MGC-02029B

Revised 06-03

Catalog Section 75

(00-02-0500)

Generator Control System FWMurphy

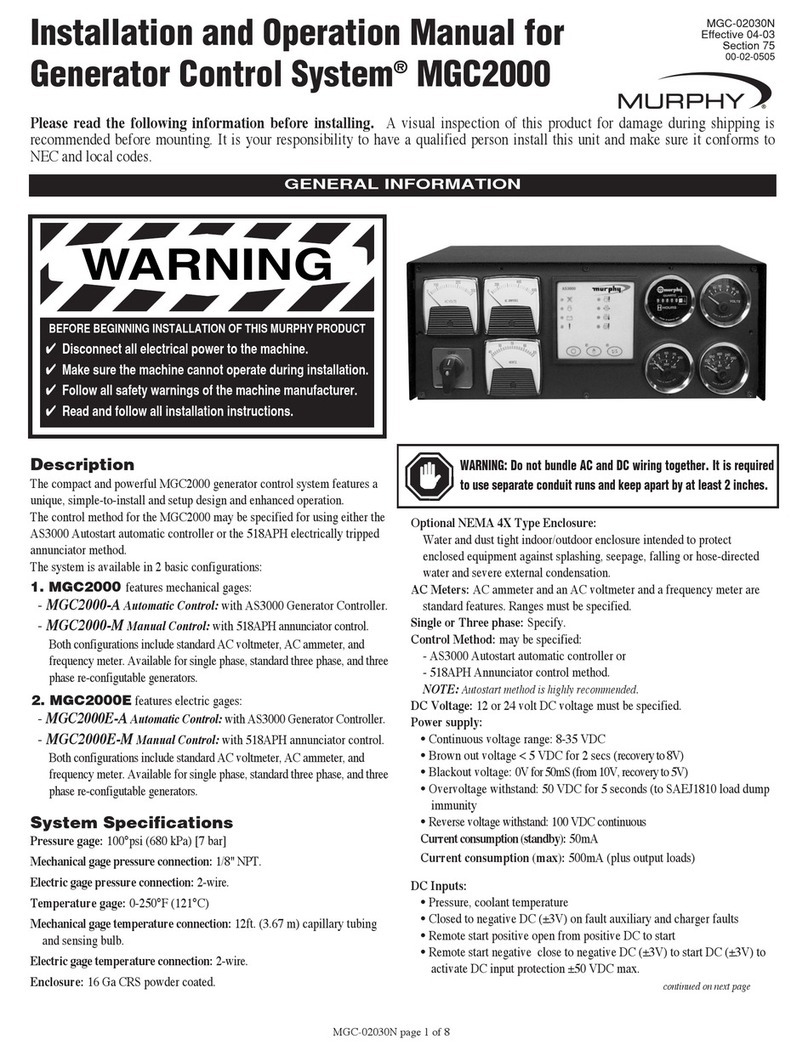

Description

The compact and powerful MGC2000 generator

control system features a unique, simple-to-install

and setup design and enhanced operation.

The control method for the MGC2000 may be

specified for using either the AS3000 Autostart

automatic controller or the 518APH electrically

tripped annunciator method.

The system is available in two basic configurations:

MGC2000

features mechanical gages:

- MGC2000-A Automatic Control: with

Murphy’s AS3000 Generator Controller.

- MGC2000-M Manual Control: with

518APH annunciator control.

Both configurations include standard AC

voltmeter, AC ammeter, and frequency meter.

Available for single-phase, standard three-phase,

and three-phase, re-configurable generators.

MGC2000E

features electric gages:

- MGC2000E-A Automatic Control: with

Murphy’s AS3000 Generator Controller.

- MGC2000E-M Manual Control: with

518APH annunciator control.

Both configurations include standard AC volt-

meter, AC ammeter, and frequency meter.

Available for single-phase, standard three-phase,

and three-phase, re-configurable generators.

Features

•

Dynamic design allows for easy installation

and full operation flexibility.

•

1/4 inch quick disconnect terminations

•

Shock mount assemblies to minimize damage

•

AC voltmeter and ammeter

•

Phase selector switch

•

Frequency meter: 45-65hz

•

Optional hourmeter; DC Voltmeter;

DC ammeter

•

First-out fault shutdown and indication

(AutoStart models only) of low oil pressure,

high temperature and auxiliary inputs

•

Inputs can be from engine-mounted fault

switches or panel-mounted SWICHGAGE®

instruments.

•

Magnetic pickup or generator AC speed

sensing (AutoStart models only). For automat-

ic crank release and overspeed fault shutdown.

Speed calibration is automatic–adjustment free.

Additional switch inputs allow optional remote

control of crank disconnect and overspeed fault.

•

Generator AC Hz meter output: 0-1 mA.

•

User-friendly: Well-thought-out routine for

faster and easier set up.

•

Interfaces with existing equipment: functions

seamlessly with many other Murphy instru-

ments and controls (AutoStart models only).

Specifications

Pressure Gage: 100°psi (680 kPa) [7 bar]

Mechanical Gage Pressure Connection: 1/8” NPT.

Electric Gage Pressure Connection: 2-wire.

Temperature Gage: 0-250°F (121°C)

Mechanical Gage Temperature Connection: 12ft.

(3.67 m) capillary tubing and sensing bulb.

Electric Gage Temperature Connection: 2-wire.

Enclosure: 16 Ga CRS powder coated.

Optional NEMA 4X Type Enclosure:

Water and dust tight indoor/outdoor enclosure

intended to protect enclosed equipment against

splashing, seepage, falling or hose-directed

water and severe external condensation.

AC Meters: AC ammeter and an AC voltmeter

and a frequency meter are standard features.

Ranges must be specified.

Single or Three Phase: Specify.

Control Method: may be specified:

- AS3000 Autostart automatic controller or

- 518APH Annunciator control method.

NOTE: Autostart method is highly recommended.

DC Voltage:

12 or 24 volt DC voltage must be specified.

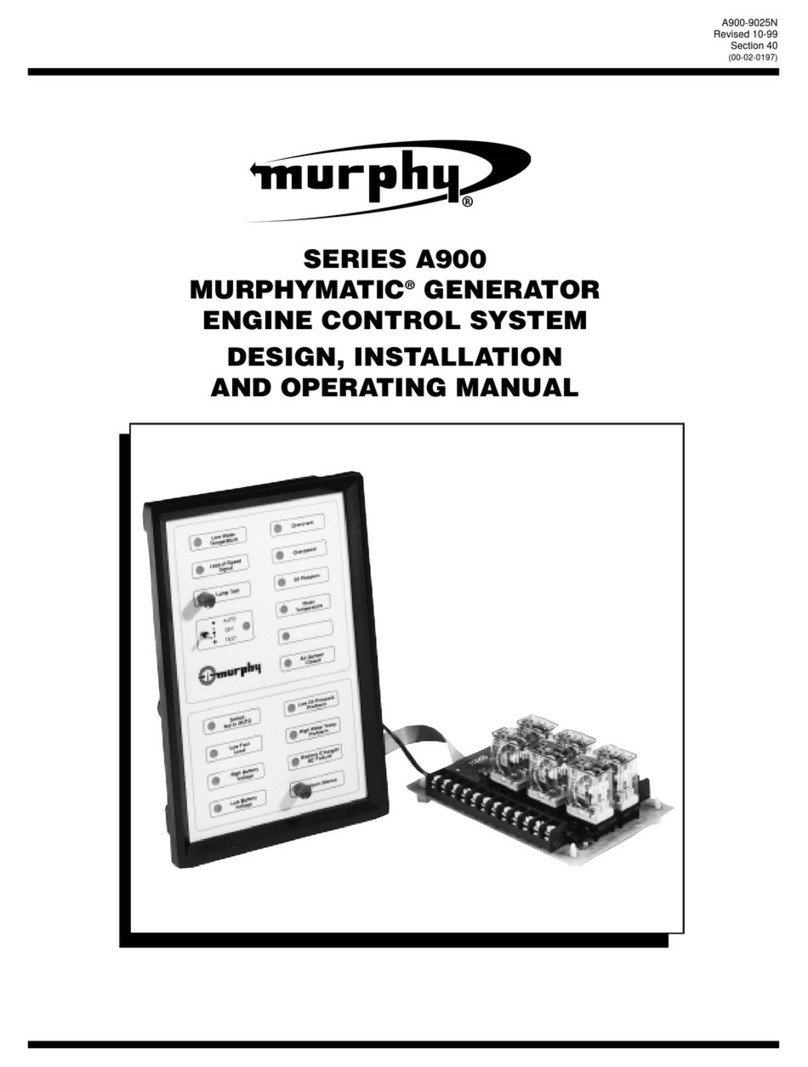

MGC2000

■

New Dynamic Design Allows for

Easy Installation and Full Operation

Flexibility

■

Features Murphy’s AS3000 Engine/

Generator Controller

■

User-Friendly, Well Thought-out

Routine for Faster/Easier Setup

AS3000 Autostart

Generator Controller Voltmeter

Hourmeter

Pressure Gage

Temperature Gage

Frequency Meter

1 - 3 Phase

Selector Switch 16 ga CRS Enclosure,

NEMA 4 Optional

AC Ammeter

AC Voltmeter