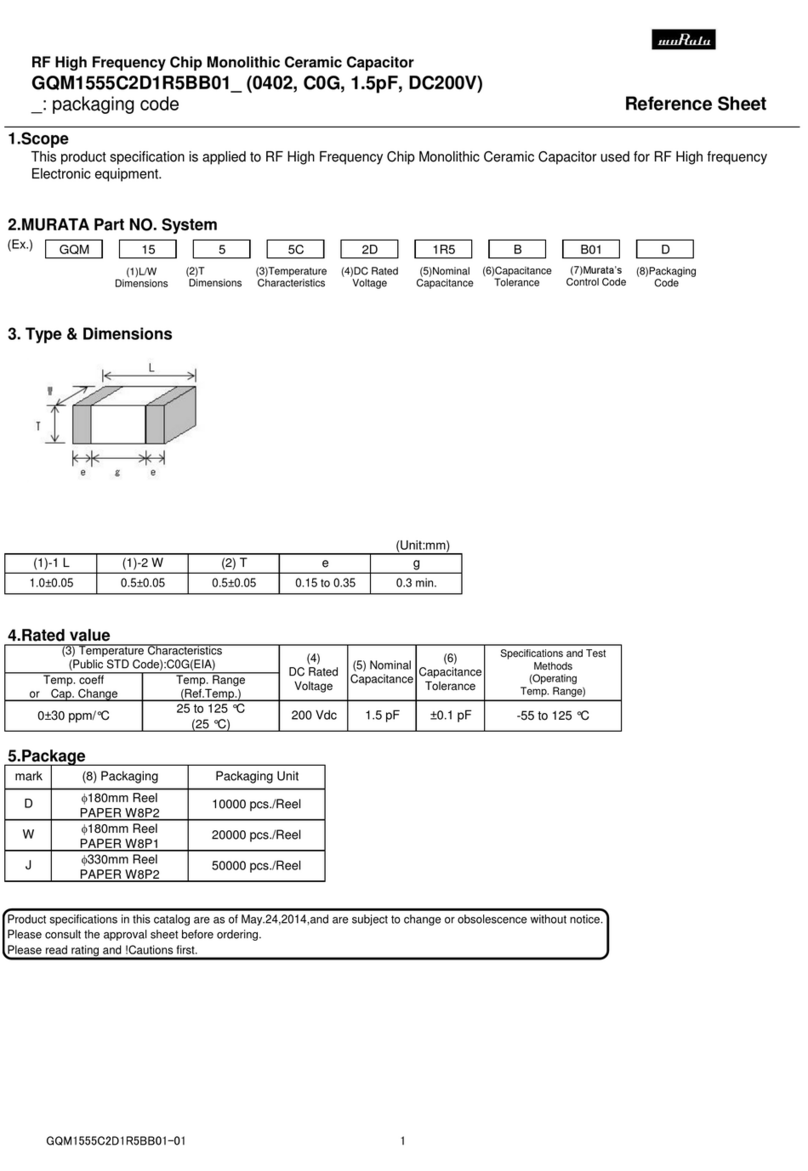

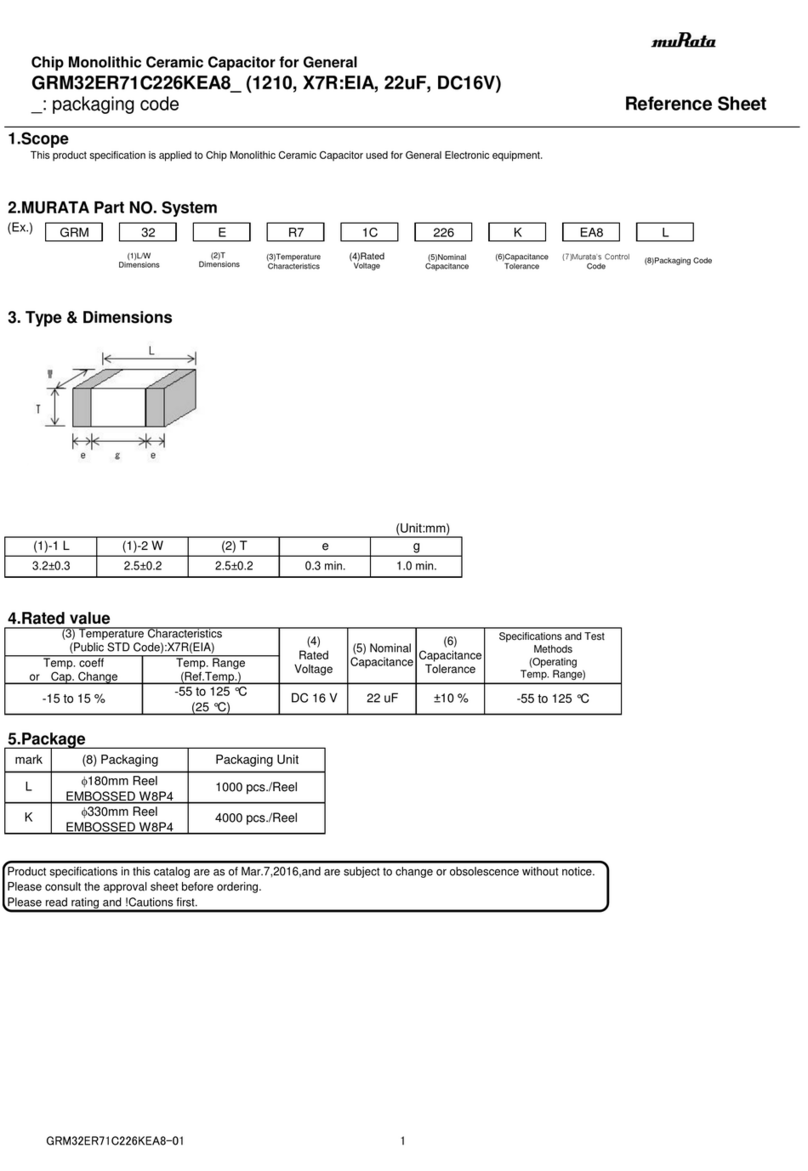

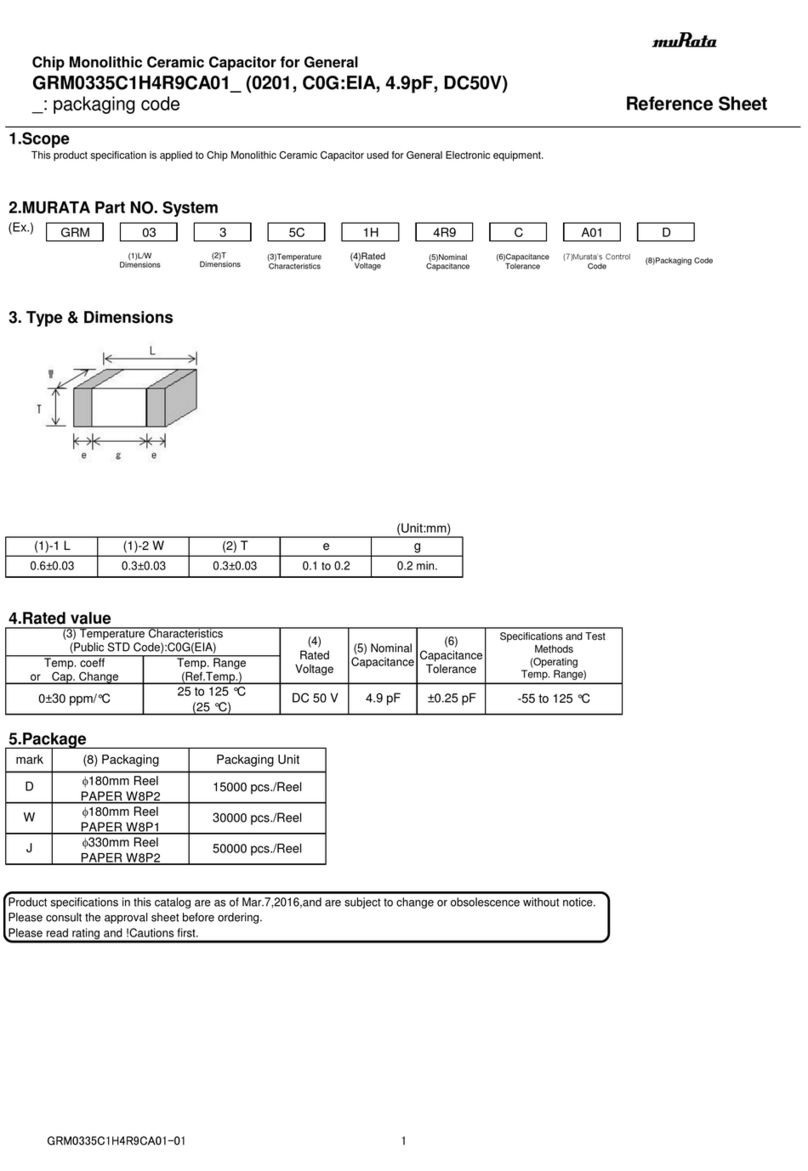

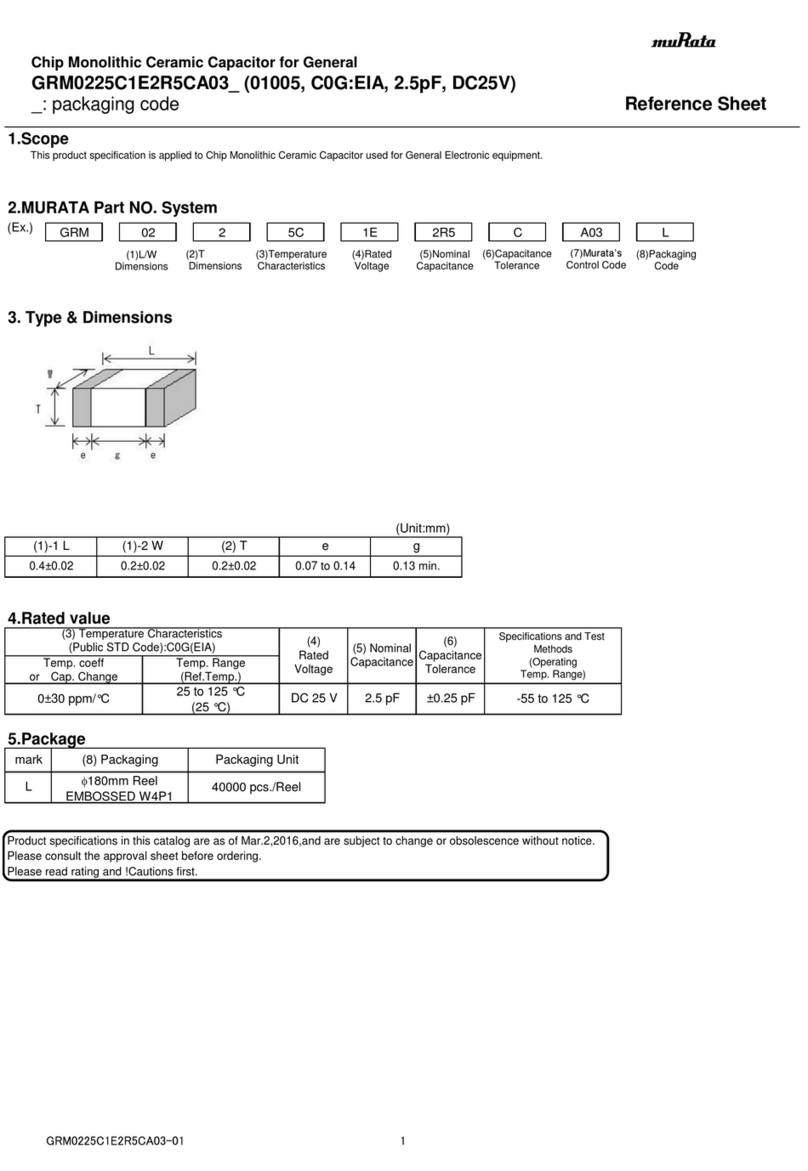

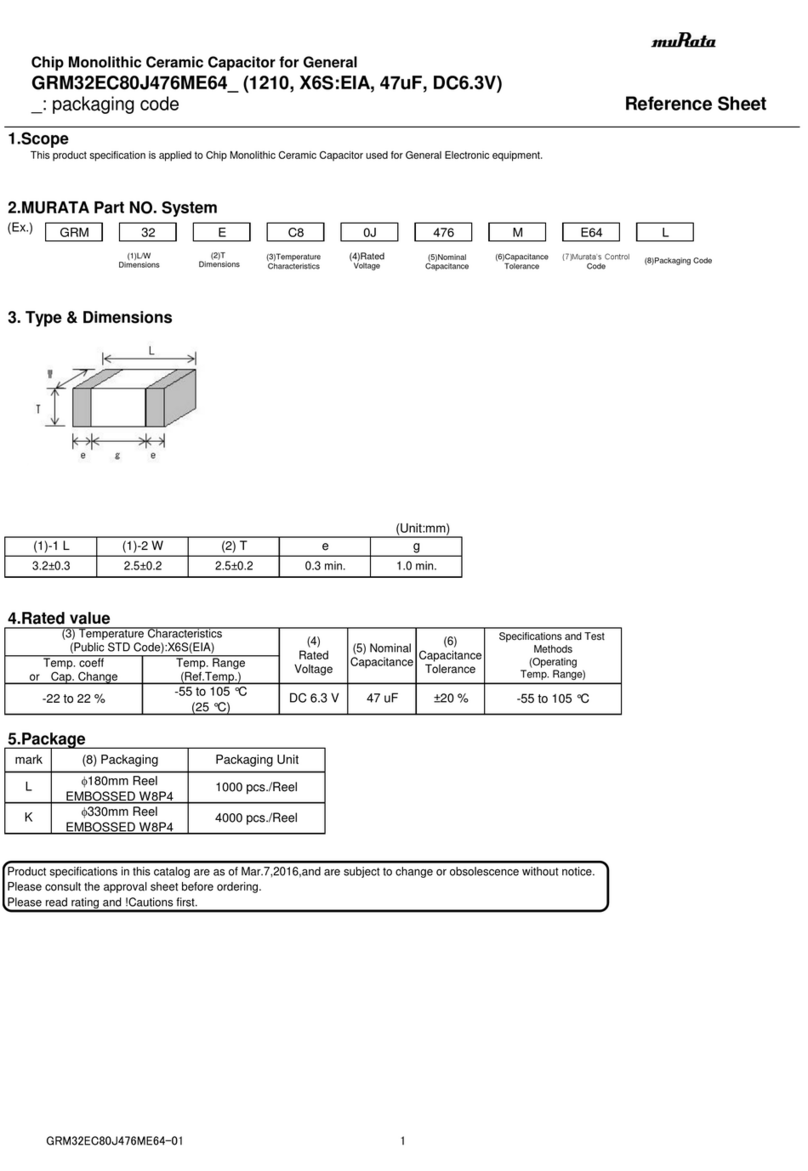

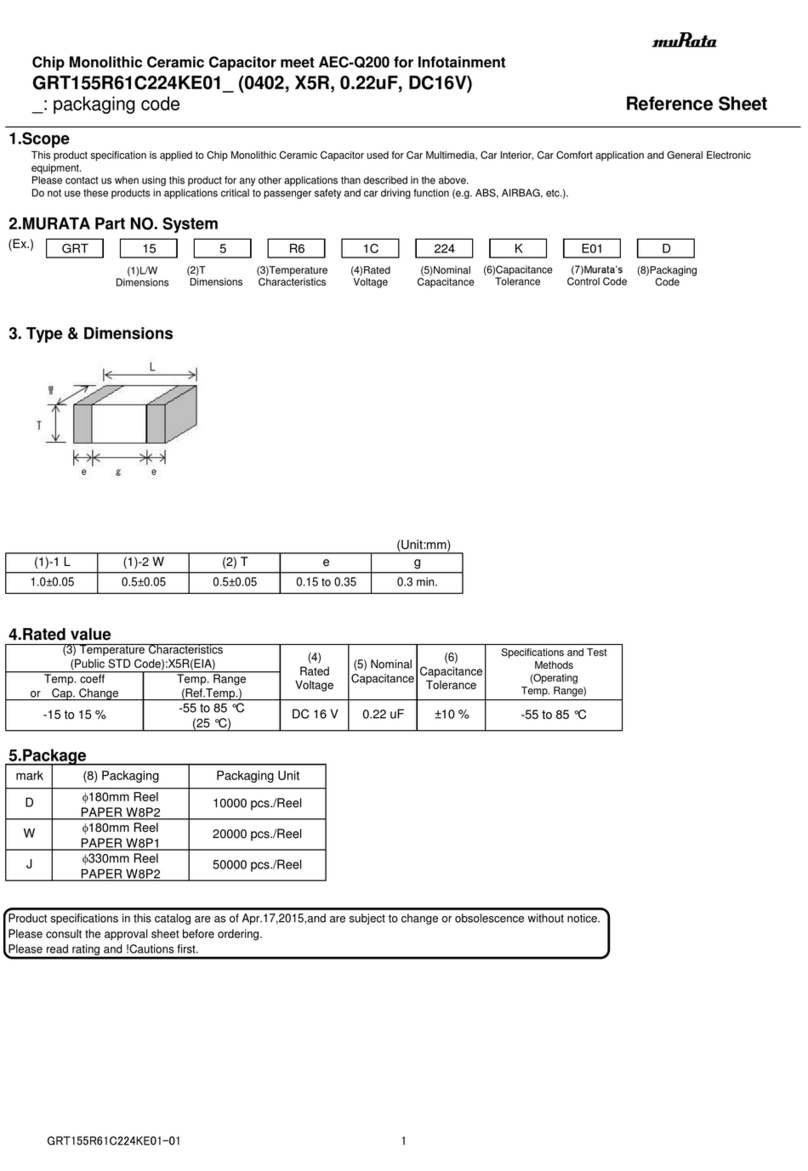

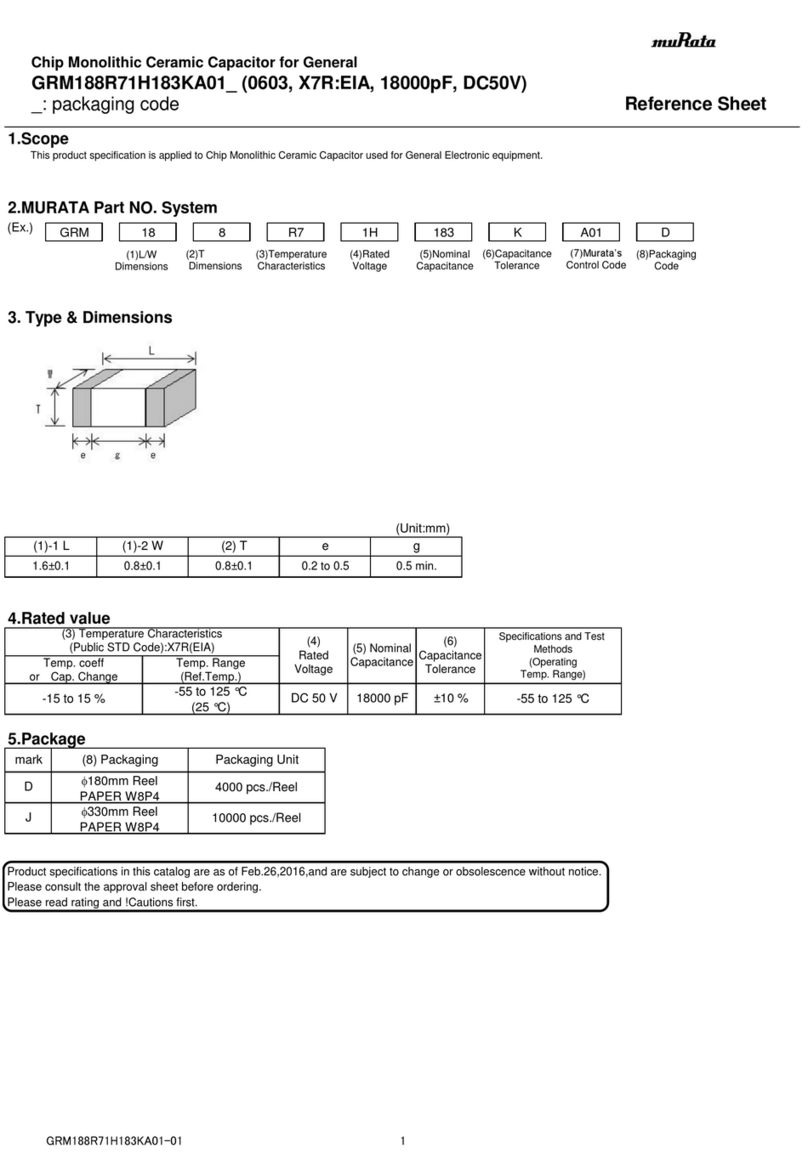

9 Physical Dimension Within the specified dimensions Using calipers

10 Resistance to Appearance No marking defects

Per MIL-STD-202 Method 215

Solvents Capacitance Within the specified tolerance Solvent 1 : 1 part (by volume) of isopropyl alcohol

3 parts (by volume) of mineral spirits

Q/D.F.

30pFmin. : Q≧1000 R7/L8 : W.V.: 25Vmin.: 0.025 max. Solvent 2 : Terpene defluxer

30pFmax.: Q ≧400+20C W.V.: 16V/10V : 0.035 max. Solvent 3 : 42 parts (by volume) of water

C: Nominal Capacitance(pF) R9 : 0.05max.

1 part (by volume) of propylene glycol monomethyl ether

1 part (by volume) of monoethanolamine

・F

(Whichever is smaller)

11 Mechanical Appearance No marking defects

Three shocks in each direction should be applied along 3 mutually

Shock Capacitance Within the specified tolerance

perpendicular axes of the test specimen (18 shocks).

The specified test pulse should be Half-sine and should have a

30pFmin. : Q≧1000 R7/L8 : W.V.: 25Vmin.: 0.025 max. duration :0.5ms, peak value:1500g and velocity change: 4.7m/s.

30pFmax.: Q ≧400+20C W.V.: 16V/10V : 0.035 max.

C: Nominal Capacitance(pF) R9 : 0.05max.

I.R.

・F

(Whichever is smaller)

12 Vibration Appearance No defects or abnormalities

Solder the capacitor to the test jig (glass epoxy board) in the same

Capacitance Within the specified tolerance

manner and under the same conditions as (19). The capacitor

should be subjected to a simple harmonic motion having a total

30pFmin. : Q≧1000 R7/L8 : W.V.: 25Vmin.: 0.025 max. amplitude of 1.5mm, the frequency being varied uniformly between

30pFmax.: Q ≧400+20C W.V.: 16V/10V : 0.035 max. the approximate limits of 10 and 2000Hz. The frequency range, from

C: Nominal Capacitance(pF) R9 : 0.05max. 10 to 2000Hz and return to 10Hz, should be traversed in

approximately 20 minutes. This motion should be applied for 12

I.R.

・Fitems in each 3 mutually perpendicular directions (total of 36 times).

(Whichever is smaller)

13 Resistance to The measured and observed characteristics should satisfy the

Immerse the capacitor in a eutectic solder solution at 260±5℃for

Soldering Heat specifications in the following table.

10±1 seconds. Set at room temperature for 24±2 hours, then

Appearance No marking defects

Capacitance Within the specified tolerance

・Initial measurement for high dielectric constant type

30pFmin. : Q≧1000 R7/L8 : W.V.: 25Vmin.: 0.025 max. Perform a heat treatment at 150+0/-10 ℃for one hour and then set

30pFmax.: Q ≧400+20C W.V.: 16V/10V : 0.035 max. for 24±2 hours at room temperature.

C: Nominal Capacitance(pF) R9 : 0.05max. Perform the initial measurement.

I.R. ・F

■AEC-Q200 Murata Standard Specification and Test Methods