651-439-91202

www.harpkit.com

BEFORE YOU BEGIN

Inventory and inspect all your parts carefully. If anything is missing

or defective, please call or email us right away.

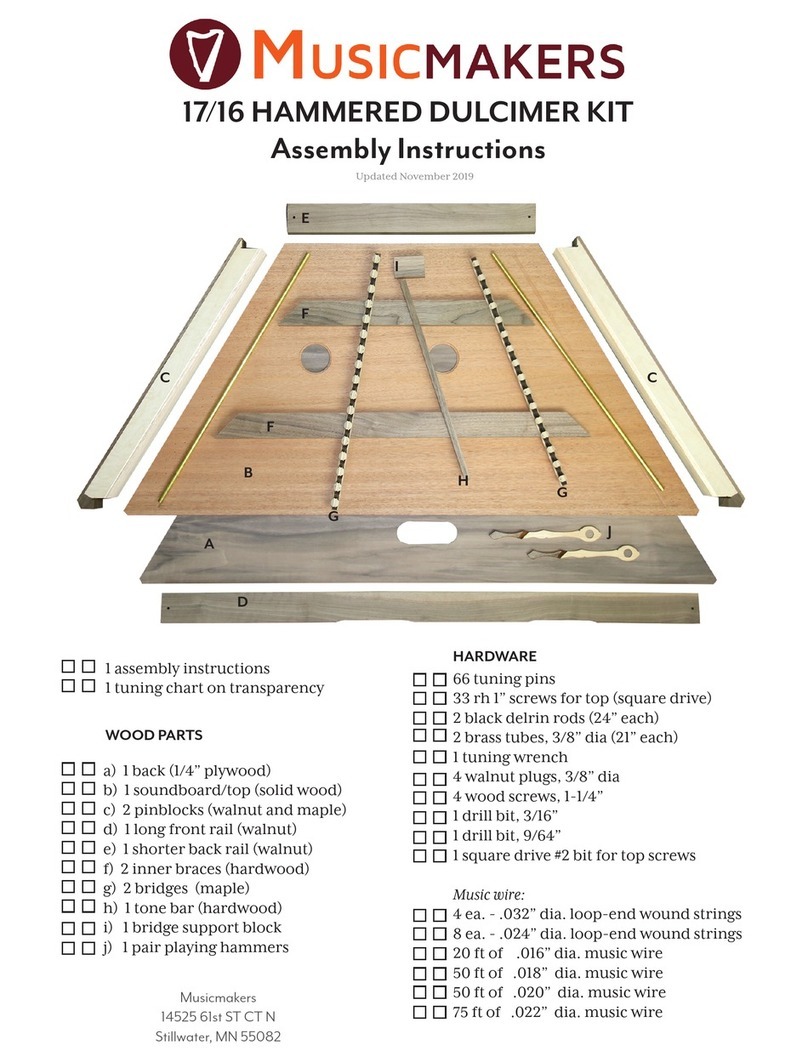

_____A.

_____B. It is a good idea to read through the entire assembly instructions before you start, just to get an

overview of the project. This will also help give you an idea of what tools you will want handy to

complete the project. We highly recommend having an orbital sander to complete this project.

It will help cut down on a lot of sanding time.

We also recommend checking off each step in the directions as you finish it. You might be skip-

ping forward to another part of the assembly while waiting for something to dry, and it helps

to keep track of where you left off.

A NOTE ABOUT GLUE

We strongly recommend that you use a common woodworking glue like Elmer’s Carpenter’s

Wood Glue or Titebond because they hold the parts more securely than most other

adhesives, and they are inexpensive and easy to use. DO NOT assemble the wood parts

of this project with 5-minute epoxy or super-glue or hot melt glue. The yellow colored

Elmer’s or Titebond is best.

When gluing parts together, be sure to put enough glue on the joint to wet the entire

surfaces to be joined. A good sign of proper gluing is that a little excess will squeeze out

around the joint when clamping pressure is applied. Too little glue may cause the parts

to separate later, whereas too much glue makes things messy. Always keep a damp rag

handy for quick cleanup, as necessary. It is especially helpful to keep your fingers clean

while gluing, because gluey fingerprints have the embarrassing tendency to appear on the

finished product in prominent places.

NOTE: Please note that some of the pictures shown in these directions are taken from

other harp models. The wood may appear a little different, but the steps to complete will

work the exact same in both kits. If you have any questions, don’t hesitate to give us a call.

p

THE SOUNDCHAMBER FRAME

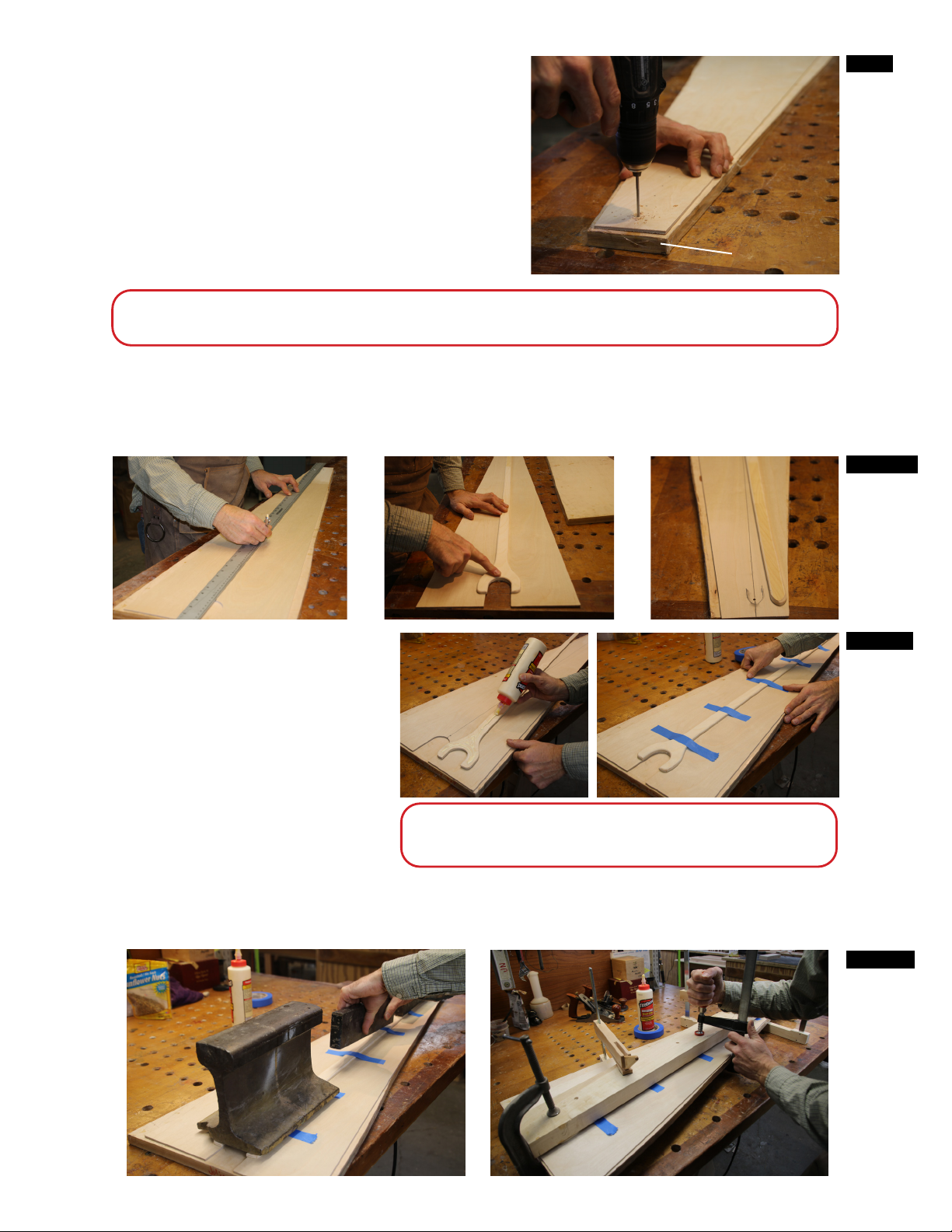

____1. Clamp the harp sides to your bench. This

will help prevent the sides from sliding

around during the assembly process. (Fig. 1)

(This may seem like an odd way to start, but

it really helps to hold both side pieces firmly

when drilling pilot holes for the screws. We

suggest reading through step 5 to under-

stand how the parts will go together.)

FIG. 1

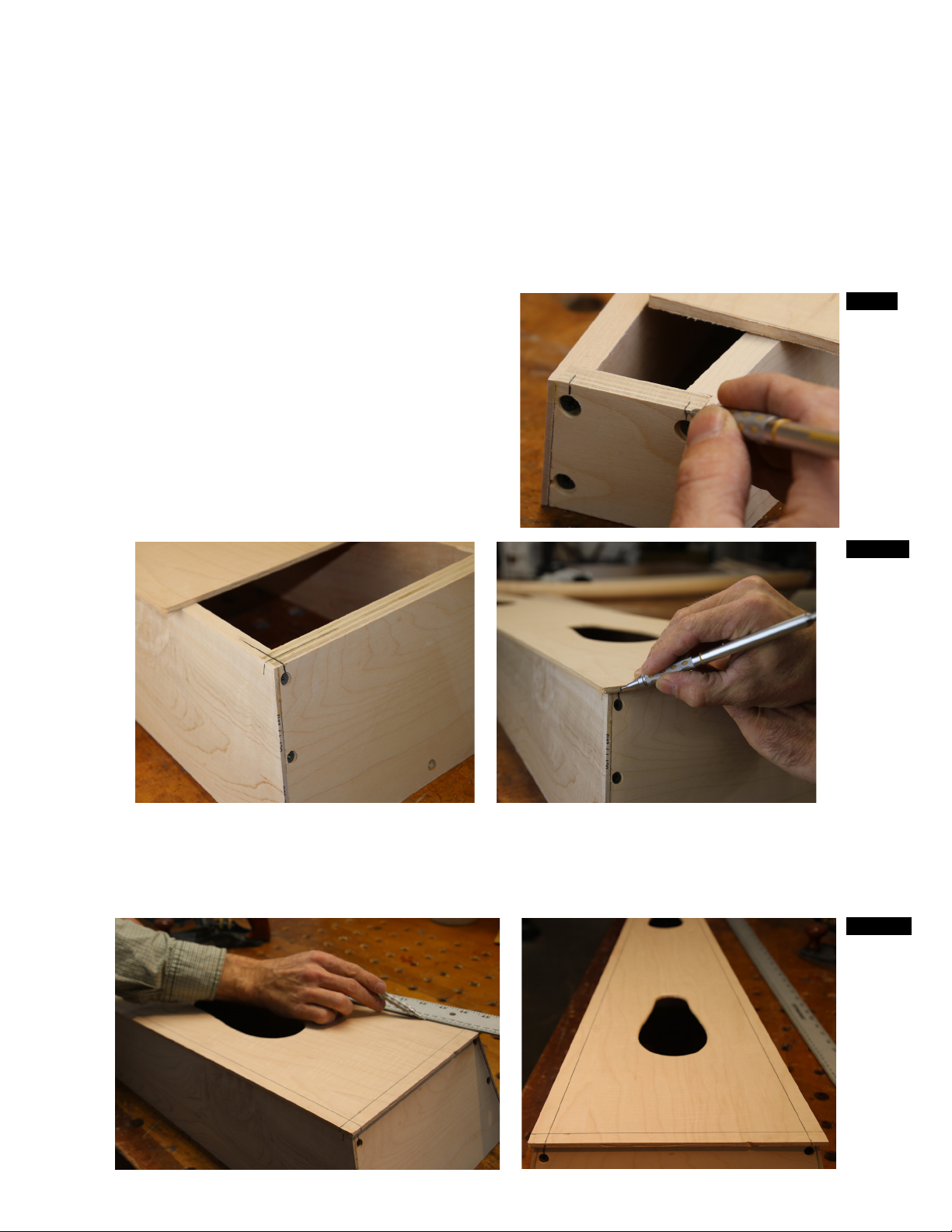

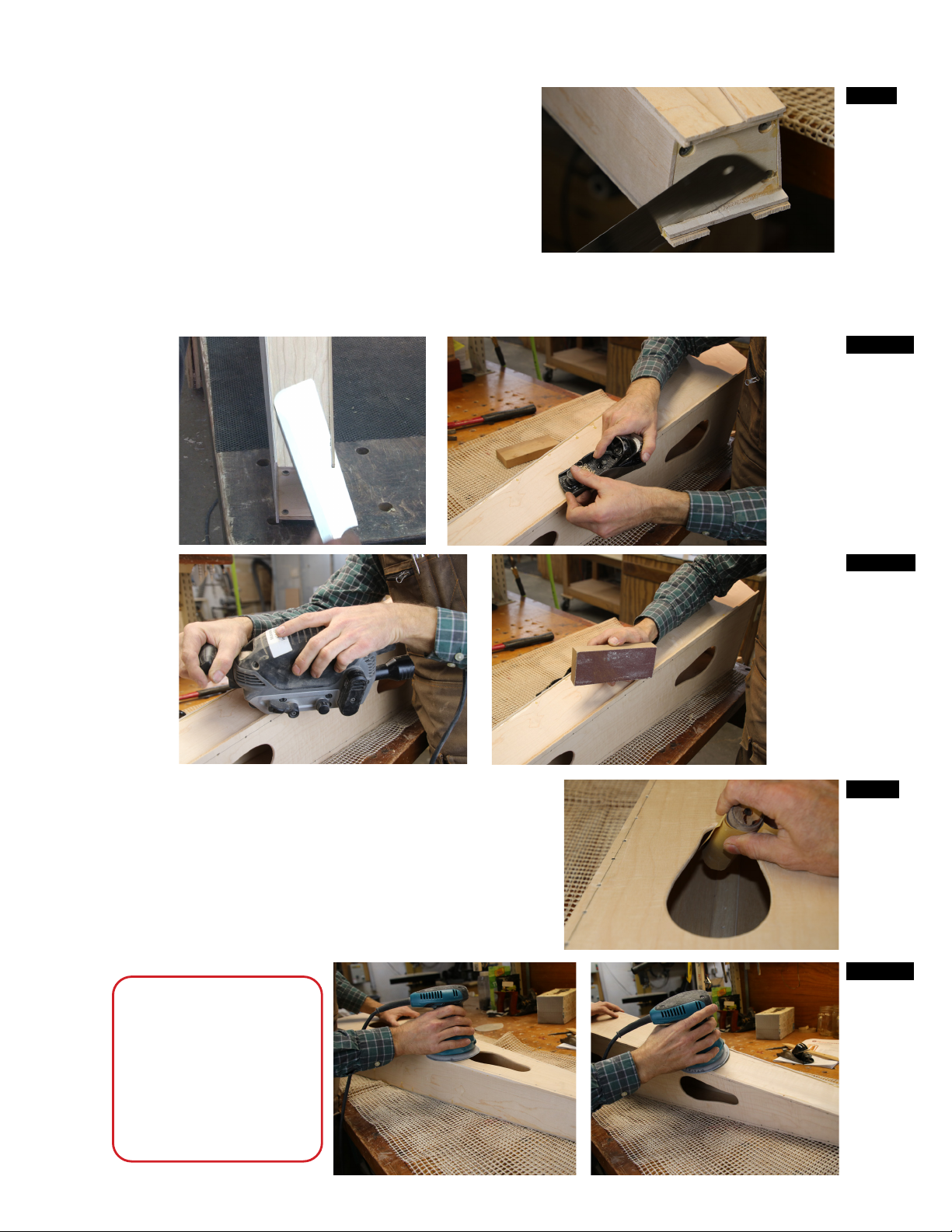

____2. Dry fit the base block and inner top block to to each side ensure a good fit. (fig. 2a) You’ll need

to check the fit on one side and then flip the part over to check the other side.

If the pieces aren’t perfect, you can adjust them with a hand plane or sanding block. It’s easier

to remove the excess BEFORE the parts are glued in place. You can remove the excess by

using a sanding block, hand plane, or power sander. (fig. 2b, 2c)

651-439-9120

Info@harpkit.com