651-439-91204

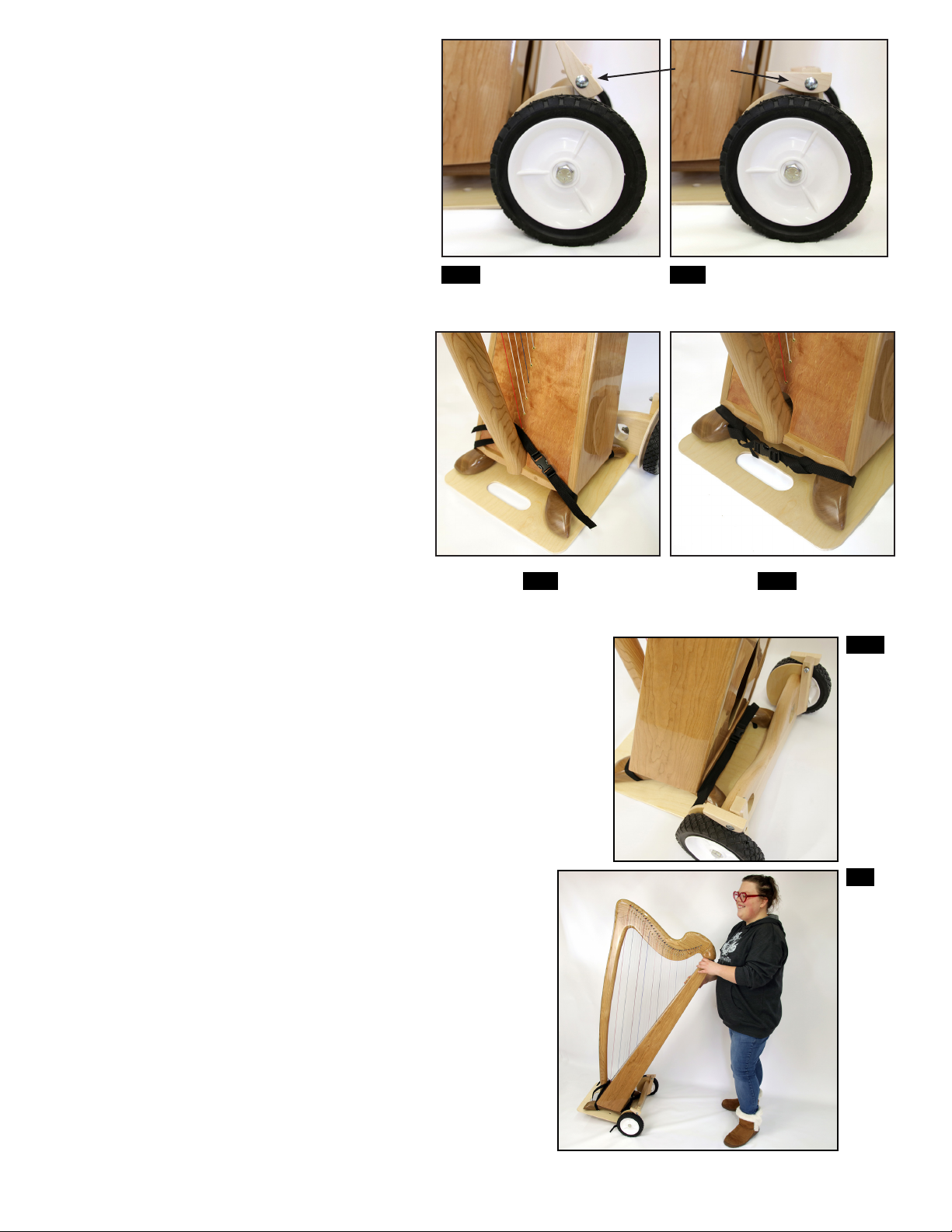

____8. The finish for the wheels needs to be durable. These

are going to move your harp across mountains and val-

leys (maybe!). We recommend multiple layers of poly-

urethane. This type of finish lends itself well to taking

a beating and staying intact. Polyurethame also holds

up well against moisture. Most hardware stores carry a

variety of finishes that are suitable for this task.

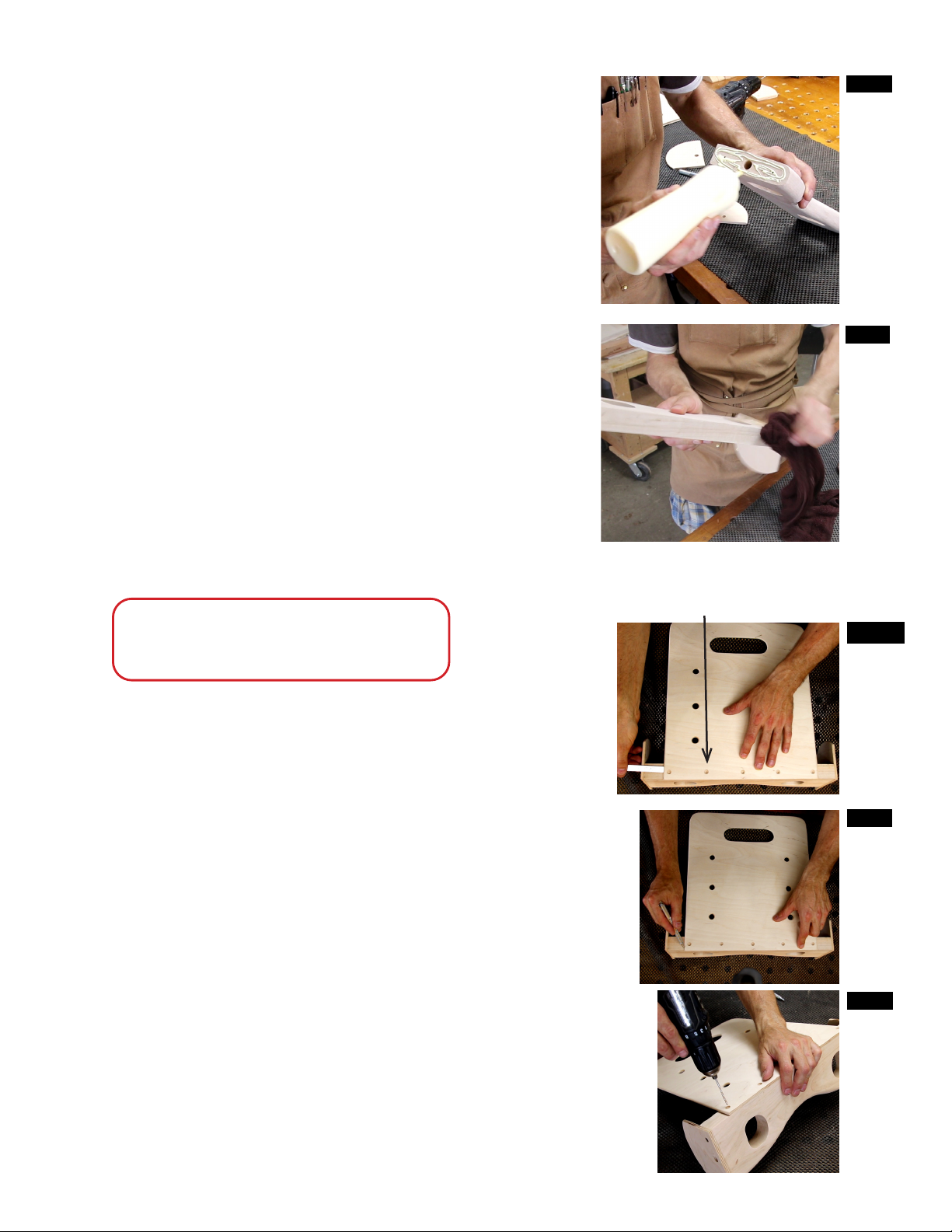

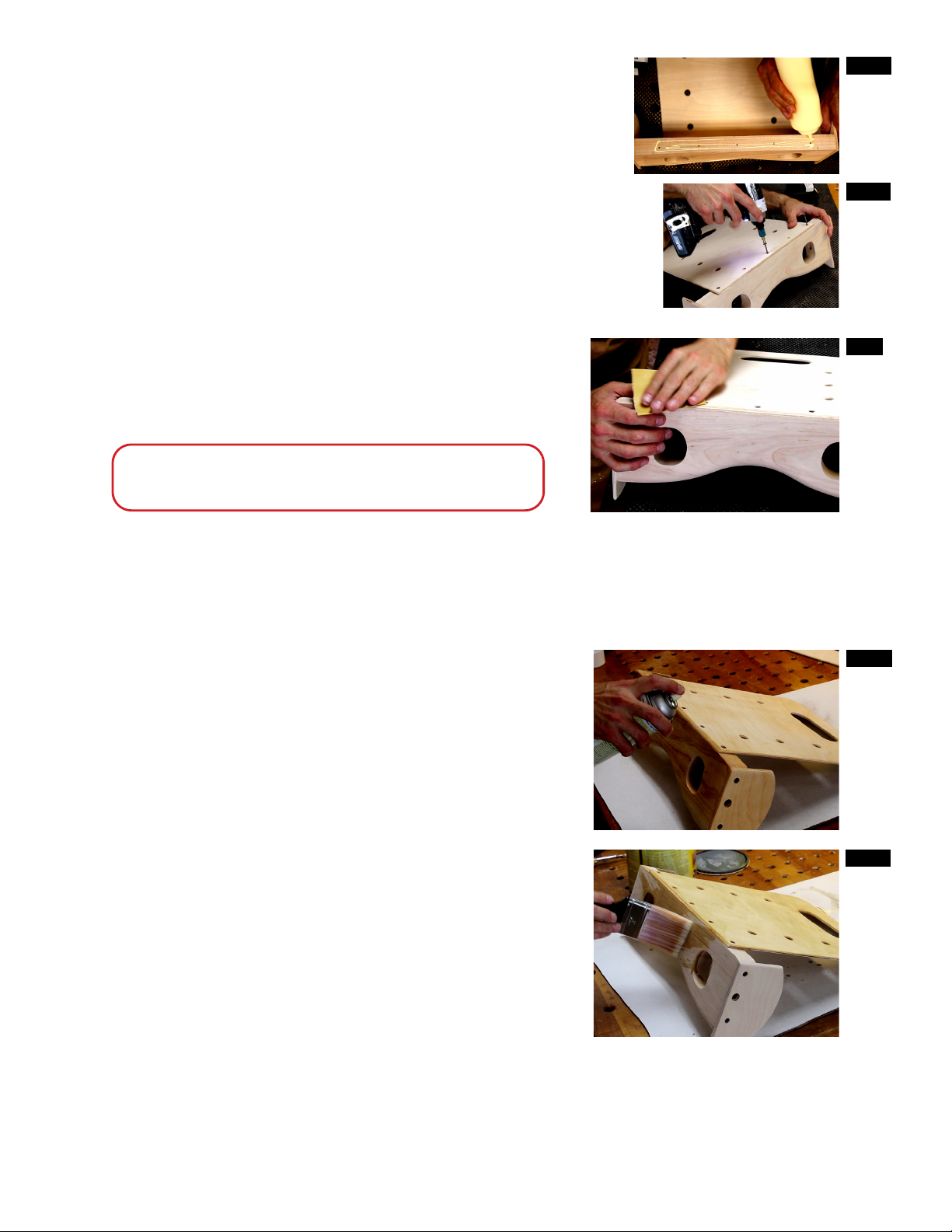

____9. Apply finish to one side of the set of wheels, using a spray

(fig. 9A), brush (fig. 9B ), or wipe on finish. Allow time

for the finish to dry, then flip over and finish the other

sides. Once the coat dries, you may want to sand with

400-600 grit sandpaper.

It’s also possible to hang the wheels for the finishing

process.

We typically apply 2-4 coats of finish. The thicker the

finish, the better.

FIG. 9A

FIG. 9B

____7. The wood in this kit is all raw and unfinished. You can

take this opportunity to add stain to the wood, if you’d

like. Choose the color you like and begin customizing

your wheels.

Be aware that if the wood is stained, it will show wear

and tear a little more than if just finished in a clear coat.

pHere are some finishing options, along with a few

hints from our experiences with finishing materials.

FINISHING

____6. Sand over all the sharp edges and uneven seams from

the assembly process.

Round over the paddle/axle edge. (fig. 6) An orbital

sander can make this a quick task. Be sure to remove all

scratch marks and glue spots from the assembly process.

FIG. 6

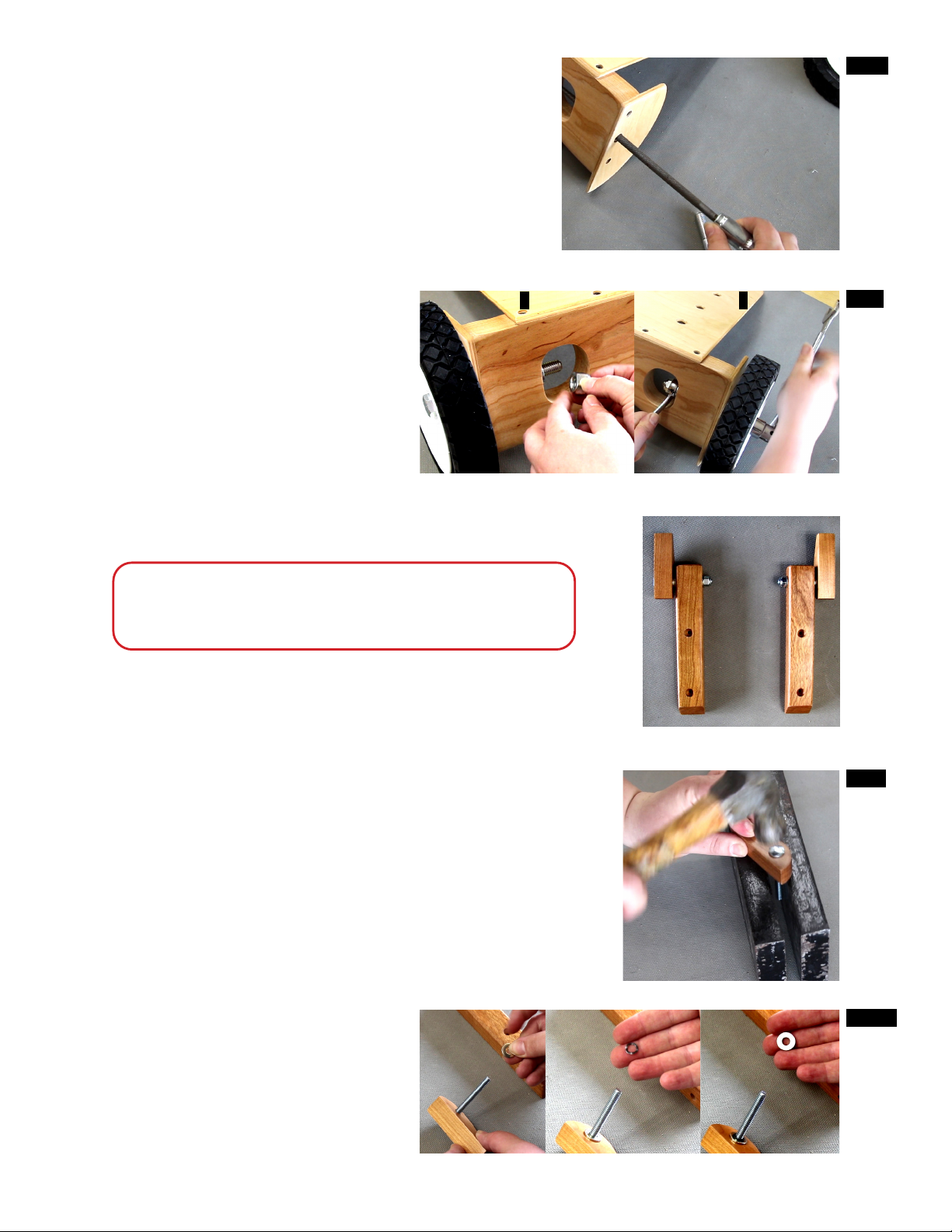

____5. Apply glue to axle and screw the paddle to the axle using

1” wood screws. (figs 5A and 5B) Tighten the screws

until the glue squeezes out. Be sure to clean up any glue

squeeze out with a wet rag.

FIG. 5A

FIG. 5B