ww.harpkit.com 7

p

SUGGESTION: As you are applying the first coat of finish, watch carefully for glue residue

that prevents the finish from penetrating the wood. Take the time to sand or scrape the

glue off, before proceeding further with the finish. Scraping a sharp chisel across the

area usually does the trick without adding deep scratches in the surface. Yes, this can get

messy, but you’ll be glad you took the time to do it. Nothing looks more amateurish than a

woodworking project with glue spots still showing.

OIL or WAX -- Oil finishes will give your wood a low luster appearance, bringing out the nat-

ural color of the grain, but it tends to soak into the wood and appear dry and “thirsty” after

awhile. Some people are fond of a beeswax finish for a natural look, but it can show water

spots if it gets wet, so you may end up needing to re-wax or touch up the surface in the future.

POLYURETHANE VARNISH -- Any regular varnish will work fine on this project, but we

think a wipe-on polyurethane is the easiest to apply because it does not drip or sag -- just wipe

on a thin coat and wipe off the excess. The advantages of this finish are its simple application,

minimal odor, good durability, and deep, soft luster.

LACQUER -- Many professional instrument makers use lacquer for their finish. The most

readily available lacquer is called Deft Clear Wood Finish. It is best to purchase a can of liquid

to brush on as a sealer coat first, and then use an aerosol can of the same product to spray on

the final coats. The advantage of this finish is its quick drying time, but the disadvantage is the

strong odor of the toxic lacquer fumes.

FINAL ASSEMBLY AND STRINGING

When the finish is dry, you can begin assembling

the parts with the hardware provided. First thing

is to make sure the t-nuts are installed in the tang

of the neck and inside the body.

We should have already installed a t-nut in the

tang of the neck (fig 14, pg 5). If it is not there

yet, then press it in carefully (don’t pound with a

hammer) so as not to crack the wood.

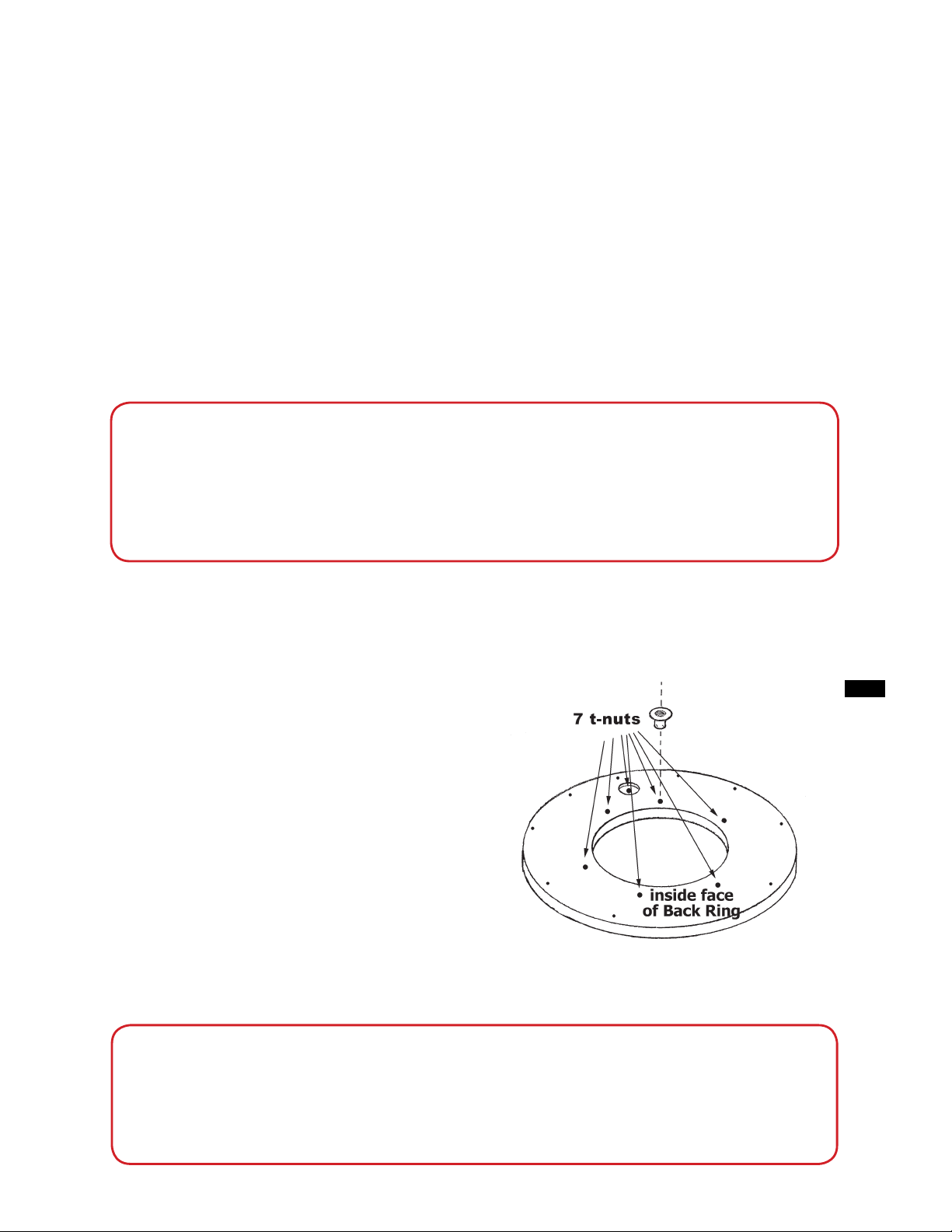

Then you’ll need to unscrew the back ring from

the body to check for seven t-nuts inside there.

Install them carefully by pressing them in against

a flat table so as not to crack the wood. (fig 15) A

drill press (turned off) works great as a pressing

tool.

FIG. 15

SUGGESTION: Sometimes the threads get a little misshapen on the t-nuts, making it hard

to start the cap-screws into them. It is helpful to take a moment now to drive a cap-screw

through each t-nut from the inside of the back ring, just to clear out any burrs or straighten

the threads. Then you’ll have an easier time with the cap screws later. Don’t leave the

screw in the t-nut though. Just thread it in and back out again to clear the threads.

p