7

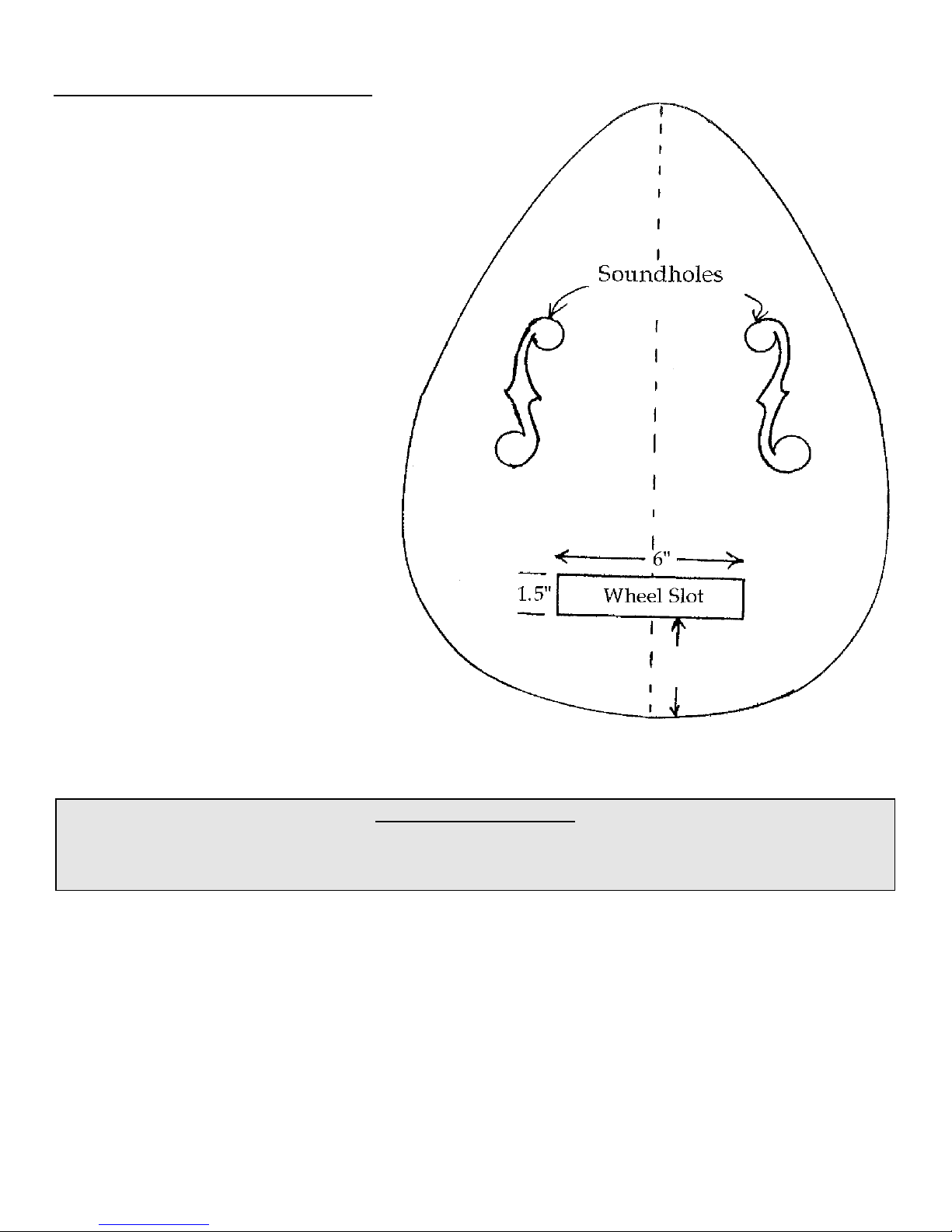

______13. Position the PREDRILLED INNER BRACE inside the SOUNDBOARD, just 1/8" from the

edge of the wheel slot, as shown.

Before gluing, taper the ends of the NYLON BUSHING and insert it

through the TAIL BLOCK and into the INNER BRACE. Then insert the

AXLE into the BUSHING, making sure that you can turn it easily with

your fingers. Glue the INNER BRACE to the SOUNDBOARD, about 1/8”

from the wheel opening, making sure the AXLE remains easy to turn. Use

weights or clamps to hold the brace until the glue dries.

______13a. Glue the

TRIANGLE INNER BRACE

along the other side of the wheel slot, 1/8"

away from the edge of the hole.

______14. This is a good time to secure the

NYLON BUSHING in place so it doesn’t slide

or turn when you play the instrument. Leave

1/8” of the BUSHING showing in the WHEEL

OPENING, as shown. The excess length

should stick out at the tail end. Put some

epoxy glue or Superglue on the BUSHING at

the inside edges of the BRACE and the TAIL

to secure it in this position, keeping the glue

away from the outside of the instrument.

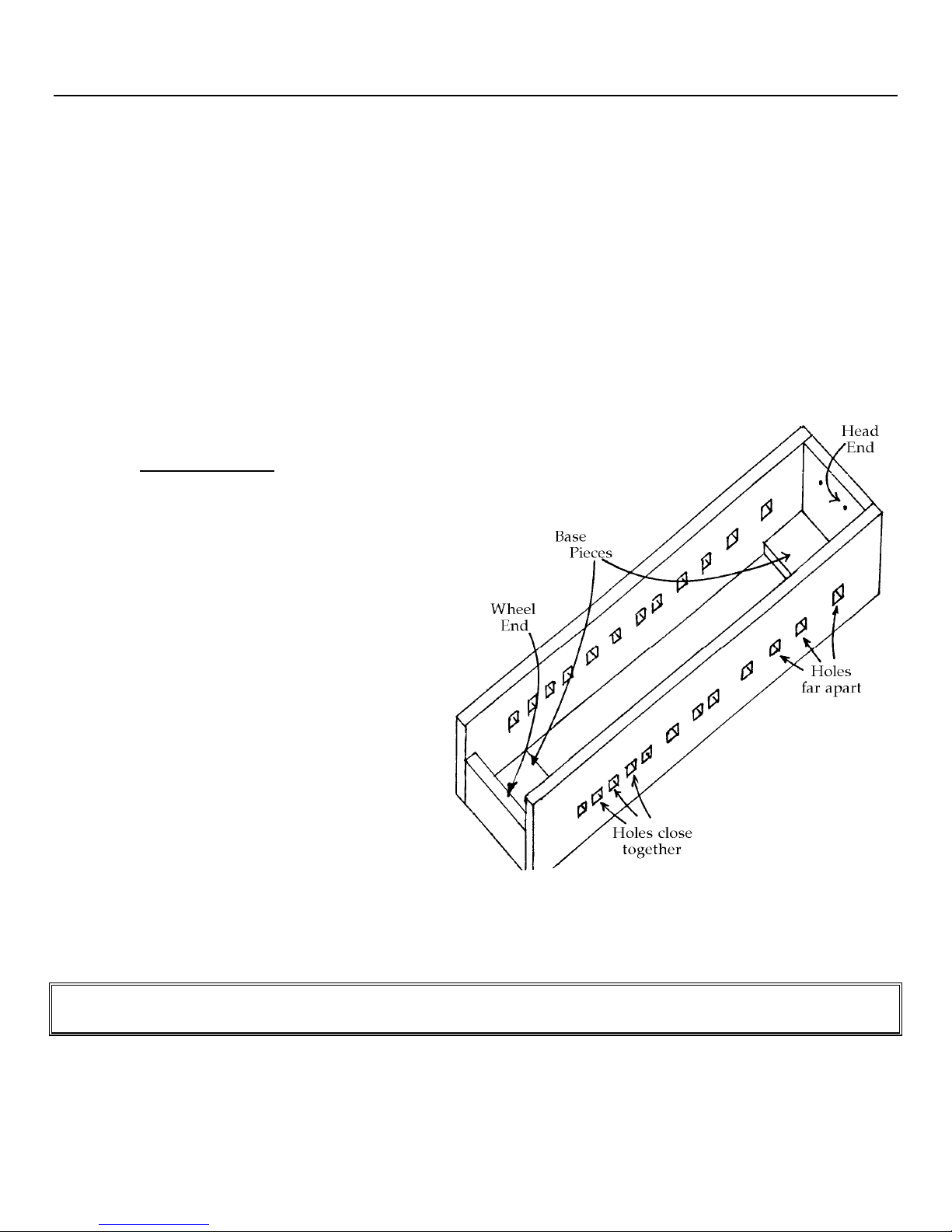

Add the two SUPPORT BLOCKS over the

ends of the PREDRILLED BRACE, gluing them onto the ends of the brace and to the inside of the

SIDES, as shown. This anchors the BRACE securely at the ends and helps reduce unwanted

overtones in the melody strings. Clamp them to the sides until dry.

THE BACK

15. Check the fit of the BACK to the soundchamber. When satisfied, glue the BACK to the

soundchamber, spreading glue all the way around the circumference, including the HEEL and TAIL

blocks. Use weights or clamps to hold the parts firmly together until the glue dries.

16. Now is a good time to trim off the excess SOUNDBOARD and BACK to match the SIDES.

A router with a flush-cutting bit makes short work of this step, but you can also accomplish it by

hand with a rasp or some coarse sandpaper wrapped around a wood block. You may, if you wish,

leave a small lip of wood overhanging the sides.

In either case, it is important to clean off any excess glue that squeezed out along the joints. Glue

blobs, smudges, and drips may be difficult to see now, but they will show up on the finished

instrument like spinach in your teeth, so it is best to take care of these things as you go along. We

like to clean away excess glue before it gets rock-hard, using a sharp chisel or knife to peel it off the

wood.