5

© Musicmaker’s Kits, Inc

All rights reserved

APPLYING THE FINISHING

STAIN -- STAINS are coloring agents and should only be used if you dislike the natural color of the wood. We

usually do not apply stains to our projects, especially when they are made with naturally beautiful hardwoods such as on

this project. These woods look very nice with just a clear finish. But, if you want to color the wood differently, your stain-

ing should be accomplished before applying a surface finish such as oil, varnish, or lacquer.

OIL -- People have had problems with oil finishes on the Reverie Harp. If the oil drips into the tuning pin holes, it

acts as a lubricant, so the pins turn too easily and won’t keep the strings in tune. Oil finish also tends to “hold” dust more

than other finishes, making it hard to keep the instrument clean under the strings. So we tell people NOT to apply an oil

finish on this instrument. If you are an expert at hand-rubbing high quality tung oil, and you can keep the oil out of the

tuning pin holes, then proceed at your own risk.

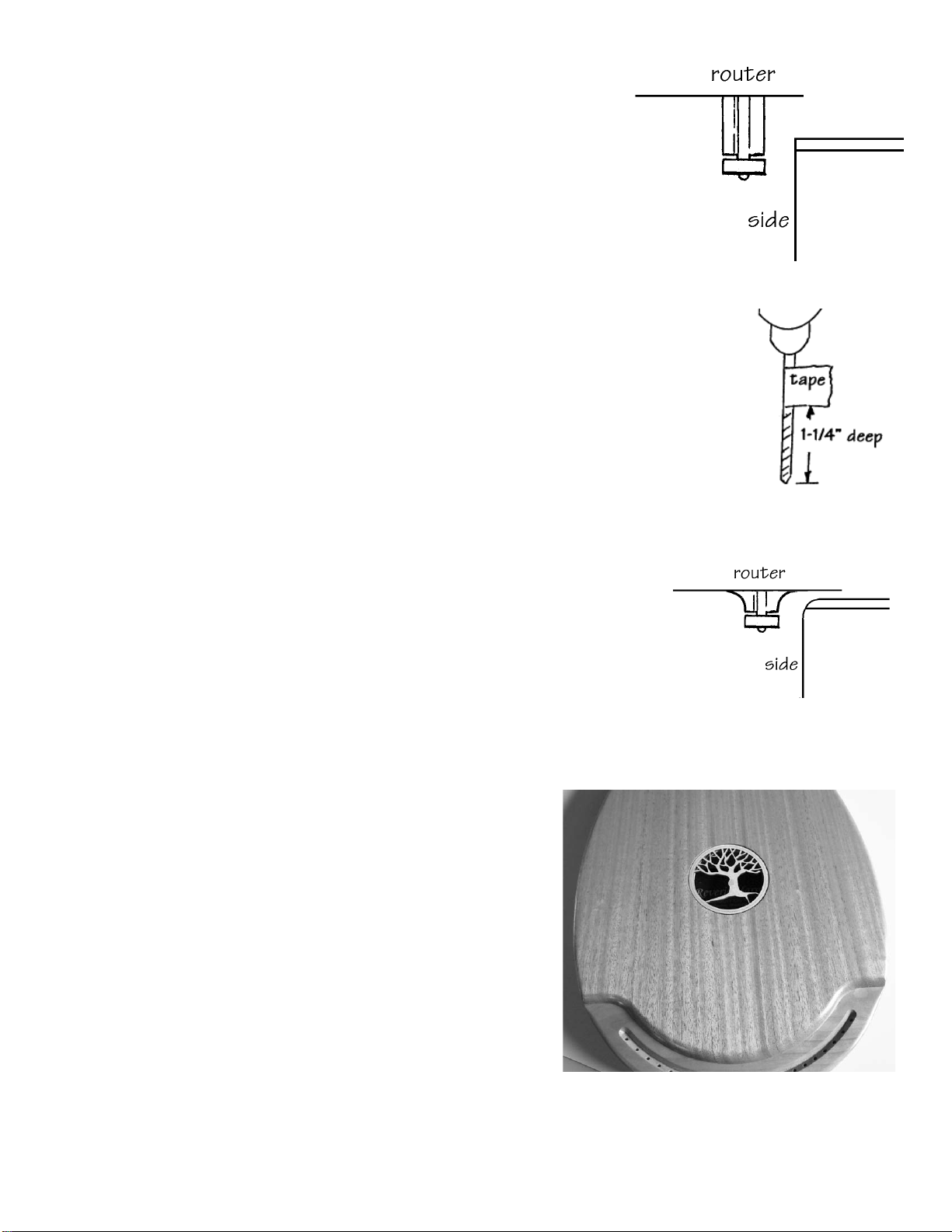

VARNISH -- Any satin or semi-gloss varnish will work on this project, but we like a wipe-on polyurethane

best. We offer this type of clear top coat, called MUSICMAKER’S INSTRUMENT FINISH. Our complete finishing kit

includes instructions and sandpaper sheets, along with a pint can of semi-gloss polyurethane varnish. The advantages of

this finish are its simple application, durability, minimal odor, and deep, soft luster.

LACQUER -- Many professional instrument makers use lacquer for their finish. The most readily available lac-

quer is called Deft Clear Wood Finish. It is best to purchase a can of liquid to brush on as a sealer coat first, and then use

an aerosol can of the same product to spray on the final coats. The advantage of this finish is its quick drying time, but the

disadvantage is the strong odor of the toxic lacquer fumes.

OUR BEST ADVICE: AVOID GLOSS FINISH unless you are an expert with spray equipment! Glossy fin-

ishes show off every speck of dust and irregularity in your sanding. Satin or semi-gloss is much easier for the amateur.

So go ahead -- choose your weapon and apply the finish of your choice, following the instructions on the container.

Sand between coats with fine (400-600 grit) sandpaper or #0000 steel wool. Consult instructions on the can for proper

drying time.

We also recommend polishing the brass tube with fine (#0000) steel wool and wiping a thin coat of varnish

on it to prevent tarnishing. Be sure to de-bur the ends of the tube if they are rough.

If you are not totally happy with the finish on your instrument when dry, try smoothing it out with #0000 steel wool

and applying a coat or two of paste wax (the same product used on wood floors) to bring out a nice luster.

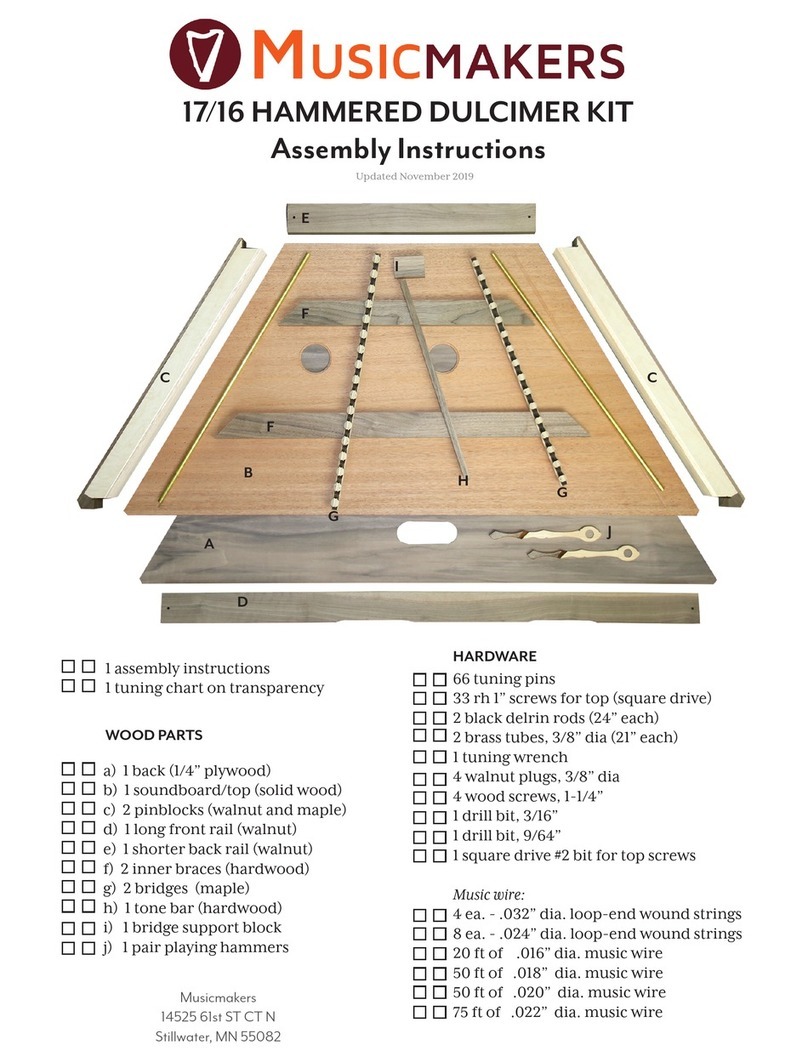

INSTALLING HARDWARE AND STRINGS

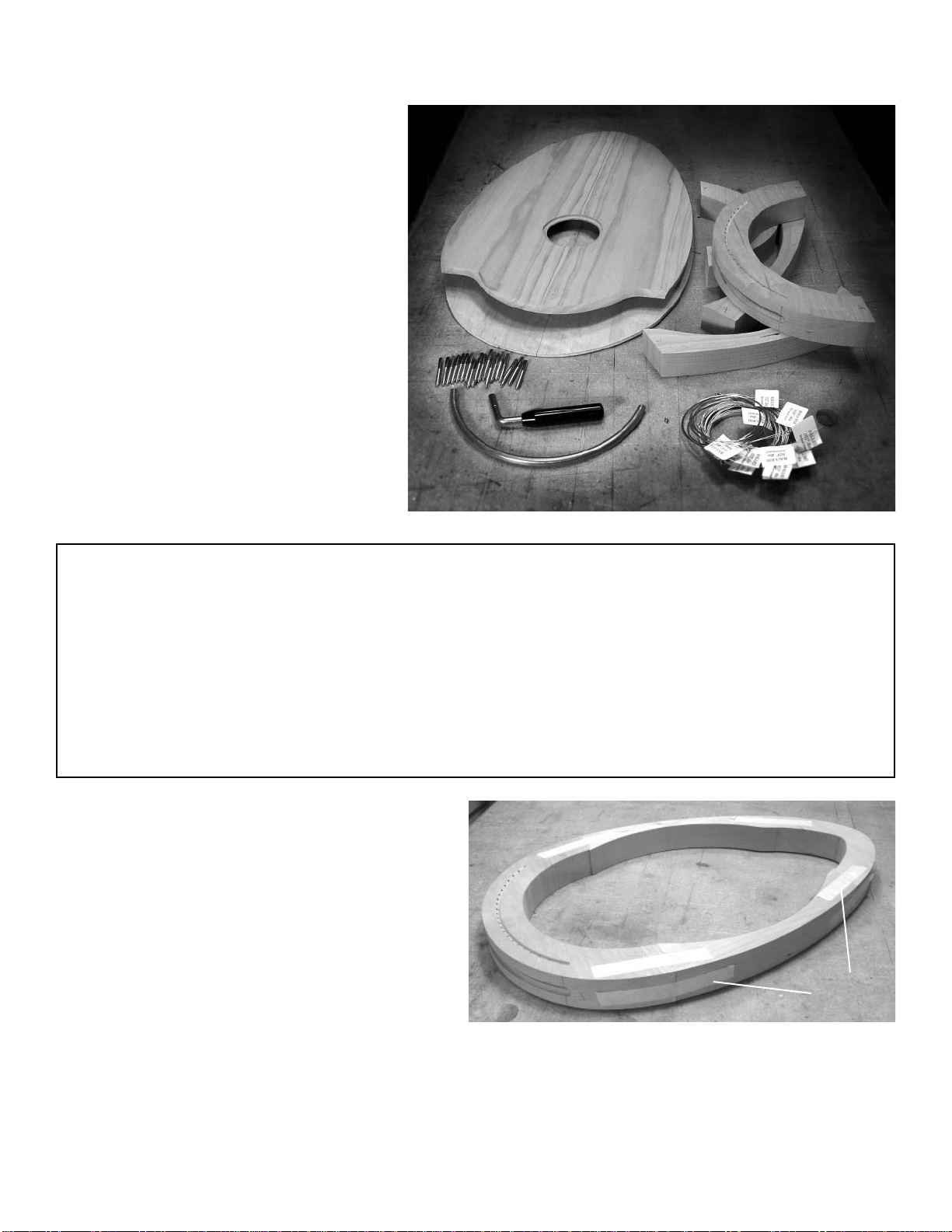

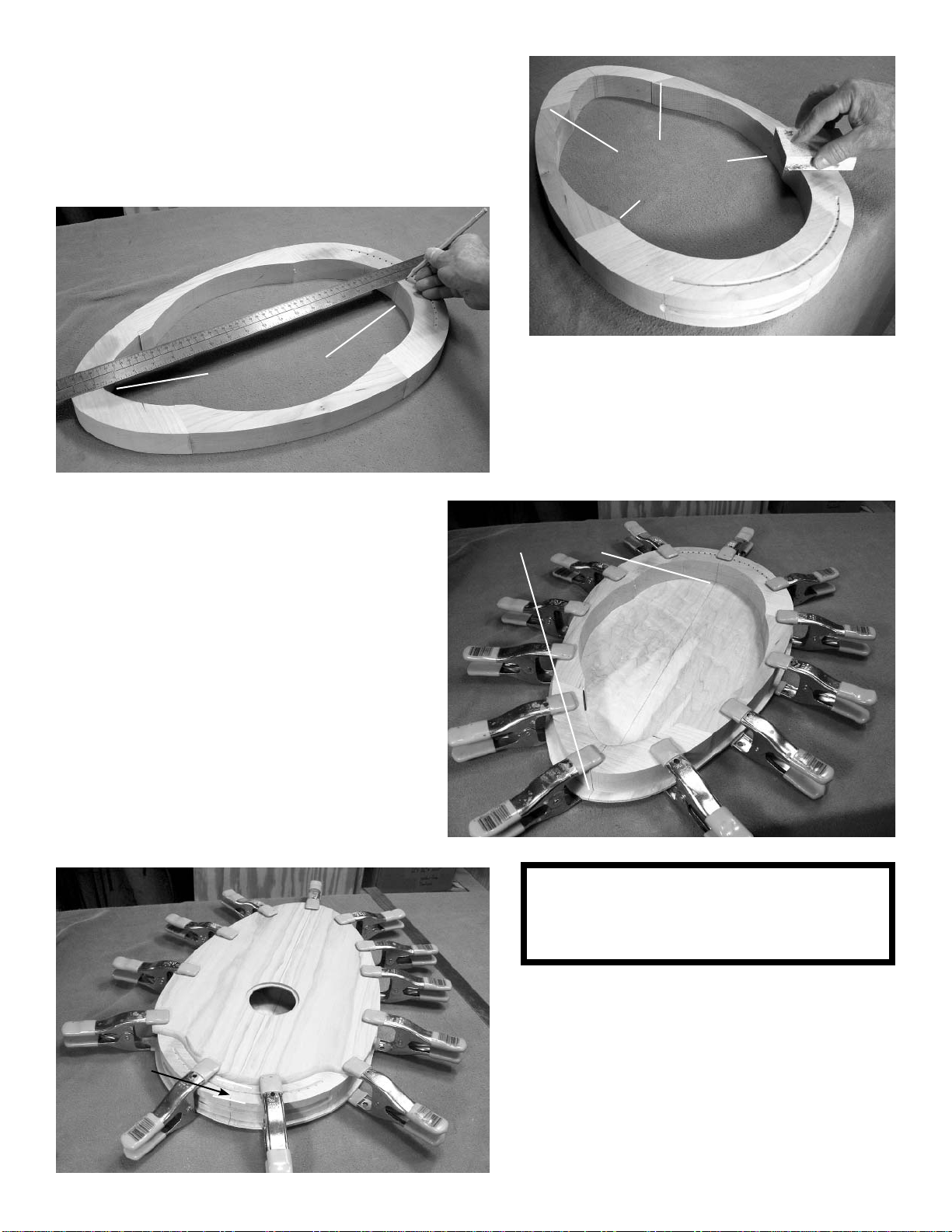

_____11. Once the finish is dry you can install the tuning pins. Use a hammer to tap them in,

threaded end first, until they stand about 7/8” above the wood surface, as shown.

_____14. Notice that you have 2-4 strings of each size in your string set. The idea is to string the instrument so

both sides are identical, with the heaviest strings in the middle and the lightest strings at the outside positions.

We have included 22 tiny washers. Thread one washer onto each string before installing. This will pre-

vent the “ball-end” of the string from digging into the wood at the tail end, thereby stabilizing the tuning

more quickly.

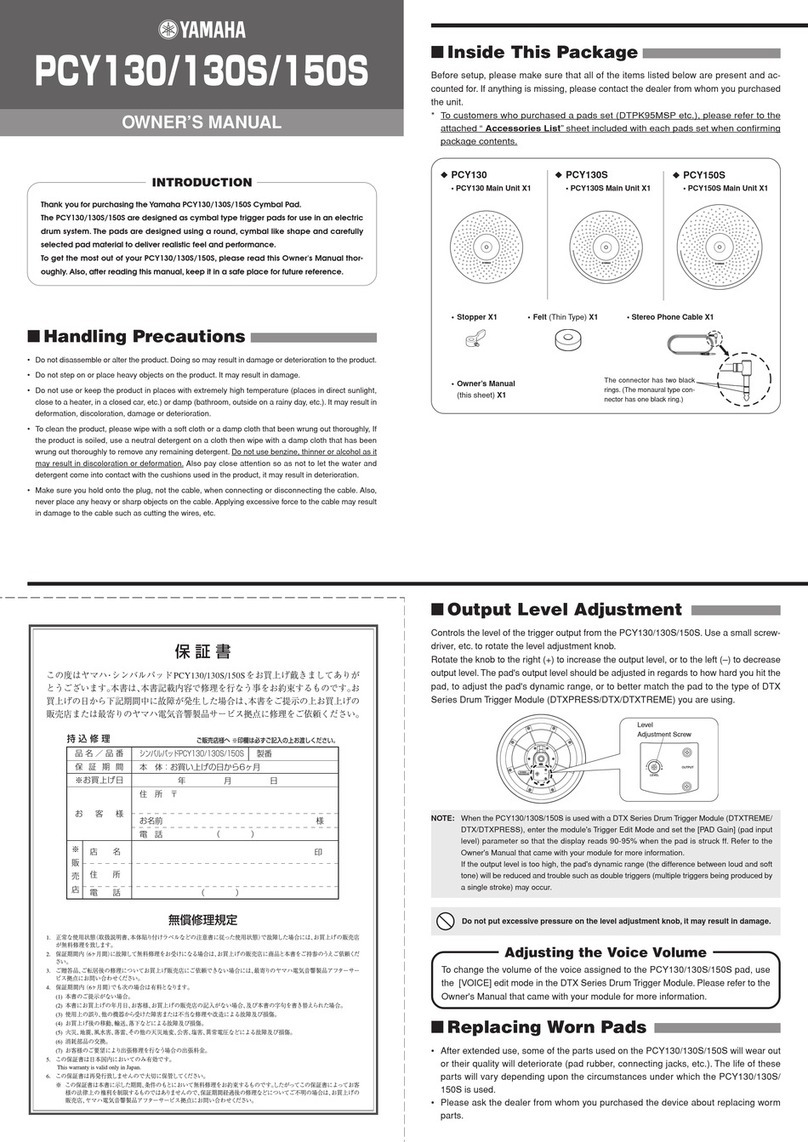

_____13. Position the curved brass tube near the

tail end of the instrument, so the ends are about

9-1/2” (240 mm) from the outermost tuning pins,

and centered between the sides of the soundboard.

Double-check to see that it sits flat without rock-

ing. If one end sticks up a little, try flipping the

tube over, or bending it slightly to get a flat fit.

Use piece of masking tape to hold it in place until

you install a couple strings.

_____12. Push the brass eyelets into the holes in the Tail End.