8.

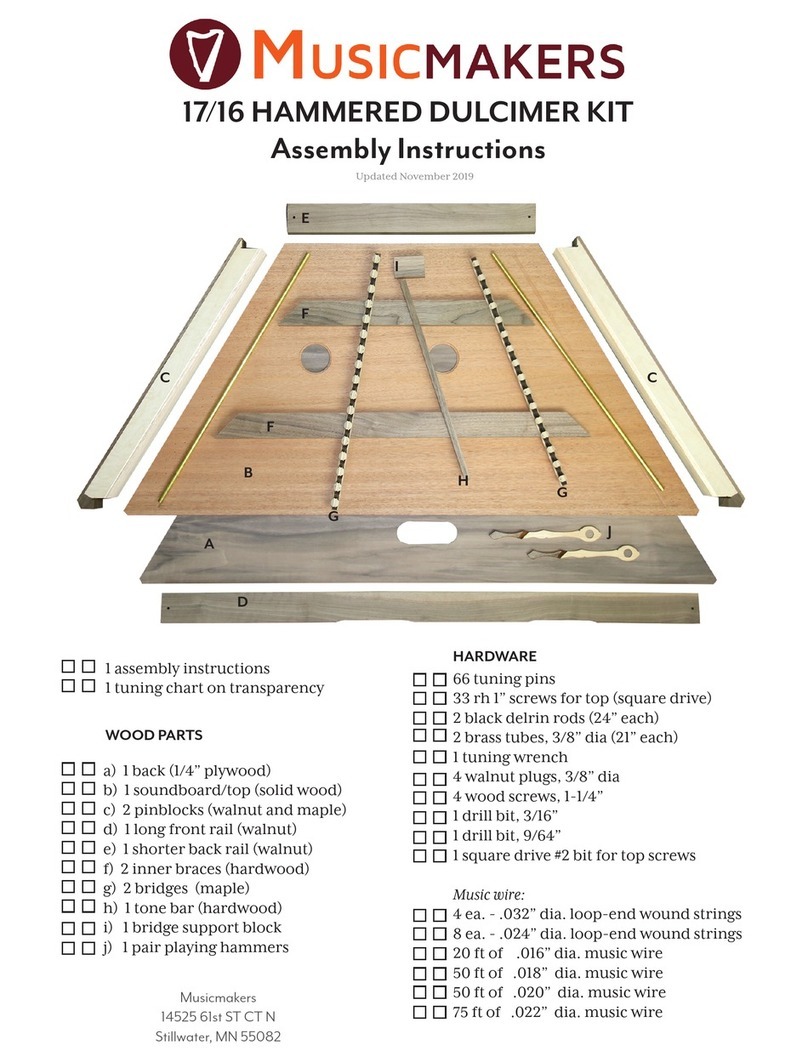

PREPARING THE FRONT (SOUNDBOARD)

Tools Required for This Stage

Pencil Spring Clamps

Wood Glue Chisel or Razor Knife

Damp Rag MaskingTape

Sandpaper (60-80 grit)

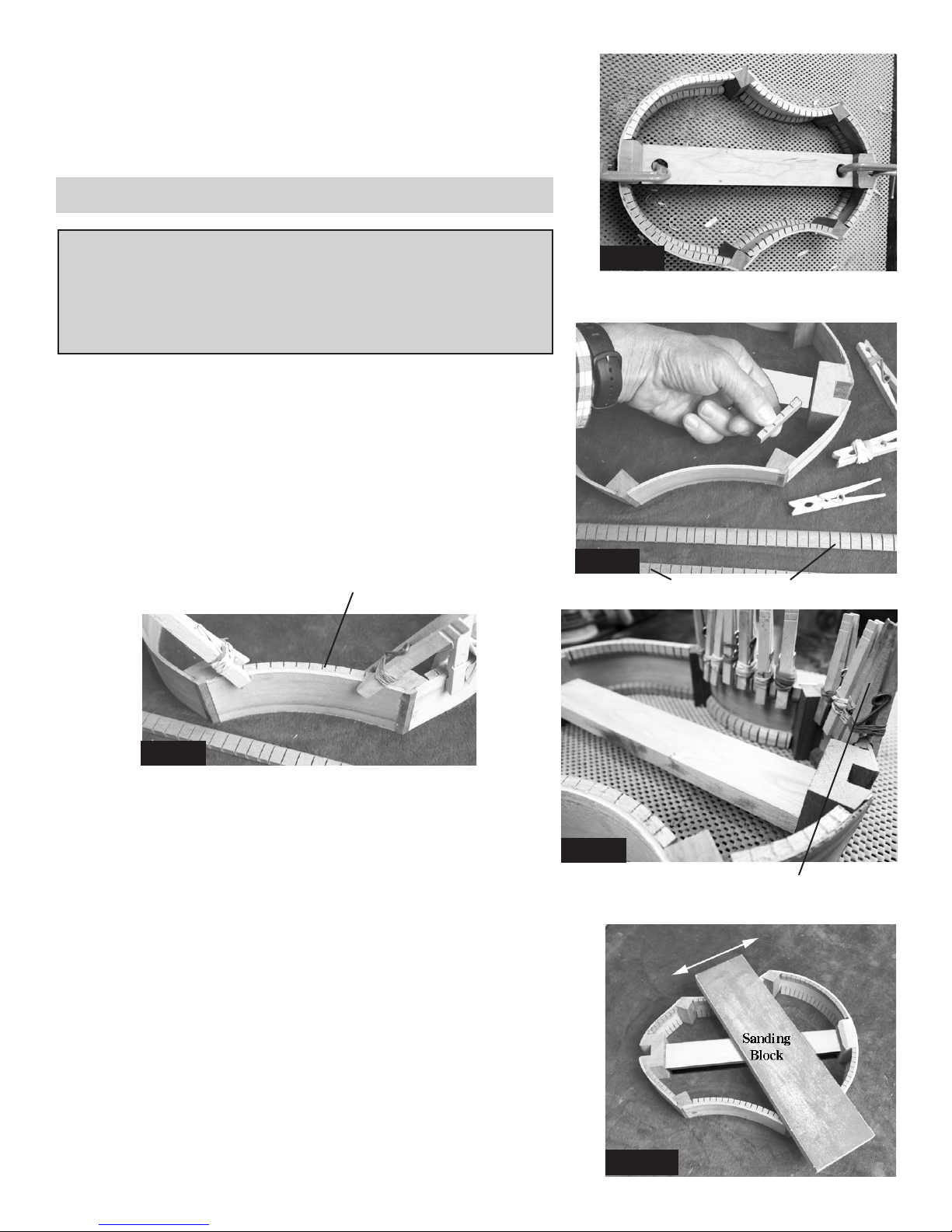

_____17. (OPTIONAL)

If you purchased

a decorative rosette for the sound hole, you’ll

need to glue a “donut ring” (fig 17a) inside the

sound hole now to provide a ledge for gluing the

rosette in place. It is easiest to see the correct

position of the donut ring if you look from the

outer face of the sound board (fig 17b). Glue

this ring to the inside of the soundboard now,

before installing the braces.

fig 17a fig 17b

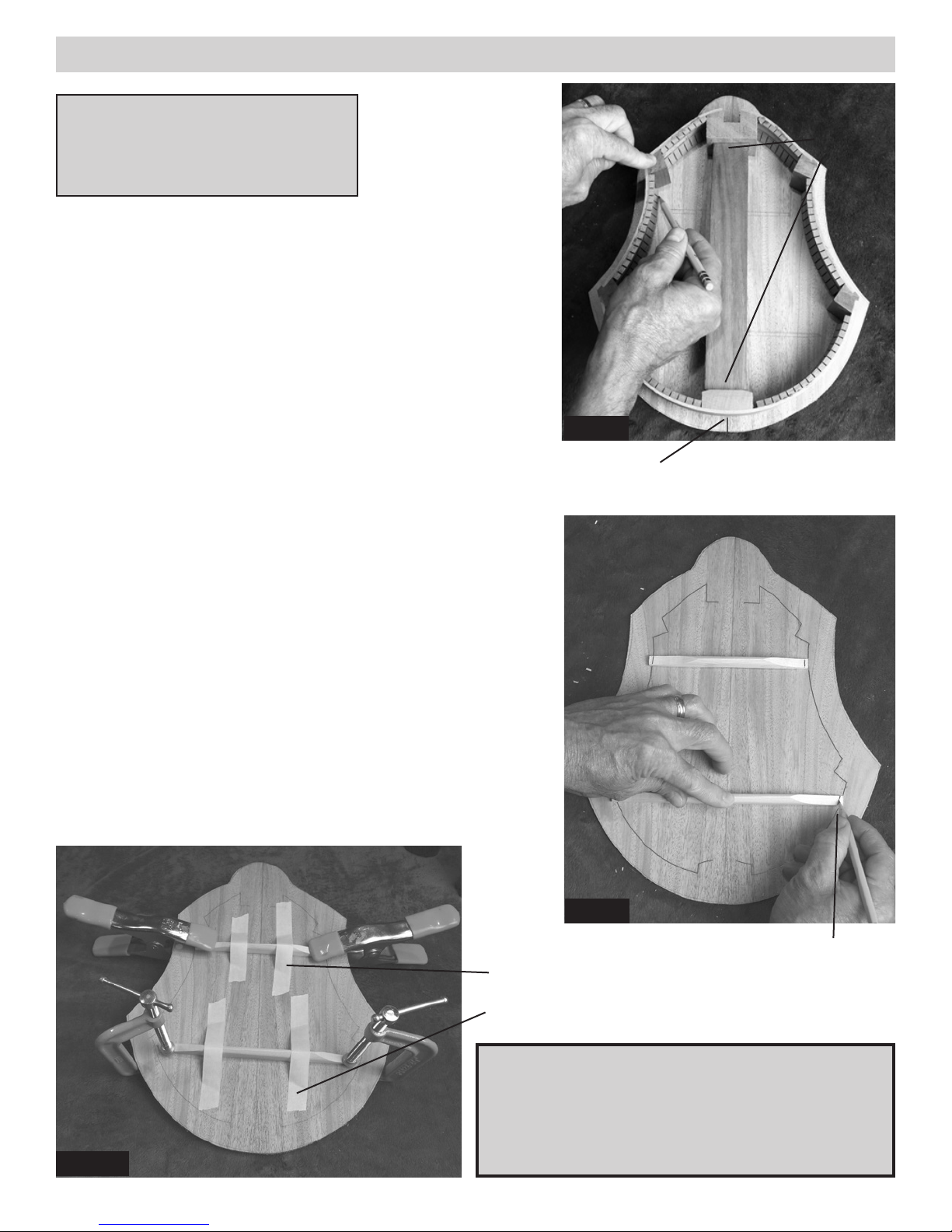

fig 19

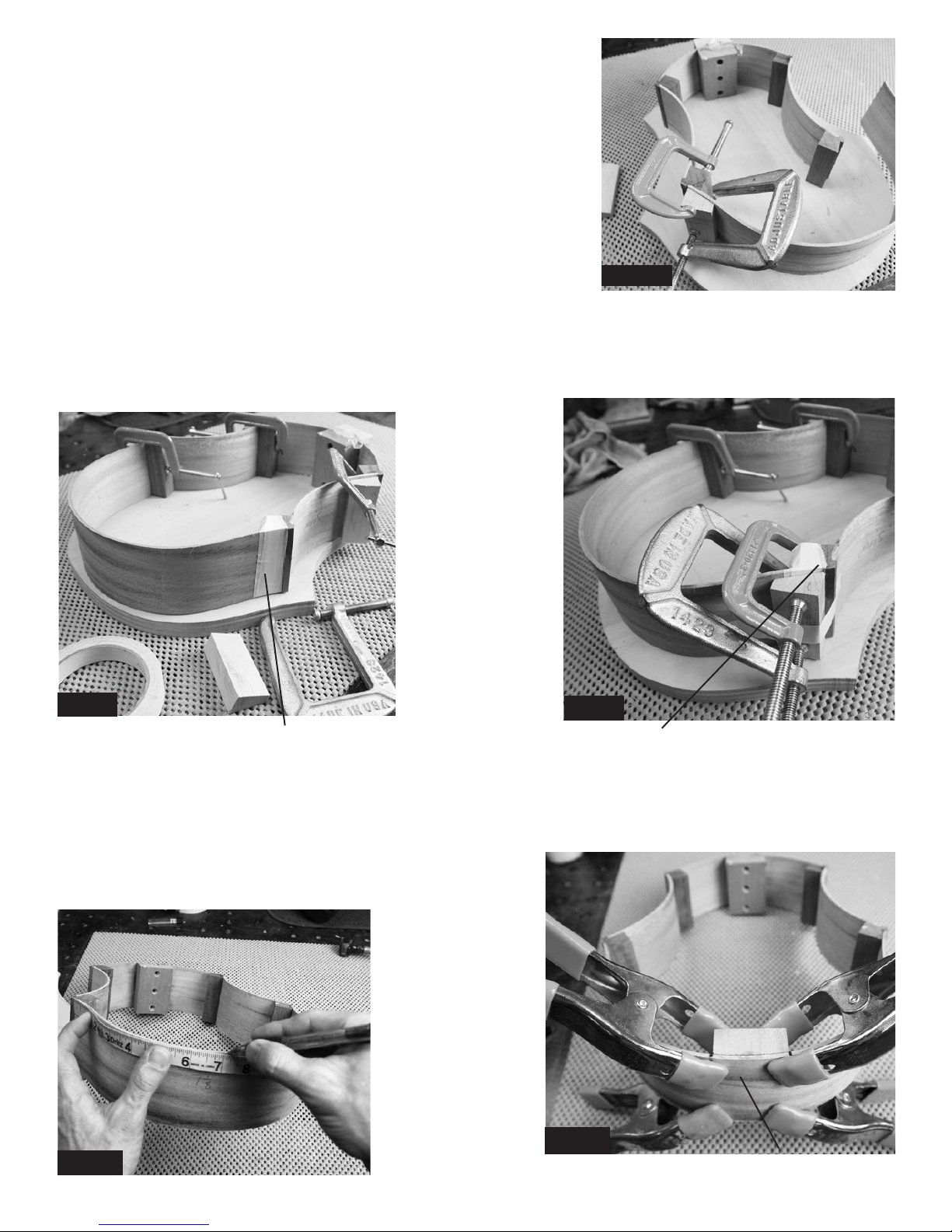

_____15. We highly recommend making

yourself a clamping pad for the body of the

instrument out of 3/4 plywood or particle

board (fig 15). Cut it at least the size of the

soundboard, or a little larger. fig 15

Clamping Pad

3/4” thick

_____16. The inside face has pencil marks showing the placement of the braces.

Place it on your work table with the inside facing up.

Center the frame of the instrument on the soundboard and outline the interior in

pencil (fig 16), just as you did for the back panel. Make certain the frame is cen-

tered in relation to the sound hole and the tail end. Slide the frame up toward

the top of the panel to make sure there will be room for the top brace and

the “donut” for the rosette.

Notice the Center Lines!

fig 16

Pencil

Outline

_____18. Find the two braces that are notched to fit

together forming an “X” (figs. 18a & 18b). These can

be joined two different ways, and we want the longer

legs to be spread as wide as they can go (fig 18a).

This will give you the maximum bracing strength on

the soundboard. Test fit the X to the soundboard, just

to be sure you have it correct.

fig 18a

THIS

fig 18b

NOT THIS

_____19. Position the X braces in place first, without glue,

and then arrange the three shorter ones as shown in fig. 19.

Trim the ends that are too long, just as you did for the back

panel.

When satisfied with the fit, glue and clamp the X braces in

place first, making sure to put glue in the joint where they

cross. Use clamps and/or weights to hold the X braces in

place firmly.

When the X braces are dry, go ahead and glue the other

small braces too, as shown in fig 19. fig 20a

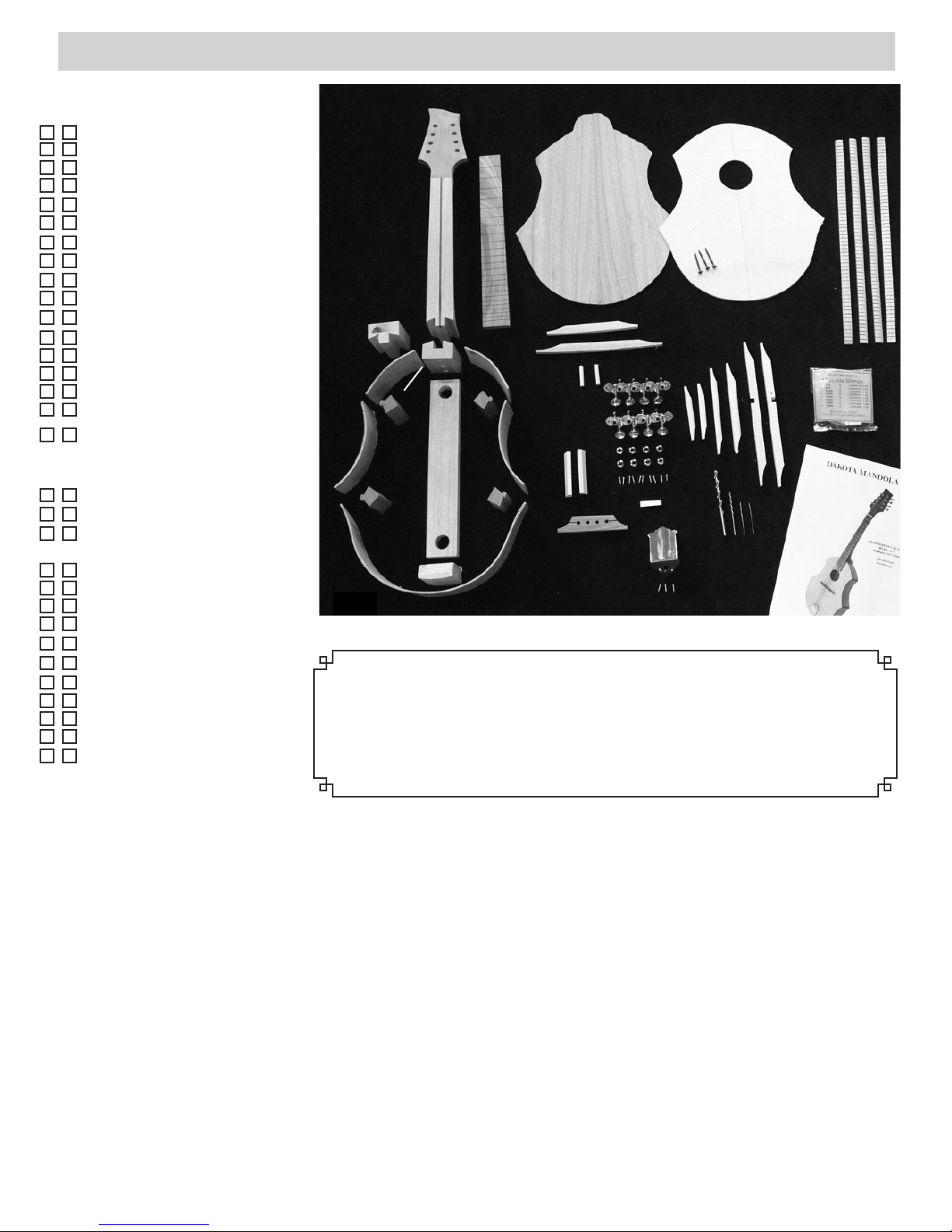

IMPORTANT NOTE ABOUT SOUNDBOARD

The front panel (soundboard) is the lighter colored piece made of solid Sitka Spruce,

and has a sound hole cut through it. If this panel has been exposed to high humidity

for more than a few hours, you will need to dry it out in an air-conditioned (de-

humidified) room for a few days to shrink the grain. This will help prevent cracks

from developing in the future. Hint: Another easy way to dry it out is to place it in

the oven at low heat (200 degrees) for 6-8 hours. Put clean tin foil under it to protect it

from any grease on the rack.