651-439-91208

____20.

____21.

____22.

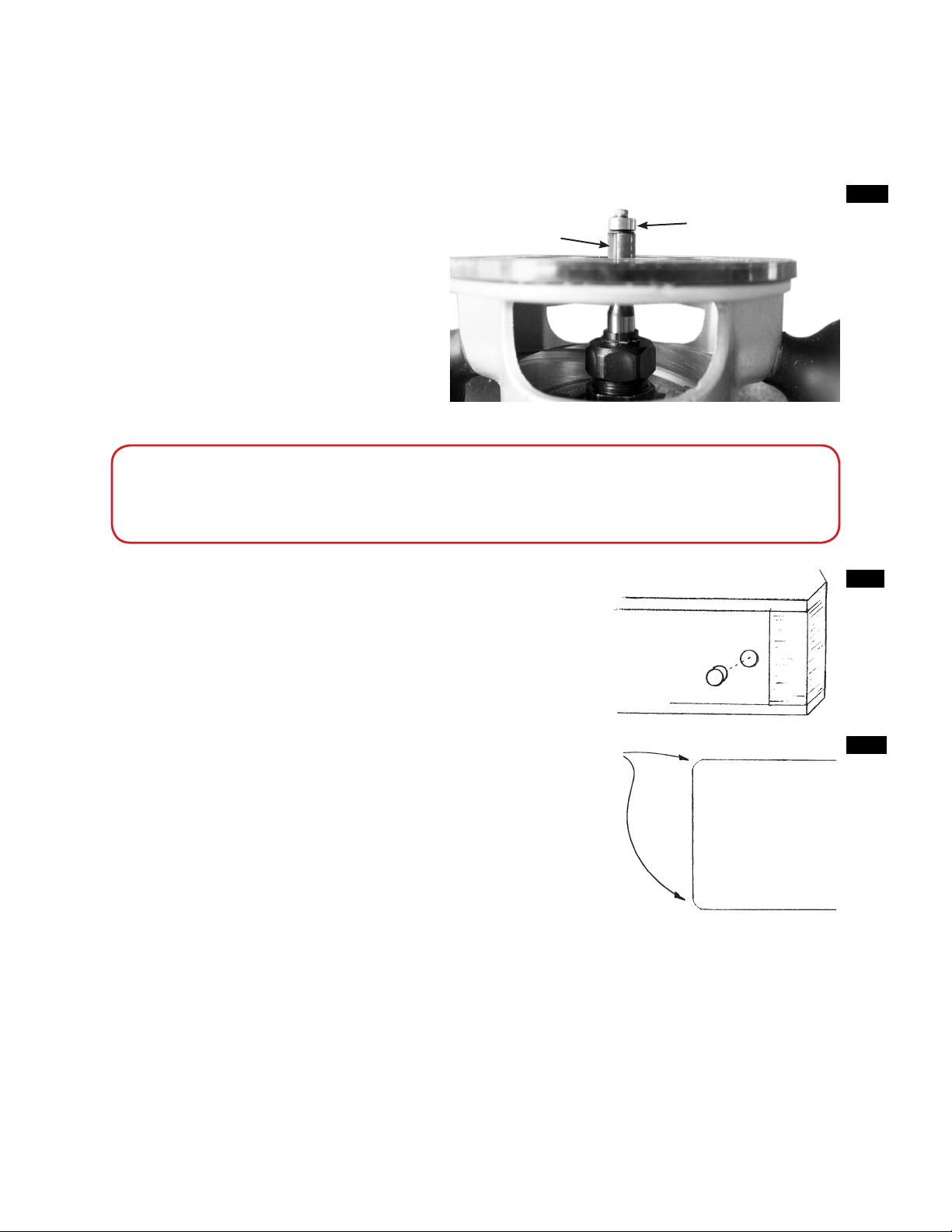

Notice that the BRIDGES have a few tiny

holes drilled along the tops. These are

for marking dots to help guide you in

your playing. You need to fill these holes

with black DELRIN (from the excess

length provided in the kit). Push one end of a DELRIN rod into a hole and clip it off as close to

the wood as you can with a wire cutter. Repeat this procedure for each hole, but be careful not

to use too much DELRIN from one rod. You must leave the rods long enough to span the entire

length of the maple BRIDGES. (fig. 15)

Sand these marking dots flush with the surface of the bridges.

FIG. 15

If the BRASS TUBES are tarnished, use steel wool or a scouring pad to clean and brighten them

up.

When satisfied with your sanding, apply the finish of your choice. Here are a few suggestions:

STAINS or DYES -- These are coloring agents and should only be used if you want to change the

natural color of the wood. We usually do not apply stains to our projects, especially when they

are made with naturally beautiful hardwoods such as cherry or walnut. These woods look best

with a clear finish. But, if you want to color the wood, your staining should be accomplished

before applying a surface finish such as oil, varnish, or lacquer.

OIL or WAX -- Be very cautious about using an oil or wax finish. If this type of finish gets into

the tuning pin holes, it will act as a lubricant, and you may have trouble keeping the instru-

ment in tune. Oil finishes will give your wood a low luster appearance, bringing out the natural

color of the grain, but it tends to soak into the wood and appear dry and “thirsty” after awhile.

Some people are fond of a beeswax finish for a natural look, but it can show water spots if it gets

wet, so you may end up needing to re-wax or touch up the surface in the future.

POLYURETHANE VARNISH -- Any regular varnish will work fine on this project, but we think

a wipe-on (gel) polyurethane is the easiest to apply because it does not drip or sag -- just wipe

on a thin coat and wipe off the excess. Our complete finishing kit includes a half-pint can of

satin gel polyurethane (instructions printed right on the can), plus sandpaper sheets, and foam

applicator for the first coat. The advantages of this finish are its simple application, minimal

odor, good durability, and deep, soft luster.

LACQUER -- Many professional instrument makers use lacquer for their finish. The most read-

ily available lacquer is called Deft Clear Wood Finish. It is best to purchase a can of liquid to

brush on as a sealer coat first, and then use an aerosol can of the same product to spray on the

final coats. The advantage of this finish is its quick drying time, but the disadvantage is the

strong odor of the toxic lacquer fumes.

Don’t forget to apply finish to the maple BRIDGES! We also like to apply one clear coat on the

BRASS TUBES to keep them shiny.

ROSETTES - Lightly sand and apply finish to the rosettes before installing them in the sound-

board. When dry, the rosettes can be glued in the soundboard holes using regular woodwork-

ing glue or super glue.